7075 aluminum alloy has high strength and is one of the main structural materials in the aviation industry. The development of modern aviation industry requires aviation structural materials to have higher strength, better fracture toughness, and resistance to stress corrosion cracking.

Chalco's capacity for producing aerospace grade aluminum: AS9100, OHSAS 18001, ISO14001, ISO9001, NADCAP HT, NADCAP NDT, IATP16949

Production standard for Chalco's 7075 aerospace aluminum profile: GB/T3190–1996, JIS H4000-1999 JIS H4080-1999, EN573-3-1994, AMS 4154, AMS 4166, BSL160 etc.Welcome contact

Specifications of 7075 aerospace grade aluminum extrusions

| Temper | T3, T6, T8, T651, T6511, etc. |

| Surface treatment | Anodizing, plating, painting/coating, polishing, sanding, chemical etching, etc. |

| Open Profile dimensions | Min 4mm*3mm, Max.850mm*50mm. |

| Closed profiles dimension | Min.6.35mm*1mm, Max. 573mm*10mm. |

| Section area | 0.2-90cm2 |

| Wall thickness | 1-100mm |

| Outline size | 10-530mm |

| Profile length | Maximum 28m (standard 6000mm) |

| Extrusion Type | Dimension range (inches) | Wall thickness range (inches) |

| 7075 aluminum round tube | 1-10 | 0.125-0.75 |

| 7075 aluminum square tube | 1-8 | 0.125-0.5 |

| 7075 aluminum rectangular tube | 1*2-8*12 | 0.125-0.5 |

| 7075 aluminum angle | 1*1-8*8 | 0.125-0.5 |

| 7075 aluminum T-profile | 1*1-6*6 | 0.125-0.5 |

| 7075 aluminum U-profile | 1*0.5-6*2 | 0.125-0.5 |

| 7075 extruded aluminum round bar diameter | Φ0.20-8.0 | - |

| 7075 extruded aluminum square bar diameter | 0.20-8.0 | - |

| 7075 extruded aluminum flat bar specifications | Thickness: 0.006-1.6 Width: 0.4-8.0 | - |

| 7075 extruded aluminum hexagonal bar diameter | 0.2-8 | - |

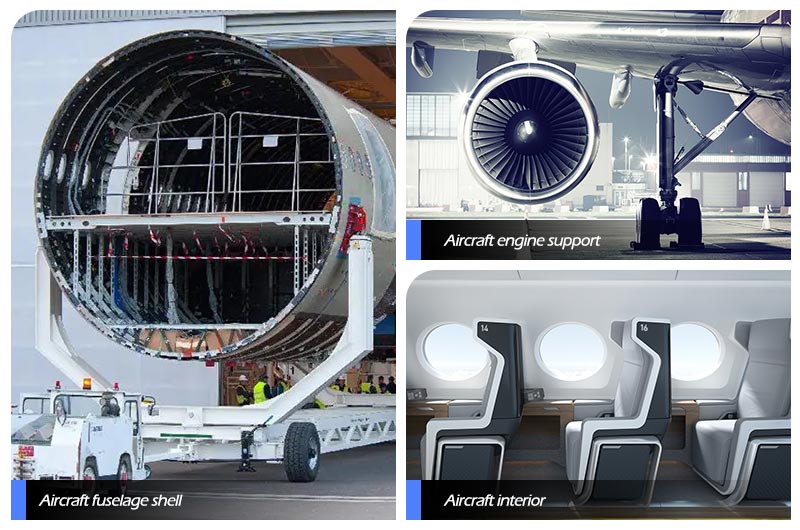

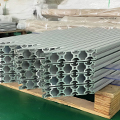

7075 aerospace grade aluminium extruded profile products

7075 T6 T651 aluminum extrusion profile

Shape: I-beams, angles, channels, and T-profiles...

Application: Structural components in fuselage, wings, and landing gear.

Contact us now

7075 T73 T7351 T73511 aluminum extrusion profile

Shape: I-beams, angles, channels, and T-profiles, etc.

Application:Critical components requiring superior corrosion resistance.

Contact us now7075 aerospace grade standard aluminum extrusion profile

7075 Extruded Tube

Shape: Round, square, rectangular, and oval profiles...

Application: Structural tubing in frames, hydraulic systems, and engines.

Contact us now

7075 Extruded Bar

Shape: Round, square, hexagonal, and flat bars...

Application:Structural components, fittings, and fasteners.

Contact us now-

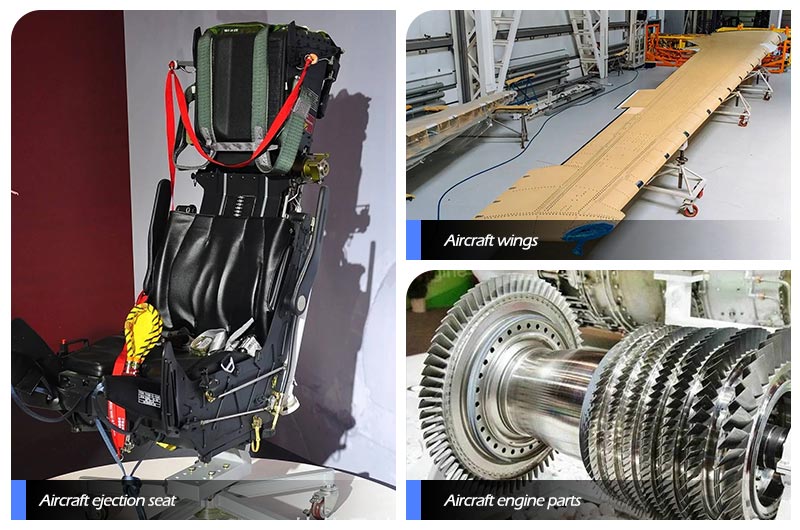

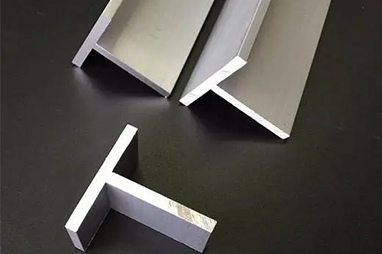

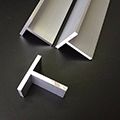

7075 Aluminium T-Section

Offers excellent bending resistance, commonly used for structural support and frameworks.

-

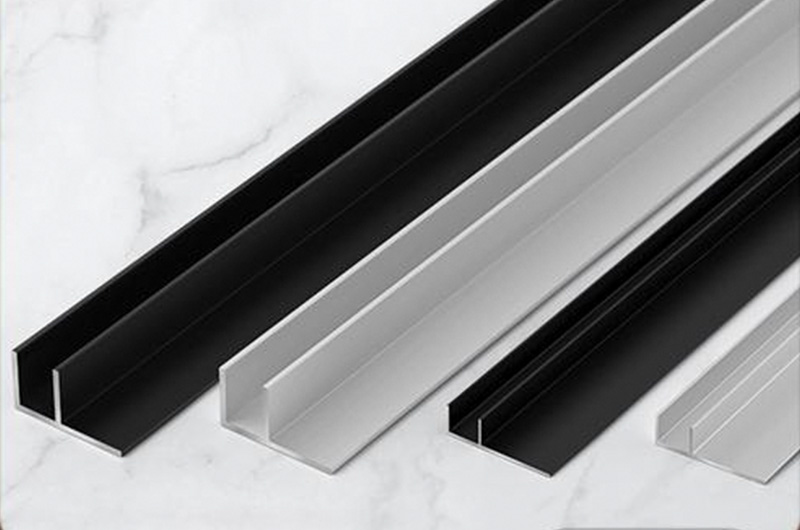

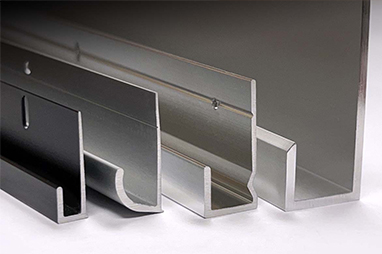

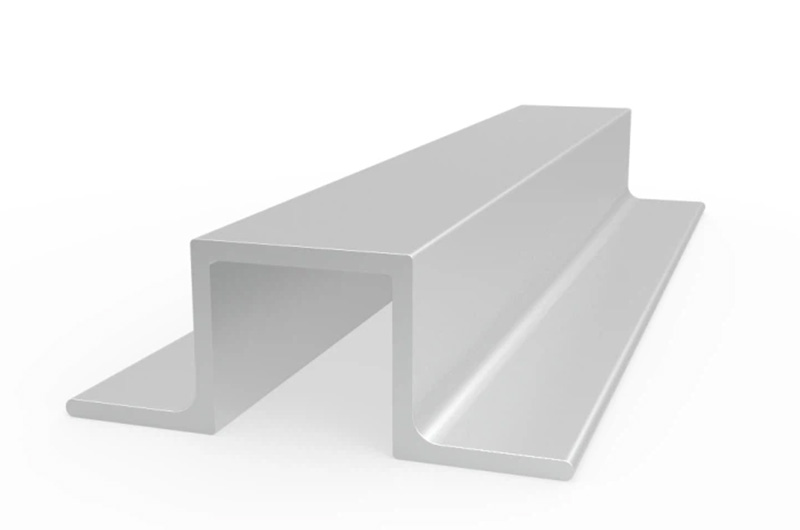

7075 Aluminum U channel

Suitable for construction and mechanical applications, providing stable support and guidance.

-

7075 Extruded Aluminum H Channel

High strength, often used in aerospace and heavy-load structures.

-

7075 Aluminium Z Section

Ideal for lightweight designs that require space and weight savings.

-

7075 Aluminium Angle

Widely used in construction and framework, providing reliable angle connections.

-

7075 Aluminum F Channel

Used for assembly and structural support, suitable for various industrial applications.

-

7075 Aluminum J Channel

Commonly used in panel and decorative applications, providing clean edge finishing.

-

7075 Aluminum Hat Channel

Suitable for lightweight structures, offering strength and stability, frequently found in construction and marine applications.

Customized/Special 7075 aluminum profiles

7075 armor piercing fin profile

7075 aluminum profiles are widely used in the military industry, such as in aircraft, vessels, missiles, armored vehicles, and mechanical components. They significantly enhance weight reduction and battlefield adaptability.

Chemical composition of 7075 aircraft grade aluminum extrusion

| Element | Composition (%) |

| Si | 0.40 |

| Fe | 0.50 |

| Cu | 1.2-2.0 |

| Mn | 0.30 |

| Mg | 2.1-2.9 |

| Cr | 0.18-0.28 |

| Zn | 5.1-6.1 |

| Ti | 0.20 |

| Other | 0.20 |

| Al | Remainder |

Mechanical properties of 7075 aircraft grade aluminum extrusion

| Aluminium Alloy/Temper | Tensile strength Rm/Mpa | Yield strength Rp0.2/Mpa | Elongation /% A | HBW |

|

7075-T6 7075-T6510 7075-T6511 |

530-540 | 460-470 | 6 | 150 |

|

7075-T73 7075-T7310 7075-T73511 |

485 | 420 | 7 | 135 |

|

7075-T76 7075-T76510 7075-T76511 |

510-515 | 440-450 | – | – |

Characteristics of 7075 aircraft grade aluminum profiles

- High tensile strength and yield strength, which can usually reach more than 550 MPa.

- Good corrosion resistance and good resistance to most corrosive media.

- Good heat treatment performance, and higher strength and hardness can be obtained through heat treatment.

- Lower density, so it has a lighter weight and is suitable for aerospace and other fields.

- Good fatigue resistance under cyclic loads and can withstand long-term dynamic loads.

- Good stability and corrosion resistance in high temperature environments, and are suitable for applications under high temperature working conditions.

- After proper heat treatment, 7075 aviation aluminum profiles can obtain higher hardness.

Other hot selling aerospace aluminum extrusion profile products in Chalco

2014 aerospace profile

2219 aerospace profile

6061 aerospace profile

6063 aerospace profile

7050 aerospace profile

2024 aerospace profile

Which one is more suitable for extrusion——6061, 7075 or 2024?

6061 Aluminum Alloy

- Advantages: 6061 is a widely used aluminum alloy known for its good formability, weldability, and corrosion resistance. It performs excellently in extrusion processes and is suitable for various industrial applications, including aerospace and transportation.

- Suitability: 6061 is highly suitable for extrusion, capable of forming complex shapes, and is commonly used for constructing structural components.

7075 Aluminum Alloy

- Advantages: 7075 is a high-strength aluminum alloy primarily used in aerospace and military applications. While it has superior strength, it has lower weldability and corrosion resistance, and it presents greater difficulty in extrusion.

- Suitability: Although 7075 can be extruded, it is often used only in applications that require high strength, such as in aerospace and military fields, due to its machining characteristics.

2024 Aluminum Alloy

- Advantages: 2024 is also used in aerospace applications and offers extremely high strength. Similar to 7075, it has limited corrosion resistance and weldability.

- Suitability: While 2024 can be extruded, its formability is not as good as that of 6061, making it less suitable for applications requiring complex shapes.

FAQ for purchasing 7075 aluminum aircraft extrusion

Q: What capabilities should the manufacture have for aerospace material production?

A: Chalco Aluminum possesses advanced aerospace materials R&D, testing, and analysis instruments, ensuring efficient new product development and swift technological advancements. Our R&D, innovation, and verification capabilities save time and cost in new product development.

Q: How is the material quality ensured for 7075 aluminum alloy?

A: Chalco Aluminum strictly adheres to standards such as A97075, AMS 4154, and AMS 4166 to produce 7075 aluminum alloy profiles. This guarantees the material quality and adherence to relevant standards.

Q: How is the heat treatment temper controlled for 7075 aviation aluminum profiles?

A: Our profiles are produced in strict accordance with aviation standards to ensure the heat treatment status, including aging and temperature, meets usage requirements.

Q: Why choose Chalco Aluminum as the aerospace grade aluminum supplier?

A: Chalco Aluminum is a reputable supplier known for its quality and reliability. Choosing us ensures confidence in your purchase, along with excellent after-sales service and quality assurance.

Q: where can buy 7075 aviation aluminum profiles at the lowest price?

A: Chalco offers competitive pricing, making us a preferred choice for aviation parts manufacturers.

Q: How do you handle delivery time and service?

A: Chalco provides timely delivery and high-quality after-sales service, ensuring your supply needs are met efficiently.

Q: How are packaging and transportation managed for 7075 aviation aluminum profiles?

A: Chalco offers suitable packaging and transportation solutions to safeguard profiles during transit, preventing damage.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote