Chalco's independent enameled wire production line has international ISO 9001, CQM, and SGS certifications. Enameled wire products comply with IEC-60317, GB/T, JIS, NEMA, RoHS standards, and have passed UL (E234565) certification.

Adopting advanced mold painting technology to solve problems such as eccentricity in felt painting and uneven pressure resistance. The paint film has good adhesion, the wire has uniform diameter and good pressure resistance. The elongation rate is up to 45%, thus the round wire can be flattened into enameled aluminum flat wire.Welcome contact

Specification of Chalco 130/155 polyester enamelled aluminium round wire

| Product type | PEWA130/PEWA155 QZ-130/QZGB155 |

| Diameter | Click to view the detailed【table of dimensions, film thickness, and tolerances】 |

| Nominal diameter of conductor |

Grade 1: Above 0.400mm but below 1.600mm; Grade 2: Above 0.400mm and below 5.000mm |

| Paint film thickness grade | 1 grade, 2 grade, 3 grade |

| Paint film characteristics | Reduce the surface friction coefficient of the paint film, with strong elasticity and scratch resistance, suitable for automated high-speed winding and mechanical embedding. Provide self-adhesive paint, corona resistant paint film, etc. |

| Minimum scratch resistance of paint film |

Grade 1 130/150 polyester enameled wire with a minimum average scratch force of 1.95N Grade 2 130/150 polyester enameled wire with a minimum average scratch force of 3.15N |

| Production standard | EC60317-3; GB/T6109.7 GB /T23312.3; MW 24-A |

| Reels | PT25 PT30 PT35 PT60 PT90 PT200 PT270 wooden spool, with a maximum weight of up to 150kg per roll Conical spools or other wire reels are available, and models can be customized according to customer requirements |

performance parameter of Chalco 130/155 class polyester enamelled aluminum round wire

| Parameter | 130 class polyester enamelled aluminum round wire | 155 class polyester enamelled aluminum round wire |

| Heat resistance level | B Grade | F Grade |

| resistivity | 0.5 - 1.0 Ω·mm²/m | 0.3-0.8Ω·mm²/m |

| Thermal Shock | Lowest temperature 155℃ | Lowest temperature 175℃ |

| Breakdown Voltage | 2 - 4 kV/mm | Above 5kV |

| Chalco also offers 180/200/220/240 temperature resistant enameled wire with a breakdown voltage of up to 7KV | ||

| Insulation performance | Anti mechanical overload, heat resistance, chemical resistance, and corona resistance, facilitating welding and sintering | |

| Elongation | 15%-48% | |

| Minimum tensile strength | 70-90 N/mm 2 | |

Features of Chalco 130/155 class polyester enamelled aluminum round wire

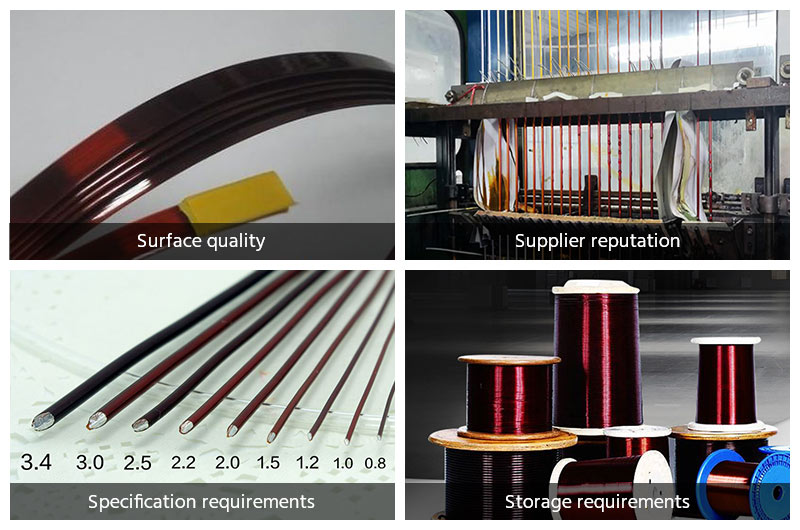

- The surface is free of pinholes, burrs, paint flow, and aluminum leakage.

- Good corona resistance, excellent softening and breakdown performance, and excellent overload resistance.

- The elongation of the round wire is good, with a flattening degree of 25-45%. After flattening, the paint surface does not crack, and the groove filling rate is high.

- Mold painting, uniform baking temperature and film thickness, and uniform voltage.

- The wiring is well arranged and there are threading holes left, no backline during use, improving the safety of electrical circuits.

Aluminum enameled wire also has some limitations, such as poor hydrolysis resistance (attention should be paid when used in enclosed motors and electrical appliances); Grade 130/155 polyester enameled aluminum round wires are not suitable for use in high-efficiency motors.Quick Quote

FAQ for purchasing enamelled aluminum wire

Q: What is the production process of Chalco enamelled aluminum round wire?

A: Enamelled wire is made by coating insulation paint on the conductor and baking it to form a uniform and smooth insulation film of a certain thickness.

Including annealing - cooling - painting - baking - cooling (repeated painting and baking cooling) - surface lubrication - online testing - finished enameled wire.

Q: How to guarantee the quality of Chalco enamelled aluminum round wire?

A: Chalco provides comprehensive quality testing to ensure the quality of enameled wires, including conductor diameter uniformity testing, paint film flexibility and adhesion testing, paint film curing testing, scratch resistance testing, elongation testing, elasticity testing, thermal shock testing, breakdown testing, friction coefficient wiping, weldability testing, etc.; It can also be tested according to customer requirements.

Q: Application field of Chalco 130/155 class polyester enamelled aluminum round wire?

A: Windings for general small and medium-sized motors; Coils of transformers and electrical instruments; Electric fans, microwave ovens, and other household appliance motors.

Q: What are the self adhesive enameled wire products available for Chalco 130/155 polyester enameled wire?

A: Chalco can provide electrified self-adhesive enameled wires, hot-melt self-adhesive enameled wires, and alcohol melt self-adhesive enameled wires.

Dimensions of Chalco enameled aluminum round wire

| Dimensional values derived from IEC 60317-0-3: 2008 Standard | |||||||

| Conductor Diameter | Minimum Enamel Thickness/mm | Maximum Overall Thickness/mm | |||||

| ICE standard | Tolerance | 1 Grade | 2 Grade | 3 Grade | 1 Grade | 2 Grade | 3 Grade |

