Chalco Aluminum produces Automotive Brazing Composite Aluminum Coil. It is a composite material composed of two or more different metal materials. This aluminum coil usually consists of alternating layers of aluminum and other metals to provide excellent mechanical properties and corrosion resistance. which is widely used as such as radiators, condensers, evaporators, and heat exchangers.

Main alloy grades for auto brazing composite aluminum coil

3000 series: such as 3003, 3103, etc., have good corrosion resistance and formability, and are suitable for the manufacture of air-conditioning equipment, radiators and other auto parts.

4000 series: such as 4045, 4343, etc., have excellent brazing performance and strength, and are suitable for manufacturing automotive radiators, condensers and other parts.

5000 series: such as 5052, 5182, etc., have good formability and corrosion resistance, and are suitable for manufacturing automobile body panels, doors and other components.

6000 series: such as 6061, 6063, etc., have good strength, wear resistance and corrosion resistance, and are suitable for manufacturing automotive engine parts, body structures, etc.

7000 series: such as 7072, etc., have high strength, corrosion resistance and fatigue resistance, and are suitable for manufacturing high-strength components such as automotive braking systems and suspension systems.

Size of auto brazing composite aluminum coil

| Brazing alloy | Core alloy | Temper | Cladding % | Thicknes (mm) | Wdith(mm) | ID | OD |

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4047, 4104, 4343 | 3A11, 3B11, 3003, 3005, 6A02, 6060, 6063, 6951, 7A11, 7072 | O, H12, H22, H14, H24, H16, H26, H18 | 3.0-25.0 | 0.050-6.000 | 7.0-1600.0 | 75.0, 150.0 , 200.0, 250.0, 300.0, 400.0, 405.0, 500.0, 505.0 | 450.0-2500.0 |

| Width(mm) | Tolerance (mm) | |||

| 7.0-100.0 | >100.0-300.0 | >300.0-900.0 | >900.0-1 400.0 | |

| >0.200-0.240 | ±0.1 | ±0.2 | ±0.3 | ±0.5 |

| >0.240-0.400 | ±0.1 | ±0.2 | ±0.3 | ±0.5 |

| >0.400-0.800 | ±0.1 | ±0.2 | ±0.5 | ±0.8 |

| >0.800-1.500 | ±0.1 | ±0.3 | ±0.8 | ±1.0 |

| >1.500-2.000 | ±0.2 | ±0.3 | ±0.8 | ±1.2 |

| >2.000-3.000 | ±0.3 | ±0.4 | ±1.0 | ±1.2 |

| >3.000-6.000 | ±0.4 | ±0.5 | ±1.2 | ±1.5 |

| Thickness | Glitch | Split level | Tower shape |

| 0.050-0.100 | ≤0.030 | ≤0.4 | ≤4 |

| >0.100-0.200 | ≤0.040 | ≤0.5 | ≤4 |

| >0.200-0.400 | ≤0.050 | ≤1.0 | ≤5 |

| >0.400-1.000 | ≤0.080 | ≤2.0 | ≤5 |

| >1.000-2.000 | ≤0.150 | ≤2.5 | ≤5 |

| >2.000-6.000 | ≤0.200 | ≤3.0 | ≤5 |

| ID(mm) | Tolerance(mm) |

| 75 | ±0.5 |

| 150.0, 200.0, 250.0 | ±1.0 |

| 300.0, 400.0, 405.0, 500.0, 505.0 | ±2.0 |

| Burrs, split layers, and tower shapes of composite tapes for pipe making | |||

| Thickness (mm) | Glitch | Split level | Tower shape |

| >0.200-0.300 | ≤0.010 | ≤0.5 | ≤2 |

| >0.300-0.600 | ≤0.015 | ≤1.0 | ≤3 |

| >0.600 | ≤0.020 | ≤1.0 | ≤3 |

Mechanical properties of auto brazing composite aluminum coil

| Alloy | Temper | Thickness(mm) | Tensile strength Rm N/mm2 | R p0.2N/ mm2 | Elongation A50mm% | |

| Brazing | core | ≥ | ||||

|

4A13 4A17 4A43 4A45 4045 4047 4343 |

3A11 3B11 3003 3005 7A11 7072 |

O | 0.050-0.100 | 95-160 | 35 | 6.0 |

| >0.100-0.200 | 10.0 | |||||

| >0.200-1.300 | 18.0 | |||||

| >1.300-6.000 | 20.0 | |||||

| H12 | 0.050-0.100 | 120-170 | 90 | 1.0 | ||

| >0.100-0.200 | 3.0 | |||||

| >0.200-1.300 | 4.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H22 | 0.050-0.100 | 120-170 | 80 | 2.0 | ||

| >0.100-0.200 | 6.0 | |||||

| >0.200-1.300 | 6.0 | |||||

| >1.300-6.000 | 7.0 | |||||

| H14 | 0.050-0.100 | 150-200 | 125 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H24 | 0.050-0.100 | 150-200 | 115 | 1.0 | ||

| >0.100-0.200 | 3.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H16 | 0.050-0.100 | 170-230 | 150 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 1.0 | |||||

| >1.300-6.000 | 2.0 | |||||

| H26 | 0.050-0.100 | 170-230 | 140 | 1.0 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 3.0 | |||||

| H18 | 0.050-0.100 | 200 | 170 | 0.5 | ||

| >0.100-0.200 | 0.5 | |||||

| >0.200-6.000 | 1.0 | |||||

|

4004 4104 |

3A11 3B11 3003 3005 7A11 7072 |

O | 0.050-0.100 | 95-165 | 35 | 6.0 |

| >0.100-0.200 | 10.0 | |||||

| >0.200-1.300 | 18.0 | |||||

| >1.300-6.000 | 20.0 | |||||

| H12 | 0.050-0.100 | 125-205 | 90 | 1.0 | ||

| >0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 6.0 | |||||

| H22 | 0.050-0.100 | 125-205 | 80 | 2.0 | ||

| 0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 7.0 | |||||

| H14 | 0.050-0.100 | 145-225 | 125 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| 0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 4.0 | |||||

| H24 | 0.050-0.100 | 145-225 | 115 | 2.0 | ||

| >0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| 4004, 4045, 4104, 4343 | 6A02, 6060, 6063, 6951 | O | 0.200-6.000 | 160 | 85 | 16.0 |

| Mechanical properties of composite tapes for pipe making | ||||||

| Alloy | Temper | Thickness (mm) | Tensile strength Rm N/mm2 | R p0.2 N/ mm2 | Elongation A50mm% | |

| Brazing | core | ≮ | ||||

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4047, 4104, 4343 | 3B11, 3003, 3005, 7072 | H14 | >0.200-1.300 | 160-230 | 150 | 0.5 |

| >1.300-3.000 | 1.0 | |||||

| H16 | >0.200-1.300 | 160-220 | 140 | 0.5 | ||

| >1.300-3.000 | 1.0 | |||||

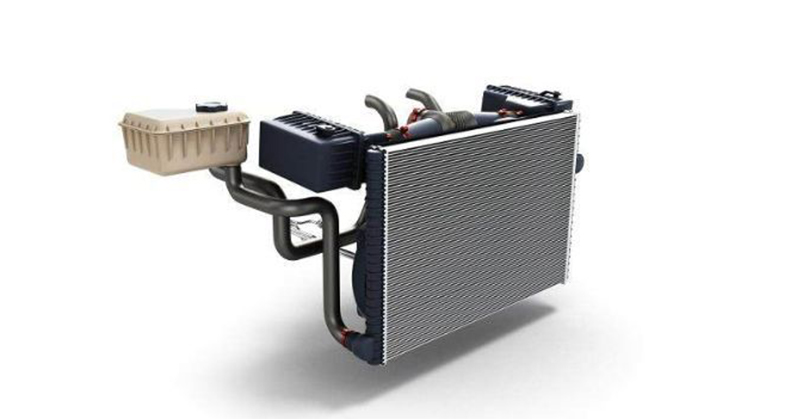

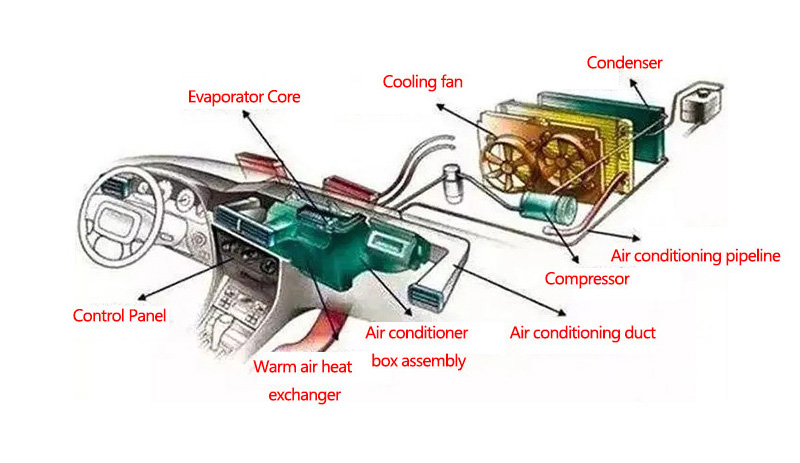

Uses of auto brazing composite aluminum coil

- Radiator

- Condenser

- Evaporator

- Heat exchanger

- Air conditioner

- Battery cooler

- Engine cooler

- Fuel radiator

- Hydraulic oil radiator

- Heat exchanger

- Other automotive cooling system components

Product features of auto brazing composite aluminum coil

High strength: due to the harshness of the environment in which the car is used, the brazed composite aluminum coil for the car needs to have high strength to withstand the pressure of high-speed driving and sudden impact. Alloy The core layer is a high-strength aluminum alloy that provides the strength and durability needed.

Good corrosion resistance: cars are often driven in harsh environments, such as high temperature, high humidity, rain, etc. Therefore, automotive brazing composite aluminum coils need to have good corrosion resistance to prevent oxidation and corrosion. Aluminum-silicon alloy cladding provides good corrosion resistance and makes brazed joints more durable.

Excellent thermal conductivity: the heat dissipation system of a car requires efficient heat dissipation to ensure the normal operation of the engine and other critical components. Automotive Brazed Clad Aluminum Coil has excellent thermal conductivity, allowing heat to be transferred quickly to the environment.

Excellent formability: auto brazing composite aluminum coils can be processed in a variety of ways, such as curling, bending, cutting, etc., and can be customized according to the needs of different auto parts.

Lightweight: brazing composite aluminum coils for automobiles have low density and good strength, which can achieve the purpose of lightweight automobiles, thereby improving the fuel economy and environmental protection of automobiles.

Precautions for use of automotive brazing composite aluminum coil

During the operation, the aluminum coil should be prevented from being impacted or subjected to excessive force, so as not to affect the surface quality and performance of the aluminum coil.

During the operation, the aluminum coil should be protected from high-temperature heat sources to avoid deformation or melting of the aluminum coil.

When using flux for brazing operations, attention should be paid to the quality and composition of the flux so as not to affect the welding effect.

When manufacturing automotive cooling system components, material selection and processing technology selection should be carried out according to design requirements and standards to ensure the safety and reliability of components.

When storing and transporting aluminum coils, the aluminum coils should be protected from vibration, collision and moisture, so as not to affect the surface quality and performance of the aluminum coils.

When using automotive brazing composite aluminum coils, relevant safety operating procedures and operating instructions should be followed to ensure the safety of personnel and equipment.