Embossed aluminum heat shields are essential components in modern automotive thermal management systems. Manufactured from high-quality alloys such as 1050, 1060, 1100, 3003, and 5052, these sheets provide excellent thermal insulation, corrosion resistance, and mechanical strength. The embossed surface increases rigidity and heat reflection efficiency, making them ideal for protecting engine bays, underbody panels, and exhaust systems from excessive heat exposure. Their lightweight nature also contributes to overall vehicle efficiency, meeting the demanding standards of today's automotive industry.

Why choose Chalco's aluminium embossed heat shield sheet?

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Chalco Aluminum supplies Tesla, Ford, Shanghai Automobile, NIO Automobile, BAIC New Energy, and Changan Automobile. We've secured material certification and completed parts for BAIC New Energy and Weilai Automobile, among others.

Specs of aluminium embossed heat shield sheet

Alloy: 1050/1050A; 1100; 1060; 1070; 3003; 5052;

Temper: O, H14, H24, H26, H32;

ABS sheet dimension: Thickness 0.3mm-3.5mm, Width 52mm-2400mm; Length 500mm-10000mm

ABS coil dimension: Thickness 0.3mm-3.5mm; Width 52mm-2400mm

Specification: GB/T 33227-2016, JIS H4000, ASTM B209, EN 485

Explore alloy options for high-performance embossed aluminum heat shields

-

1050/1060 Embossed Aluminum Heat Shield Plates

-

1100/1070 Embossed Aluminum Heat Shield Sheets

-

3003 Embossed Aluminum Heat Shield Coil

-

5052 Embossed Aluminum Heat Shield Sheets

Choose the right alloy for your aluminium embossed heat shield needs—Chalco offers 1050, 1060, 1100, 3003, and 5052 grades, each tailored for optimal thermal performance, corrosion resistance, and forming efficiency. Find the ideal match for your automotive heat protection requirements. Contact us for expert support and quick quotes.Quick Quote

Different embossing patterns for aluminum heat shields — choose what fits your needs

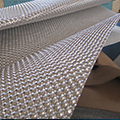

Hemisphere embossed aluminum heat shield coil

This pattern is widely used in automotive heat shields for its superior thermal reflection and enhanced rigidity. The hemispherical embossing improves heat insulation efficiency while maintaining lightweight strength.

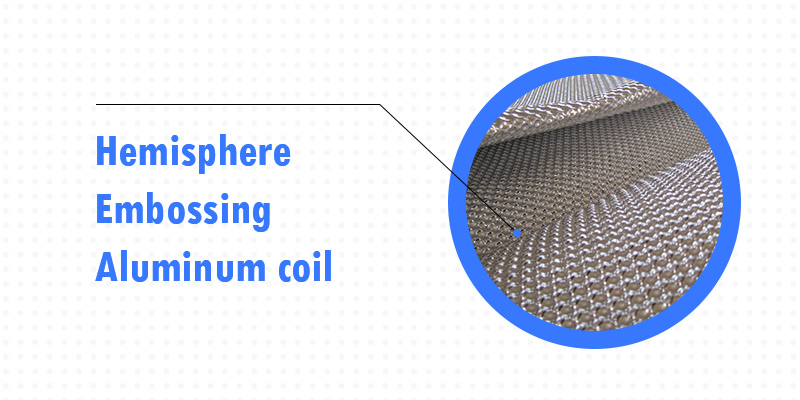

Stucco embossed aluminum heat shield coil

Stucco embossing increases surface area for better radiant heat reflection and provides excellent durability. Commonly applied in engine compartments and underbody heat shields for effective thermal management.

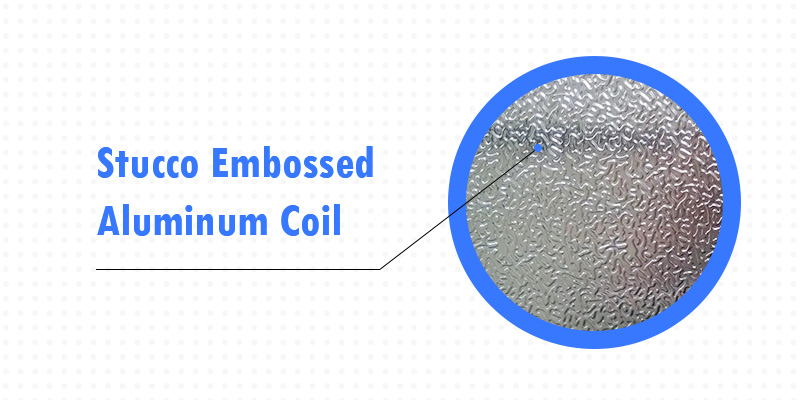

Rhombus embossed aluminum heat shield coil

Rhombus embossing offers improved structural strength and heat dispersion, making it ideal for automotive applications requiring enhanced heat shielding and mechanical stability.

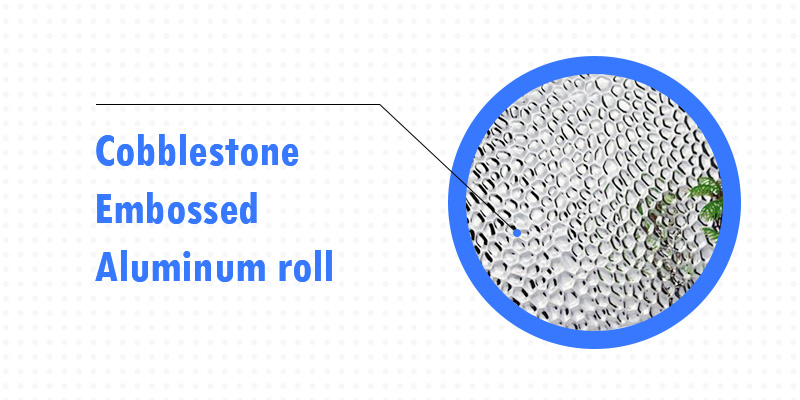

Cobblestone embossed aluminum roll

Cobblestone embossing enhances thermal insulation by creating multiple reflective surfaces, suitable for specialized heat shield panels with aesthetic and functional needs.

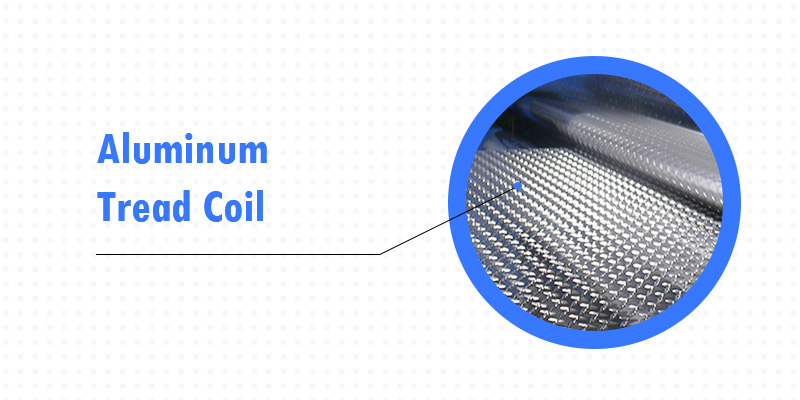

Aluminum Tread Coil

Used mainly for anti-slip plates, tread coils typically need thicker material for durability. Chalco’s advanced technology produces thinner embossed sheets that retain strong anti-slip and heat insulation properties.

Explore our range of embossing patterns tailored for different thermal and structural requirements. Whether you need enhanced heat reflection, rigidity, or formability, Chalco offers the right embossed aluminum heat shield solution. Contact us to find the pattern that fits your application best.Quick Quote

Product property and features of Chalco embossed aluminum heat shield

| Thickness mm | 0.50-1.50 | 1.50-3.00 |

| Tension Strength Rm N/mm2 | 75-105 | 75-105 |

| Yield Strength R p0.2 N/mm2 | ≥25 | ≥25 |

| Elongation A 50 min % | ≥21 | ≥24 |

| Hardness HBW | 23 | 23 |

- High Heat Resistance: Chalco's embossed aluminum heat shield can withstand radiant heat up to 1090°C (2000°F) and direct contact heat up to 590°C (1100°F), ensuring reliable protection in extreme conditions.

- High insulation performance: The embossed aluminum heat shield's textured surface increases the area for reflecting up to 90% of radiant heat, significantly enhancing thermal insulation efficiency.

- Corrosion Resistance: Made from 1000 series pure aluminum, this embossed aluminum heat shield offers excellent corrosion resistance, ideal for long-term use in harsh environments.

- Easy to Process and Install: The embossed aluminum heat shield features outstanding workability and formability, making it easy to cut, bend, and shape for various complex applications.

- Eco-friendly: Fully recyclable embossed aluminum heat shield meets sustainability standards, supporting green manufacturing and environmental responsibility.

Discover how Chalco's embossed aluminum heat shields stand out with superior heat resistance, corrosion protection, and processability. Backed by reliable performance in demanding environments, our solutions are engineered to meet your toughest specifications. Reach out now to get expert recommendations or a fast quote.Quick Quote

Parameters reference table of Chalco aluminium embossed heat shield sheet-reference value for 1050 aluminum alloy

| Chemical composition of aluminium embossed heat shield sheet | |

| Element | Composition (%) |

| Aluminum, Al | ≥99.5 |

| Silicon, Si | ≤0.25 |

| Zinc, Zn | ≤0.070 |

| Magnesium, Mg | ≤0.050 |

| Copper, Cu | ≤0.050 |

| Titanium, Ti | ≤0.050 |

| Manganese, Mn | ≤0.050 |

| Iron, Fe | ≤0.40 |

| Other (each) | ≤0.030 |

| Physical properties of aluminium embossed heat shield sheet | ||

| Properties | Metric | Imperial |

| Density | 2.705 g/cm3 | 0.09772 lb/in3 |

| Melting point | 640°C | 1184°F |

| Mechanical behavior of aluminium embossed heat shield sheet | |

| Properties | Metric |

| Tensile strength (@diameter 12.7 mm/0.500 in) | 75 MPa |

| Elongation at break | 32% |

| Elastic modulus | 73 GPa |

| Shear strength | 50 MPa |

| Hardness, Brinell | 20 |

| Hardness, Vickers | 22 |

| Thermal properties of aluminium embossed heat shield sheett | ||

| Properties | Metric | Imperial |

| Thermal conductivity | 121-193 W/mK | 838-1338 BTU in/hr.ft2.°F |

Need help selecting the right specifications? Our engineering team is here to provide technical guidance and recommend the optimal embossed aluminum heat shield solution for your application. Contact our experts today.Quick Quote

Chalco OEM services for automotive heat shields

Chalco offers comprehensive OEM solutions to customize embossed aluminum heat shields tailored precisely to your specifications. Whether you require unique sizes, shapes, or special design features, our advanced manufacturing capabilities ensure high-quality, reliable products that perfectly fit your automotive applications. Partner with us for expert support, flexible production, and timely delivery to keep your projects on track.

Looking for tailored heat shield solutions? Chalco provides full OEM services to match your exact specifications—from alloy selection to shape, thickness, and embossing pattern. Contact us to start your custom project with our expert team.Quick Quote

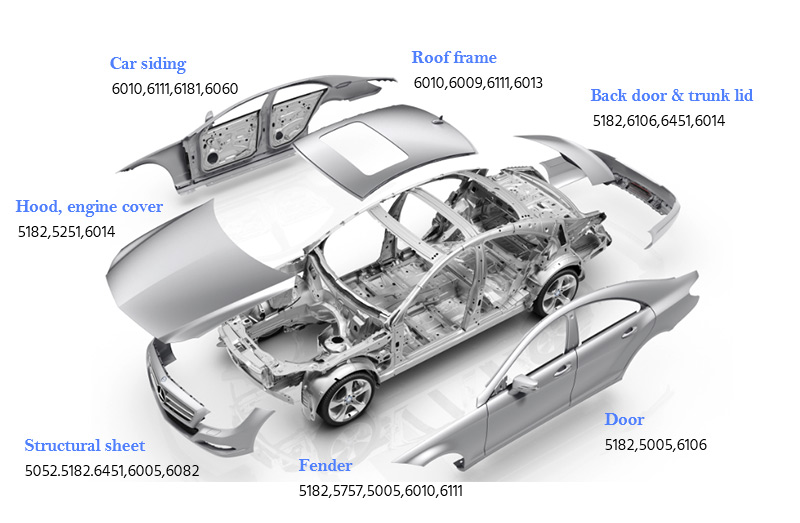

Uses of aluminum embossed heat shield sheet coil in auto and other industries

- Aluminum embossed heat shield sheet coils, commonly made from alloys like 1050, 1100, or 3003, offer excellent thermal insulation and corrosion resistance. Therefore, it is suitable for the production of stamping parts of various automobile engine heat shields, heat shield parts, engine heat shields, automobile water tanks, exhaust pipe heat shield parts, etc. in the automotive industry.

- In the automotive industry, they are used in engine hoods and underbody panels to protect components from high heat. In other industries, these embossed sheets are applied in HVAC systems, industrial equipment, and building insulation, where thermal management and durability are essential.

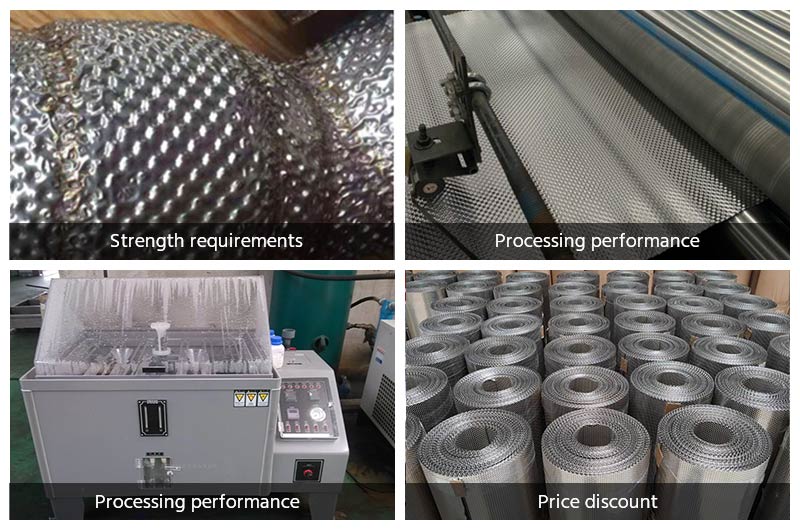

FAQ for selecting aluminum embossed heat shield sheet coil

Strength requirements: aluminium heat shield sheet have good formability and welding performance, but compared with other aluminum alloys, their strength is lower. Therefore, attention should be paid to the strength requirements of structural parts when selecting materials to ensure that the selected materials can meet the design requirements.

Corrosion resistance: automobiles often operate in harsh environments, such as wet roads, salt water, sand and dust, etc. The structural parts of the body need to have good corrosion resistance to ensure long-term service life. Aluminium heat shield sheet have good corrosion resistance, but there may still be corrosion problems in extreme environments, so protective measures need to be considered in the design.

Processing performance: aluminium heat shield sheet have excellent formability and can be processed in various ways, including stretching, compression, bending, etc., but care should be taken to avoid surface scratches and cracks during processing to ensure the processed material Performance and appearance quality.

Price and availability: 1aluminium heat shield sheet are relatively cheap and have a wide range of applications, but material supply and production cycles need to be considered to ensure timely supply and meet production needs.

To sum up, when selecting aluminium heat shield sheet, you need to pay attention to the above aspects to ensure that the selected materials meet the design requirements and can meet production needs.

Chalco other featured sheet coil products in auto industry

Lightweight, durable aluminum panels designed for automotive exterior use. They provide excellent strength and corrosion resistance, ensuring long-lasting protection and a smooth finish for vehicle bodies.

Contact us nowFeatures: Ultra-lightweight, high strength, and good thermal insulation with honeycomb core.

Applications: automotive manufacturing, high-speed trains, aerospace.

Contact us now

Anodized aluminum sheet coil

Features: Increased surface area and stiffness with raised patterns

Applications: Auto body panels, building panels, furniture, decorative sheets

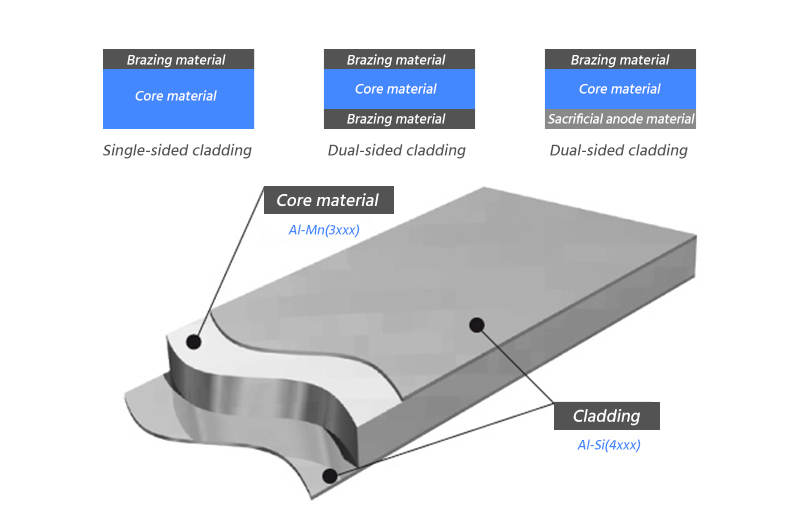

Contact us nowAluminum brazed clad sheet and strip

Aluminum brazed clad sheet and strip have excellent thermal conductivity and corrosion resistance.

They are widely used in automotive heat exchangers, radiators, and HVAC systems.

Contact us now

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote