Automotive - Accelerating Efficiency

Aluminum is the fastest, safest, greenest and most valuable way to reduce weight, improve vehicle performance, increase fuel efficiency, extend battery range and reduce emissions. Aluminum makes cars better - and more so!

As the industry prepares for a wave of electric powertrains and EV platforms, aluminum is the first choice for many automakers because of its ability to reduce vehicle weight - extending vehicle range and offsetting the impact of heavy components such as EV batteries.

Specifications of aluminum for automobiles

Alloy: 1100, 2024, 3003, 3004, 3105, 4032, 5005, 5052, 5083, 5182, 5251, 5754, 6016, 6061, 6181, 7003, 7046

Popular product types: Aluminum plates, sheets, bars, tubes, special section profiles, forgings, castings.

Classic applications of aluminum in automobiles: automobile bodies, electronics, automobile interiors, powertrains and chassis, and automobile parts

Certifications and automotive standards: AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949 (British Standards Institution)

How to choose the most suitable aluminum alloy grade in automobiles

1100 automotive aluminum

1xxx series aluminum is the purest aluminum currently available. 1100 aluminum sheet is 99% pure and extremely ductile. It also has excellent corrosion resistance and is primarily used for thermal insulation.Quick Quote

2024 automotive aluminum

2xxx series aluminum is alloyed with copper. 2024 is commonly used to make pistons, brake parts, rotors, cylinders, wheels, and gears because of its high strength and excellent fatigue resistance.

3003, 3004, 3105 automotive aluminum

- 3003 has high strength, good formability, machinability, and elongation. It is commonly used in automotive ducts, panels, and power castings for hybrid and electric vehicles.

- 3004 has many of the properties of 3003 and can also be used for hood grille panels and radiators.

- 3105 has excellent corrosion resistance, formability, and welding characteristics. It is used in automotive body panels for fenders, doors, and floor paneling.

4032 automotive aluminum

4032 will be used for pistons, compressor scrolls and engine parts because of its excellent weldability and wear resistance.

5005, 5052, 5083, 5182, 5251 automotive aluminum

The 5xxx series is one of the most popular series of aluminum alloys for car bodies. Its main alloying element is magnesium, which is known for increasing strength.

- 5052 is found in automotive parts such as fuel tanks, truck trailers, suspension panels, display panels, brackets, disc brakes and drum brakes.

- 5083 is ideal for making complex automotive parts such as engine mounts and body panels.

- 5182 is a structural pillar of the vehicle body. From structural brackets to doors, hoods and front wing end panels.

- 5251 can be seen in automotive paneling.

6016, 6022, 6061, 6082, 6181 automotive aluminum

The 6xxx aluminum series has the best extrusion and casting capabilities and offers the best surface finishes.

- 6016 and 6022 are used in automotive body coverings, doors, trunks, roofs, fenders and outer panels where dent resistance is critical.

- 6061 ahas excellent surface treatment characteristics, corrosion resistance and high strength. It is used to make beams, brakes, wheel drive shafts, truck and bus bodies.

- 6082 has the best impact resistance. Therefore, it can be used in load-bearing frames.

- 6181 is used as exterior body paneling.

7003, 7046 automotive aluminum

7xxx The strongest alloy grade.Quick Quote

- 7003 is an extrusion alloy used primarily for welded shapes of crash beams, seat sliders, bumper reinforcements, motorcycle frames and rims.

- 7046 has hollow extrusion properties and good welding characteristics. Its applications are similar to 7003.

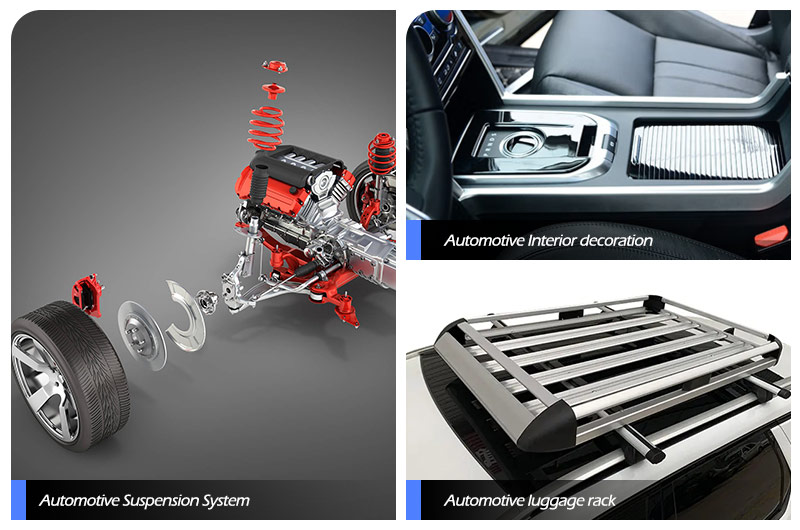

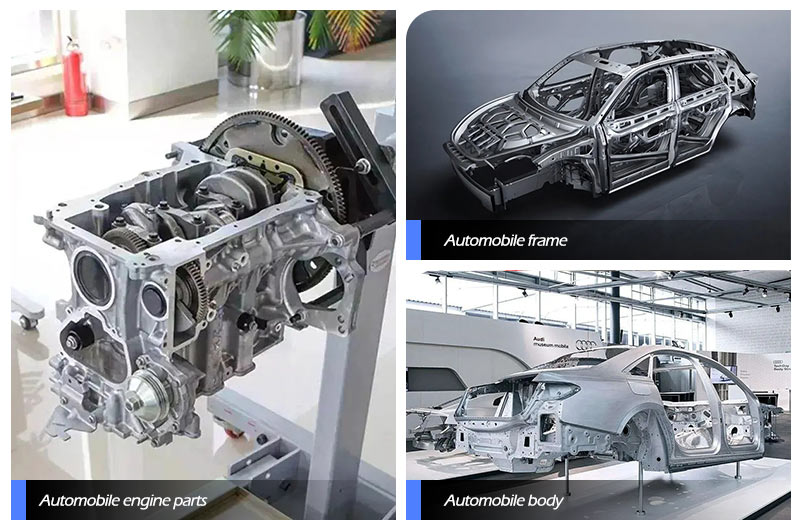

Where is aluminum used in cars?

Alloys offer a variety of benefits including strength, corrosion resistance, impact resistance, formability, weldability and electrical conductivity to meet the safety and performance needs of the industry.

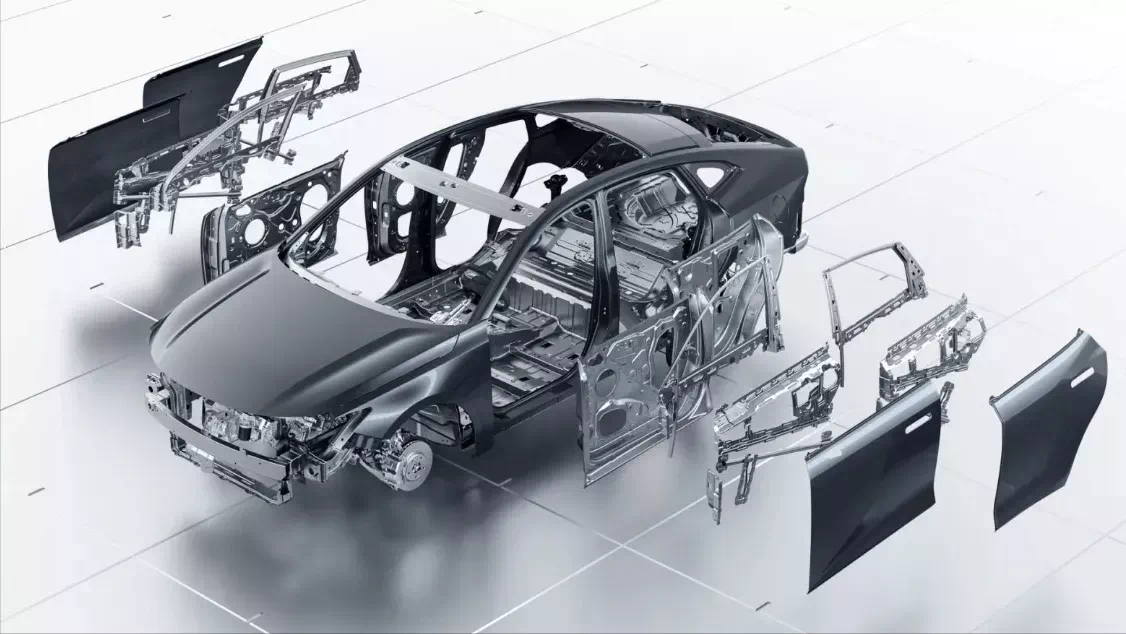

Automotive Body

Aluminum alloys used in automotive bodies require excellent corrosion resistance, surface finish, and machinability. Common alloys include 3105, 5005, 5083, 5182, 6016, and 6181.

- Body parts: hoods, quarter panels, fenders, bumpers, spoilers, roof racks, grilles, hoods, decklids, headers, pillars, rims and hubcaps, trunks, valances.

- Doors: central locks, hinges, latches, handles.

- Windows: motors, sunroofs, sunroof rails.

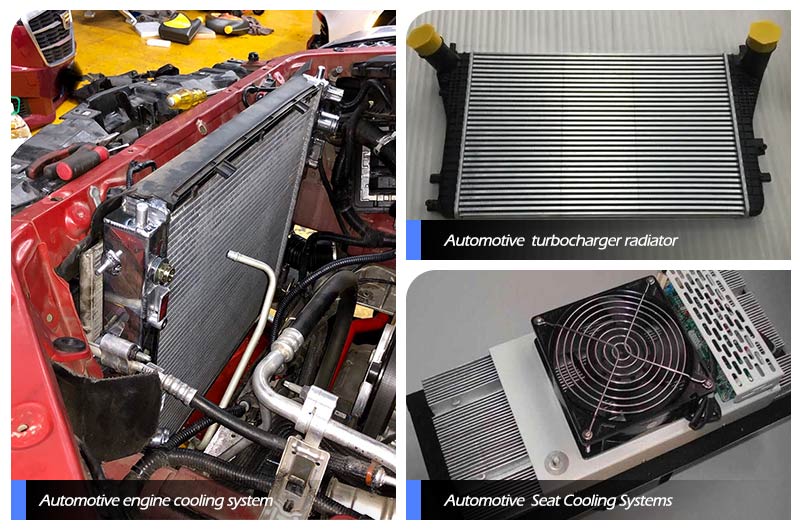

Automotive Electronics

Although aluminum has a lower electrical conductivity than copper, its low weight makes it ideal for automotive electronics.

1350 alloy is commonly used in audio and video equipment, backup cameras and displays, power systems, instruments and gauges, ignition systems, lighting and signals, sensors, switches, and wires in wiring harnesses.

Automotive interiors

Aluminum alloys such as 1100, 3105, and 5052 are used in automotive interiors for floor components and parts, automotive seats, insulation materials, air conditioning, bearings, and hoses, offering a lightweight, durable, and efficient solution that meets customer demands for performance and comfort.

Powertrain and chassis

These complex components require high strength, fatigue resistance and weldability. Common alloys are 2024, 4032, 5052, 5005, 5083, 6016, 6082 and 6111.

These complex components require high strength, fatigue resistance, and weldability, with common alloys including 2024, 4032, 5052, 5005, 5083, 6016, 6082, and 6111, making them ideal for braking systems, electric powertrain components, engine components, engine cooling systems.

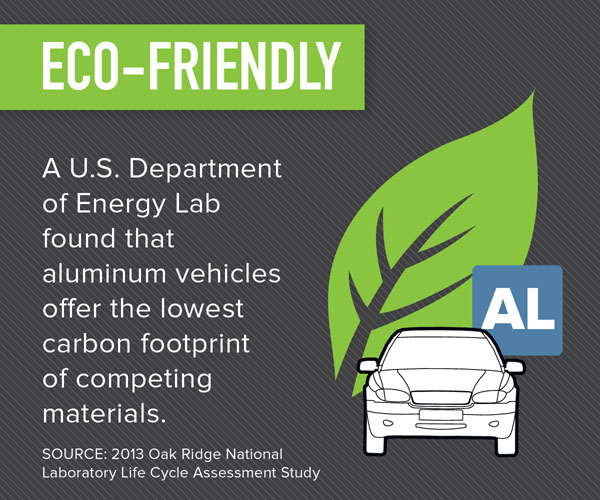

Aluminium in cars has the lowest overall carbon footprint

More than 95% of automotive aluminum scrap (more than 1.5 million tons per year) is recycled for reuse. To put it in perspective: recycling one ton of aluminum saves the energy equivalent of 21 barrels of oil.Quick Quote

Research from the U.S. Department of Energy’s Oak Ridge National Laboratory found that aluminum-intensive vehicles can reduce lifecycle energy consumption by up to 20% and reduce CO2 emissions by up to 17%.

The most complete range of aluminum automotive plate

-

1050/1050A auto aluminum plate Temper: O

Applications: automotive body and interior panels, fuel tank, etc.

High strength Easy processing -

1070 auto aluminum plate Temper: O

Applications: body structure, heat shield, evaporator, heat exchanger, etc.

Formability Weldability Light weight -

1100 auto aluminum plate Temper: O

Applications: heat insulation of automobile engine and exhaust, etc.

Corrosion resistance High thermal conductivity -

2024 auto aluminum plate Temper: O, T4

Applications: car body structure, chassis, transmission system, etc.

Excellent mechanical property Good weldability -

3A21 auto aluminum plate Temper: H14, H24

Applications: car body parts such as doors and roofs.

Good formability Good corrosion resistance -

5049 auto aluminum plate Temper: O, H111

Applications: automobile body, hood, wheels, suspension system, fuel tank.

Good strength Plasticity -

5052 auto aluminum plate Temper: O, H32, H26, H34

Applications: automotive body plate, structural parts, etc.

Excellent formability Welding performance -

5754 auto aluminum plate Temper: O

Applications: automotive doors, roof, hood, etc.

Good stamping effect Good paint hardening -

5182 auto aluminum plate Temper: O

Applications: body panel, fuel tank, condenser, sound insulation panel, etc.

High strength Corrosion resistance -

5083 auto aluminum plate Temper: O, H111, H32

Applications: body structural parts, bumper, wheel hubs, fenders, etc.

Good weldability Excellent heat resistance -

6A16 auto aluminum plate Temper: T4Pa, T6Bb

Applications: body panels, doors, car roof, etc.

Easy processing Good surface treatment -

6111 auto aluminum plate Temper: T4, T6

Applications: automotive body panels, doors, hoods, trunk lids, etc.

Good formability Good strength -

6013 auto aluminum plate Temper: T4, T6

Applications: automotive frame, hood, door panel, etc.

High strength Good corrosion resistance -

6014 auto aluminum plate Temper: T4Pa, T6Bb

Applications: auto body sheet inners, outers and structures, etc.

High strength Lght weight Weldability -

6016 auto aluminum plate Temper: T4Pa, T6Bb

Applications: automobile bodies, doors, roof, hood, luggage rack, etc.

Good mechanical property Good surface quality -

6022 auto aluminum plate Temper: T4Pa, T6Bb

Applications: automotive body panel and hydraulic box body, etc.

Anticorrosive Weldability Formability -

6061 auto aluminum plate Temper: O, T4

Applications: structural body parts, door panels, engine, etc.

Thermal conductivity Thermostability -

6063 auto aluminum plate Temper: O, T4

Applications: door frames, front and rear bumpers, roof racks and trunks, etc.

High strength and stiffness Light weight -

6181 auto aluminum plate Temper: T4Pa, T6Bb

Applications: commonly used in automobile body panels.

Plasticity Weldability -

6082 auto aluminum plate Temper: O, T4

Applications: structural parts for material strength, stiffness, conductivity, etc.

Good mechanical property Wear resistance

The most complete range of aluminum automotive profiles

Surface treatment supplied: anodizing; anodizing+electrophoretic painting; powder spraying; Liquid spraying.

Shapes supplied: tube profile, flat bar profile, round bar profile, rectangle profile, hexagonal profile, T profile, L profile, I profile, U profile, etc.

Other special shaped profiles can be extruded and machined by setting up molds according to customer drawings.

-

1100 auto aluminum profile

Height: 0.8mm-8.0mm

Wall thickness: above 0.12mm

Hole No.: 2-35

GB∕T 33230-2016

-

1200 auto aluminum profile

Out diameter: 4.0mm-19mm

Wall thickness: 0.45-3mm

Length: coil type

GB/T 20250-2006

-

2008 auto aluminum profile

Open profile:

Min. 4×3, Max. 850×50.Closed profiles:

Min. 6.35×1, Max. 573×10.ASTM B221-14a 2008-T6 Extrusion

-

2010 auto aluminum profile

Diameter: 10-250mm

Thickness: 0.5-50mm

special-shaped profiles: customable

GB/T 33910, ASTM B221, EN755

-

2036 auto aluminum profile

Thickness: 2mm-10mm

Length and width: according to the specific vehicle and application

GB/T 33910, ASTM B221, EN755

-

2017 auto aluminum profile

Weight per meter:

0.03kg/m-124kg/mProfile length: maximum 28m (standard 6000mm)

GB/T 33227-2016, JIS H4000, EN 485

-

2117 auto aluminum profile

Open profile:

Min. 4×3, Max. 850×50Closed profiles:

Min. 6.35×1, Max. 573×10.GB/T 33227-2016, JIS H4000, EN 485

-

2024 auto aluminum profile

Diameter: 10-250mm

Thickness: 0.5-50mm

Special shaped profiles are of different sizes

GB/T 33910, ASTM B221, EN755

-

3002 auto aluminum profile

Length: 20-100mm

With: 10-80mm

Height: 0.5-10mm

GB/T 33910

-

3003 auto aluminum profile

Coil inner diameter:

400-550mmCoil outer diameter:

700-1500mmGB/T 33230-2016

-

3005 auto aluminum profile

Thickness: 0.5-6mm

Length & width:

according to the specific vehicle and applicationGB/T 33910

-

4B01 auto aluminum profile

Size: 20*20 to 150*150

Wall thickness: 1.5mm-6mm

High strength, high temperature stability, formability.

-

4B91 auto aluminum profile

T profile:

20×20×2, 25×25×2, 30×30×2U profile:

20×10×2, 25×12×2, 30×15×2Good processability, good corrosion resistance.

-

5005 auto aluminum profile

Section area: 0.2-90cm²

Outline size: 10-530mm

Profile length: maximum 28m (standard 6000mm)

High strength and excellent toughness.

-

5252 auto aluminum profile

Round pipe: 1-10 inch

Square pipe: 1-8 inch

Rectangular tube:

1*2 to 8*12 inchDoors, roofs, luggage racks.

-

5454 auto aluminum profile

Open profile:

Min. 4×3, Max. 850×50Closed profiles:

Min. 6.35×1, Max. 573×10GBT 33910-2017

-

5457 auto aluminum profile

Profile length: Maximum 28m (standard 6000mm)

Weight per meter:

Min. 0.03kg/m, Max. 124kg/mGBT 33910-2017

-

5657 auto aluminum profile

Thickness: 2mm-10mm

Length: Generally, it can be about 6m long.

GB/T 33910, ASTM B221, EN755

-

6005/6005A auto aluminum profile

Wall thickness: 1-3mm

Length: about 6m long.

Round pipe: Φ15mm, Φ20mm, Φ30mm, Φ40mm…

GB/T 33910, ASTM B221, EN755

-

6061 auto aluminum profile

Open profile:

Min. 4×3, Max. 850×50.Closed profiles:

Min. 6.35×1, Max. 573×10.GB/T 33227-2016, JIS H4000, ASTM B209, EN 485

-

6463 auto aluminum profile

Section area: 0.2-90cm²

Wall thickness: 1-100mm

Outline size: 10-530mm

Workability, high strength, corrosion resistance.

-

6106 auto aluminum profile

Weight per meter:

Min. 0.03kg/m, Max. 124kg/mSection area: 0.2-90cm²

High strength, plasticity, ductility, easy welding.

-

6009 auto aluminum profile

Square: 10×10-150×150

Round: Φ10-Φ150

Rectangle: 10*20 to 150*200

Good machinability, good aesthetics.

-

6010 auto aluminum profile

Tube Hex: 10-100

U-shaped: 10*10 to 100*100

T-shaped: 10*10 to 100*100

Lightweight and high strength, high reliability.

-

6011 auto aluminum profile

Square tube: 10*10-150*150mm

Round tube: 10-250mm

Rectangular tube:

10*20 to 200*300mmGood plasticity, good fatigue resistance.

-

6016 auto aluminum profile

Rectangular tube:

10*20 to 200*300T-profile: T10, T20, T30, T40

U-profile: U10, U20, U30, U40

Corrosion resistance, good weldability.

-

6151 auto aluminum profile

Open Profile:

Min. 4×3, Max. 850×50.Closed profiles:

Min. 6.35×1, Max. 573×10.Door frames, chassis, control arms.

-

6053 auto aluminum profile

Weight per meter:

Min. 0.03kg/m, Max. 124kg/m.Profile length: Maximum 28m (standard 6000mm)

Door frames, roofs, suspension systems.

-

6A61 auto aluminum profile

Diameter: 10-250mm

Thickness: 0.5-50mm

Length and width: according to vehicle and application

GB/T 33910, ASTM B221, EN755

-

6S02 auto aluminum profile

Length: 20-100mm

Width: 10-80mm

Height: 0.5-10mm

GB/T 33910, ASTM B221, EN755

-

6060 auto aluminum profile

Thickness: 1.0-3.0

Width: 10-200mm

Chassis components, interior decoration, radiator...

-

6063 auto aluminum profile

Thickness: 0.5-5.0mm

Width:

between 10 and 200mmLength: 2020/3030/4040mm...

Automotive interiors, exterior body structures and chassis.

-

6008 auto aluminum profile

Section area: 0.2-90cm²

Wall thickness: 1-100mm

Outline size: 10-530mm

Good solderability, wide adaptability.

-

6014 auto aluminum profile

Open Profile:

Min. 4×3, Max. 850×50Closed profiles:

Min. 6.35×1, Max. 573×10.Excellent formability, good strength-toughness ratio.

-

6082 auto aluminum profile

circular profiles diameter:

10-250mmLength and width: according to vehicle and application

Good thermal conductivity, good electrical conductivity.

-

6A01 auto aluminum profile

Length: 20-100mm

Width: 10-80mm

Height: 0.5-10mm

GB/T 33910, ASTM B221, EN755

-

7003 auto aluminum profile

Square tube:10×10-150×150

Round tube: Φ10-Φ150

Solid round bar: Φ6-Φ80

Body and frame, chassis.

-

7005 auto aluminum profile

U-channel: width 10-300mm, height 5-50mm

H-beam: width 10-300mm, height 5-50mm

Good corrosion resistance, easy to process and form.

-

7129 auto aluminum profile

Round tube: 6-300mm

Rectangular tube:

10*20 to 200*400mmT-profile: 20*20 to 300*300mm

Chassis and suspension system, electrical system.

-

7A46 auto aluminum profile

Square tube: 10*10 to 200*200mm

Round tube: 10-300mm

U-profile: 10*20 to 200*400mm

Excellent strength and hardness, good heat resistance.

-

7021 auto aluminum profile

Thickness:

between 0.5mm and 20mmWidth:

between 20mm and 300mmGB/T 33910, ASTM B221, EN755

-

7B05 auto aluminum profile

Thickness: 0.5mm-10mm

Width and length:

depending on vehicle and applicationBody structural parts, chassis structural parts.

The most comprehensive range of aluminum automotive forgings

-

6082-T6 auto aluminum forging

Chalco supplies forged aluminum 6082 T6, used for control arms, wheel hubs, brakes, and suspension wall parts of auto.

GB/T38958-2020 GB/T33823-2017 GB∕T 26036-2020 -

6061-T6 auto aluminum forging

6061-T6 aluminum forgings are suitable for many automotive applications such as engine parts, body structural parts, chassis parts, wheels and steering systems.

High strength Light weight Corrosion resistance -

6A10-T6 auto aluminum forging

Chalco produces 6A10 T6 forged auto parts that are widely used in passenger vehicle control arms and other components.

GBn 223-84 GJB2351-95 GB/T 26036-2010

The most complete range of aluminum automotive brazing materials

-

Auto brazed composite aluminum sheet, brazed deep-drawn sheet

Brazed composite aluminum sheet is made by bonding two or more layers of different aluminum alloys using a special brazing process.

Body shells Radiator Condenser -

Auto brazing composite aluminum coil

Automotive brazing composite aluminum coil usually consists of alternating layers of aluminum and other metals to provide excellent mechanical properties and corrosion resistance.

Radiators Condensers Evaporators Heat exchangers -

Auto brazing clad foil

3003 4343 4045 7072 H14/H16 brazing composite aluminum foil for automobiles. It is able to withstand the high temperatures and pressures of automotive engines and other heat sources while providing a reliable connection.

Radiator and cooling system Air-conditioning system -

Auto brazing welding non-clad aluminum strip

Chalco specializes in the production of non-clad welding strips for brazing sheets for automobiles 4104 4004 4047 6951 4045, with excellent welding performance, improved production efficiency and good corrosion resistance.

Body and chassis Exhaust system Heat dissipation system -

Clad aluminium HF welded tubes for heat exchangers of vehicles

Cladding layer: 4045, 4343, 7072; core material: 3003, 3305; including condenser header tube, D-Type condenser header aluminium tube, square rectangular condenser header tube etc.

Automotive refrigerators New energy vehicles Heat exchanger cores

The most complete range of aluminum automotive microchannel

-

Automotive aluminum micro-channel-tube

Chalco produces 1050 1100 3003 3102 H12 micro-channel aluminum flat tubes with the characteristics of efficient heat transfer, light weight, high strength, good plasticity, etc.

Automotive engine cooling systems Air conditioning systems Battery radiators