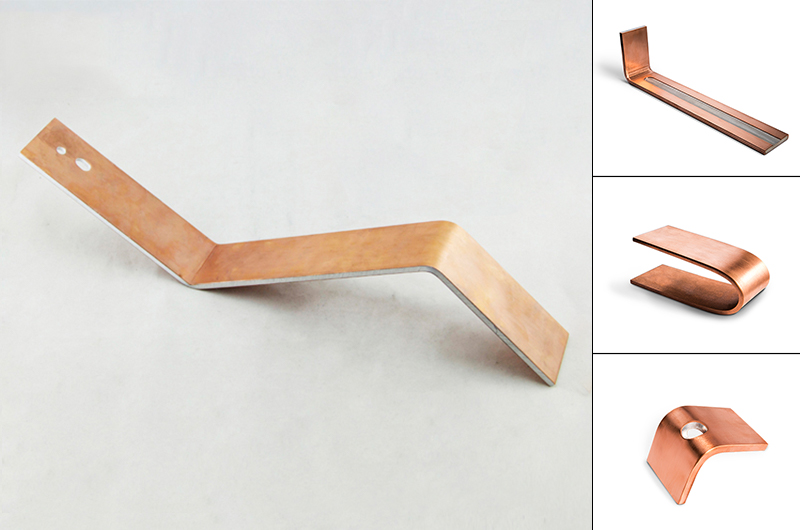

Copper-clad aluminum busbar, also known as CCA busbar and bimetal conductive bar, is the third generation of "new energy-saving conductor material" after copper and aluminum. It is a conductive material commonly used in power transmission and distribution systems. It consists of an aluminum core wrapped in a copper layer. The copper-clad aluminum busbar combines the advantages of copper and aluminum, with high electrical conductivity and low weight.

Chalco can customize copper-clad aluminum busbars of various sizes and supply them to one of the world-renowned power company suppliers such as SIEMENS, HITACHI (ABB), TOSHIBA, LEGRAND, EATON, etc.

Copper clad aluminum busbar /CCA busbar specifications

| Copper material | T2 |

| Aluminum material | 1050/1060/1070/1100 |

| Temper | H28/H26/H24/O |

| Copper-aluminum composite ratio (%) | 10%/15%/20%/25%/30%/35% |

| Thickness (mm) | 3.0mm~120mm |

| Width (mm) | 10mm~250mm |

| Length (mm) | 1000mm/2000mm/3000mm |

| Production standard | GB/T 30586-2014, ASTM B1005 − 17 |

| Remarks: | The above specifications are for reference, special specifications can be customized |

Copper clad aluminum busbar /CCA busbar size deviation

| Thickness/mm | Thickness Tolerance/mm | Width/mm | Width Tolerance/mm |

| >3.00~6.00 | ±0.10 | ≤30.00 | ±0.50 |

| >6.00~10.00 | ±0.15 | >30.00~100.00 | ±0.80 |

| >10.00 | ±0.20 | >100.00 | ±1.20 |

Copper clad aluminum busbar /CCA busbar chemical composition

The copper layer of the copper-clad aluminum busbar is made of T2 copper or C11000, the chemical composition

| Element | Composition |

| (Cu) | 99.9 |

| (P) | <0.015 |

| (Pb) | <0.005 |

| (Zn) | <0.005 |

| (Fe) | <0.005 |

| (Sn) | <0.002 |

The core layer of the copper-clad aluminum busbar is made of 1000 series pure aluminum, commonly used are 1050, 1060, 1070, 1100, etc., the chemical composition

| Element (%) | Composition (%) | |||

| 1050 | 1060 | 1070 | 1100 | |

| (Al) | 99.5 | 99.6 | 99.7 | 99 |

| (Si) | 0.25 | 0.25 | 0.2 | 0.95 |

| (Fe) | 0.4 | 0.35 | 0.25 | 0.7 |

| (Cu) | 0.05 | 0.05 | 0.04 | 0.05 |

| (Mn) | 0.05 | 0.03 | 0.03 | - |

| (Zn) | 0.05 | 0.05 | 0.04 | 0.1 |

| (Ti) | - | - | - | 0.2 |

| Other | 0.15 | 0.15 | 0.15 | 0.15 |

Bimetal conductive busbar room temperature physical properties

| Coating layer volume ratio/% | Temper | Density (g/cm3) | interface bonding strength/MPa | Tensile strength/MPa | Elongation/% | Maximum DC resistance (Ω·mm2/m) | volume conductivity not less than (%IACS) | Brinell Hardness HB |

| 20% | H28 | 3.94 | ≥40 | ≥220 | ≥3 | 0.02596 | 66.4% | ≥80 |

| H26 | ≥40 | ≥190 | ≥7 | 0.02596 | 66.4% | 65-75 | ||

| H24 | ≥40 | ≥160 | ≥12 | 0.02596 | 66.4% | 50-60 | ||

| O | ≥40 | ≥110 | ≥25 | 0.0255 | 67.6% | 20-30 | ||

| 25% | H28 | 4.25 | ≥40 | ≥230 | ≥3 | 0.02548 | 67.7% | ≥80 |

| H26 | ≥40 | ≥200 | ≥8 | 0.02548 | 67.7% | 65-75 | ||

| H24 | ≥40 | ≥170 | ≥16 | 0.02548 | 67.7% | 50-60 | ||

| O | ≥40 | ≥115 | ≥30 | 0.02498 | 69% | 20-30 | ||

| 30% | H28 | 4.56 | ≥40 | ≥230 | ≥3 | 0.02477 | 69.6% | ≥80 |

| H26 | ≥40 | ≥200 | ≥8 | 0.02424 | 72.4% | 65-75 | ||

| H24 | ≥40 | ≥170 | ≥16 | 0.02498 | 72.4% | 50-60 | ||

| O | ≥40 | ≥115 | ≥30 | 0.02477 | 71.1% | 20-30 | ||

| 35% | H28 | 4.87 | ≥40 | ≥230 | ≥3 | 0.02424 | 72.4% | ≥80 |

| H26 | ≥40 | ≥200 | ≥8 | 0.02498 | 72.4% | 65-75 | ||

| H24 | ≥40 | ≥170 | ≥16 | 0.02477 | 72.4% | 50-60 | ||

| O | ≥40 | ≥115 | ≥30 | 0.02424 | 74.1% | 20-30 |

CCA busbar specification and AC ampacity reference table

The AC ampacity of a single product is shown in the table below, and the DC ampacity should be increased appropriately by referring to the table below.

The data in the table below are indoor test data, without considering the influence of outdoor factors such as wind speed.

The data in the table is the AC current carrying capacity when the sample is placed vertically without coating. When the sample is placed flat, when the width is ≤60.00mm, the data in the table should be multiplied by 0.95; when the width is >60.00mm, the data in the table should be multiplied by 0.92.

The product works stably in an environment of 25°C, and the AC ampacity when the temperature rise is 50K, 65K and 75K.

To learn about the current carrying capacity of different specifications, you can download the PDF. If you want to know more about copper-aluminum composite busbar products, please contact Chalco aluminum, and we will provide you with a good solution.

| Size(W×T)mm×mm | Current carring capacity(25℃)/A | ||||||||

| VPCu=20% | VPCu=25% | VPCu=30% | |||||||

| 50K | 65K | 75K | 50K | 65K | 75K | 50K | 65K | 75K | |

| 15.00×4.00 | 193 | 213 | 222 | 196 | 210 | 225 | 200 | 213 | 229 |

| 20.00×4.00 | 250 | 276 | 288 | 254 | 273 | 293 | 259 | 277 | 298 |

| 25.00×4.00 | 310 | 341 | 355 | 314 | 339 | 363 | 321 | 345 | 370 |

| 30.00×4.00 | 326 | 361 | 375 | 336 | 362 | 387 | 347 | 372 | 399 |

| 30.00×5.00 | 425 | 453 | 476 | 438 | 453 | 489 | 450 | 466 | 503 |

| 30.00×6.00 | 486 | 538 | 562 | 499 | 539 | 579 | 514 | 554 | 595 |

| 30.00×8.00 | 579 | 643 | 678 | 596 | 644 | 697 | 613 | 662 | 717 |

| 30.00×10.00 | 638 | 711 | 724 | 658 | 712 | 745 | 676 | 733 | 767 |

| 40.00×4.00 | 453 | 498 | 517 | 465 | 500 | 532 | 479 | 513 | 547 |

| 40.00×5.00 | 538 | 604 | 633 | 554 | 605 | 652 | 570 | 622 | 670 |

| 40.00×6.00 | 612 | 677 | 708 | 630 | 679 | 728 | 649 | 698 | 750 |

| 40.00×8.00 | 725 | 805 | 847 | 746 | 806 | 873 | 767 | 829 | 897 |

| 40.00×10.00 | 790 | 894 | 949 | 814 | 896 | 977 | 837 | 921 | 1005 |

| 50.00×5.00 | 665 | 735 | 765 | 684 | 736 | 788 | 703 | 758 | 810 |

| 50.00×6.00 | 755 | 836 | 872 | 777 | 836 | 898 | 799 | 861 | 923 |

| 50.00×8.00 | 891 | 989 | 1042 | 918 | 990 | 1072 | 944 | 1019 | 1103 |

| 50.00×10.00 | 969 | 1061 | 1107 | 998 | 1061 | 1139 | 1026 | 1092 | 1172 |

| 60.00×5.00 | 759 | 856 | 892 | 781 | 858 | 918 | 804 | 882 | 945 |

| 60.00×6.00 | 861 | 952 | 995 | 886 | 953 | 1025 | 911 | 980 | 1053 |

| 60.00×8.00 | 1011 | 1123 | 1182 | 1041 | 1124 | 1216 | 1070 | 1156 | 1252 |

| 60.00×10.00 | 1093 | 1215 | 1279 | 1125 | 1218 | 1318 | 1157 | 1253 | 1355 |

| 80.00×6.00 | 1081 | 1197 | 1250 | 1113 | 1198 | 1287 | 1145 | 1232 | 1323 |

| 80.00×8.00 | 1265 | 1405 | 1479 | 1302 | 1407 | 1523 | 1340 | 1448 | 1566 |

| 80.00×10.00 | 1362 | 1505 | 1583 | 1402 | 1507 | 1629 | 1442 | 1550 | 1676 |

| 100.00×6.00 | 1283 | 1419 | 1483 | 1320 | 1422 | 1527 | 1358 | 1462 | 1571 |

| 100.00×8.00 | 1504 | 1669 | 1758 | 1548 | 1672 | 1811 | 1593 | 1719 | 1862 |

| 100.00×10.00 | 1620 | 1790 | 1883 | 1668 | 1793 | 1938 | 1716 | 1844 | 1993 |

| 120.00×8.00 | 1740 | 1932 | 2035 | 1791 | 1935 | 2095 | 1842 | 1990 | 2154 |

| 120.00×10.00 | 1890 | 2090 | 2197 | 1946 | 2094 | 2261 | 2002 | 2153 | 2326 |

| 140.00×8.00 | 1996 | 2216 | 2333 | 2054 | 2218 | 2402 | 2114 | 2282 | 2471 |

| 140.00×10.00 | 2199 | 2447 | 2556 | 2264 | 2452 | 2631 | 2329 | 2522 | 2706 |

| 160.00×8.00 | 2223 | 2468 | 2599 | 2289 | 2472 | 2660 | 2354 | 2543 | 2753 |

| 160.00×10.00 | 2449 | 2718 | 2846 | 2521 | 2730 | 2929 | 2594 | 2809 | 3014 |

| 180.00×8.00 | 2465 | 2736 | 2882 | 2538 | 2740 | 2967 | 2611 | 2819 | 3053 |

| 180.00×10.00 | 2717 | 3023 | 3157 | 2796 | 3029 | 3250 | 2877 | 3116 | 3343 |

| 180.00×12.00 | 2816 | 3156 | 3297 | 2902 | 3165 | 3398 | 2989 | 3258 | 3498 |

| 200.00×8.00 | 2701 | 2998 | 3157 | 2784 | 3007 | 3255 | 2866 | 3095 | 3330 |

| 200.00×10.00 | 2980 | 3317 | 3463 | 3069 | 3324 | 3566 | 3159 | 3422 | 3671 |

| 200.00×12.00 | 3093 | 3464 | 3627 | 3187 | 3474 | 3734 | 3282 | 3577 | 3840 |

The main application fields of copper clad aluminum busbar

Power transmission and distribution station: Copper-clad aluminum busbar is used to connect transformers, switchgear and power distribution equipment, and transmit electric energy to different power transmission and distribution stations.

Industrial field: In the industrial field, copper-clad aluminum busbars are often used to connect power equipment, machines, and power distribution systems in factories, such as generators, motors, and electrical control cabinets.

Architecture and Buildings: Copper-clad aluminum bus bars are used in power distribution and grounding systems in buildings and buildings, including commercial buildings, office buildings, residential buildings and public facilities.

New energy power station: In new energy power stations such as solar power generation and wind power generation, the copper-clad aluminum busbar is used to connect the power transmission between the generator set, the converter and the grid.

Electric vehicle charging facilities: With the popularity of electric vehicles, copper-clad aluminum busbars play an important role in electric vehicle charging facilities, used to transmit power to charging piles and charging equipment.

