- Chalco-high quality EC grade aluminum products supplier

- Conductive aluminum busbar

- EC Grade aluminum wire rod

- Electrical aluminum tubular bus pipe

- Aluminum plate strip foil for capacitor and transformer

- Aluminum wire for electrical application

Chalco - high quality EC grade aluminum products supplier

Supply products: Chalco offers a complete range of conductive aluminum products. Our products cover conductive aluminum busbars, EC grade aluminum wire rod, electrical aluminum tubular bus pipe, aluminum plates foils for capacitors, aluminum wire for electrical application, copper aluminum composite materials, various types of paper wrapped wires, enameled wires, etc.

Cooperative partner: Chalco conductive aluminum products have established connections with a large number of manufacturers such as transformers, switchgear, power capacitors, electric tools, etc., and are widely used in power engineering such as transmission and transformation stations, as well as in power equipment such as transformers.

Conductive aluminum busbar

Chalco EC grade aluminum busbar, complying with standards such as ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, EN 573-3, etc., is widely used in electrical conductors of distribution systems. Quick Quote

-

1060 EC aluminum busbare T3 T4 T5 T6 T8

It is usually formed by extrusion or rolling, and has good processing performance.

High conductivity Corrosion resistance -

1350 EC aluminum busbar H14 H16 H19

The minimum weight percentage is 99.5%, which is the material used for battery busbars.

Conductivity Thermal conductivity -

6060 EC aluminum busbar T4 T5 T6

It can effectively transmit and distribute electricity, reducing energy loss and line power loss

Lightweight Processability -

6082 EC aluminum busbar T3 T4 T5 T6

It has high strength and hardness, while maintaining good conductivity.

Excellent properties High strength and rigidity -

6101 EC aluminum busbar T6 T61 T63 T64 T65

Containing magnesium and silicon, has high mechanical strength. Better anti creep than 1350.

Thermal stability Easy processing -

6061 aluminum busbar has strong conductivity and is a universal material for most processing technologies.

Smooth surface Strong moisture resistance -

6063 EC aluminum busbar T4 T5 T6 T52 T66

In high-power applications, it can dissipate heat, reduce equipment overheating, improve equipment reliability.

Strong plasticity Heat dissipation performance -

Bimetallic conductivoty; the third generation "new energy-saving conductor material" after copper and aluminum.

Conductivity Scalability Reliability

EC Grade aluminum wire rod

Chalco EC Grade aluminum round wire rods comply with standards such as ASTM B 800, BS EN 573-3, GB/T6892, ASTM B221, ASTM B233, GOST 13843-78, EN 1715, EN 755, IS 5487: 1997, etc. The productions are widely used in fields such as cable manufacturing. Quick Quote

-

1350 EC aluminum wire rod O H11 H12 H14 H16 H18

Widely used in power transmission and distribution systems, suitable for small and medium-sized circuits.

High purity Lightweight -

1370 EC aluminum wire rod H11 H12 H13 H14 H16

Suitable for long-distance transmission lines and large distribution systems, with high load carrying capacity.

Excellent conductivity Good processability -

1050 EC aluminum wire rod O H11 H12 H14 H16 H18

Commonly used in small circuits and equipment in power distribution systems, suitable for low load applications.

Excellent thermal conductivity Good weldability -

1070 1080 EC aluminum wire rod O H11 H12 H14 H16 H18

Suitable for power transmission systems with special environments and high conductivity requirements.

Good conductivity High temperature resistance -

Belong to heat-treatable and strengthened aluminum alloy; for long-distance transmission lines, etc.

Excellent conductivity Medium strength -

Conductivity is close to pure copper, but lighter in weight; can effectively transmit and distribute electricity.

High mechanical strength

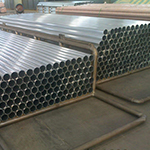

Electrical aluminum tubular bus pipe

Chalco Electrical aluminum tubular bus pipe products comply with standards such as ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, EN 573-3, etc.

The product is delivered in a tubular structure, with straight pipes, smooth and flat surfaces, and no defects such as cracks, wrinkles, twists, etc. Compared with other shapes of busbars, they are lighter in weight, larger in cross-sectional area, stronger in load-bearing capacity, and more convenient to install. Quick Quote

-

1350 tubular buspipe H111 H112 F

It has the highest conductivity among all extruded aluminum conductors, reaching or exceeding 61.0% IACS.

