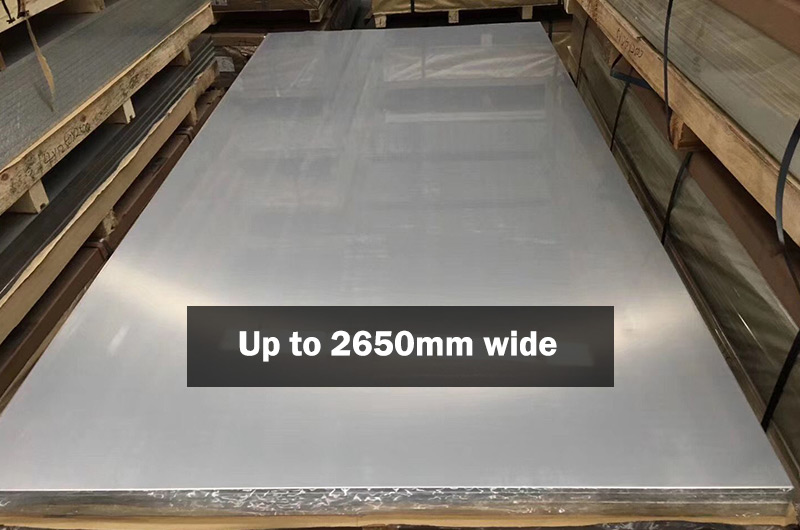

Extra-wide aluminum plates refer to aluminum plates with a width exceeding 1500mm, typically used in industrial and construction applications that require large dimensions, such as aerospace, shipbuilding, architectural decoration, and transportation. Due to their large width, they reduce the need for splicing, offering greater structural integrity and aesthetic appeal.

Chalco can produce aluminum sheet coils up to 2600mm wide and aluminum thick plates up to 3000mm wide. Welcome to inquire about purchasing, consulting, and project cooperation.Welcome contact

Specification of Chalco ultra-wide aluminum sheet coil foil

- Chalco ultra-wide aluminum sheet coil can be 2650mm, commonly used width is 800-2000mm. The features ultra wide & ultra thick plate can be 3000mm wide.

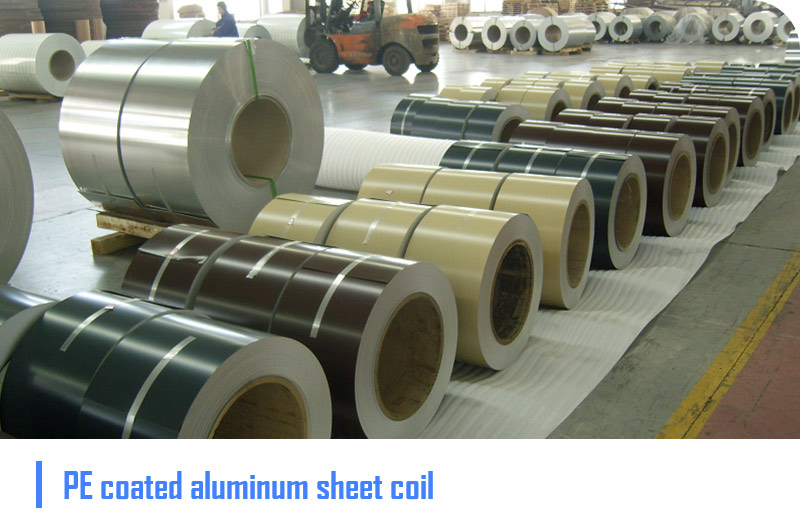

- Coating types: PE, PVDF, HDP, FEVE, etc., colors can be customized; Single or double sided coating can be applied according to customer needs.

- Thickness of coating film:Standard 18-25 microns, maximum 60 microns, and customized.

| Hot selling alloy | 1050, 1100, 3003, 6061, 7075, 5005, 5052, 5083, 5182, 5754 |

| Hot selling width | 800-2000mm Max. width 2650mm |

| Thickness | Sheet: 4.5-100mm; Coil: 0.2-8mm |

| Deep processing | Stamping, color coating, etc. |

| Packaging and transportation | Waterproof paper+anti polymer film+steel plate cover, with steel edge protectors and sufficient steel strips. More packaging details can be customized according to customer requirements |

| Standard | ASTM B209 EN485 GB/T33227 GB/T3880 etc. |

Chalco hot selling aluminum wide coil——aluminum coil for roofing

Alloy: 1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003,

Nominal thickens: 0.021mm, 0.026mm, 0.03mm, 0.04mm, 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.1mm

Width: 20inch, 24inch, 48inch, 914mm, 912mm, customized

Color: Terracotta, width, black, blue, Green, White;

Lacquered: one side or both side

Contact us now

Advantage of Chalco aluminum coils for roofing

- Ultra-wide, strong integrity: The ultra-wide design reduces seams, enhancing the structural strength and weather resistance of the building, improving overall protection.

- Custom coating system: Tailored coatings are applied based on the specific location and needs of each project, offering strong resistance to cracking, peeling, and chalking. Multiple color options are available.

- Stain-free surface: The surface of the aluminum coil is free from stains, cracks, holes, or scratches, ensuring excellent appearance and quality.

- Durability: Aluminum has natural corrosion resistance, rust resistance, and weatherproof properties, allowing it to withstand harsh weather conditions like rain, snow, hail, and UV rays, ensuring long-term building protection.

- Lightweight: Aluminum is one of the lightest roofing materials, making it easy to transport, handle, and install, reducing the structural load and lowering installation costs.

- High energy efficiency: Aluminum's high reflectivity helps reflect sunlight, reducing heat absorption by the building, thus lowering cooling energy consumption, particularly in hot climates.

Environmental Certifications of Chalco aluminum coils for roofing

- Green Standards: Strictly adhere to green environmental protection standards, ensuring all production processes comply with environmental requirements.

- Eco-friendly Coating: Utilizes eco-friendly coatings that are free from lead (Pb), chromium (Cr), and isophorone (IF), ensuring safety.

- Compliance with International Regulations: Fully complies with the EU REACH regulation (Regulation No. 1907/2006) and the RoHS Directive (2002/95/EC) on hazardous substance restrictions.

- Conformity with European Norms and Quality Standards: Coating processes meet all European norms and quality standards, including DIN, ASTM, BS, EN, ISO, and ECCA.

- ISO Certification: Certified under ISO 14001:2004, ensuring a high standard of environmental management systems.

- Industrial Emissions Directive Compliance: Fully compliant with the EU Industrial Emissions Directive (IED) 2010/75/EU, ensuring emissions meet regulatory standards.

Application fields of Chalco aluminum coils for roofing

- Residential Roofing: Durable, low-maintenance, and available in various colors and finishes to suit different home styles.

- Commercial Roofing: Lightweight and strong, ideal for large commercial buildings needing weather resistance and reduced structural load.

- Industrial Roofing: Highly durable and corrosion-resistant, perfect for industrial facilities exposed to harsh chemicals and conditions.

- Agricultural Buildings: Durable and low-maintenance, providing reliable protection for barns, sheds, and farm equipment.

- Institutional Buildings: Energy-efficient and visually appealing, suitable for schools, hospitals, and government buildings.

- Recreational Facilities: Durable and attractive roofing solution for sports centers, community facilities, and resorts.

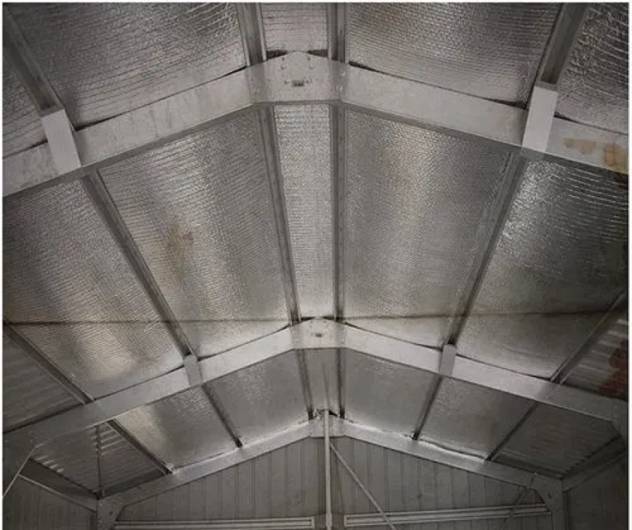

Chalco hot selling aluminum wide foil——Aluminum foil roof insulation

Alloy: 1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003,

Commonly used width: about 1000mm(912/914mm), or more.

Roof thermal insulation aluminum foil is typically provided in wide rolls. This roll format allows the aluminum foil to be easily laid out and installed, especially for large-area applications. Wide rolls help reduce seams, improve thermal insulation performance, and simplify the construction process.

Advantages of Chalco aluminum foil roof insulation

- Roof thermal insulation aluminum foil is supplied in wide rolls, making it easy and efficient to cover and install.

- No stains, no marks, no cracks, no holes: Ensures a clean and flawless surface.

- Chromated surface: Oil-free, enhances adhesive properties, and facilitates bonding with other materials.

- High reflectivity: Reflects up to 97% of radiant heat, keeping indoor temperatures cool.

- UV and heat stability: Maintains performance under various environmental conditions.

- Moisture barrier (WVTR): Effectively prevents moisture infiltration.

- Health safe: Does not release harmful fibers.

- In many cases, aluminum foil is combined with plastic films (such as polyester (PET), polypropylene (PP), or polyethylene (PE)). This composite foil increases tensile strength and makes the aluminum foil easier to bond with insulation materials.

Chalco aluminum roof insulation types and their application fields

| Aluminum foil type | Properties | Main areas of application | Advantages |

| Standard aluminum foil | Non-perforated, reflective | General roof and wall insulation | High heat reflection, cost-effective |

| Perforated aluminum foil | Perforated, permeable to air | Roof insulation to prevent condensation | Prevents mold, allows air circulation |

| Air foil with bitumen lamination | Bitumen layer, protective | Basement walls and areas susceptible to moisture | Additional protection against moisture and damage |

| Aluminum composite film | Laminated with plastic, tear-resistant | Industrial applications, large insulation projects | Increased tear resistance, easy handling |

| Alu-polyester foil | PET-coated, durable | Packaging industry, protective insulation | Protection against environmental influences, durable |

Chalco hot selling aluminum wide sheet——Aluminum sheet coil for Vehicle skin

Specification

Alloy: 5052, 3003, 5083

Hot selling size: 48''*96'' 48''*120'' 48''*110'' 49''*96'' 4'*8'

Color coated: white, black, red

Contact us now

-

5052 wide sheet coil for the outer skin of box car

5052 wide sheet coil for the outer skin of box carCompared with 3003, 5052 offers superior corrosion resistance and mechanical properties, along with better color coating and coloring performance, making it ideal for use as the outer skin of box trucks, RVs, and refrigerator cars.

-

3003 ultra wide aluminum sheet coil for inner skin of van

3003 ultra wide aluminum sheet coil for inner skin of van3003 aluminum sheet coil's high surface smoothness makes it ideal for inner linings in box trucks, while its painted version is widely used in construction for roof and wall panels, ceilings, and corrugated panels, offering good thermal insulation and refrigeration.

-

5083 aluminum sheet coils for trucks, tank trucks, and refrigerated trucks

5083 aluminum sheet coils for trucks, tank trucks, and refrigerated trucksThe excellent weldability and formability of 5083 ultra-wide aluminum coils make them easier to process and connect during truck and refrigerated truck manufacturing, and suitable for complex processing like deep drawing and bending, commonly used in truck body and tank body manufacturing.

- Width Advantage: Ultra-wide coils reduce seams, enhancing surface integrity and aesthetics, and simplifying manufacturing and installation processes.

- Excellent Weldability: Facilitates easier connection and processing of aluminum sheets during manufacturing and assembly, ensuring structural stability.

- Superior Formability: Suitable for complex processing such as deep drawing and bending, accommodating various vehicle design requirements.

- Corrosion Resistance: Provides good resistance to corrosion, adapting to different environmental conditions and extending service life.

- Weather Resistance: Offers excellent weather performance and color retention, reducing damage from environmental factors.

- Lightweight: Reduces the overall weight of the vehicle, improving fuel efficiency and operational performance.

- High Strength: Features excellent mechanical properties to withstand physical stresses during vehicle use.

- Aesthetic Appeal: Compatible with various surface treatments, such as painting and plating, enhancing the vehicle's overall appearance.

- Thermal Reflectivity: Improves heat reflectivity, helping to maintain stable interior temperatures.

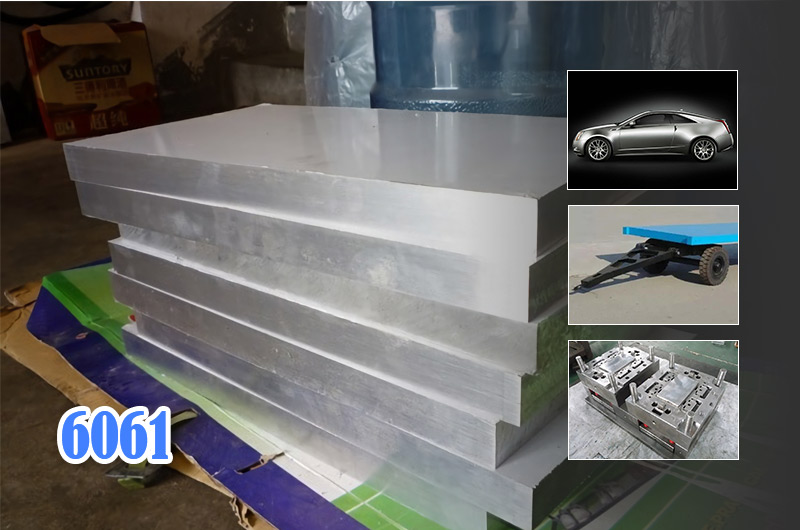

Need extra-thick and extra-wide aluminum plates? Chalco has you covered

3000mm wide aluminum thick plate

Extra-wide aluminum thick plates reduce seams, enhance structural integrity, and increase durability. They are widely used in aerospace, shipbuilding, construction, and transportation.

Contact us now

- Aerospace: used to manufacture high-strength components like aircraft wings and fuselage structures. Common alloys: 2024, 7075.

- Shipbuilding: used to make hulls and decks, requiring high corrosion resistance. Common alloys: 5083, 5754.

- Construction: used in building facades, large-span roofs, and bridges. Common alloys: 6061, 6082.

- Machinery: used to manufacture large mechanical parts and molds. Common alloys: 6061, 7075.

- Transportation: used in high-speed trains, subways, and automotive body structures. Common alloys: 6061, 6082, 7075.

Choose Chalco ultra-width aluminum sheet coil foil by alloy grade

Chalco offeres a variety of aluminum alloy coils with different alloys and coatings to meet the needs of different customers. Common alloys include 1050, 1060, 1100, 3003, 5052, 6061, 7075, 2024 and others, each with its unique properties and applications. If you have project requirements, please feel free to contact us, and we will provide you with customized solutions.

-

1050 aluminum alloy

High purity

Good corrosion resistance

Easy to process

-

1060 aluminum alloy

Excellent corrosion resistance

Good electrical conductivity

High formability

-

1100 aluminum alloy

Excellent corrosion resistance

Good workability

Lower strength

-

1200 aluminum alloy

Good corrosion resistance

Easy to form

Lower strength

-

8011 aluminum alloy

Excellent corrosion resistance

Good formability

Low cost

-

5052 aluminum alloy

Excellent corrosion resistance

High strength

Good formability

-

5083 aluminum alloy

Exceptional corrosion resistance

High strength

Good weldability

-

3003 aluminum alloy

Good corrosion resistance

Excellent formability

Lower strength

-

5754 aluminum alloy

Excellent corrosion resistance

High strength

Good formability

-

6061 aluminum alloy

Good strength

Excellent weldability

Good corrosion resistance

-

2024 aluminum alloy

High strength

Good corrosion resistance (heat-treated)

Good machinability

-

7075 aluminum alloy

High strength

Good fatigue resistance

Moderate corrosion resistance

Chalco ultra wide aluminum sheet coil surface treatment-coating, anodizing and electrophoresis

Chalco's coated aluminum wide coils commonly use alloys such as 5052, 5754, 5083, and 5182. These alloys are known for their excellent resistance to acids and alkalis, non-cracking characteristics during bending of the coating, uniform coating, and offering a variety of color choices.

Chalco's coated aluminum wide coils are primarily used in the following areas: vehicle coated aluminum coils, roofing materials with super-wide coated aluminum coils, and front or rear panels of honeycomb panels.

- Coating: applying liquid or powder materials onto metal surfaces forms a protective, decorative, or functional film, improving corrosion resistance, abrasion resistance, and aesthetics.

- Anodizing: electrochemically treating aluminum creates a durable oxide layer, enhancing hardness, wear resistance, and corrosion resistance.

- Electrophoresis: depositing charged particles onto metal surfaces via electric field ensures strong adhesion and uniformity, ideal for high corrosion resistance and aesthetic applications like automotive coatings.

| Surface Treatment | Features | Common Applications | Common Colors | Common Coating Types |

| Coating | Controlled thickness, diverse colors, good corrosion resistance and aesthetics | Construction, appliances, automotive, industrial equipment | Various colors including red, blue, green, black, white | PE, PVDF, EPOXY, HDP, PTFE, LDPE, carbon coated, sliding lubricant |

| Anodizing | High surface hardness, good wear resistance and corrosion resistance, can be dyed, environmentally friendly | Aerospace, electronics, consumer goods, construction | Silver, black, gold, red, blue | None (natural oxide film formation) |

| Electrophoresis | Uniform coating, strong adhesion, good corrosion resistance, suitable for complex-shaped parts | Automotive, appliances, construction, electronics | Black, white, transparent, gold | Acrylic, polyurethane, epoxy, etc. |

Produce capacity and quality assurance of Chalco ultra-width aluminum sheet coil

- Chalco has 8 melting and casting production lines, as well as 1+4 "hot rolling production lines and supporting equipment. Can efficiently produce high-quality domestic largest wide aluminum sheet coils, with a maximum width of 2650mm.

- Chalco cross cutting production line has functions such as trimming, straightening, fixed length cutting, and automatic stamping. The sheet metal products have high dimensional accuracy and excellent shape. And it has online testing equipment such as Alscan hydrogen analyzer and slag analyzer.

- Chalco has quality system certifications such as ISO 9001, GJB 9001, AS9100, TS16949, and Nadcap (Non Destructive/Heat/Materials Testing) certificates.

- Chalco ultra wide aluminum sheet coils are widely used in fields such as automobiles, vans, RVs, special vehicles, and building roofs, containers, etc. We have established long-term cooperative relationships with numerous well-known enterprises and have obtained numerous material certifications from them.

- With its strong production and R&D capabilities, Chalco also offers a wide range of large-sized products. Feel free to inquire for more details.

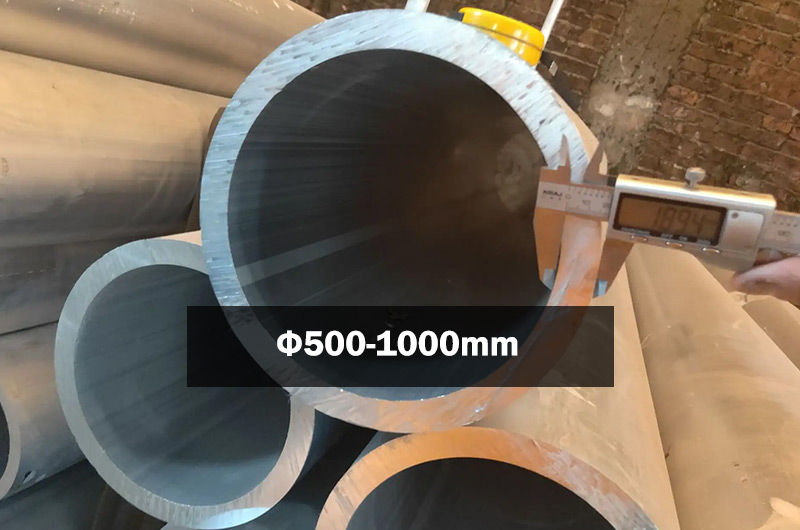

500-1000mm aluminum tube

Ultra large diameter aluminum bar

Spiral welding aluminum tube pipe

1528mm aluminum tube pipe

Super large diameter forged ring

Ultra thick aluminum block

Properties reference table of Chalco ultra-width aluminum sheet coil

| Properties reference table | |||||

| 3003 Alloy | 5052 Alloy | 5754 Alloy | 5083 Alloy | 5182 Alloy | |

| Brinell Hardness | 28-65 | 46-83 | 52-88 | 75-110 | - |

| Elastic Modulus GPa | 70 | 68 | 68 | 68 | 68 |

| Elongation at Break % | 1.1-28 | 1.1-22 | 2.0-19 | 1.1-17 | 1.1-12 |

| Fatigue Strength MPa | 39-90 | 66-140 | 66-140 | 93-190 | 100-130 |

| Shear Strength MPa | 68-130 | 120-180 | 120-190 | 170-220 | 170-240 |

| Tensile Strength: Ultimate MPa | 110-240 | 190-320 | 200-330 | 290-390 | 280-420 |

| Tensile Yield Strength: MPa | 40-210 | 75-280 | 80-280 | 110-340 | 130-360 |

| Performance parameters table for Chalco color coated aluminum coil | ||

| Property | Method | paint |

| Top layer | Coloured lacquer, polyester, PE | |

| Aluminium | 8011/8079/1200/1100/1060 O | |

| Bottom layer | Coloured lacquer, polyester, PE | |

| Standard colours | Wide range of colours RAL | |

| Bending | ECCA 7(0≤T BEND ≤1) | OK |

| Curing | Resistance to MEK | > 50 d.f. |

| Heat Resistance | 240 ℃/2 min. | OK |

| Corrosion Resistance( Neutral Salt Spray) | ASTM B117 (NaCI 5%/35℃ | >500h(According to specification >1000h) |

| U.V. Resistance | ASTM G154(500 h., ; UV -313 4h.60℃/Condensation 4h.40℃) | OK |