Chalco can produce 120, 130 , 155 , 180 and 200 Class enameled aluminum round wires. All enameled aluminum wires utilize advanced mold coating technology to address issues such as eccentricity and uneven pressure resistance in felt coating. They possess excellent adhesion of enamel film, uniform wire diameter, good pressure resistance, with an elongation rate reaching up to 45%.

As a specialized supplier of enameled aluminum wire, Chalco holds international certifications like ISO 9001, CQM, SGS, and more. All enameled wire products comply with IEC-60317, GB/T, JIS, NEMA, RoHS standards and have been UL certified (E234565).Welcome to contact

Hot Selling Products of Chalco Enamelled Aluminum Wire

120 Class Acetal Enameled Aluminum Round Wire

Diameter:0.25-6.0mm

Thermal Shock:155℃

Paint film thickness:1 grade, 2 grade, 3 grade

Contact us now130/155 Class Polyester Enamelled Aluminium Round Wire

Diameter:0.25-6.0mm

Thermal Shock:155℃-175℃

Paint film thickness:1 grade, 2 grade, 3 grade

Contact us now180 Class PoIyesterimide Enamelled Round Aluminum Wire

Diameter:0.25-6.0mm

Thermal Shock:200℃

Paint film thickness:1 grade, 2 grade, 3 grade

Contact us now200 Class Polyester With Polyamide-imide Enamelled Aluminium Wire

Diameter:0.25-6.0mm

Thermal Shock:220℃

Paint film thickness:1 grade, 2 grade, 3 grade

Contact us nowIf the above-mentioned products do not meet your project requirements, Chalco can also produce Polyester (imide) Overcoat With Polyimide-imide Enameled Aluminum Wire, Thermal Class 200/220, and High-temperature Resistance Enameled Aluminum Round Wire, Thermal Class 240. For specific production capabilities, you can contact our sales team for further information.Customized enameled alu wire

Chalco's Featured Enameled Wire Products

-

High Temperature Resistant Enameled Wires

Exceptional Adhesion

Voltage withstands 5-12KV

No cracking of paint film at 350°C baking

-

Corona ResistantEnameledWires

Good Corona Resistance

High-Temperature Resistance

Outstanding Dielectric Properties

-

Self-Adhesive Enameledwires

Alcohol-based Heating Bondinge

Better Winding Compactness

Smaller Volume

-

Straight Welding Enameled Flat Wires

No need for paint stripping

Can be directly welded

Time-saving, labor-saving

-

Copper-CladAluminum Enameled Wires

It merges copper's conductivity with aluminum's lightweight, easy processing, and cost-effectiveness, ensuring a great cost-to-performance ratio.

-

Micro-Enameled Flat Aluminum Wires

The minimum specification can reach 0.2*1mm, with a high slot fill rate, small production volume, and not restricted by coil size.

-

Super-Large Enameled Round Aluminum Wires

Diameters range from 3.0 to 15mm in extra-large sizes, featuring strong adhesion, suitability for vertical winding, and high-temperature resistance.

-

Super-Large Enameled Flat Aluminum Wires

The product features include large dimensions of 3.5*35mm, strong adhesion, suitability for vertical winding, and high-temperature resistance.

-

Ultra thick paint film enameled aluminum wire

Primary paint film: 0.5-0.8mm

Secondary paint film: 1.2mm

Ultra-thick paint film: 0.45mm

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

The Ultimate Guide to Enameled Aluminum Wire

Here is comprehensive information about enameled aluminum wire. If you have any questions about enameled aluminum wire, you can find answers here.

You'll gain insights into classifications, production processes, specifications, various types of enameled wire parameter tables, and more.

What is enameled wire?

Enameled wire refers to a metal wire that uses insulating varnish as an insulating coating and is used to wind an electromagnetic coil, also known as an electromagnetic wire. It is a main variety of winding wire. It consists of conductor and insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. In most cases, enameled wire is wound into coils of different shapes to provide electromagnetic fields for motors, transformers, electromagnets and other products.

Classification of enameled wires

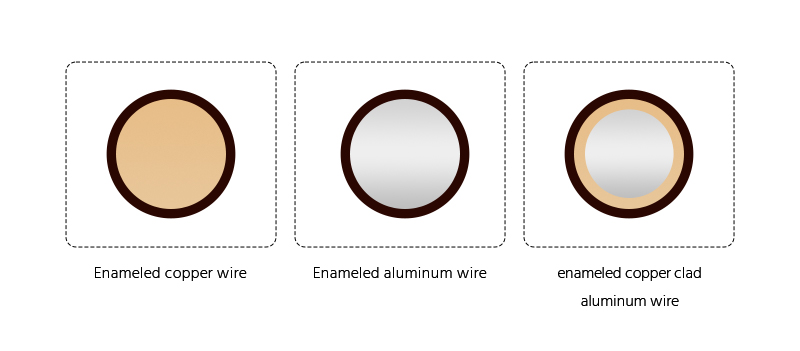

1. According to the classification of conductor materials, Chalco Aluminum mainly includes enameled copper wire, enameled aluminum wire and enameled copper clad aluminum wire;

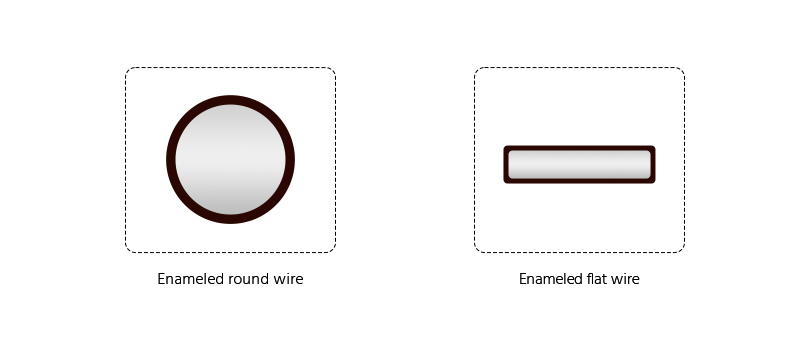

2. According to the shape classification, Chalco Aluminum mainly produces enameled round wire and enameled flat wire;

|

|

Size | Thermal level | Standard |

| Enameled flat wire |

A: 1-10mm B: 3-30mm |

180, 200, 220 | IEC, NEMA, GB, JI |

| Enameled round wire | Diameter: 0.15mm-6.00mm | 130, 180, 200, 220 | IEC, NEMA, GB, JIS |

3. According to the classification of temperature resistance grades, Chalco Aluminum mainly produces enameled wires with temperature resistance grades of 105, 130, 155, 180, 200, 210, 220, 240;

4. According to the classification of insulating paint, Chalco Aluminum mainly produces: Polyurethane enameled wire paint (PUR), weldable polyesterimide enameled wire paint (PEI), polyamideimide enameled wire paint (PAI), acetal enameled wire paint (PVF), self-bonding enameled wire paint (SB).

The use of enameled wire

Acetal enameled wire

Acetal enameled wire has two thermal grades of 105 and 120. This product has good mechanical strength, adhesion, transformer oil resistance and refrigerant resistance, but it has poor moisture resistance, low thermal softening breakdown temperature, weak performance of durable benzene-alcohol mixed solvent and other defects. So, only a small amount has been used on oil-immersed transformers or oil-filled motor windings.

Polyester and modified polyester enameled wires

The thermal grade of ordinary polyester enameled wire is 130, and the thermal grade of modified enameled wire is 155. The product has high mechanical strength, good elasticity, adhesion, electrical properties and solvent resistance. Its weaknesses are poor thermal shock resistance and low moisture resistance. It is widely used in various motors, electrical appliances, instruments, telecommunication equipment and home appliances.

Polyurethane enameled wire

The thermal grades of polyurethane enameled wire are 130, 155, 180, 200. The biggest feature is that it has direct welding, good high frequency resistance, easy coloring, and good moisture resistance. It is widely used in electronic appliances and precision instruments, telecommunications, and some other instruments. But it also has some weaknesses, such as its mechanical strength is slightly poor, its heat resistance is not high, the flexibility and adhesion of large-sized wires are poor. So, the specifications of this product are mostly small and medium-sized wires.

Polyesterimide/Polyamide composite enameled wire

The thermal class of the Polyesterimide/Polyamide Composite Enameled Wire is 180, the product has good thermal shock resistance, high softening breakdown temperature, excellent mechanical strength, good solvent resistance and refrigerant resistance, and its weakness is that it is easy to be hydrolyzed under closed conditions. It is widely used in windings with high heat resistance requirements such as motors, electrical appliances, instruments, power tools, dry-type power transformers, etc.

Polyesterimide/Polyamideimide composite layer enameled wire

This is a kind of widely used heat-resistant enameled wire. Its thermal class is 200. The product has high heat resistance, refrigerant resistance, severe cold resistance, radiation resistance, etc. It also has the high strength, stable electrical properties, good chemical resistance and strong overload capacity. It is widely used in refrigerator compressors, air-conditioning compressors, power tools, explosion-proof motors and motors and electrical appliances used in high temperature, high cold, radiation resistance, overload and other conditions.

The production process of Chalco Aluminum enameled wire

Wire drawing process

Using 8mm copper rod/aluminum rod as raw material, it is thinned to the required bare wire size in several stages through a wire drawing die. The drawing process is carried out sequentially on a series of drawing machines with different diameter ranges. The bare wire is permanently stretched through the eye mold in several stages to become thinner and longer, while the volume remains the same.

Painting process

Painting is a continuous process, mainly composed of annealing, insulating paint coating, curing, lubricant coating, tension control and wiring.

Annealing process

During the wire drawing process, the grain structure of the bare wire has changed after cold deformation. The annealing process can make the copper recrystallize and soften again. In order to avoid oxidation of the wire surface, this high temperature stress relief process is carried out in an environment with protective gas. If the wire is oxidized, it will affect the adhesion between the copper wire and the insulating coating during the subsequent painting process. The softness of the wire is very important for good winding characteristics, especially the number of wire breaks can be significantly reduced.

There are two main ways of coating enameled wire: felt coating and die coating. Felt painting is mainly used for the production of thin wires, and mold painting is mainly used for the production of thick wires. Insulating paint should always be applied in as many coats as possible, avoiding the use of few and thick coats, in order to obtain better mechanical and electrical properties.

Curing oven

The solvent contained in the liquid insulating varnish will be evaporated in a high-temperature curing oven, and then catalytically burned in an energy-saving and environmentally friendly way. Temperature control of the curing process is very important. If the temperature is too low, too much solvent can remain in the insulating varnish coating, resulting in poor adhesion and reduced mechanical and electrical properties. If the temperature is too high, the paint layer can become hard and brittle, causing the insulation to crack under mechanical stress.

Lubricant

The surface of the enameled wire needs to be precisely coated with a specified amount of lubricant. Lubrication of enameled wire is very important to obtain stable winding characteristics and guarantee zero defects under high-speed winding conditions.

Tension control

In the paint production process, continuous and stable tension control can make the wire arrangement on the spool be uniform. Through effective tension control, the resistance change of the wire can be avoided due to being stretched, and the spool can also be guaranteed to have good pay-off performance when it is used at the customer's place.

Wiring

Wire spacing and spool speed are production process variables that need to be tightly controlled. This results in consistent and excellent electrical winding performance and minimizes other issues such as wire jams and stray wires. The wiring process parameters such as wiring spacing and spool speed are closely controlled. As a result, the wire has stable and good pay-off performance, and the occurrence of problems such as pinching and stray lines is minimized.

