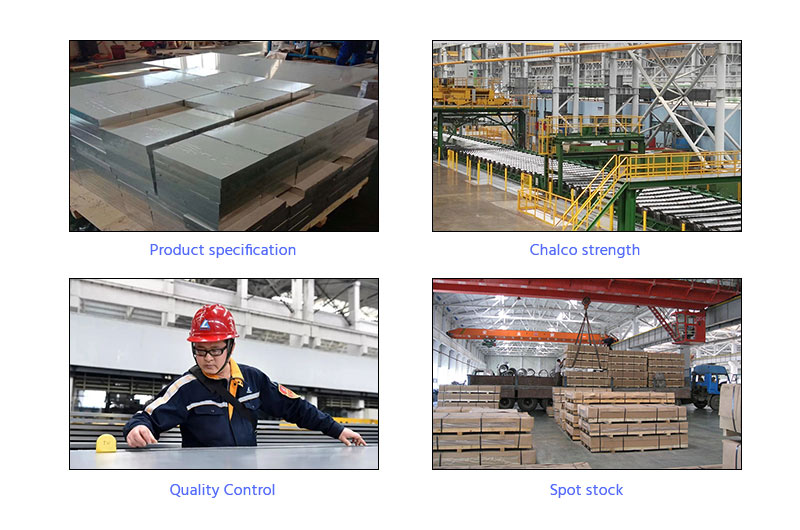

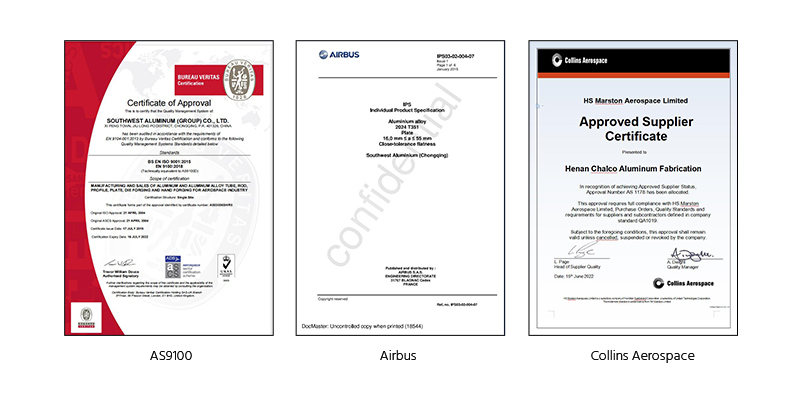

Chalco Aluminum could produce 2024 2A12 T3 T4 T351 T851 aircraft aluminum sheet plate, product meet AMS ane EN standard, who is the supplier of Collins Aerospace, Boeing and Airbus etc.

Bare aircraft aluminum sheet plate standard:QQ-A-250/4, AMS 4035, AMS 4037, AMS 4027, FMS 10101

Clad aircraft aluminum sheet plate standard:QQ-A-250/5, AMS 4040, AMS 4041, BMS 7-305

Chalco accreditations: AS9100,OHSAS 18001,ISO14001,ISO 9001,NADCAP HT,NADCAP NDT,IATP16949

Custom Alu sheet

Specs of 2024 2A12 aluminum sheet plate

| Alloy | 2024, 2A12 |

| Temper | O, T3, T4, T351, T851, T81, H112 |

| Thickness | 0.5mm-300mm |

| Width | 500-2650mm |

| Length | 500-12000mm |

| Standard | GB/T3880, GJB1541, GJB2662, STMB209, EN485, QQ-A-250/4, AMS 4035, AMS 4037, FMS 10101, QQ-A-250/5, AMS 4040, AMS 4041, BMS 7-305 |

| 2024 2A12 plate stock size | Thickness: 0.6mm-300mm Temper: O, T1, T4, T6, H112, T351 Size: 1500mm×3000mm; 2000mm×4000mm |

What are the characteristics of 2024 2A12 aluminum plate?

High strength: 2024 2A12 aluminum sheet is a high-strength aluminum alloy material with an excellent strength-to-weight ratio, so it is widely used in the aerospace field.

Strong corrosion resistance: 2024 2A12 aluminum plate contains alloy elements such as copper, which has good corrosion resistance and stress corrosion cracking resistance, and can be used in harsh environments.

Good processing performance: 2024 2A12 aluminum plate has good processing performance, and can be processed by cold working, hot working, forming and welding.

Good fatigue strength: 2024 2A12 aluminum plate has excellent fatigue strength and can be used in applications subject to reciprocating loads.

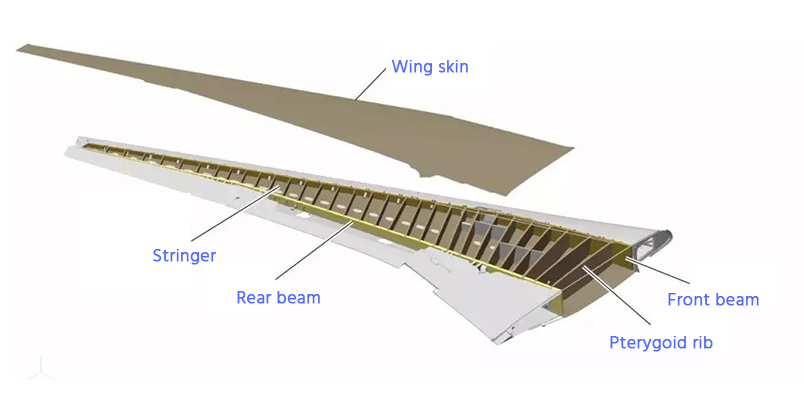

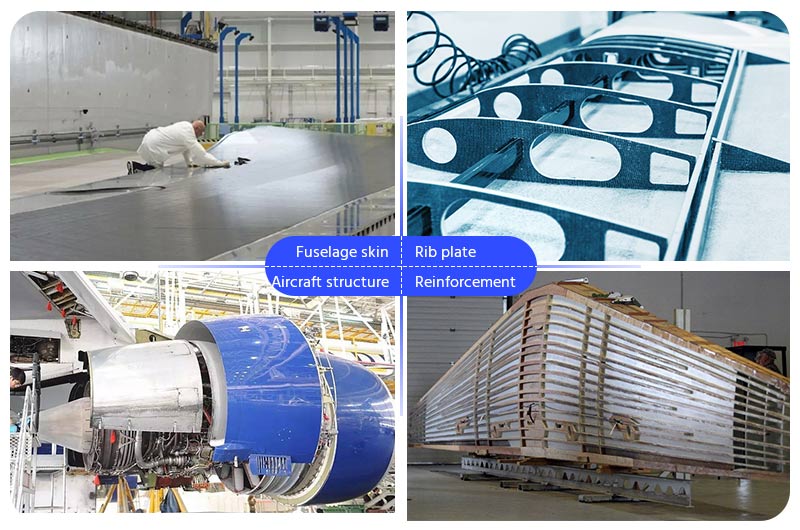

Application of 2024 aluminum plate sheet

2024 T3 T4 aluminum sheet

2024 T3 T4 aluminum sheet is widely used in the aerospace industry for its high strength and fatigue resistance to make wing skins, webs, stiffeners and other structural components.

Quick Quote

2024 T351 T851 aluminum plate

2024 T351 T851 aluminum plate is a special state of 2024 aluminum alloy, known for its high strength-to-weight ratio and good corrosion resistance. Here are their common uses.

Quick Quote2024 T351 aluminum plate

Known for its improved formability and weldability, 2024 T351 aluminum plate is ideal for applications requiring complex shapes and high strength, such as aircraft skins, fuselages, and other aerospace structures.

Quick Quote2024 T451 aluminum plate

2024 T451 aluminum plate provides greater strength and stability than T3 and T4 temper aluminum plate. It is commonly used in applications requiring high strength, high fatigue resistance and good toughness, such as aerospace structural components.

Quick Quote2024 T851 aluminum plate

2024 T851 aluminum plate provides greater strength and stability than T3 and T4 temper aluminum plate. Commonly used in aircraft components as well as industrial machinery components.

