Henan Chalco is committed to producing high-quality hot-rolled hard aluminum plates, cast aluminum plates, and forged aluminum plates in various specifications. The main alloy series include high-end alloys such as the 2000, 5000, 6000, and 7000 series. With tens of thousands of tons in stock, we can supply various customer needs promptly.Welcome to contact

Chalco Aluminum - a reliable partner

- Rich experience, advanced equipment and advanced frontier, as well as excellent R&D and manufacturing team, to ensure a continuous and stable high level of product quality.

- All shipped plates meet ASTM or AMS specifications and can undergo ultrasonic testing according to customer requirements.

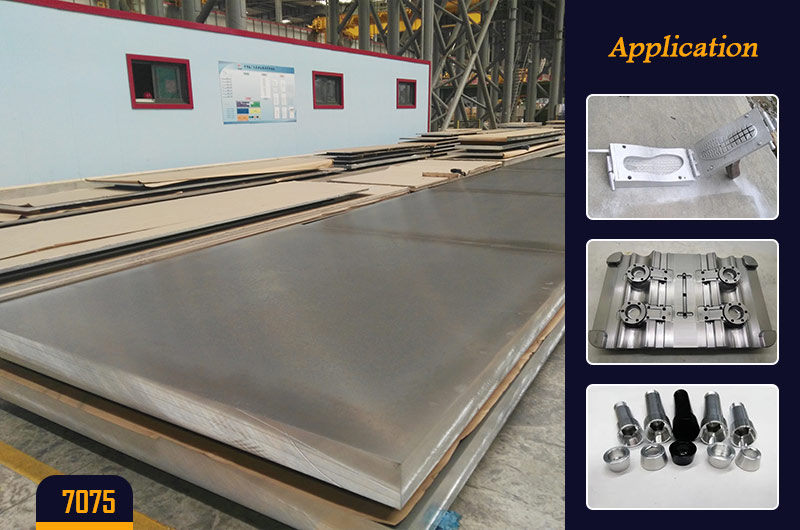

- Popular alloys like 2024, 7075, 5083, 6061, and 6082 are in stock in a full range of sizes. We also stock common sizes of other alloys, with tens of thousands of tons available.This makes us a preferred choice for aluminum distributors and stockists.

- Henan Chalco's aluminum plates are widely used in aerospace, automobile, shipbuilding, weaponry, and various industrial fields. We collaborate with leading industry clients including, but not limited to, Boeing, Airbus, Tesla, Ford, ABB and SIEMENS.

Accreditations

Specifications:EN 485, EN573, EN515, ASTM B209, ASTM B928M

Aerospace aluminum plates:AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Marine aluminum plate certificate: BV, DNV, NK, CCS, ABS, KR, LR.

Automotive standards:IATP16949 (British Standards Institution)

Aluminum tank plate for pressure equipment: 2014/68 EU, EN14286, TUV Certificate and LR Certificate

Introduction to Chalco's Aluminum Plates

Types: Rolled aluminum plates, cast aluminum plates, forged aluminum plates

Thickness: Aluminum sheets, aluminum plates, aluminum thick plates, ultra-thick aluminum plates

Surface: Polished aluminum plates, anodized aluminum plates, color-coated aluminum plates

Deep processing: Precision ground aluminum plates, brushed aluminum plates, aluminum checkered plates, aluminum corrugated plates, perforated aluminum plates

Applications: Aircraft aluminum plates, marine aluminum plates, armor aluminum plates, automotive aluminum plates, aluminum closure sheets

Special features: Aluminum mirror sheet, aluminum brazing sheet, sublimation aluminum sheets, pre-sensitized aluminum sheet, ctp aluminum plates, deep drawing aluminum plates

Large sizes: Ultra-wide aluminum plates, ultra-thick aluminum plates

Chalco's Aluminum Plate Processing Capabilities

- Surface Treatment:Includes coating, polishing, anodizing, plating, and spraying.

- Secondary Processing:Precision machining of aluminum plates through cutting, milling, drilling, and turning.

- Cutting:Waterjet cutting, plasma cutting, laser cutting, and precision sawing.

- Welding:Utilizes advanced TIG and MIG welding techniques for high quality and reliability.

- Bending:Bends aluminum plates to the required angles and shapes.

- Stamping:Punching, engraving, or embossing on aluminum plates.

Available Aluminum Plate Sizes at Chalco

Chalco's Stock Aluminum Plate Size Range

Aluminum Sheet Stock Sizes

| Thickness/mm | Size/mm | |||

| 0.5 | 0.6 | 0.8 | 1 |

1250x2500 1500x3000 1520x3020 |

| 1.2 | 1.5 | 2 | 2.5 | |

| 3 | 4 | 5 | 6 | |

Aluminum plate Stock Sizes

| Thickness/mm | Size/mm | ||||||

| 8 | 10 | 12 | 14 | 15 | 16 | 18 |

1250x2500 1500x3000 1520x3020 1525x3660 2000x4000 2400x4000 |

| 20 | 22 | 25 | 28 | 30 | 35 | 40 | |

| 45 | 50 | 55 | 60 | 65 | 70 | 75 | |

| 80 | 85 | 90 | 95 | 100 | 110 | 120 | |

| 130 | 140 | 150 | 160 | 170 | 180 | 190 | |

| 200 | 210 | 220 | 230 | 240 | 250 | 260 | |

Aluminum cast plate Stock Sizes

| Thickness/mm | Size/mm | |||

| 100 | 150 | 200 | 250 |

Can be sawed Can be precision ground |

| 300 | 350 | 400 | 450 | |

| 500 | 550 | 600 | Can be customized | |

Aluminum forged Plate Stock Sizes

| Thickness/mm | Size/mm | ||||||

| 250 | 260 | 270 | 280 | 290 | 300 | 310 |

1520*2500 1520*3020 |

| 320 | 330 | 340 | 350 | 370 | 380 | 390 | |

| 400 | 410 | 420 | 430 | 440 | 450 | 460 | |

| 470 | 480 | 490 | 500 | 510 | 520 | 530 | |

| 540 | 550 | 560 | 570 | 580 | 590 | 600 | |

Don't see the aluminum plate size you need in our stock range? Check out the custom aluminum plate sizes below or contact our aluminum plate experts.Contact us

Chalco's Hot-Rolled Aluminum Plate Production Range

| Alloy | Temper | Dimension(mm) | Executive Standard | ||

| Thickness | Width | Length | |||

| Series 1, 3, 8 |

O, F, H111, H112, H12, H14, H16, H18, H19, H22, H24, H26 |

0.2~0.5 | 500~1500 | 500~4000 |

ASTM B209 ASME SB-209 EN 485 YS/T91 GB/T3880 |

| 0.6~4.0 | 1000~2650 | 2000~10000 | |||

| 4.1~12.0 12.1~20 21~200 |

1000~2650 1000~3800 1000~3800 |

2000~20000 | |||

| Series 5 |

O, F, H111, H112, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H116, H321 |

0.2~0.5 0, 6~4, 0 |

1000~1500 1000~2650 |

2000~10000 |

ASTMB209 ASME SB-209 EN485 ASTMB928M GB/T3880 GJB1541 GJB2662 |

| 4.1~12.0 12.1~20 21~200 |

1000~2650 1000~3800 1000~3800 |

2000~20000 | |||

| Series 2, 6, 7 |

O, F, H111, H112, T3, T4, T6, T7 |

0.3~0.7 0.8~2.0 2.1~12.0 |

1000~1500 1000~2650 1000~2650 |

2000~10000 |

ASTM B209 ASME SB-209 EN 485 GB/T3880 GJB1541 GB/T167 GJB2053 GJB2662 |

| 12.1~20 21~200 |

1000~3800 1000~3800 |

2000~20000 | |||

|

T351, T451, T651, T851, T7451, T74, T87 |

5.0~12.0 | 1000~2650 | 2000~10000 | GJB1741 | |

| 12.1~20 | 1000~3800 | 2000~20000 | |||

Don't see the standard hot-rolled sizes you want? Looking for special specifications? We can supply those too. Please continue below or contact us for custom options.Quick Quote

Diverse Aluminum Plate Sizes by Chalco

Aluminum Thick Plate

Ultra-Thick Aluminum Plate

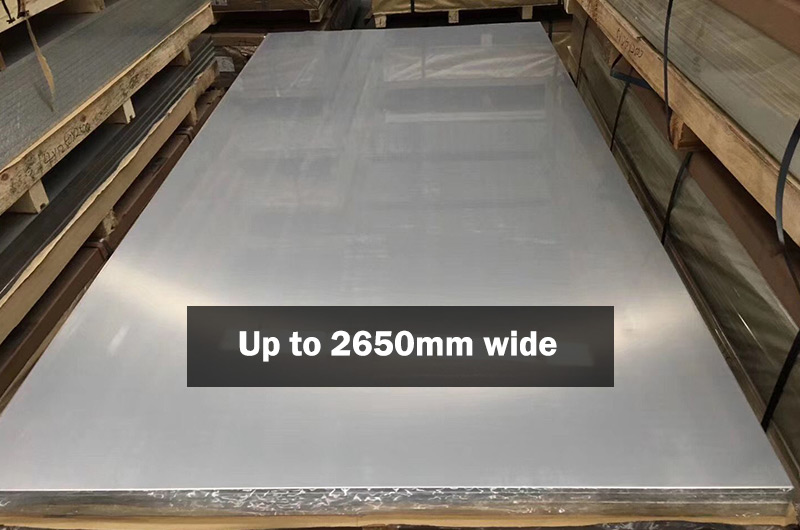

Ultra-wide Aluminum Plate

1 4 Aluminum Plate

4x8 Aluminum Sheet Plate

5x10 Aluminum Sheet Plate

Metal Distributor & Large-Scale Project Bulk Purchasing Policy

Chalco offers bulk purchasing services tailored for distributors, stockists, and large-scale projects. This is ideal for major project tenders, bulk procurement plans for metal stockists, and custom requirements for large quantities of plates.

With tens of thousands of tons in stock and a comprehensive range of standard sizes, you can significantly shorten procurement cycles by selecting the specifications you need.

Additionally, our competitive pricing and delivery terms are designed to help you minimize capital investment and meet your strategic purchasing needs, ultimately saving your company on procurement costs.

Examples of Bulk Purchasing Projects

| Customer Type | Size/mm | Product | Specification | Country | Tonnage |

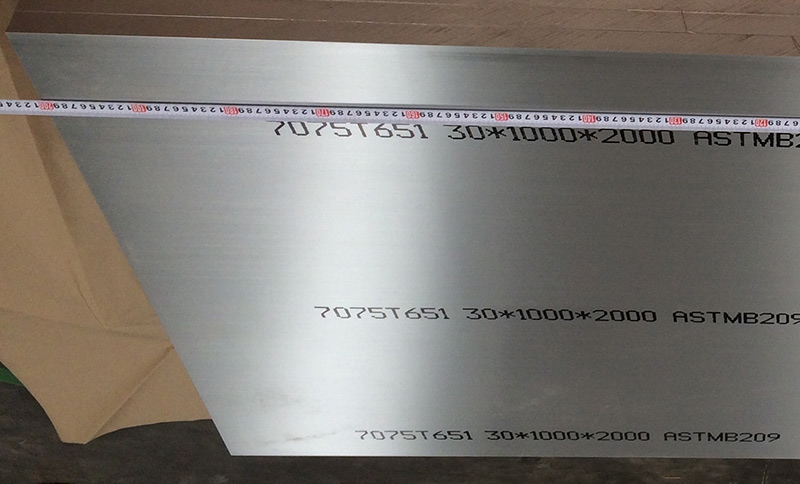

| Distributor | 30*1520*3020 | 7075-T651 | EN 485, EN515, EN573-3 | Türkiye | 50T |

| Distributor |

12.7*1219*3657 25.4*1219*3657 50.8*1219*3657 |

6061-T651 | AMS 4027 | Türkiye | 16T |

| Distributor |

80*1400*2805 90*1400*2805 100*1400*2805 200*1400*2805 |

7075-T651 | EN 485, EN515, EN573-3 | Poland | 51T |

| Distributor | 22*1520*3020 25*1520*3020 | 6061-T651 | EN 485, EN515, EN573-3 | Türkiye | 60T |

| Terminal |

2*1500*3000 5*1500*3000 20*1500*3000 30*1500*3000 |

5083-H111 | ASTM B209 | USA | 72T |

| Distributor |

2624*1380 2624*1452 2655*1062 |

7075-T651 | EN 485, EN515, EN573-3 | Spain | 50T |

| Terminal |

15*1520*3020 60*1520*3020 40*1520*3020 20*2000*4000 |

2024-T4 | EN 485, EN573-3 | Spain | 120T |

| Distributor |

50*1500*3000 60*1500*3000 70*1500*3000 80*1500*3000 |

5083-H111 | ASTM B209 | Ukraine | 20T |

| Terminal | 20*1520*3020 35*1520*3020 | 2024-T351 | EN 485, EN515, EN573-3 | Ukraine | 12T |

| Distributor |

20*1520*3020 40*1520*3020 60*1520*3020 80*1520*3020 |

6082-T651 | EN 485, EN515, EN573-3 | U.K. | 32T |

| Distributor | 120*1219*3657 45*1219*3657 | 7075-T7351 | AMS 4078 | Türkiye | 25T |

Do you have bulk aluminum plate purchasing needs? Enjoy discounts through our bulk purchasing program. Contact our sales manager today!Click to order

Chalco Aluminum's best-selling aluminum sheets

1000 series aluminum sheet plate

The 1000 series aluminum plates are known for their excellent corrosion resistance and high thermal and electrical conductivity. They have high purity, typically 99% or higher, making them very soft and ductile.Quick Quote

2000 series aluminum sheet plate

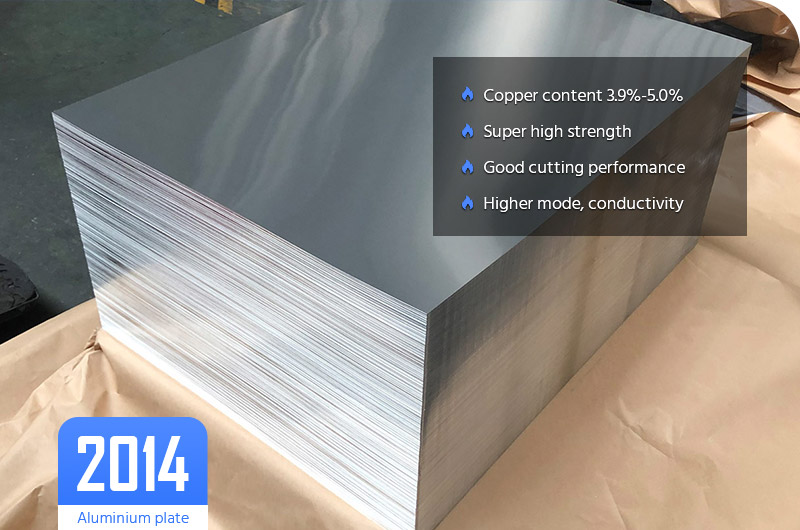

The 2000 series aluminum plates are known for their high strength and excellent machinability. They have good fatigue resistance but are less corrosion-resistant, often requiring a cladding of pure aluminum (1050), as seen in alloys like 2014/2024 Alclad aluminum sheets. These properties make them ideal for aerospace and high-stress applications.Quick Quote

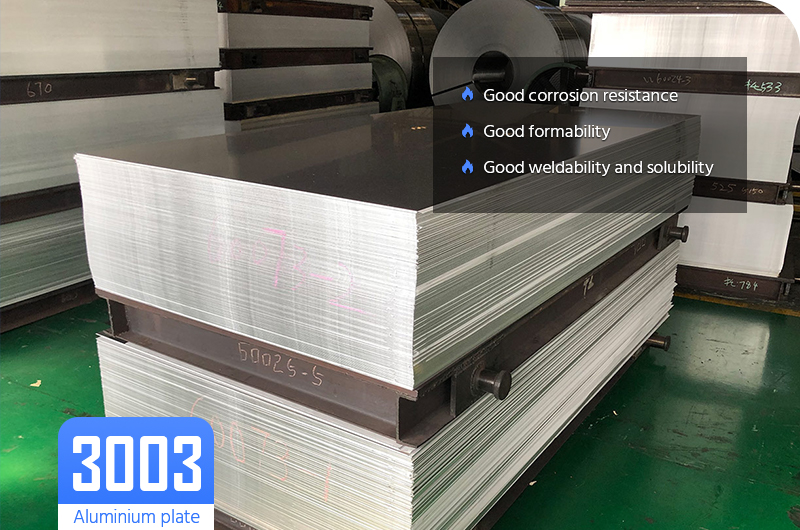

3000 series aluminum sheet plate

The 3000 series aluminum plates offer good corrosion resistance and moderate strength, making them suitable for various applications. They are known for excellent workability and are often used in environments where moisture and chemicals are present. Typical alloys like 3003 are commonly used in HVAC, roofing, and cooking utensils.Quick Quote

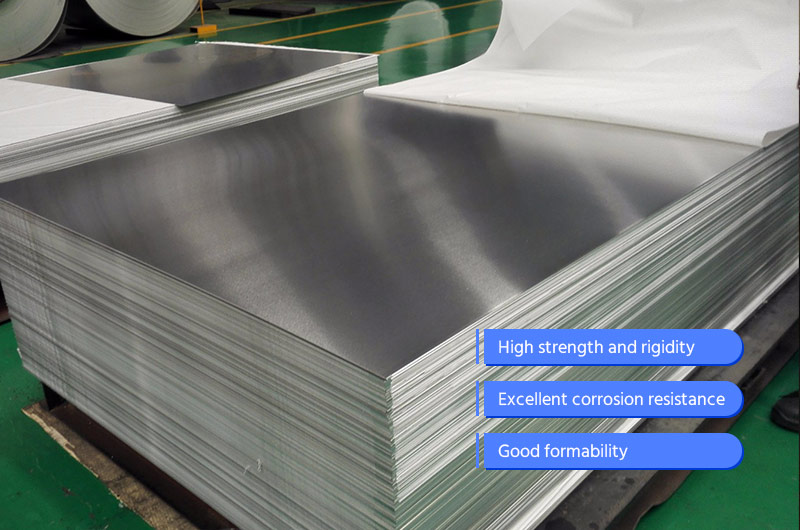

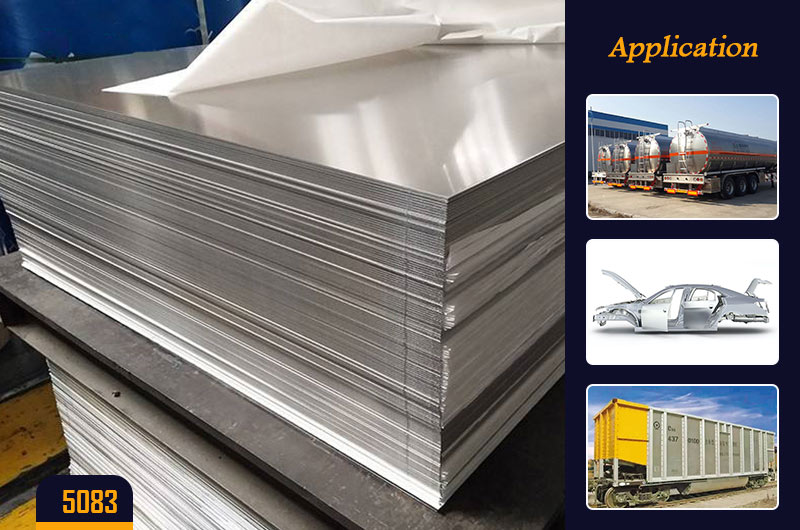

5000 series aluminum sheet plate

The 5000 series aluminum plates are known for their excellent corrosion resistance and high strength. They offer good weldability, making them ideal for marine vessels, oil tanker, and pressure vessels.Quick Quote

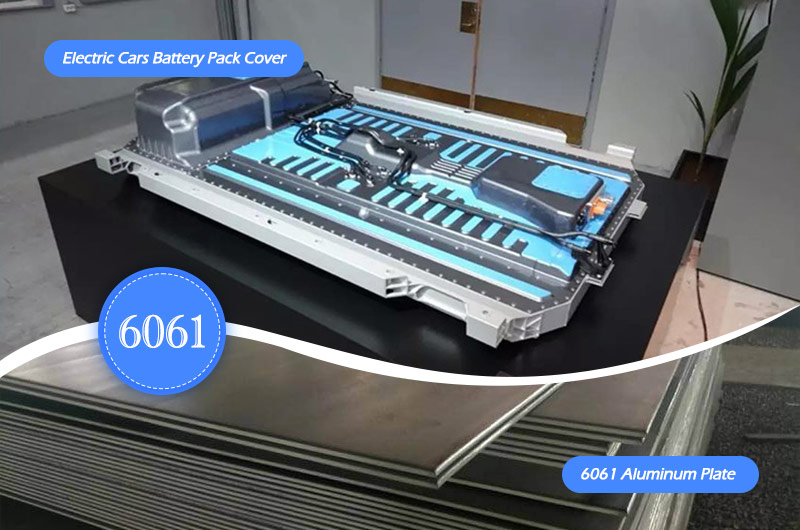

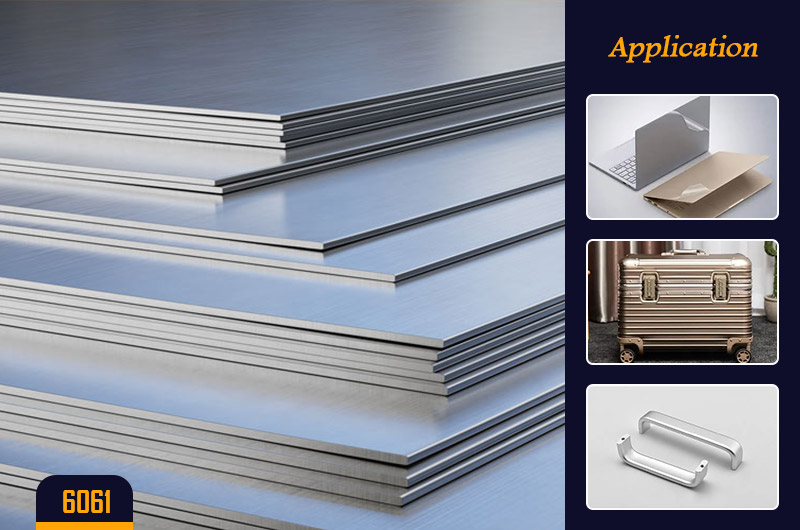

6000 series aluminum sheet plate

The 6000 series aluminum plates are heat-treatable alloys that combine moderate to high strength with excellent corrosion resistance, good machinability, and good weldability. They are the most versatile alloy series.Quick Quote

7000 series aluminum sheet plate

The 7000 series aluminum plates are known for their exceptionally high strength and good fatigue resistance. They have lower corrosion resistance, often requiring a cladding of pure aluminum (1050). These properties make them ideal for aerospace and other high-performance applications.Quick Quote

Types of Chalco's Aluminum Plate Products

Chalco offers a wide range of aluminum plates with various surface treatments and deep processing options, including but not limited to anodized aluminum plates, color-coated aluminum plates, and heat transfer printed aluminum plates. We can meet the diverse needs of customers across different industries. The details are as follows:

-

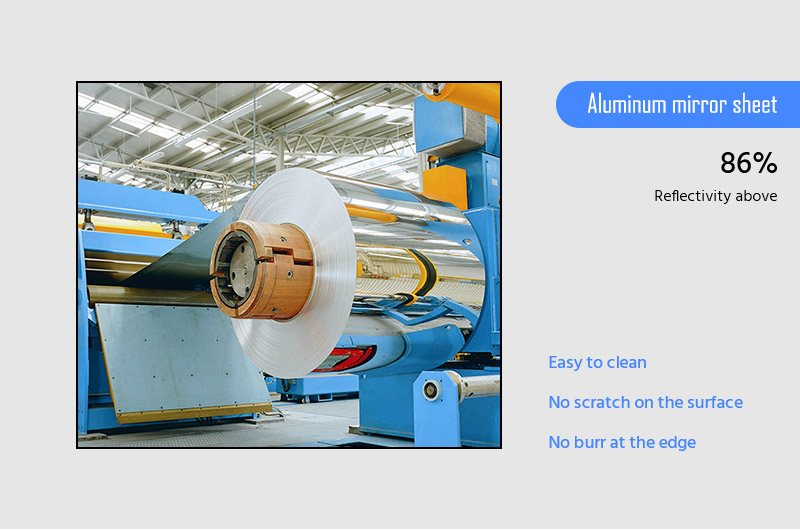

Aluminum Mirror Sheet

Aluminum mirror sheets are produced through rolling and polishing processes to achieve high reflectivity. They are widely used in industries such as architecture, automotive, and lighting due to their aesthetic appeal and reflective properties.

1050 1085 3003 3105 5454 5182 -

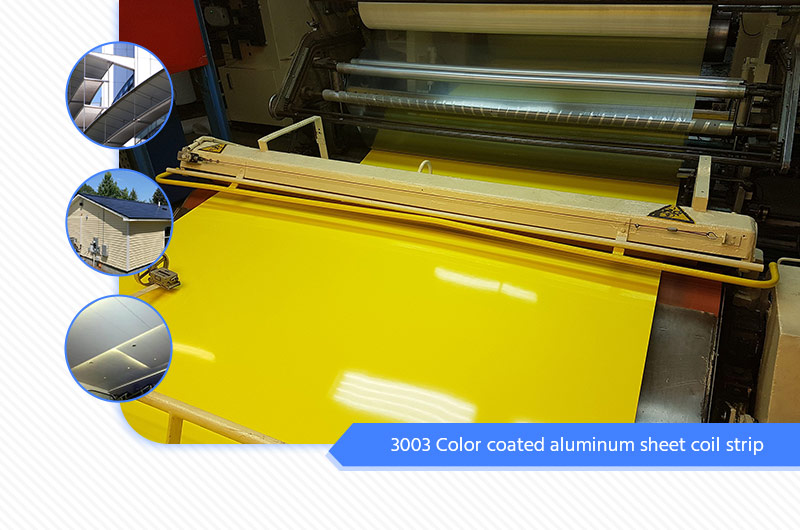

Color Coated Aluminum Sheet Coil

Color coated aluminum sheet is made from aluminum coil with a paint coating. It has excellent flatness, decoration, and weather resistance, and is widely used in composite panels, roofing, louvers, ceilings, and electronics.

1050 1060 1070 3003 3004 3105 5052 -

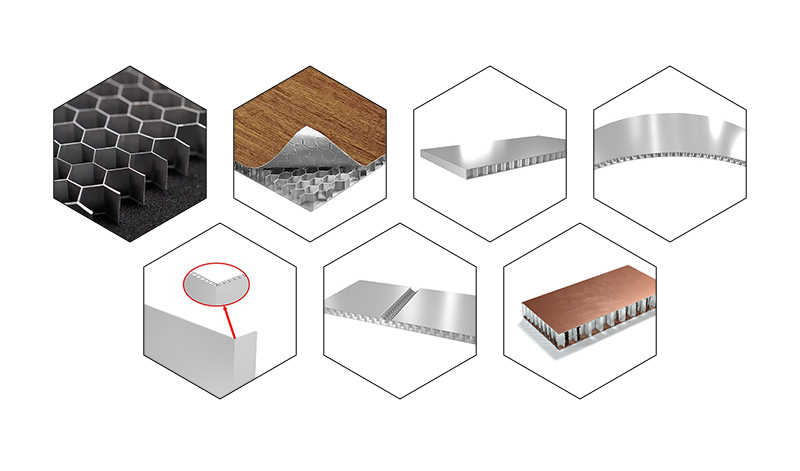

Aluminum Honeycomb Panel

Chalco's aluminum honeycomb plates are lightweight, strong, and exceptionally flat, offering great thermal insulation, sound absorption, and corrosion resistance. They are ideal for aerospace, transportation, and architecture, with various specifications available.

honeycomb core honeycomb plate Film adhesive -

Anodized Aluminum Sheet Plate

Anodized aluminum sheets are immersed in an electrolyte and exposed to electrical current, forming a dense oxide layer. This improves weather resistance, hardness, abrasion resistance, heat resistance, and insulation.

Electrolytic anodizing Hard anodizing -

Stucco Embossed Aluminum Sheet Coil

Stucco embossed aluminum coils offer anti-slip, decorative, and corrosion-resistant features, ideal for construction, refrigeration, and automotive industries. Chalco Aluminum supplies these coils in various specifications to meet diverse needs.

Rhombus Hemisphere Cobblestone Corrugated -

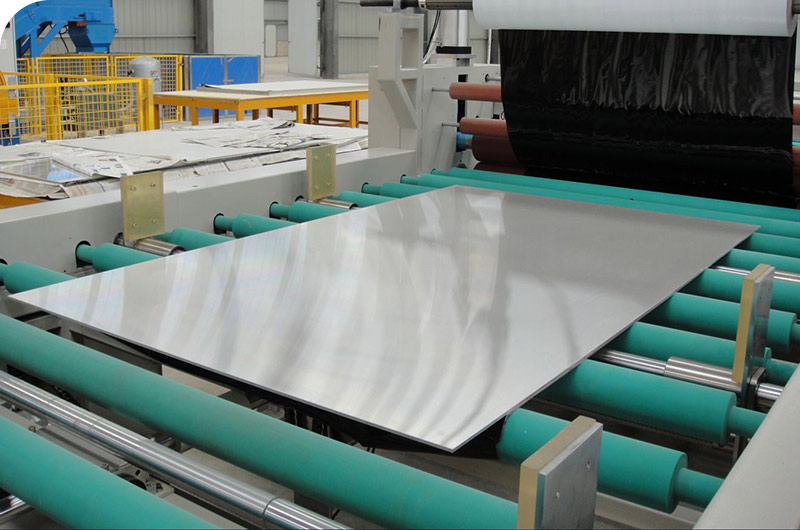

High Precision Aluminum Plates

Chalco offers high-precision aluminum plates with excellent machinability, flatness, strict thickness tolerances, and superior surface quality. They are widely used in electronics, medical devices, structural components, and aerospace.

5052 5083 6061 7075 -

Aluminum Tooling Jig Plate

Chalco provides high-quality aluminum tooling plates with excellent flatness, stability, and warp resistance, ideal for precision machining, jigs, fixtures, and molds.

Cast alu tooling plate Rolled alu tooling plate Mold alu tooling plate -

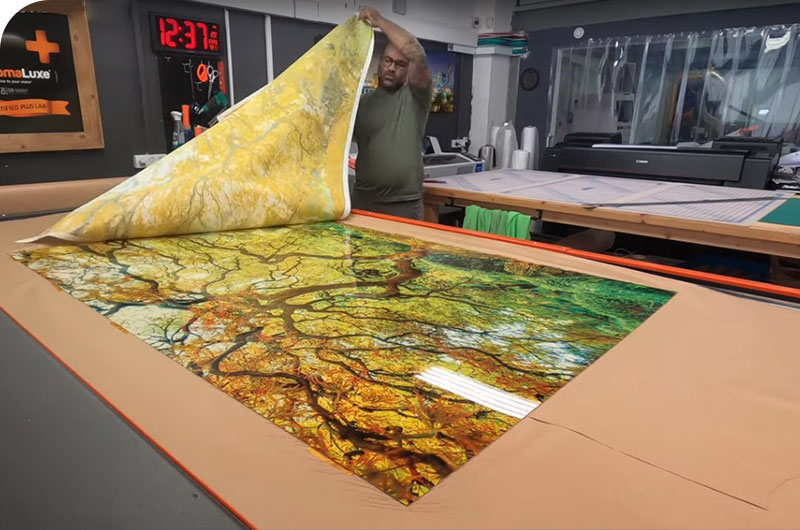

Sublimation Aluminum Sheet

The Sublimation Aluminum Sheet transfers film patterns to aluminum via heat and pressure, creating vibrant colors. It's widely used in signage, furniture, device casings, and curtain walls.

mirror gold mirror silver brushed gold brushed silver white -

Aluminum Tread Checkered Plate

Chalco's tread plates, featuring 2-bar, 3-bar, 5-bar, and diamond patterns, offer anti-slip, decorative purposes, durability, corrosion resistance, and easy cleaning. They are used in flooring, stair treads, and industrial equipment.

diamond 2bar 3bar 5 bar Lentil pattern -

Aluminum Corrugated Metal

Chalco's corrugated aluminum sheets are lightweight, durable, corrosion-resistant, and offer great structural stability. Ideal for roofing, cladding, and decoration, they suit diverse construction and industrial needs.

1050 1060 1100 3003 5005 5052 6061 6063 -

Deep Drawing Aluminum Plates

Chalco's deep drawing aluminum plates offer high formability, excellent surface quality, and uniform thickness, making them ideal for cookware, lighting, automotive components, and industrial uses.

1070 1100 1200 3004 3104 5182 6063 -

Stretched Aluminum Plate

Chalco's stretched aluminum plates offer high strength, excellent flatness, and good machinability, ideal for aerospace, automotive, and industrial uses. They undergo heat treatment and stretching to enhance mechanical properties and stability.

T351 T451 T651 T851 T7351 T7451 T7651 T7751

Best application reas for luminum aheet lates

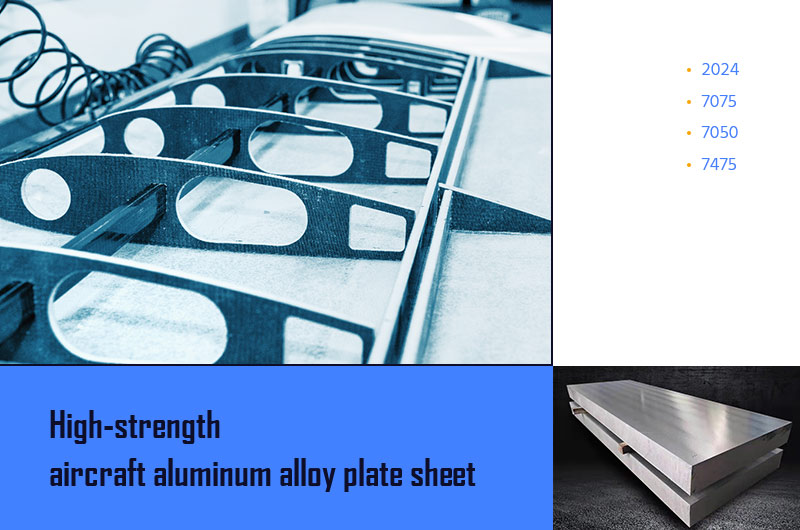

High-strength aircraft aluminum alloy plate sheet

2xxx: 2024, 2014, 2219, 2618

6xxx: 6061, 6082, 6013

7xxx: 7075, 7049, 7050, 7150, 7475

Contact us nowAerospace aluminum plates are primarily used in the aerospace industry, focusing on attributes such as lightweight, high strength, excellent fracture toughness, outstanding fatigue resistance, heat resistance, and superior corrosion resistance. Commonly used aluminum alloys include the 2000 series, 6000 series, and 7000 series.

Accreditations:AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Specifications:AMS, MIL, ASTM, EN, QQ-A-250/2, QQ-A-250/3

-

2024 aerospace aluminum plate

Temper: O, T3, T4, T6, T81, T351, T451, T851

Thickness: 0.5mm-300mm

Width: 500-2650mm

QQ-A-250/4, QQ-A-250/5; AMS 4035, AMS 4037, AMS 4040, etc.

-

2219 aerospace aluminum plate

Temper: O, T351, T851

Thickness : 0.02"-2.0"

Width: 48.5"/60"

QQ-A-250/30 etc.

-

2014 aerospace aluminum plate

Temper: O, T4, T6, T651 etc.

Thickness: 0.5mm-100mm

Width: 1000mm, 1220mm, 1500mm

AMS 4028, AMS 4029, BS L156, QQ-A-250/3, EN 2088, etc.

-

4047 aerospace aluminum plate

Temper: O, F, H112

Thickness: 0.5-150mm

Width: 1000-2600mm

BS N2

-

6061 aerospace aluminum plate

Temper: T651

Thickness: 0.2mm-300mm

Width: 500mm-2500mm

AMS 4027; HP20; HS20; QQ-A-250/11; EN 4213

-

6082 aerospace aluminum plate

Temper: T6, T651

Thickness: 0.5mm-300mm

Width: 500-2650mm

BS L113, BSL115, BS HP30, BS HS30, etc.

-

6013 aerospace aluminum plate

Temper: T4, T6

Thickness:0.0125-3.000"

Width: 12.0-72.0"

A97050, AMS 4344, AMS 4341, AMS 4216 etc.

-

7050 aerospace aluminum plate

Temper: F, O, T6, T7351, T762, T73, T7651, T7451, T7452, etc.

Thickness: 0.2mm-300mm

Width: 500mm-2600mm

AMS 4050, QQ-A-430, EN 3982

-

7075 aerospace aluminum plate

Temper: F, O, H112, T3, T4, T62, T351, T651, T7351, T7451 etc.

Thickness: 1.0mm-500mm

Width: 500mm-2800mm

AMS QQ-A-250/12, BS 2 L95, AMS 4038, AMS 4045 etc.

-

7049 aerospace aluminum plate

Temper: T7651, T7451, etc.

Thickness:1.0mm-10.0mm

Width: 1000mm, 1500mm, 2000mm, etc.

AMS 4201, 4202, 4203, 4342

-

7150 aerospace aluminum plate

Temper: T7751, T6151 etc.

Thickness:0.5-150mm

Width: 1000-2600mm

AMS 4252, AMS 4306, etc.

-

7475 aerospace aluminum plate

Temper: T61, T761 T7651, etc.

Thickness: 0.8-200mm

Dimension: 1250×2500mm, 1500mm×3000mm, etc.

AMS 4084, AMS 4085, AMS 4089, AMS 4090, AMS 4100, etc.

Corrosion-resistant marine grade aluminum

Due to environmental factors, materials used in marine engineering or shipbuilding require excellent corrosion resistance, superior strength-to-weight ratio, and good weldability. Therefore, the choice of aluminum alloy is crucial.

The 5000 series aluminum-magnesium alloys offer superior rust resistance and fatigue strength, making them suitable for damp and corrosive environments.

The 6000 series aluminum alloys are lightweight, strong, corrosion-resistant, and easy to process, making them ideal for constructing complex ship structures.

Certification by classification societies: CCS, DNV, NK, CCS, ABS, BV, LR, KR, etc.

-

5083 marine grade aluminum plate

Rust resistance, good welding performance, good strength after welding;

Manufacturing of hull, deck, control console, etc.

Temper: O H111 H116 H32 H321

-

5086 marine grade aluminum plate

Compatible with various welding methods;

Hull shell, deck, cargo warehouse, and storage area.

Temper: O H112

-

5383 marine grade aluminum plate

High strength and good welding performance;

Used for High speed ships, decks, hulls.

Temper: O H112

-

5052 marine grade aluminum plate

High formability, durable and sturdy, resistant to oxidation.

Used for hull, superstructure, and fuel tank panels.

Temper: O H111 H112 H22 H32

-

5059 marine grade aluminum plate

High tensile performance and good low-temperature performance;

Non-magnetic aluminum plate.

Temper: O H111 H116 H321

-

5454 marine grade aluminum plate

Strong weather resistance and good weldability;

Ship structure of fast boats, fishing boats, large cargo ships, etc.

Temper: O H111 H22 H32 H112

-

5754 marine grade aluminum plate

Maintain rated value at 150-300 degrees Fahrenheit;

Ship structure, offshore facilities, and chemical container handling.

Temper: H111 H112 O

-

6061 marine grade aluminum plate

Lightweight, solderability and slip resistance;

Sailboats, catamarans, ship decks and floors;

Temper: O T4 T6 T651 T6511

-

6082 Marine ribbed aluminum plate

High strength, good corrosion resistance;

Structural alloy, suitable for hull and superstructure;

Temper: T6

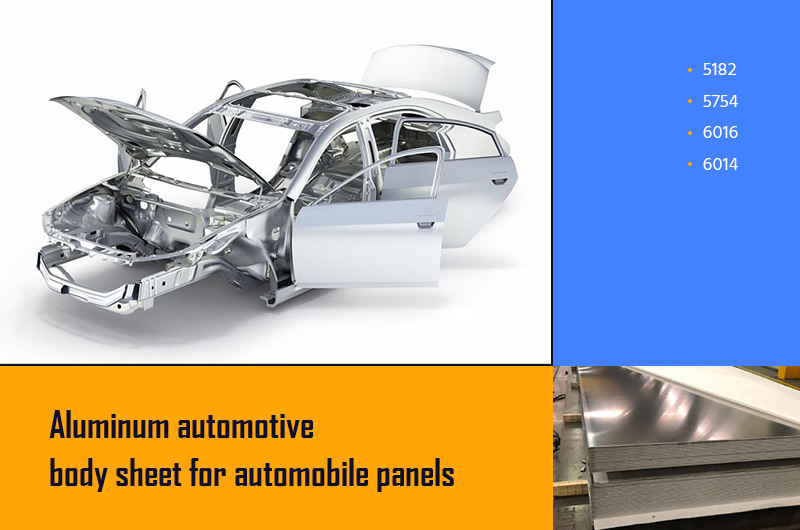

Good formability of automobile body aluminum sheet

Automobile body aluminum sheet

6xxx: 6013, 6016, 6061, 6063, 6082, 6111, 6022, 6181

5xxx: 5052, 5182, 5083, 5754, 5049

Other: 2024, 7075, 1100

Contact us nowAutomotive aluminum plates are favored by many manufacturers due to aluminum’s high strength, excellent corrosion resistance, impact resistance, formability, and superb weldability.

The 6000 series aluminum is primarily used for automotive applications, offering outstanding formability and a smooth surface finish.

Automotive standards:IATP16949 (British Standards Institution)

-

6013 auto body aluminum sheet

Auto door outer panel

Fender panel

Auto roof panel

Temper: T4 T6

-

6014 auto body aluminum sheet

Engine hood inner and outer panels

Door outer panel

Trunk outer panel

Temper: T4Pa T6Bb

-

6016 auto body aluminum sheet

Engine hood inner panel

Auto door panel

Inner and outer trunk panels Car bracket plate

Temper: T4Pa T6Bb

-

6022 auto body aluminum sheet

Auto body covering panel

Carriage side panel

Auto roof panel

Temper: T4Pa T6Bb

-

6111 auto body aluminum sheet

Door outer panel

Fender and car wall panel

Body structural components and reinforcements

Temper: T4 T6

-

6181 auto body aluminum sheet

Door and car wall panel

Auto roof panel

Body structural components

Temper: T4Pa T6Bb

-

6061 auto body aluminum sheet

Car bracket inner plate

Temper: T4Pa T6Bb

-

6063 auto body aluminum sheet

Auto body structural components

Auto body reinforcement

Temper: O T4

-

6082 auto body aluminum sheet

Auto body structural components

Auto body reinforcement

Temper: O T4

-

2024 auto body aluminum sheet

Auto body structural components

-

7075 auto body aluminum sheet

Auto body structural components

Auto body reinforcement

-

1100 Embossed Heat Shield Sheet

Corrosion resistance, High thermal conductivity

heat insulation of automobile engine and exhaust, etc.

Corrosion-resistant aluminum plate for tank trucks

Alloy: 5182, 5083, 5454, 5754, 5052

Size: Max width 2650, Max length 16m

Type: Mirror alu plate, alu checkered plates

Contact us nowThe 5000 series aluminum plates are favored by tank truck manufacturers due to their lightweight, high strength, excellent weldability, and outstanding corrosion resistance. Chalco offers tank truck aluminum plates up to 2650mm wide and 16m long, and also supplies mirror-finish plates popular in the Middle East.

Standard: ASTM B209, EN14286(European standard for the safety of liquid transport tank trucks)

-

5083 tanker aluminum plate

Good welding, processing performance, corrosion resistance

Used for tanks, wave-breaking plates, bulkheads, etc.

Temper: O H111

-

5182 tanker aluminum plate

New high-magnesium alloy with high strength

Tank body, tank cover, etc. of dangerous goods transport tank trucks

Temper: O H111

-

5454 tanker aluminum plate

Good strength and high temperature resistance

Used for polishing tank bodies, tank heads, washing plates, etc.

Temper: O H111

-

5754 tanker aluminum plate

Good corrosion resistance, workability, medium strength

Used in tank materials, internal partitions, top and side panels

Temper: O H111

-

5052 tanker alu tread plate

Corrosion resistance, Processing performance

Used in top walkway and door steps

Temper: O H114

-

3003 tanker alu tread plate

Good corrosion resistance, Strong wear resistance

Used in top walkway and door steps

Temper: O H14

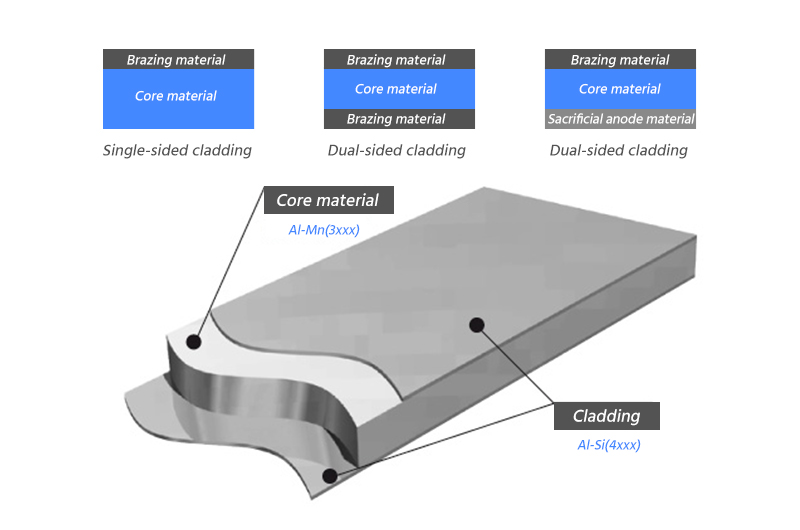

Aluminum brazing sheets for heat exchangers

Aluminum brazing sheet coil strip

Brazing sheet is a layered aluminum alloy with a lower melting temperature than the core material, clad on one

or both sides.Primarily employed in crafting heat exchange system components for motor vehicles.

Non-clad alloy:4104, 4004, 4047, 4045, 6951

Clad alloy: 4343/3003/4343, 4343/3003/7072, 4045/3003/4045, 4104/3003/4104, 4004/3003/4004

Advantages:

- Select the best combination of core materials and brazing materials according to the use environment and each specific customer's needs, and combine them into products;

- By determining the brazing material and cladding ratio of alloy and using flow control to form highly reliable layer bonding, highly reliable aluminum materials can be developed;

- By determining the compatibility of brazing materials with the materials to be connected (fin materials or pipes), determine the alloy used as the core material, its metal composition and the best tempering, so as to develop products with high corrosion resistance;

- The products are exported to countries all over the world.

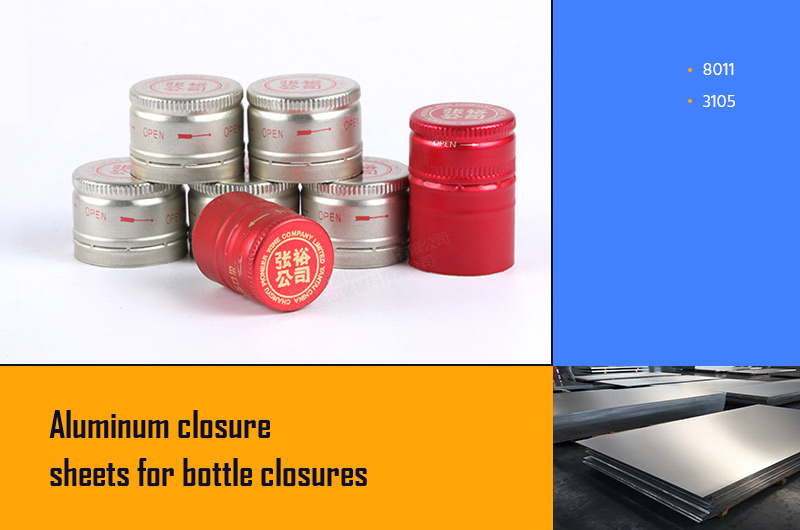

Aluminum closure sheets for bottle closures

Advantages:

- Control rolling temperature and annealing temperature to achieve good earing rate and deep drawing performance.

- The surface is treated with DOS to improve the paint adhesion.

- The flatness of the product is good, and the diagonal tolerance control is good, so as to avoid misplacement of printing.

- Mill finish, DOS lubricated, color coated, Logo printed all available.

Application:Aluminum screw caps, ROPP caps, vial seals, Omnia cap, twist off cap, EOE end and cosmetic packaging.

Aluminum sheets for beverage containers

Aluminum materials for beverage cans

Can body: 3004, 3104

Can lid: 5052, 5182

Pull-tab ring: 5182

Contact us nowAdvantages:

- Good performance, high pressure resistance;

- By adjusting the proportion of raw materials, control the downward pressure and temperature control on the roll during production, so as to achieve the best strength and processing hardness;

- Soaking temperature and duration, downward pressure and temperature control of the roll are used to achieve the best metal structure and control the amount of solute and precipitate.

Aluminum cast tool and jig plate

Typical alloy: 2024, 5052, 5083, 5086, 6061, 7075

Thickness: 6~150mm

Width: 1000~2500

Contact us nowAdvantages:

- High strength, good corrosion resistance and oxidation resistance.

- Stress relief state, small processing deformation, good formability and weldability.

- The product is easy to process and has good surface treatment effect.

- The product is isotropic with high dimensional stability.

3C Electronic Devices Shell Aluminum Sheet

3C Electronic Devices Shell Aluminum Sheet

Mobile phones: 5252, 6013, 6063, 7021, 7075

Computers: 5052, 5252, 6061, 6063

3C Electronic Devices: 1050, 1060, 1070, 5052, 5252, 6063

Contact us nowAdvantages:

- High thermal conductivity and high strength.

- Good formability, good drawability, tensile properties and bending formability.

- Aluminum is lighter than stainless steel or copper and is a good choice for heat transfer and weight reduction.

Pre-Sensitized Plate Substrat

Advantages:

- Excellent surface quality - no dirt or surface defects.

- It has excellent heat softening resistance to prevent the sheet from changing shape.

- Use high-quality materials that do not deform and have high flatness.

- Electrochemical treatment is used to ensure consistent surface roughness.

Introduction to Aluminum Alloys (Comprehensive Overview)

1060 aluminum sheet plate has high elongation, tensile strength, excellent conductivity and high formability, which can meet the requirements of conventional processing (stamping, stretching).

1070 aluminum plate has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, and its advantages are often used to manufacture some structural parts with specific performance, such as protective mesh of wires and cables, core and ventilation system parts and decorative parts.

1100 H14 aluminum plate sheet is industrial pure aluminum, which has the advantages of high elongation, tensile strength, excellent conductivity, high formability, etc. It is usually used for parts that require good formability, high corrosion resistance, and do not need high strength.

2024 T3 aluminum sheet plate is one of the superior products of Chalco Aluminum. The product belongs to high-strength duralumin and has certain heat resistance. The formability is good in thermal state, annealing and new quenching state, and the heat treatment strengthening effect is significant. The product is widely used in the field of molds, parts, etc.Quick Quote

2A12 aluminum plate is one of the superior products of Chalco Aluminum. The product belongs to high-strength duralumin, which can be strengthened by heat treatment and has good spot welding performance.

2017 aluminum plate is a typical duralumin alloy in the Al Cu Mg system, with good comprehensive performance and a large amount of duralumin. Widely used in molds, precision parts, rivets, truck hubs, propeller components and other various structural parts.

2014 aluminum plate has high strength and good pin cutting processing performance. 2014 aluminum plate is used in occasions requiring high strength and hardness (including high temperature), such as molds, high-strength machine parts, heavy forgings, thick plates and extrusion materials, wheels, truck frames and suspension system parts.

3003 H14 aluminum sheet has good formability, corrosion resistance and weldability, and is often used to make power battery shells, cooking utensils, food storage devices, tanks and warehouses on transportation equipment, metal sheet pressure vessels and pipes in lightweight vehicles.

3004 aluminum sheet plate has higher strength than 3003 aluminum plate, good formability, solubility and corrosion resistance, and requires parts with higher strength than 3003 aluminum plate, which are widely used in factory building panels, louvers, lamp caps, LCD backplates, signs, curtain wall materials, pop top cans and other places.

3105 aluminum sheet has good rust resistance, good conductivity, good rust resistance, good conductivity, and high formability. It is commonly used as aluminum substrate for room partition, color coating, lamp cap material, shutter, bottle cap, bottle stopper, etc.