Chalco Aluminum's enameled wire

Chalco Aluminum produces and manages various types of enameled wire and magnet wire, with mature and exquisite craftsmanship. Chalco Aluminum strictly implements ISO9001 quality management system, ISO14001 environmental management system, IATF16949 automotive quality management system and other management standards. The products have obtained the US UL safety certification, and comply with the EU RoHS and Reach and other environmental hazardous substances management regulations.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteChalco Enamelled Aluminum Wire Parameter Table

General Winding Wire

| Characteristics/type | Polyvinyl Formal Enamelled Wire | Polyurethane Enamelled wire | Polyurethane Nylon Enamelled wire | Polyester Enamelled wire | Polyester Nylon Enamelled wire | |||

| PVF | UEW | UEW-N | PEW | PEW-N | ||||

| Heat Resistance Temperature Index | 105°C | 130°C | 130°C | 155°C | 155°C | |||

| Dimension | Overall (mm) | 1.066 | 1.066 | 1.066 | 1.066 | 1.066 | ||

| Conductor Diameter (mm) | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | |||

| Film Thickness (mm) | 0.033 | 0.033 | 0.033 | 0.033 | 0.033 | |||

|

Thermal Characteristics |

Resistance to cut through (°C) | 290 | 230 | 230 | 320 | 300 | ||

| Heat Shock Resistance | Temperature | - | 130°C | 130°C | 150°C | 150°C | ||

| Time | - | 1hr | 1hr | 1hr | 1hr | |||

| Mandrel | - | 1d ok | 1d ok | 2d ok | 1d ok | |||

| Mechanical Characteristics | Flexibility | Good | Good | Good | Good | Good | ||

| Adhesion | Good | Good | Good | Good | Good | |||

| Abrasion Resistance (N) | 13.0 | 12.9 | 13.7 | 12.7 | 13.7 | |||

| Static Friction Coefficient | 0.12 | 0.12 | 0.05 | 0.10 | 0.05 | |||

| Electrical Characteristics | Pinhole | 0 | 0 | 0 | 0 | 0 | ||

| Dielectric Breakdown (kv) | 11.5 | 11.5 | 11.5 | 11.5 | 11.5 | |||

| Chemical Characteristics | Solderability | Solder Temperature | no | 380°C | 380°C | no | no | |

| Time | 2seconds | 2seconds | ||||||

| Solvent Resistance | 4H | 4H | 4H | 4H | 5H | |||

| Chemical Resistance | 5H | 5H | 5H | 5H | 5H | |||

Solderable winding wire

| Characteristics/type | Polyurethane Enamelled wire | Polyurethane Nylon Enamelled wire | Solderable Polyester Enamelled wire | Solderable Polyester Nylon Enamelled wire | Solderable Polyester-lmide Enamelled wire | |||

| UEW | UEW-N | SMPEW | SMPEW-N | SMHEIW | ||||

| Heat Resistance Temperature Index | 130°C | 130°C | 155°C | 155°C | 180°C | |||

| Dimension | Overall (mm) | 0.378 | 0.378 | 0.378 | 0.378 | 0.378 | ||

| Conductor Diameter (mm) | 0.350 | 0.350 | 0.350 | 0.350 | 0.350 | |||

| Film Thickness (mm) | 0.014 | 0.014 | 0.014 | 0.014 | 0.014 | |||

|

Thermal Characteristics |

Resistance to cut through (°C) | 230 | 230 | 250 | 250 | 290 | ||

| Heat Shock Resistance | Temperature | 130°C | 130°C | 150°C | 150°C | 180°C | ||

| Time | 1hr | 1hr | 1hr | 1hr | 1hr | |||

| Elongation | 10% ok | 10% ok | 10% ok | 10% ok | 20% ok | |||

| Mechanical Characteristics | Flexibility | Good | Good | Good | Good | Good | ||

| Adhesion | Good | Good | Good | Good | Good | |||

| Abrasion Resistance (N) | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | |||

| Static Friction Coefficient | 0.12 | 0.05 | 0.10 | 0.05 | 0.10 | |||

| Electrical Characteristics | Pinhole | 0 | 0 | 0 | 0 | 0 | ||

| Dielectric Breakdown (kv) | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 | |||