Welcome contact

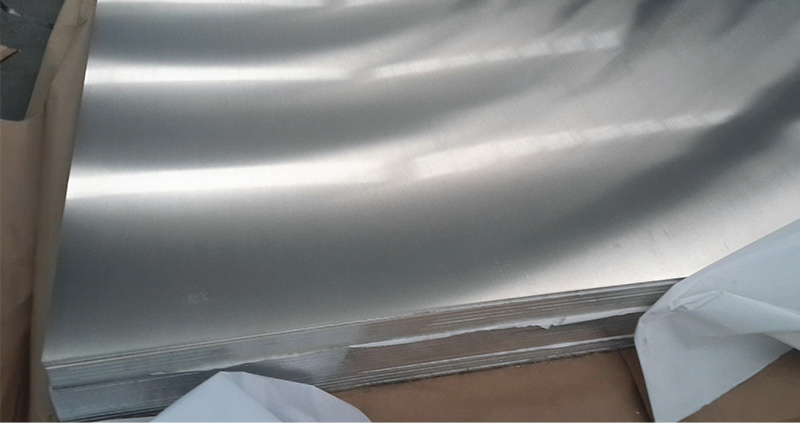

Alcald 2024 T3 T4 aluminum sheet

Due to relatively lower corrosion resistance, 2024 is commonly offered in a clad form (Alclad), featuring a thin layer of high-purity aluminum on the surface.

Quick QuoteChalco 2024 aerospace grade aluminum related products

2024 Aerospace Aluminum Rod Bar

2024 aerospace aluminum tube

2024 aerospace aluminum wire

2024 aerospace aluminum foil

2024 aerospace extrusion

2024 aluminum military profiles

Chemical composition of 2024 2A12 Aluminum Alloy

| Chemical Composition % | ||

| 2024 Alloy | 2A12 Alloy | |

| Si | 0.5 | 0.50 |

| Fe Cu | 0.5 | 0.50 |

| 3.8 - 4.9 | 3.8 - 4.9 | |

| Mn | 0.3-0.9 | 0.3-0.9 |

| Mg | 1.2-1.8 | 1.2-1.8 |

| Cr | 0.10 | - |

| Ni | 0.10 | |

| Zn | 0.25 | 0.30 |

| Ti | 0.15 | 0.15 |

| Zr | - | - |

| Al | Remainder | Remainder |

2024 2A12 alloy typical mechanical properties

| 2024-O | 2024-T3 | 2024-T4 | 2024-T351 | 2024-T851 | |

| Tensile Strength | 100-200 MPa | 320-480 MPa | 310-480 MPa | 330-460 MPa | 450-510 MPa |

| Shear Strength | 130 MPa | 290 MPa | 290 MPa | 290 MPa | 300 MPa |

| Fatigue Strength | 90 MPa | 140 MPa | 140 MPa | 140 MPa | 140 MPa |

| Elastic Modulus | 71 GPa | 71 GPa | 71 GPa | 71 GPa | 68 GPa |

| Brinell Hardness | 49 | 120 | 120 | 120 | 140 |

| Elongation at Break | 15% | 15% | 16% | 13% | 5% |

Mechanical property of 2024 2A12 aluminum sheet plate

| Temper | Specified thickness mm | Tensile strength Rm MPa | Yield strength Rp0. 2 MPa | Elongation min. % | ||||

| over | up to | min. | max. | min. | max. | A50 mm | A | |

| O | 0. 4 | 1. 5 | - | 220 | - | 140 | 12 | - |

| O | 1. 5 | 3. 0 | - | 220 | - | 140 | 13 | - |

| O | 3. 0 | 6. 0 | - | 220 | - | 140 | 13 | - |

| O | 6. 0 | 9. 0 | - | 220 | - | 140 | 13 | - |

| O | 9. 0 | 12. 5 | - | 220 | - | 140 | 13 | - |

| O | 12. 5 | 25. 0 | - | 220 | - | - | - | 11 |

| T4 | 0. 4 | 1. 5 | 425 | - | 275 | - | 12 | - |

| T4 | 1. 5 | 6. 0 | 425 | - | 275 | - | 14 | - |

| T3 | 0.4 | 1. 5 | 435 | - | 290 | - | 12 | - |

| T3 | 1. 5 | 3. 0 | 435 | - | 290 | - | 14 | - |

| T3 | 3. 0 | 6. 0 | 440 | - | 290 | - | 14 | - |

| T3 | 6. 0 | 12. 5 | 440 | - | 290 | - | 13 | - |

| T3 | 12. 5 | 40. 0 | 430 | - | 290 | - | - | 11 |

| T3 | 40. 0 | 80. 0 | 420 | - | 290 | - | - | 8 |

| T3 | 80. 0 | 100. 0 | 400 | - | 285 | - | - | 7 |

| T3 | 100. 0 | 120. 0 | 380 | - | 270 | - | - | 5 |

| T3 | 120. 0 | 150. 0 | 360 | - | 250 | - | - | 5 |

| T351 | 0. 4 | 1. 5 | 435 | - | 290 | - | 12 | - |

| T351 | 1. 5 | 3. 0 | 435 | - | 290 | - | 14 | - |

| T351 | 3. 0 | 6. 0 | 440 | - | 290 | - | 14 | - |

| T351 | 6. 0 | 12. 5 | 440 | - | 290 | - | 13 | - |

| T351 | 12. 5 | 40. 0 | 430 | - | 290 | - | - | 11 |

| T351 | 40. 0 | 80. 0 | 420 | - | 290 | - | - | 8 |

| T351 | 80. 0 | 100. 0 | 400 | - | 285 | - | - | 7 |

| T351 | 100. 0 | 120. 0 | 380 | - | 270 | - | - | 5 |

| T351 | 120. 0 | 150. 0 | 360 | - | 250 | - | - | 5 |

| T42 | 0. 4 | 6. 0 | 425 | - | 260 | - | 15 | - |

| T42 | 6. 0 | 12. 5 | 425 | - | 260 | - | 12 | - |

| T42 | 12. 5 | 25. 0 | 420 | - | 260 | - | - | 8 |

| T8 | 0. 4 | 1. 5 | 460 | - | 400 | - | 5 | - |

| T8 | 1. 5 | 6. 0 | 460 | - | 400 | - | 6 | - |

| T8 | 6. 0 | 12. 5 | 460 | - | 400 | - | 5 | - |

| T8 | 12. 5 | 25. 0 | 455 | - | 400 | - | - | 4 |

| T8 | 25. 0 | 40. 0 | 455 | - | 395 | - | - | 4 |

| T851 | 0. 4 | 1. 5 | 460 | - | 400 | - | 5 | - |

| T851 | 1. 5 | 6. 0 | 460 | - | 400 | - | 6 | - |

| T851 | 6. 0 | 12. 5 | 460 | - | 400 | - | 5 | - |

| T851 | 12. 5 | 25. 0 | 455 | - | 400 | - | - | 4 |

| T851 | 25. 0 | 40. 0 | 455 | - | 395 | - | - | 4 |

Chalco 2024 aluminum sheet materials supplier

Chalco is equipped with an advanced German-made 1+4 4500mm hot rolling production line from SMS Group. The line is furnished with Siemens electrical configurations and features a German IMS curvature gauge, enabling closed-loop control for thickness and sheet shape. The hot rolling mill is equipped with hydraulic adjustment systems, CVCplus technology, work roll bending with a multi-zone cooling system, and temperature control systems. It also includes a light and heavy shear, edge trimming equipment, coiling machinery, waste transport systems, and flue gas purification systems. For cold rolling, they utilize German-made 2800mm single-stand and double-stand CVC cold rolling mills from SMS Group, offering a maximum rolling force of 20, 000 kN and speeds reaching up to 1800m/min. These advanced production lines and technologies guarantee superior plate shape and surface quality, minimizing common quality issues.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Chalco hot selling A92024 aviation aluminum plate products

If you are considering purchasing 2024 aluminum sheet, there are several factors you should consider to ensure you are getting the best product for your needs.

Alloy: Make sure the EN-AW 2024 T3 T4 aluminum sheet you are considering is made of the correct alloy.

State: The 2024 aluminum plate produced by Chalco Aluminum has various states, including O, T3, T4, T351, T851, T81, H112, suitable for various mechanical performance requirements.

Thickness: Consider the thickness of the 2024 aluminum sheet, as this affects its weight, strength and cost.

Width and length: Chalco Aluminum'2024 sheet specifications are 1500mm×3000mm; 2000mm×4000mm, suitable for customer processing and use.

Quality control: Chalco Aluminum has a complete aviation quality control system, which ensures the overall quality and consistency of 2024 aluminum sheets.

Cost: Considering the EN-AW 2024 T3 clad aluminum sheet price, Chalco Aluminum is affordable and popular with aerospace parts manufacturers.

Whether there is stock: Chalco Aluminum has stock of various thicknesses, which can be provided in time, and the whole piece can be sold in zero cuts, which is convenient and fast.Chalco 2024 aluminum plate stock is very complete. If you customize in small batches or have delivery requirements, you can purchase the stock products directly;

By considering these factors, you can ensure that you are getting the best 2024 aluminum sheet for your needs. It is also a good idea to discuss your specific requirements and application with a knowledgeable supplier or manufacturer who can assist you in selecting the correct product and provide additional guidance and advice.