High conductivity Corrosion resistance -

A new type of conductor that replaces traditional rectangular groove and strip busbar.

Low temperature rise Low loss -

6101 tubular buspipe T6 T61 T63 T64 T65 T7 H14 H18 O

It is important for the safty transmission of power transmission and transformation systems.

Good corrosion resistance Weldability -

6061 tubular buspipe T6 T651 H112

It has small Skin effect coefficient, uniform current distribution, and current density up to 1.4A/mm2.

Extremely sturdy Light weight -

6063 tubular buspipe T5 T6 T10

Operate safely in 150-200 ℃, and the tensile strength at 250 ℃ can be maintained over 88% at room temperature.

High current carrying capacity -

It can provide good corrosion resistance and moderate strength after appropriate surface treatment.

Good conductivity More reliable

Aluminum plate strip foil for capacitor and transformer

Chalco produces and supplies aluminum alloy plate and foil products for capacitors, which comply with ASTM B479-18, IEC 60384-1, JIS H 4120, GB/T 3618-2019 and other GB, EN, BS, AMS and other standards. They can be used to manufacture various types and specifications of capacitors. Quick Quote

-

Aluminum plate strip for capacitor

Alloy: 1050 1060 1070 1100 3004

These alloys have the advantages of lightweight, good conductivity, good thermal conductivity, good mechanical properties, and good corrosion resistance, making them ideal materials for manufacturing capacitor shells. -

Aluminum foil for capacitor

Alloy: 1050 1060 1070 1100 1235 3003 8001

The main application of aluminum foil is in Electrolytic capacitor. Set the aluminum foil as the anode. After the electrolyte is electrified, a layer of oxide film (Al2O3) will form on the surface of the aluminum foil. The oxygen film acts as a dielectric. -

Aluminum strip for transformer

Alloy: 1050 1060 1070 1350

Aluminum strip is crucial in transformer manufacturing for its lightweight, strength, and excellent conductivity. We partner with global leaders like LEGRAND, ABB, SIEMENS, EATON, and TOSHIBA, supplying high-quality strip to innovate power equipment and energy solutions.

Aluminum wire and connecting terminals for electrical application

-

Aluminum cable conductor

Chalco 8017 8030 8076 8130 8176 8177 aluminum cable conductor are widely used in overhead conductors and other wire and cable fields.

-

Aluminum wire for cable shielding

Important conductive material that provides reliable shielding function for cables; used in the power, communication, and control field.

-

Aluminum wire for electric traction

Widely used in electrical transportation and lifting systems such as railways, mines, and urban transportation.

-

High strength aluminum wire (AAAC)

6101 6021 6061 8006 8030 8170 high-strength aluminum alloy wires; used in overhead lines to provide reliable power transmission and distribution.

-

Medium-strength aluminum wire (ACSR)

Exhibit moderate strength and high load-bearing capability; used in power distribution and overhead transmission lines.

-

Heat-resistant aluminum wire (TACSR)

Design with high temperature resistance, ideal for overhead transmission lines in high-temperature environments.

-

Paper covered aluminum wire

It has excellent voltage resistance and thin insulation thickness, with a maximum heat resistance of 220 ℃.

-

Copper clad aluminum wire

Chalco prepares high-quality copper clad aluminum wire billets, ensuring the bonding ability of the copper aluminum interface.

-

130/155 polyester enameled wire

High-quality aluminum round wire for polyester enameled wire with good electrical insulation and conductivity properties.

-

120 acetal enameled aluminum round wire

It has good mechanical strength and excellent high-temperature hydrolysis resistance; widely used in oil-immersed transformers.

-

polyesterimide enameled aluminum round wires

Provide polyesterimide enameled aluminum round wires with good electrical insulation and high temperature resistance.

-

200 polyester/ polyamideiImide wire

It has high temperature and electrical insulation performance, corrosion resistance, mechanical strength, and lightweight.

-

Connecting terminal

Aluminum, copper, and copper aluminum claded connecting terminal (DL, DT, DTL); used in power systems, transformers, cable connections, etc.