| Chemical Characteristics | Solderability | Solder Temperature | 380°C | 380°C | 400°C | 400°C | 470°C | |

| Time | 1second | 1second | 1second | 1second | 5seconds | |||

| Solvent Resistance | 4H | 4H | 4H | 4H | 5H | |||

| Chemical Resistance | 5H | 5H | 5H | 5H | 5H | |||

Heat-resistance winding wire

| Characteristics/type | Polyester-lmide /Polyamide-Imide Enamelled wire | Highly Polyester-lmide Enamelled wire | Polyamide-Imide Enamelled wire | Polyamide Enamelled wire | ||

| ATZ-300 | UTZ | AIW | PIW | |||

| Heat Resistance Temperature Index | 200°C | 200°C | 220°C | 220°C | ||

| Dimension | Overall (mm) | 1.066 | 1.066 | 1.066 | 1.066 | |

| Conductor Diameter (mm) | 1.000 | 1.000 | 1.000 | 1.000 | ||

| Film Thickness (mm) | 0.033 | 0.033 | 0.033 | 0.33 | ||

|

Thermal Characteristics |

Resistance to cut through | 420 | 420 | 450 | 500 | |

| Heat Shock Resis | Temp | 200°C | 200°C | 220°C | 300°C | |

| Time | 1hr | 1hr | 1hr | 1hr | ||

| Elongation | 1d ok | 1d ok | 1d ok | 1d ok | ||

| Dielectric Breakdown(kv) | 220/168hr | 9.3 | 9.3 | 9.6 | 11.3 | |

| 240/168hr | 8.5 | 8.5 | 8.8 | 10.9 | ||

| 280/168hr | 1.3 | 1.3 | 7.9 | 10.4 | ||

| Mechanical Characteristics | Flexibility | Good | Good | Good | Good | |

| Adhesion | Good | Good | Good | Good | ||

| Abrasion Resistance (N) | 15.7 | 18.6 | 17.6 | 11.8 | ||

| Static Friction Coefficient | 0.10 | 0.05 | 0.10 | 0.10 | ||

| Electrical Characteristics | Pinhole | 0 | 0 | 0 | 0 | |

| Dielectric Breakdown (kv) | 11.5 | 11.5 | 11.5 | 11.5 | ||

| Chemical Characteristics | Solderability | no | no | no | no | |

| Solvent Resistance | 6H | 6H | 6H | 5H | ||

| Chemical Resistance | 6H | 6H | 6H | 5H | ||

Scrape-resistance winding wire

| Characteristics/type | Highly Adhesive Polyester-lmide /Highly Lubricated Polyamide-Imide Enamelled wire | Polyamide-Imide/Highly Lubricated Polyamide-Imide Enamelled wire | Highly Adhesive Polyamide-Imide/Highly Lubricated Polyamide-Imide Enamelled wire | ||

| UTZ | slaiw | UAIW | |||

| Heat Resistance Temperature Index | 200°C | 220°C | 220°C | ||

| Dimension | Overall (mm) | 1.066 | 1.066 | 1.066 | |

| Conductor Diameter (mm) | 1.000 | 1.000 | 1.000 | ||

| Film Thickness (mm) | 0.033 | 0.033 | 0.033 | ||

|

Thermal Characteristics |

Resistance to cut through | 420 | 450 | 450 | |

| Heat Shock Resis | Temp | 200°C | 220°C | 220°C | |

| Time | 1hr | 1hr | 1hr | ||

| Elongation | 1d ok | 1d ok | 1d ok | ||

| Dielectric Breakdown(kv) | 220/168hr | 9.3 | 9.6 | 9.6 | |

| 240/168hr | 8.5 | 8.8 | 8.8 | ||

| 280/168hr | 1.3 | 7.9 | 7.9 | ||

| Mechanical Characteristics | Flexibility | Good | Good | Good | |

| Adhesion | Good | Good | Good | ||

| Abrasion Resistance (N) | 18.6 | 17.6 | 18.6 | ||

| Static Friction Coefficient | 0.05 | 0.05 | 0.05 | ||

| Electrical Characteristics | Pinhole | 0 | 0 | 0 | |

| Dielectric Breakdown (kv) | 11.5 | 11.5 | 11.5 | ||

| Chemical Characteristics | Solderability | no | no | no | |

| Solvent Resistance | 6H | 6H | 6H | ||

| Chemical Resistance | 6H | 6H |

6H |

||

Dimensions of Chalco enameled aluminum round wire

| Dimensional values derived from IEC 60317-0-3: 2008 Standard | |||||||

| Conductor Diameter | Minimum Enamel Thickness/mm | Maximum Overall Thickness/mm | |||||

| ICE standard | Tolerance | 1 Grade | 2 Grade | 3 Grade | 1 Grade | 2 Grade | 3 Grade |

| 0.250 | ±0.004 | 0.017 | 0.032 | 0.048 | 0.281 | 0.297 | 0.312 |

| 0.280 | ±0.004 | 0.018 | 0.033 | 0.050 | 0.312 | 0.329 | 0.345 |

| 0.315 | ±0.004 | 0.019 | 0.035 | 0.053 | 0.349 | 0.367 | 0.384 |

| 0.355 | ±0.004 | 0.020 | 0.038 | 0.057 | 0.392 | 0.411 | 0.428 |

| 0.400 | ±0.005 | 0.021 | 0.040 | 0.060 | 0.139 | 0.459 | 0.478 |

| 0.450 | ±0.005 | 0.022 | 0.042 | 0.061 | 0.491 | 0.513 | 0.533 |

| 0.500 | ±0.005 | 0.024 | 0.045 | 0.067 | 0.544 | 0.566 | 0.587 |

| 0.560 | ±0.006 | 0.025 | 0.047 | 0.071 | 0.606 | 0.630 | 0.653 |

| 0.630 | ±0.006 | 0.027 | 0.050 | 0.075 | 0.679 | 0.704 | 0.728 |

| 0.710 | ±0.007 | 0.028 | 0.053 | 0.080 | 0.762 | 0.789 | 0.814 |

| 0.800 | ±0.008 | 0.030 | 0.056 | 0.085 | 0.855 | 0.884 | 0.911 |

| 0.900 | ±0.009 | 0.032 | 0.060 | 0.090 | 0.959 | 0.989 | 1.018 |

| 1.000 | ±0.010 | 0.034 | 0.063 | 0.095 | 1.062 | 1.094 | 1.124 |

| 1.120 | ±0.011 | 0.034 | 0.065 | 0.098 | 1.184 | 1.217 | 1.248 |

| 1.250 | ±0.013 | 0.035 | 0.067 | 0.100 | 1.316 | 1.349 | 1.381 |

| 1.400 | ±0.014 | 0.036 | 0.069 | 0.103 | 1.468 | 1.502 | 1.535 |

| 1.600 | ±0.016 | 0.038 | 0.071 | 0.107 | 1.670 | 1.706 | 1.740 |

| 1.800 | ±0.018 | 0.039 | 0.073 | 0.110 | 1.872 | 1.909 | 1.944 |

| 2.000 | ±0.020 | 0.040 | 0.075 | 0.113 | 2.074 | 2.112 | 2.148 |

| 2.240 | ±0.022 | 0.041 | 0.077 | 0.116 | 2.316 | 2.355 | 2.392 |

| 2.500 | ±0.025 | 0.042 | 0.079 | 0.119 | 2.578 | 2.618 | 2.656 |

| 2.800 | ±0.028 | 0.043 | 0.081 | 0.123 | 2.880 | 2.922 | 2.961 |

| 3.150 | ±0.032 | 0.045 | 0.084 | 0.127 | 3.233 | 3.276 | 3.316 |

| 3.550 | ±0.036 | 0.046 | 0.086 | 0.130 | 3.635 | 3.679 | 3.721 |

| 4.000 | ±0.040 | 0.047 | 0.089 | 0.134 | 4.088 | 4.133 | 4.176 |

| 4.500 | ±0.045 | 0.049 | 0.092 | 0.138 | 4.591 | 4.637 | 4.681 |

| 5.000 | ±0.050 | 0.050 | 0.094 | 0.142 | 5.093 | 5.141 | 5.186 |

| Dimensional values derived from NEMA MW1000-1997 Standard | ||||||

| AWG | Conductor Diameter | Single Build | Heavy build | |||

| Minimum Increase in Diameter | Maximum Increase in Diameter | Minimum Increase in Diameter | Maximum Increase in Diameter | |||

| (mm) | (inch) | (inch) | (inch) | (inch) | (inch) | |

| 4 | 5.189 | 0.2043 | ||||

| 5 | 4.620 | 0.1819 | ||||

| 6 | 4.115 | 0.1620 | 0.0002 | 0.1665 | 0.0019 | 0.1671 |

| 7 | 3.666 | 0.1443 | 0.0003 | 0.1485 | 0.0020 | 0.1491 |

| 8 | 3.264 | 0.1285 | 0.0003 | 0.1324 | 0.0020 | 0.1332 |

| 9 | 2.906 | 0.1144 | 0.0005 | 0.1181 | 0.0021 | 0.1189 |

| 10 | 2.588 | 0.1019 | 0.00'.)5 | 0.1054 | 0.0021 | 0.1061 |

| 11 | 2.304 | 0.0907 | 0.0006 | 0.0941 | 0.0021 | 0.0948 |

| 12 | 2.052 | 0.0808 | 0.0006 | 0.0840 | 0.0021 | 0.0847 |

| 13 | 1.829 | 0.0720 | 0.0007 | 0.0750 | 0.0021 | 0.0757 |

| 14 | 1.628 | 0.0641 | 0.0016 | 0.0666 | 0.0032 | 0.0682 |

| 15 | 1.450 | 0.0571 | 0.0015 | 0.0594 | 0.0030 | 0.0609 |

| 16 | 1.290 | 0.0508 | 0.0014 | 0.0531 | 0.0029 | 0.0545 |

| 17 | 1.151 | 0.0453 | 0.0014 | 0.0475 | 0.0028 | 0.0488 |

| 18 | 1.024 | 0.0403 | 0.0013 | 0.0424 | 0.0026 | 0.0437 |

| 19 | 0.912 | 0.0359 | 0.0012 | 0.0379 | 0.0025 | 0.0391 |

| 20 | 0.813 | 0.0320 | 0.0012 | 0.0339 | 0.0023 | 0.0351 |

| 21 | 0.724 | 0.0285 | 0.0011 | 0.0303 | 0.0022 | 0.0314 |

| 22 | 0.643 | 0.0253 | 0.0011 | 0.0270 | 0.0021 | 0.0281 |

| 23 | 0574 | 0.0226 | 0.0010 | 0.0243 | 0.0020 | 0.0253 |

| 24 | 0511 | 0.0201 | 0.0010 | 0.0217 | 0.0019 | 0.0227 |

| 25 | 0.455 | 0.0179 | 0.0009 | 0.0194 | 0.0018 | 0.0203 |

| 26 | 0.404 | 0.0159 | O.0009 | 0.0173 | 0.0017 | 0.0182 |

| 27 | 0.361 | 0.0142 | 0.0008 | 0.0156 | 0.0016 | 0.0164 |

| 28 | 0.320 | 0.0126 | 0.0008 | 0.0140 | 0.0016 | 0.0147 |

| 29 | 0.287 | 0.0113 | 0.0007 | 0.0126 | 0.0015 | 0.0133 |

| 30 | 0.254 | 0.0100 | 0.0007 | 0.0112 | 0.0014 | 0.0119 |

| 31 | 0.226 | 0.0089 | 0.C006 | 0.0100 | 0.0013 | 0.0108 |

| 32 | 0.203 | 0.0080 | 0.0006 | 0.0091 | 0.0012 | 0.0098 |