Electronic communication equipment: Copper-clad aluminum busbars are also used in electronic communication equipment, such as base stations, communication equipment and data centers, for power distribution and grounding systems.

It should be noted that the specific application areas may vary according to power requirements, system scale and design requirements. Therefore, in specific applications, appropriate busbar materials and specifications should be evaluated and selected according to actual conditions.

The price of copper clad aluminum busbar

Copper-clad aluminum bus bar price: (LME copper price + processing fee) x weight + packaging fee + transportation fee

The price of copper-clad aluminum bus bars will be affected by many factors, such as market supply and demand, copper raw material prices, processing costs, specifications, and other factors. Different manufacturers and suppliers may have different pricing strategies and price levels. In addition, it is also affected by factors such as currency exchange rate and international economic situation.

Therefore, please contact Chalco aluminum for inquiry, we will provide you with the best quotation and service.

Points to note when purchasing copper-clad aluminum bus bars

Material quality: Make sure to choose a reliable copper-clad aluminum busbar supplier or manufacturer to ensure that the material meets international standards and relevant specifications. Consider the reputation of the supplier and the product quality control system.

Composite ratio: Select a suitable composite ratio according to specific application requirements and technical requirements. Different compounding ratios may affect aspects such as electrical conductivity, current carrying capacity, and mechanical strength.

Dimensions: Choose appropriate dimensions according to actual needs, including thickness, width and length. Make sure the size selected meets the project requirements to ensure proper current carrying capacity and installation requirements.

Surface treatment: Consider the surface treatment of the copper-clad aluminum busbar, such as tin plating, silver plating or other anti-corrosion coatings. Surface treatments can improve electrical conductivity, extend service life and provide corrosion resistance.

Technical support: Cooperate with suppliers or manufacturers to obtain technical support and consultation. They can provide expert advice on product selection, installation guidance and performance evaluation.

Standard certification: ensure that the selected copper-clad aluminum busbar meets international standards and certification requirements, such as ASTM, EN, JIS, etc. Check relevant certification documents or product specification sheets to ensure that the product meets the required quality and performance standards.

Price and performance comparison: During the purchase process, comprehensively consider price, performance and quality for comparison and evaluation. Not only focus on price, but also consider the long-term reliability and performance requirements of the product.

Reference testimonials and experiences: Knowing the testimonials and experiences of other users or professionals with different brands and suppliers can help you make more informed choices.

How to produce double-sided copper-clad aluminum busbar?

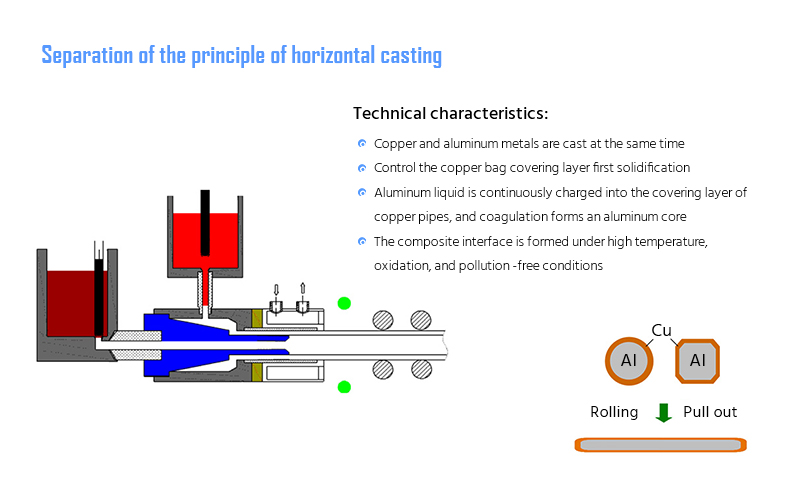

The copper-aluminum composite busbar produced by Chalco is different from traditional production processes such as static pressure extrusion method, rolling crimping method, cladding welding method, sleeve rolling method, etc., and adopts the original "horizontal continuous casting-drawing method" - Rolling annealing high-efficiency forming technology enables the bonding interface of copper-aluminum composite busbars to achieve a certain metallurgical bond, enhances the shear strength of the two metal interfaces, ensures the mechanical and electrical properties of the product, and improves the stability of the product.

Chalco-copper clad aluminum busbar quality assurance

The copper-aluminum composite row produced by Chalco will go through the following quality inspections to ensure that the product quality is qualified before delivery.

Quality inspection includes: salt spray test; eddy current conductivity test; metallographic microscope; spectral analysis; high and low temperature alternating experiment; Brinell hardness statistics; analytical balance;