| 0.250 | ±0.004 | 0.017 | 0.032 | 0.048 | 0.281 | 0.297 | 0.312 |

| 0.280 | ±0.004 | 0.018 | 0.033 | 0.050 | 0.312 | 0.329 | 0.345 |

| 0.315 | ±0.004 | 0.019 | 0.035 | 0.053 | 0.349 | 0.367 | 0.384 |

| 0.355 | ±0.004 | 0.020 | 0.038 | 0.057 | 0.392 | 0.411 | 0.428 |

| 0.400 | ±0.005 | 0.021 | 0.040 | 0.060 | 0.139 | 0.459 | 0.478 |

| 0.450 | ±0.005 | 0.022 | 0.042 | 0.061 | 0.491 | 0.513 | 0.533 |

| 0.500 | ±0.005 | 0.024 | 0.045 | 0.067 | 0.544 | 0.566 | 0.587 |

| 0.560 | ±0.006 | 0.025 | 0.047 | 0.071 | 0.606 | 0.630 | 0.653 |

| 0.630 | ±0.006 | 0.027 | 0.050 | 0.075 | 0.679 | 0.704 | 0.728 |

| 0.710 | ±0.007 | 0.028 | 0.053 | 0.080 | 0.762 | 0.789 | 0.814 |

| 0.800 | ±0.008 | 0.030 | 0.056 | 0.085 | 0.855 | 0.884 | 0.911 |

| 0.900 | ±0.009 | 0.032 | 0.060 | 0.090 | 0.959 | 0.989 | 1.018 |

| 1.000 | ±0.010 | 0.034 | 0.063 | 0.095 | 1.062 | 1.094 | 1.124 |

| 1.120 | ±0.011 | 0.034 | 0.065 | 0.098 | 1.184 | 1.217 | 1.248 |

| 1.250 | ±0.013 | 0.035 | 0.067 | 0.100 | 1.316 | 1.349 | 1.381 |

| 1.400 | ±0.014 | 0.036 | 0.069 | 0.103 | 1.468 | 1.502 | 1.535 |

| 1.600 | ±0.016 | 0.038 | 0.071 | 0.107 | 1.670 | 1.706 | 1.740 |

| 1.800 | ±0.018 | 0.039 | 0.073 | 0.110 | 1.872 | 1.909 | 1.944 |

| 2.000 | ±0.020 | 0.040 | 0.075 | 0.113 | 2.074 | 2.112 | 2.148 |

| 2.240 | ±0.022 | 0.041 | 0.077 | 0.116 | 2.316 | 2.355 | 2.392 |

| 2.500 | ±0.025 | 0.042 | 0.079 | 0.119 | 2.578 | 2.618 | 2.656 |

| 2.800 | ±0.028 | 0.043 | 0.081 | 0.123 | 2.880 | 2.922 | 2.961 |

| 3.150 | ±0.032 | 0.045 | 0.084 | 0.127 | 3.233 | 3.276 | 3.316 |

| 3.550 | ±0.036 | 0.046 | 0.086 | 0.130 | 3.635 | 3.679 | 3.721 |

| 4.000 | ±0.040 | 0.047 | 0.089 | 0.134 | 4.088 | 4.133 | 4.176 |

| 4.500 | ±0.045 | 0.049 | 0.092 | 0.138 | 4.591 | 4.637 | 4.681 |

| 5.000 | ±0.050 | 0.050 | 0.094 | 0.142 | 5.093 | 5.141 | 5.186 |

| Dimensional values derived from NEMA MW1000-1997 Standard | ||||||

| AWG | Conductor Diameter | Single Build | Heavy build | |||

| Minimum Increase in Diameter | Maximum Increase in Diameter | Minimum Increase in Diameter | Maximum Increase in Diameter | |||

| (mm) | (inch) | (inch) | (inch) | (inch) | (inch) | |

| 4 | 5.189 | 0.2043 | ||||

| 5 | 4.620 | 0.1819 | ||||

| 6 | 4.115 | 0.1620 | 0.0002 | 0.1665 | 0.0019 | 0.1671 |

| 7 | 3.666 | 0.1443 | 0.0003 | 0.1485 | 0.0020 | 0.1491 |

| 8 | 3.264 | 0.1285 | 0.0003 | 0.1324 | 0.0020 | 0.1332 |

| 9 | 2.906 | 0.1144 | 0.0005 | 0.1181 | 0.0021 | 0.1189 |

| 10 | 2.588 | 0.1019 | 0.00'.)5 | 0.1054 | 0.0021 | 0.1061 |

| 11 | 2.304 | 0.0907 | 0.0006 | 0.0941 | 0.0021 | 0.0948 |

| 12 | 2.052 | 0.0808 | 0.0006 | 0.0840 | 0.0021 | 0.0847 |

| 13 | 1.829 | 0.0720 | 0.0007 | 0.0750 | 0.0021 | 0.0757 |

| 14 | 1.628 | 0.0641 | 0.0016 | 0.0666 | 0.0032 | 0.0682 |

| 15 | 1.450 | 0.0571 | 0.0015 | 0.0594 | 0.0030 | 0.0609 |

| 16 | 1.290 | 0.0508 | 0.0014 | 0.0531 | 0.0029 | 0.0545 |

| 17 | 1.151 | 0.0453 | 0.0014 | 0.0475 | 0.0028 | 0.0488 |

| 18 | 1.024 | 0.0403 | 0.0013 | 0.0424 | 0.0026 | 0.0437 |

| 19 | 0.912 | 0.0359 | 0.0012 | 0.0379 | 0.0025 | 0.0391 |

| 20 | 0.813 | 0.0320 | 0.0012 | 0.0339 | 0.0023 | 0.0351 |

| 21 | 0.724 | 0.0285 | 0.0011 | 0.0303 | 0.0022 | 0.0314 |

| 22 | 0.643 | 0.0253 | 0.0011 | 0.0270 | 0.0021 | 0.0281 |

| 23 | 0574 | 0.0226 | 0.0010 | 0.0243 | 0.0020 | 0.0253 |

| 24 | 0511 | 0.0201 | 0.0010 | 0.0217 | 0.0019 | 0.0227 |

| 25 | 0.455 | 0.0179 | 0.0009 | 0.0194 | 0.0018 | 0.0203 |

| 26 | 0.404 | 0.0159 | O.0009 | 0.0173 | 0.0017 | 0.0182 |

| 27 | 0.361 | 0.0142 | 0.0008 | 0.0156 | 0.0016 | 0.0164 |

| 28 | 0.320 | 0.0126 | 0.0008 | 0.0140 | 0.0016 | 0.0147 |

| 29 | 0.287 | 0.0113 | 0.0007 | 0.0126 | 0.0015 | 0.0133 |

| 30 | 0.254 | 0.0100 | 0.0007 | 0.0112 | 0.0014 | 0.0119 |

| 31 | 0.226 | 0.0089 | 0.C006 | 0.0100 | 0.0013 | 0.0108 |

| 32 | 0.203 | 0.0080 | 0.0006 | 0.0091 | 0.0012 | 0.0098 |

Chalco other hot selling enameled wire produts

120 acetal enameled wire

180 poiyesterimide enamelled wire

200 polyester-polyamideimide enamelled wire

Copper clad aluminum wire

Heat-resistant aluminum wire

Aluminum strip for capacitor

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote