Chalco can produce GB/T 33910, ASTM B221, EN755 copper aluminum alloy grade extrusions profile 2024, has IATF16949 automotive material certification, used to windshield frames, luggage racks, seat rails, sliding door rails, door accessories, ABS valve bodies, etc. The product meets aerospace grade, with excellent quality and competitive prices. Feel free to inquire. Welcome contact

Why choose Chalco Aluminum's 2024A aluminum extrusion?

Automotive IATF16949 standard

The 2024 T6 Aluminum auto profiles produced by Chalco adopt a strict quality and environmental management system, and have passed ISO 9001 and ISO 14001 certification, and IATF16949 certification

Well-known brand material certifications

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

Specifications of Chalco Aluminium 2024 extrusion profile

Alloy: 2024 T4 T6 T4511 T6511 T8 T8510 T8511

Specification: GB/T 33910, ASTM B221, EN755

Surface treatment: Anodizing, electrophoretic coating, sandblasting and other methods

Length and Width: according to specific vehicle and application

Size:

- commonly used circular profiles with diameter 10-250mm, thickness 0.5-50mm;

- rectangular profiles with length, width and height 20-100mm, 10-80mm, 0.5-10mm;

- special shaped profiles of different sizes.

Hot selling extrusion shpapes of Chalco 2024 aluminum profile

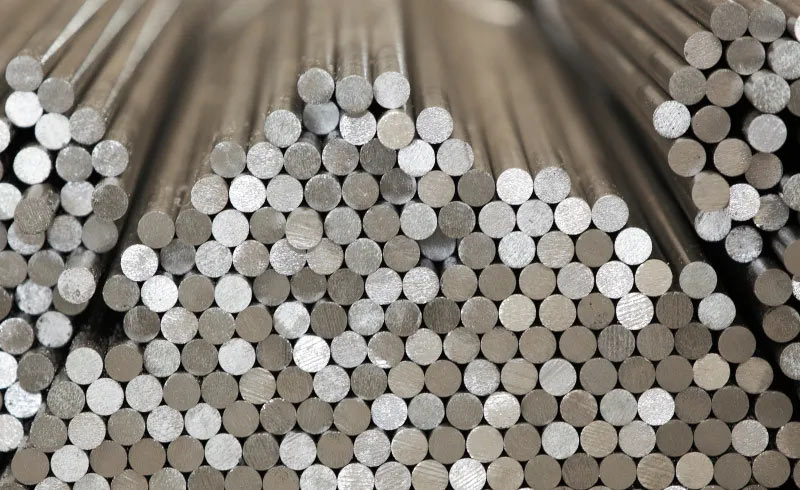

2024 extruded aluminum bar profile

High strength, good toughness, corrosion resistance, and easy machining. Used for aircraft structures, automotive parts, and mechanical components..

Contact us now

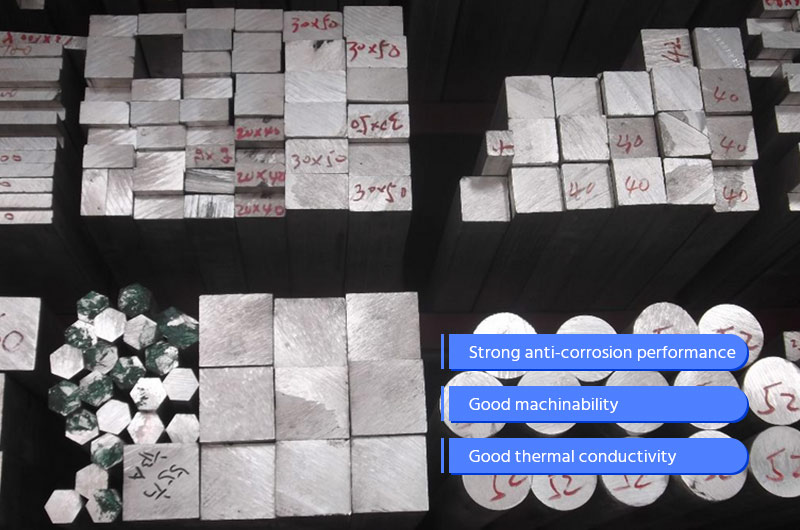

2024 extruded square/flat/hex bar profile

Good thermal conductivity, corrosion resistance, and easy machining. Used for aerospace structures, military equipment, automotive bodies, and suspensions.

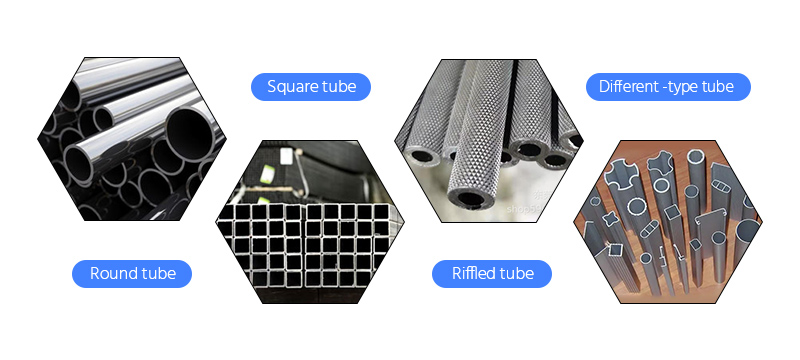

Contact us now2024 extruded aluminum tube pipe profile

Lightweight, high strength, corrosion resistance, and easy machining. Mainly used for manufacturing automotive fuel lines, air conditioning, and hydraulic pipelines.

Contact us now

2024 aluminum ring profile

High strength, good toughness, high fatigue strength, excellent corrosion resistance. Used for aircraft engines, automotive hubs, mechanical gears, etc.

Contact us now2024 extruded profile in special shape

2024 aluminum alloy angle aluminum

2024 aluminum alloy U profile

2024 aluminum alloy T profile

2024 aluminum alloy H profile

Contact us now

Chemical composition of Chalco 2024A automotive aluminum alloy

| Element | Composition (%) |

| Si | 0.5 |

| Fe | 0.5 |

| Cu | 3.8-4.9 |

| Mn | 0.3-0.9 |

| Mg | 1.20-1.8 |

| Ti | 0.15 |

| Cr | 0.10 |

| Zn | 0.25 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of Chalco 2024 automotive high quality extrusion

| Mechanical property | Value |

| Tensile strength | 455MPa |

| Yield strength | 380 Min MPa |

| Elongation | 5% |

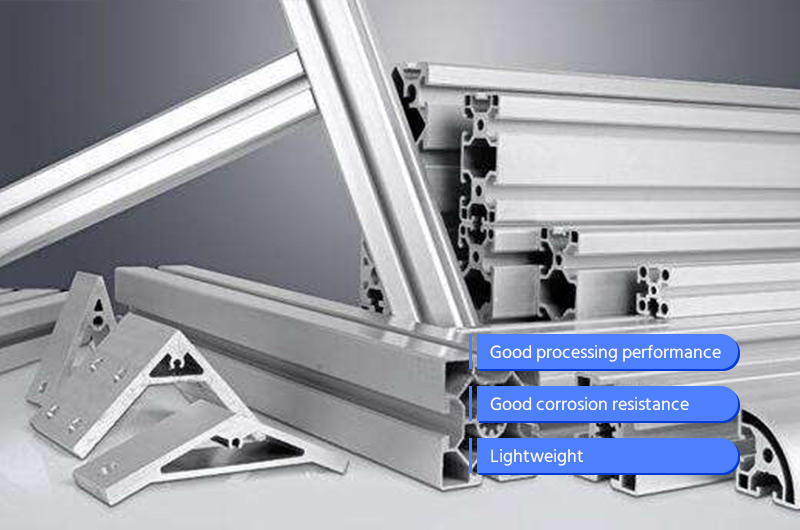

Product features of Chalco 2024 automotive aluminum alloy Extrusion

- 2024 Extrusions AMS 4152 has high strength, which is more than double that of ordinary aluminum alloys, which makes it an ideal choice for manufacturing auto parts.

- 2024 Extrusions AMS 4152 has good processing performance, and various processing methods (such as extrusion, stretching, rolling, etc.) can be used to manufacture automotive aluminum profiles of different shapes.

- 2024 Extrusions AMS 4152 has good corrosion resistance, can be used in harsh environments, and can also improve the service life of the car.

- 2024 Extrusions AMS 4152 is much lighter than steel, which can reduce the overall weight of the car and improve the fuel economy and power performance of the car.

- 2024 Extrusions AMS 4152 has good thermal and electrical conductivity, can work in high temperature environments, and can prevent static electricity from accumulating.

Application of Chalco 2024A industrial automotive grade aluminium extrusion

Body structure: the high strength and lightness of aluminum alloy 2024 make it an ideal material for the manufacture of body structures, which can reduce the weight of the vehicle and improve vehicle performance.

Engine components: aluminum alloy 2024 is also widely used in the production of automotive engine components, such as cylinders, connecting rods, pistons and other components.

Braking system: the high strength and corrosion resistance of aluminum alloy 2024 make it the preferred material for manufacturing automotive braking systems, such as the production of brake discs, brake calipers and other components.

Wheels: aluminum alloy 2024 has light weight, high strength, excellent corrosion resistance and plasticity, so it is widely used in the production of automobile wheels.

Fuel system: fuel system components made of aluminum alloy 2024, such as fuel pumps and injectors, have good corrosion resistance and high strength, which can ensure the reliability and safety of the automotive fuel system.

Production process of Chalco aluminum alloy 2024 (UNS A92024) extrusion

At present, the production process of aviation aluminum profiles mainly includes casting, extrusion and rolling.

Melting and casting is the method of heating the aluminum material to a liquid state and cooling it through a mold;

Extrusion is to extrude the aluminum material into profiles of various cross-sectional shapes;

Rolling is to pass the aluminum material through multiple passes of pressure. It is tapered and formed into profiles of the desired shape.

Chalco 2024 aerospace grade aluminum related products

2024 Aerospace Aluminum Rod Bar

2024 aerospace aluminum tube

2024 aluminum wire

2024 aluminum foil

2024 aluminum plate

2024 aluminum military profiles

FAQ for purchasing 2024 aluminum profiles

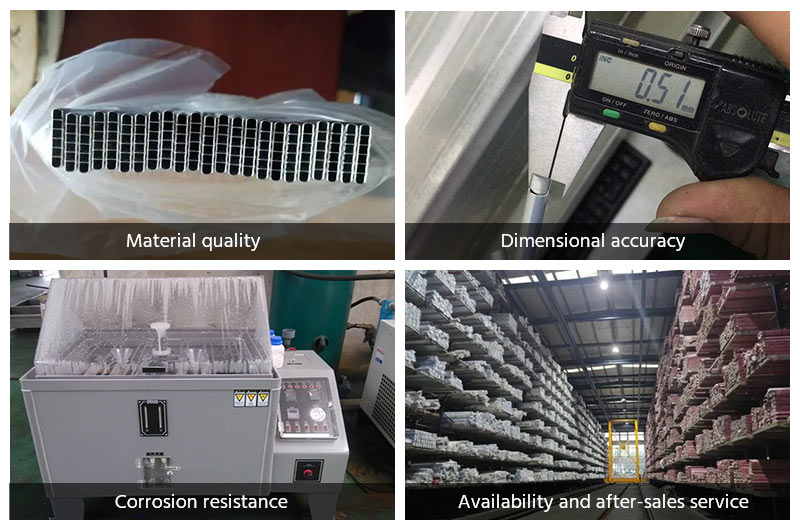

Material certification

When selecting suppliers, suppliers with qualifications and experience should be given priority, and qualified material certification certificates should be required at the same time.

The material certification certificate should include information such as the chemical composition, mechanical properties, processing technology and surface treatment of the material to ensure that the purchased 2024 aluminum profiles meet the corresponding standards and requirements.

Specification and size

According to the required specific use and design requirements, select the appropriate 2024 aluminum profile specification and size. Pay attention to the performance and price differences between different specifications and sizes, and make choices and trade-offs according to actual needs.

Surface treatment

The surface treatment of 2024 aluminum profiles includes oxidation, anodic oxidation, electrophoretic coating, sandblasting and other methods.

Choose the appropriate surface treatment method according to the specific requirements to improve the corrosion resistance, wear resistance and aesthetics of the 2024 aluminum profile.

Supply cycle and delivery method

When negotiating with suppliers, details such as supply cycle and delivery method need to be clarified. Ensure that the purchased 2024 aluminum profiles can be supplied in a timely manner.

At the same time, suppliers are required to provide reasonable transportation and delivery methods to ensure that the goods arrive at their destination safely and in time.

Price and after-sales service

Price is a factor that cannot be ignored in the procurement process. The price and after-sales service of different suppliers should be evaluated and compared, and the cost-effective supplier should be selected for cooperation.

At the same time, establish a good cooperative relationship with suppliers to obtain better service and support in future cooperation.