Why choose Chalco 6009 T4 T6 automotive aluminum profile?

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Serving Tesla, Ford, Shanghai Automobile, Weilai Automobile, BAIC New Energy, Changan Automobile and other famous new energy automobile manufacturers, confirmed the material certification relationship, and completed the parts of many automobile factories such as BAIC New Energy and Weilai Automobile Model car plate material certification.

Specs of 6009 T4 T6 automotive aluminum profile

| Alloy | Sectional shape | Sectional size (mm) |

| 6009-T4 | square | 10×10-150×150 |

| round | Φ10-Φ150 | |

| rectangle | 10×20-150×200 | |

| oval | 15×30-100×200 | |

| hexagon | Length 10-80 | |

| 6009-T6 | U-shaped | 10×20-100×200 |

| C-shaped | 10×20-100×200 | |

| T-shaped | 10×20-100×200 |

Chemical composition of 6009 T4 T6 automotive aluminum profile

| Element | Composition(%) |

| Al | 91.5-94.5 |

| Mg | 0.5-1.2 |

| Si | 0.4-0.9 |

| Cu | 0.1-0.6 |

| Mn | 0.6-1.2 |

| Cr | ≤0.05 |

| Zn | ≤0.25 |

| Ti | ≤0.1 |

| Other | ≤0.05 |

Mechanical property of 6009 T4 T6 automotive aluminum profile

| Alloy | Tensile strength(MPa) | Yield strength(MPa) | Elongation(%) |

| 6009-T4 | ≥230 | ≥180 | ≥10 |

| 6009-T6 | ≥290 | ≥260 | ≥8 |

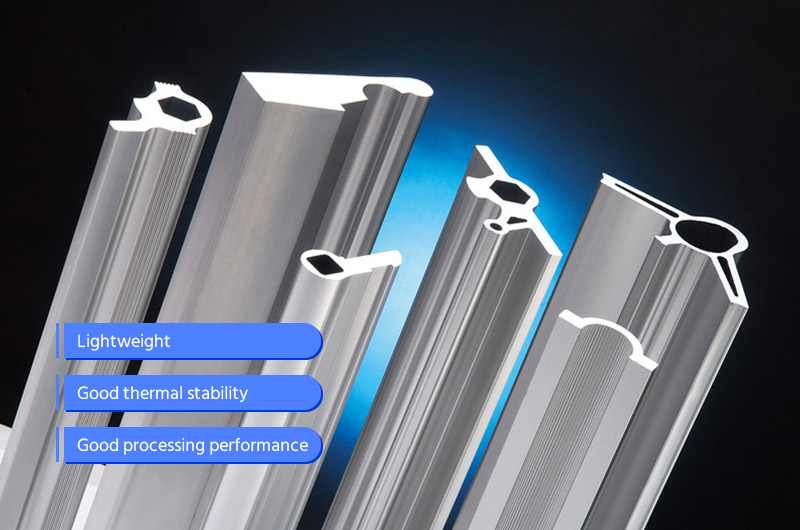

Features of 6009 T4 T6 automotive aluminum profile

High strength: 6009 aluminum alloy material has high strength, and its tensile strength and yield strength are about 30% higher than that of ordinary aluminum alloy materials, which can meet the strength requirements of automobile structural parts.

Good corrosion resistance: due to the addition of elements such as copper and magnesium in the 6009 aluminum alloy material, it has good corrosion resistance and wear resistance, which can meet the requirements of automobiles in harsh environments.

Good machinability: 6009 aluminum profiles can be formed by various processing methods such as extrusion, stretching, and die-casting, and have good processing performance, which can meet the requirements of complex shapes and high-precision processing of auto parts.

Light weight: compared with steel, aluminum has a lower density, so the weight of 6009 aluminum profiles is relatively light, which can effectively reduce the weight of the vehicle, improve fuel economy and reduce exhaust emissions.

Good aesthetics: 6009 aluminum profiles have a high surface finish, and can be surface treated by anodizing, spraying, etc., with good decorative and anti-corrosion effects, and are suitable for the manufacture of automotive exterior and interior parts.

Usage of 6009 T4 T6 automotive aluminum profile

Automotive body structural parts: 6009 aluminum profiles are used to manufacture various components of the car body, such as door panels, roofs, front and rear bumpers, side skirts, wheel arches, etc., which can effectively reduce the weight of the vehicle and improve fuel efficiency and driving performance.

Automotive chassis structural parts: 6009 aluminum profiles can be used to manufacture supporting structural parts of the car chassis, such as front suspension, rear suspension, tie rods, stabilizer bars, etc., which can improve the rigidity and stability of the vehicle.

Automobile engine parts: 6009 aluminum profiles can also be used to manufacture automobile engine parts, such as water tanks, fuel tanks, radiators, intake pipes, etc., which can improve the cooling efficiency and operating efficiency of the engine.

Other uses: 6009 aluminum profiles can also be used in other fields that require lightweight and high-strength materials, such as aerospace, high-speed trains, etc.

Precautions for use of 6009 T4 T6 automotive aluminum profile

Prevent scratches and collisions: the surface hardness of aluminum is relatively low, and it is easy to be scratched and bumped, so it needs special attention during transportation, storage and processing.

Reasonable storage and protection: aluminum is susceptible to moisture, oxidation and corrosion, so it needs to be stored in a dry and ventilated environment, and moisture-proof, oxidation-proof and anti-corrosion measures should be taken. During storage, try to avoid direct contact with other metal materials to prevent corrosion caused by electrochemical reactions.

Appropriate processing methods: 6009 aluminum alloy materials can be processed by forging, stretching, extrusion and die-casting, but different processing methods have different effects on the performance and appearance of the material, so it is necessary to choose the appropriate processing method according to the specific situation.

Strict quality control: in the production process, strict quality control is required for each link to ensure that the performance and quality of 6009 aluminum profiles meet the requirements.

Safe use: during use, you need to pay attention to safety to avoid accidents caused by improper operation. For example, when performing operations such as cutting, drilling and welding, appropriate protective equipment should be worn, and operators should be ensured to have relevant skills and experience.