3104 aluminum sheet plate has good deep drawing performance, which is suitable for thinning, stretching and lightening to reduce the material consumption. The requirements for each process of beverage can cover and bottom materials are strict, and our company strictly controls each process, so that the product has appropriate strength and formability.

The strength of 3005 aluminum sheet plate is about 20% higher than that of 3003 aluminum plate, and the corrosion resistance is also better. It can also be called rustproof aluminum plate. The main application scopes are battery shell material, radiator, cosmetic plate, photocopier drum, etc.

The brazing performance of 4047 aluminum sheet plate is very good, and it is often used as the cladding plate of brazing aluminum plate, or as the welding pad alone.

5052 H32 H34 aluminum sheet plate is a high sales product of Chalco Aluminum. It has sophisticated processing technology, stable product performance, good molding and processing performance, and corrosion resistance. It is a widely used rust proof aluminum. The product is widely used in the fields of trolley box, fuel tank material, LCD backplane, tank body material, door plate material, high-voltage switch housing, etc.

5083 marine aluminum plate has high strength, corrosion resistance and light weight. 5083 H116/H321/H112 marine aluminum plate has been successfully used on yachts, cruise ships and other hulls.

5083 aluminum plates are also used in vehicles, such as aluminum alloy tank car body, tank body, car fuel tank, air reservoir, bus skin, C82 coal truck, roof and bottom guard board, etc. 5083 aluminum mold tool plate is commonly used for making molds, LNG tanks, flange materials, GIS high-voltage switch shells, precision machining, etc.

5754 H22 H111 aluminum sheet plate has the characteristics of good corrosion resistance, excellent processing performance, weldability and easy processing and forming, It is used in high-speed rail sound barrier, tank car body materials, high-grade alloy doors and windows, aluminum for construction, transportation, automobile and other fields.

5182 aluminum sheet has good corrosion resistance, good cold workability, medium strength, high tensile strength and yield strength. It has been applied in batches in many industries, such as auto interior parts, pull ring materials, pop can tube covers, refrigeration devices, electrical enclosures, cabinets and other parts.

5454 aluminum sheet can adapt to harsh corrosion environment. It is a typical rust proof aluminum with high strength. It is widely used in automobile, aluminum tank car cylinder and other fields, and has a good reputation.

5A06 aluminum plate has high strength, corrosion resistance and stability, and is widely used for maritime purposes, such as ships, automobiles, aircraft weldments, and metro light rail.

5005 alloy aluminum sheet has medium strength and good corrosion resistance, good fusion and processability, and the anodizing film is brighter than that on 3003 alloy. It is commonly used as conductor, cooker, instrument panel, shell and architectural decoration, interior and exterior decoration materials of building materials, interior decoration materials of vehicles, etc.

5086 H111 H321 H116 aluminum plate is widely used in situations where high corrosion resistance, good weldability and medium strength are required, such as weldable parts of ships and automobiles, pressure vessel, refrigeration device, TV tower, installation and exploration equipment, transportation equipment, etc.

5059 aluminum plate with good corrosion resistance and tensile strength, is a 5-series product with excellent comprehensive performance, widely used in ships, tank cars and other fields, and the market demand is rising.

6061 aluminum plate sheet can eliminate internal stress and cut without deformation, It is widely used in 3C fields such as mobile phone card slot, keys, computer bracket, computer shell, and trolley case, aluminum furniture, door panel and handle, etc.

6063 alloy aluminum plate sheet has superior processing performance, excellent weldability, extrudability and electroplating, good corrosion resistance, toughness, easy polishing, coating, and excellent anodizing effect. It is widely used in automobile lightweight, mobile phone shell and other fields.

6082 aluminum plate has good corrosion resistance, can be machined, welded, and has excellent molding performance. It has good anodic reaction performance. It is often used as a mold and fixture.

6101 aluminum sheet plate can be used for high-strength conductive materials. It has good corrosion resistance and weldability, and is used for processing high-strength bus conductor.

6060 aluminum plate has the characteristics of impact resistance, moderate strength, good weldability, etc. It is a class of nonferrous metal structural materials widely used in industry, and has been widely used in automobile, machinery manufacturing, shipbuilding and chemical industry.

6005 aluminum plate is widely used in the construction industry.

7075 T6 aluminum plate sheet can eliminate internal stress and cut without deformation. It is suitable for shoe mold, high-strength mold, high-strength parts and other fields.

7050 T7451 aluminum plate has high strength and strong corrosion resistance. It is mainly used for mold processing, mechanical equipment, tooling and fixtures, especially for high stress structures.

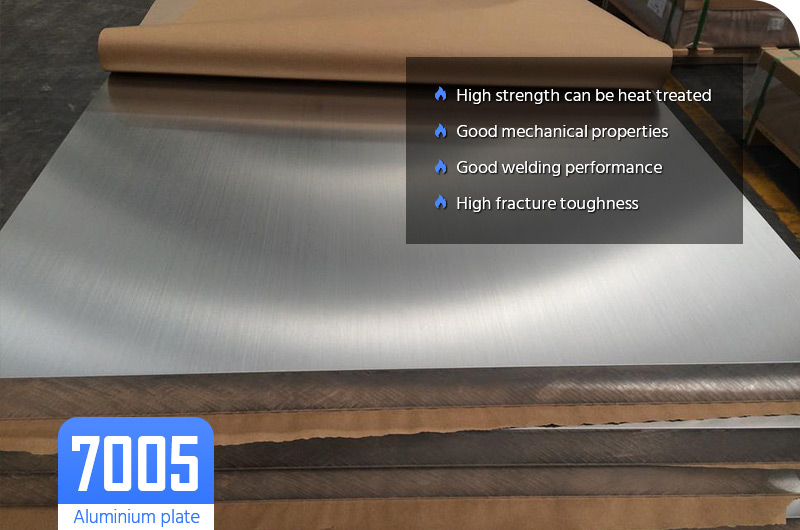

7005 aluminum plate is super hard aluminum with good welding performance and can be strengthened by heat treatment. It is a typical lightweight aluminum material. It is often applied to welded structures with high strength and high fracture toughness, such as vehicle trusses, bars and containers, large heat exchanger, etc.

7475 aluminum plates are used for aluminum clad and non aluminum clad plates, wing frames, purlins and other parts with high strength and fracture toughness.

8011 aluminum sheet has good deep drawing performance and is often used as packaging material, bottle cap material, etc.

Heat treated aluminum plates and non-heat treated aluminum plates

Non-heat treated aluminum sheets plates

- 1000: 1060, 1070, 1100

- 3000: 3003, 3105, 3104, 3004

- 4000: 4104, 4004, 4047, 4045, 4043

- 5000: 5052, 5754, 5454, 5182, 5083, 5353, 5086

- 8000: 8011, 8079, 8006

| Temper | O, F, H111, H112, H12, H14, H16, H18, H19, H22, H24, H26, H38, H116, H321 |

| Thickness | 0.2mm-200mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

| Standard | GB/T3880, GJB1541, GJB2662, STMB209, ASME SB-209, EN485, ASTMB928M |

Heat treated aluminum plates sheets

- 2000: 2A12, 2011, 2014, 2017, 2024, 2618

- 6000: 6061, 6082, 6063, 6101, 6060

- 7000: 7075, 7005, 7050, 7475, 7175

| Temper | O, F, H111, H112, T3, T4, T6, 7, T351, T451, T651, T851, T7451, T74, T87 |

| Thickness | 0.3mm-200mm |

| Width | 1000-38000mm |

| Length | 2000-12000mm |

| Standard | GB/T3880, GJB1541, GB/n167, JB2053, GJB2662, ASTM B209, ASME SB-209, EN 485 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote