2618 is a heat -resistant deformation aluminum alloy that can be strengthened by thermal treatment. In the field of aerospace, supersonic aircraft structural parts used to manufacture long -term work, such as fuselage and wing skin frameworks, rear wings, etc.Quick Quote

Why Chalco 2618A/2618 aluminum forgings?

Quality could full meet world wide aviation standard

DTD 745A 2618A Forging stock

DTD 717A 2618 A-T6 Forging Stock and Forgings

DTD 731B 2618 T6 Forging Stock and Forgings

AMS 4132 2618-T61 Die & Hand forgings

We meet international aviation certification

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Chalco can ensure that our 2618A/2618 aluminum forgings have sufficient strength, toughness, corrosion resistance and reliability in aerospace applications.

Specification for 2618A/2618 aluminum forgings

| FORGING | TYPE | MAX WEIGHT | MAX DIMENSION |

| Open Die Forging | Cube | ≤9T |

Length≤7000mm, Width≤2000mm, Height≤500mm |

| Disk | ≤5T | Diameter≤2500mm | |

| Ring | ≤5T |

Outer diameter of quenching parts≤2500mm, Outer diameter of non-quenching parts≤4000mm, Height≤500mm |

|

| Cylinder | ≤5T |

Outer diameter 200-800mm, Length≤2000mm; Outer diameter 801-2000mm, Length≤1500mm; |

|

| Axle | ≤8T |

Length≤7000mm, Diameter≤800mm |

|

| Backward Extrusion | Forged Pipe |

Outer diameter≤830mm, Inner diameter≤650mm, Length≤1800mm |

|

| Closed Die Forging | Common Closed Die Forgings | - | PVA≤3.0㎡(Diameter≤1950mm) |

| Complex Closed Die Forgings | - | PVA≤1.5㎡(Diameter≤1400mm) |

Chemical composition of 2618A/2618 aluminum forgings

| Element | Composition(%) |

| Aluminum (Al) | 93.0-95.0 |

| Copper (Cu) | 2.20-2.80 |

| Iron (Fe) | 0.30 max |

| Magnesium (Mg) | 1.50-2.50 |

| Manganese (Mn) | 0.10 max |

| Silicon (Si) | 0.50-0.90 |

| Zinc (Zn) | 0.20 max |

| Titanium (Ti) | 0.10 max |

| Chromium (Cr) | 0.10 max |

| Other Elements | 0.05 max each, 0.15 max total |

Material properties for 2618A aluminum forging

| Material Specification | Density (g/cm3) | Melting Point (°C) | Thermal Conductivity (W/mK) | Coefficient of Thermal Expansion (10-6/K) |

| DTD 717A 2618A-T6 Forging Stock and Forgings | 2.78 | 515-635 | 127 | 23.2 |

| DTD 731B 2618 T6 Forging Stock and Forgings | 2.78 | 515-635 | 127 | 23.2 |

| AMS 4132 2618-T61 Die & Hand forgings | 2.78 | 515-635 | 127 | 23.2 |

Characteristics of 2618A aluminum forgings?

High strength

2618A aluminum alloy has excellent mechanical properties, and its strength and hardness are superior to many other aluminum alloys.

Good workability

2618A aluminum alloy is easy to process and shape, and can be manufactured by various processes such as casting, forging, rolling, etc.

Corrosion resistance

2618A aluminum alloy has good corrosion resistance and can maintain good performance in high temperature, high humidity, and chemical corrosion environments.

Good welding performance

2618A aluminum alloy has good welding performance and can be connected by various welding methods such as TIG, MIG, arc, etc.

Adapt to high temperature environments

2618A aluminum alloy can maintain good strength and hardness in high temperature environments, making it suitable for the manufacturing of high temperature, high stress, and high load aerospace components.Quick Quote

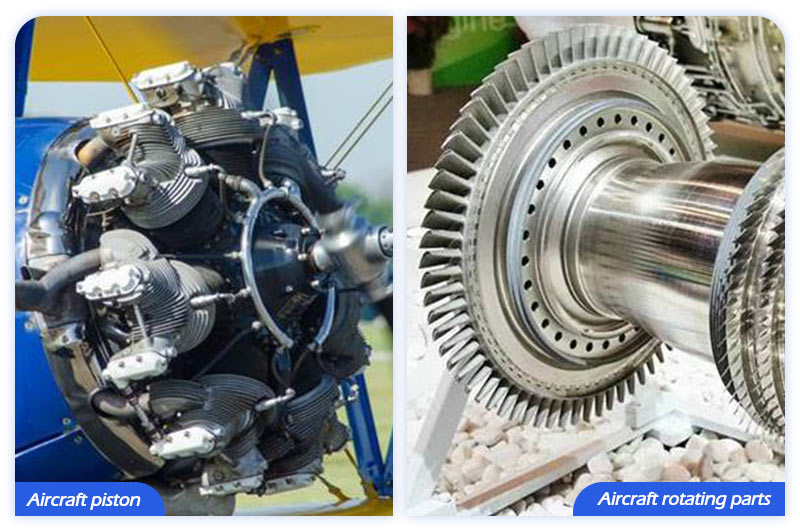

Application of 2618A T6/T61/T651 aerospace aluminum forgings

2618A/2618 T6/T61/T651 aluminum forgings are a high-strength alloy containing copper (2%) and magnesium (1.5%) with good machinability and resistance to atmospheric corrosion. Due to its ability to operate at higher temperatures, 2618A is commonly used for pistons and rotating aircraft components.