Acetal enamelled aluminum round wire has good mechanical strength and excellent high temperature hydrolysis resistance, so it is widely used in oil-immersed transformers.

Why choose Chalco Grade 120 acetal enameled aluminum round wire?

Production standards

The quality of acetal enamelled round aluminum wire produced by Chalco complies with GB/JIS standards

Production ability

The production and management strictly implement the GB/T 6109.3-2008/technical agreement, and it still has outstanding hydrolysis resistance in a sealed high-humidity environment.

Customer reference in the power industry

SIEMENS, ABB, TOSHIBA, LEGRAND, EATON, HITACHI

Specifications for grade 120 acetal enamelled round aluminum wire

| Temperature class | 120 |

| Specification range | 0.25-1.60mm;0.25-5.00mm |

| Insulation layer thickness | 0.03mm |

| Wrap Material | Acetal |

| Rated voltage | 300 volts |

| Rated Current | 1 Amp |

| Reference standard | GBT 23312.2-2009;IEC 60317-0-3-2019 |

Please note that the above specifications are for reference only, actual product specifications may vary depending on the manufacturer, application needs or region. It is recommended to obtain accurate specification information from the manufacturer or supplier at the time of purchase.

The chemical composition of grade 120 acetal enamelled round aluminum wire

The chemical composition of acetal enamelled aluminum round wire is mainly composed of the following components:

Aluminum (Al): As the main component of conductor materials, aluminum has good electrical conductivity and appropriate mechanical properties.

Acetal (Enamel): Acetal is a resin material used to coat the insulating layer. Common acetals include polyaldehyde, polyurethane, etc. It has good electrical insulation properties and can effectively isolate the conductor from the external environment.

In addition to the above main components, acetal enamelled aluminum round wire may also contain some auxiliary components, such as solvents, stabilizers, fillers, etc. The exact composition of these auxiliary ingredients may vary by manufacturer and product type.

Please note that the chemical composition of specific products may vary by manufacturer, product specification and region. It is recommended to consult the technical information of the relevant product or contact the manufacturer for accurate chemical composition information.

The mechanical properties of Grade 120 Acetal enameled aluminum round wire

| Minimum elongation | Minimum tensile strength N/mm² | Thermal shock temperature |

| 10%-15%- | 70-90 | at least 155°C |

Features of grade 120 acetal enamelled round aluminum wire

Excellent electrical performance: Grade 120 acetal enamelled aluminum round wire has good electrical insulation performance, which can effectively isolate the conductor from the external environment and prevent current leakage and arc occurrence.

Lightweight and efficient: Due to the use of aluminum as the conductor material, 120-grade acetal enamelled aluminum round wire has a lower specific gravity than copper wire, so it has lighter weight and higher conductive efficiency.

Good electrical conductivity: Aluminum has good electrical conductivity, which can provide stable and efficient current transmission.

Strong corrosion resistance: Aluminum has good corrosion resistance, can maintain good performance under certain environmental conditions, and is not easy to be corroded by moisture and chemicals.

Excellent flexibility and bending performance: Grade 120 acetal enamelled aluminum round wire usually has good softness and bendability, and is suitable for application scenarios that require bending or buckling.

Good heat resistance: Grade 120 acetal enamelled aluminum round wire can maintain good performance at higher temperatures, with high heat resistance temperature and thermal stability.

Easy to process and install: 120-grade acetal enamelled round aluminum wire has a smooth and flat surface, easy to cut, weld and connect, and easy to process and install.

In addition, it has the characteristics of excellent thermal shock resistance, excellent scratch resistance, excellent adhesion performance, good hydrolysis resistance and excellent transformer oil resistance.

Limitations: the paint film is subject to winding stress and is prone to cracks (before dipping, it must be heated at about 120°C for more than 1 hour to eliminate stress); the softening breakdown temperature is low, and the heat resistance is poor.

Note that specific product features may vary depending on manufacturer, product specification and application needs. When selecting and using grade 120 acetal enamelled aluminum round wire, it is recommended to refer to the technical information of the relevant product or consult the manufacturer to obtain accurate characteristic information.

The main application of grade 120 acetal enamelled round aluminum wire

Grade 120 acetal enamelled round aluminum wire is widely used in electrical engineering and electronics. Below are some common uses.

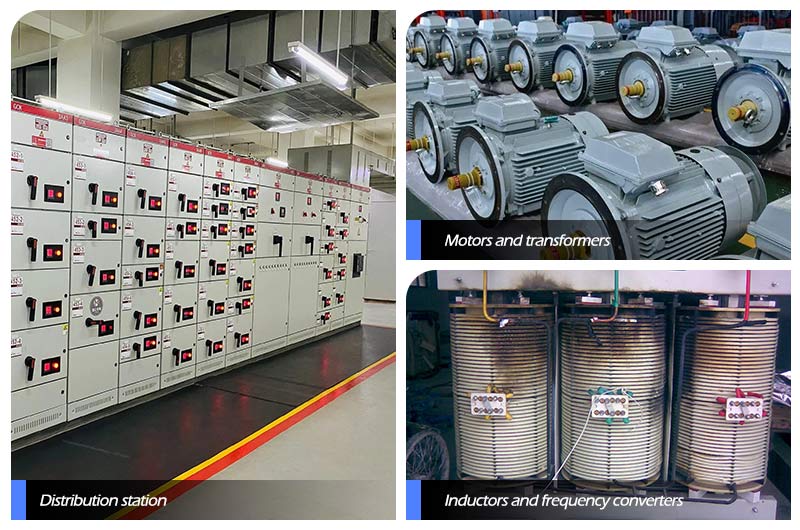

Motors and transformers: acetal enamelled aluminum round wire is often used in small and medium-sized motors with low temperature rise, micro-motor windings and coils of oil-immersed transformers; coils for electrical instruments; coils for medium and large oil-filled motors.

Inductors and frequency converters: In electronic equipment, acetal enamelled aluminum round wire can be used to manufacture inductors and frequency converters for functions such as power conversion, circuit filtering and signal conditioning.

Power generation equipment and transmission lines: acetal enamelled aluminum round wire is used in power generation equipment to manufacture power generation coils and generator components, and can also be used as a conductive material in power transmission lines.

Electromagnetic coils and inductive components: Acetal enamelled aluminum round wire can be used to manufacture various electromagnetic coils and inductive components, such as relays, solenoid valves, induction coils, etc.

Electronic components and connecting wires: acetal enamelled aluminum round wires can be used as connecting wires for the internal connection of electronic components, such as wiring of circuit boards, leads of electronic devices, etc.

Lighting equipment: In the lighting industry, acetal enamelled aluminum round wire can be used to make bulbs, lamp tubes and coil parts of lighting devices.

It should be noted that the specific application depends on the specification, performance and manufacturer's requirements of the acetal enamelled round aluminum wire. When selecting and using, it should be selected according to specific application requirements and relevant standards, and follow the manufacturer's recommendations and guidance.

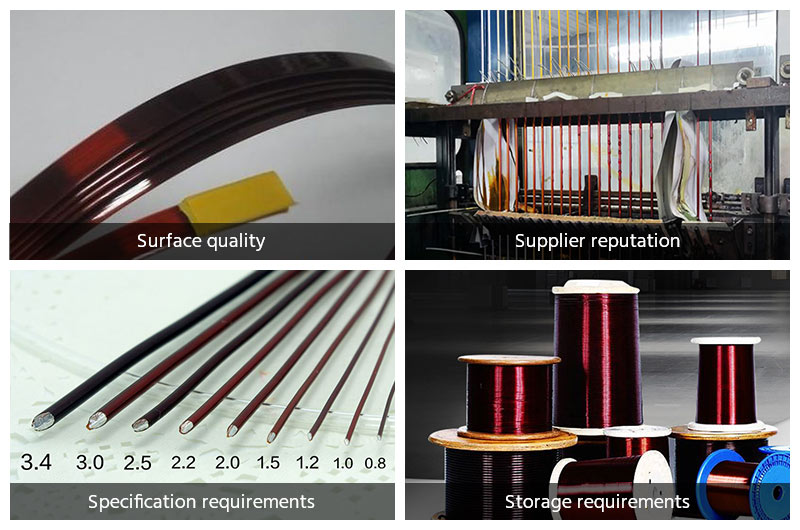

Items for selecting 120-grade acetal enamelled round aluminum wire

Specifications and dimensions: According to specific application requirements, select appropriate specifications such as diameter, conductor cross-sectional area, and coil length.

Electrical performance: ensure that the acetal enamelled aluminum round wire has the required electrical characteristics, such as withstand voltage, temperature resistance, resistance value, etc., to meet the required current transmission and insulation performance.

Heat resistance: According to the application scenario and working temperature requirements, select acetal enamelled aluminum round wire with sufficient heat resistance to ensure stable operation in high temperature environments.

Corrosion resistance: If there are corrosive substances such as moisture, acid and alkali in the application environment, choose acetal enamelled aluminum round wire with good corrosion resistance to prolong the service life and ensure reliability.

Manufacturer reputation and quality certification: Choose a well-known and reputable manufacturer to ensure that the product meets relevant quality standards and certification requirements.

Application field matching: Make sure that the selected acetal enamelled aluminum round wire is suitable for specific application fields and scenarios, such as motors, transformers, electronic devices, etc.

Supply chain and after-sales service: Understand the reliability of the supply chain and the support of after-sales service to ensure product availability and problem-solving capabilities.

Generally speaking, when selecting 120-grade acetal enamelled aluminum round wire, it is necessary to comprehensively consider its specifications, performance, applicability and reliability to meet specific application requirements. Before purchasing, you can communicate and consult with the manufacturer or supplier to obtain more detailed and accurate information, and choose according to the actual situation.