Why choose Chalco brazed composite aluminum sheet, brazed deep-drawn sheet?

Authentication

Chalco products are manufactured in our advanced factories using strict quality and environmental management systems, and have passed ISO 9001 and ISO 14001 certifications, as well as IATF16949 certifications.

Production strength

Production equipment, production standards and capabilities, production lines for automotive panels: cleaning, passivation, stretching

Reference

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Nextev, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers, determines the material certification relationship, and has completed the certification of some models of automobile plate materials of Beiqi New energy, Nextev and other automobile factories.

Mechanical properties of brazed composite aluminum sheet, brazed deep-drawn sheet

| Room temperature tensile mechanical properties of composite materials | ||||||

| Alloy | temper | Thickness mm | Tensile strength Rm N/mm2 | Yield strength R p0.2N/ mm2 | Elongation A50mm% | |

| Brazing layer | Substrate | Not less than | ||||

|

4A13 4A17 4A43 4A45 4045 4047 4343 |

3A11 3B11 3003 3005 7A11 7072 |

O | 0.050-0.100 | 95-160 | 35 | 6.0 |

| >0.100-0.200 | 10.0 | |||||

| >0.200-1.300 | 18.0 | |||||

| >1.300-6.000 | 20.0 | |||||

| H12 | 0.050-0.100 | 120-170 | 90 | 1.0 | ||

| >0.100-0.200 | 3.0 | |||||

| >0.200-1.300 | 4.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H22 | 0.050-0.100 | 120-170 | 80 | 2.0 | ||

| >0.100-0.200 | 6.0 | |||||

| >0.200-1.300 | 6.0 | |||||

| >1.300-6.000 | 7.0 | |||||

| H14 | 0.050-0.100 | 150-200 | 125 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H24 | 0.050-0.100 | 150-200 | 115 | 1.0 | ||

| >0.100-0.200 | 3.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 5.0 | |||||

| H16 | 0.050-0.100 | 170-230 | 150 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 1.0 | |||||

| >1.300-6.000 | 2.0 | |||||

| H26 | 0.050-0.100 | 170-230 | 140 | 1.0 | ||

| >0.100-0.200 | 1.0 | |||||

| >0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 3.0 | |||||

| H18 | 0.050-0.100 | 200 | 170 | 0.5 | ||

| >0.100-0.200 | 0.5 | |||||

| >0.200-6.000 | 1.0 | |||||

|

4004 4104 |

3A11 3B11 3003 3005 7A11 7072 |

O | 0.050-0.100 | 95-165 | 35 | 6.0 |

| >0.100-0.200 | 10.0 | |||||

| >0.200-1.300 | 18.0 | |||||

| >1.300-6.000 | 20.0 | |||||

| H12 | 0.050-0.100 | 125-205 | 90 | 1.0 | ||

| >0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 6.0 | |||||

| H22 | 0.050-0.100 | 125-205 | 80 | 2.0 | ||

| 0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 7.0 | |||||

| H14 | 0.050-0.100 | 145-225 | 125 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

| 0.200-1.300 | 2.0 | |||||

| >1.300-6.000 | 4.0 | |||||

| H24 | 0.050-0.100 | 145-225 | 115 | 2.0 | ||

| >0.100-0.200 | 2.0 | |||||

| >0.200-1.300 | 3.0 | |||||

| >1.300-6.000 | 5.0 | |||||

|

4004 4045 4104 4343 |

6A02 6060 6063 6951 |

O | 0.200-6.000 | 160 | 85 | 16.0 |

| Room temperature tensile mechanical properties of composite plates for deep drawing | |||||||

| Alloy | temper | Thickness mm | Tensile strength Rm N/mm2 | Yield strength R p0.2N/ mm2 | Elongation A50mm% | ||

| Brazing layer | Substrate | Not less than | |||||

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4047, 4104, 4343 | 3B11, 3003, 3005, 7072 | O | 0.300-1.300 | 95-160 | 35 | 20.0 | |

| >1.300-6.000 | 25.0 | ||||||

| 4004, 4045, 4104, 4343 | 6A02, 6060, 6063, 6951 | O | 0.300-6.000 | ≤160 | 85 | 18.0 | |

| Cupping value of composite plates for deep drawing | ||||

| Alloy | temper | thickness mm | Cupping value mm | |

| Brazing layer | Substrate | |||

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4047, 4104, 4343 | 3B11, 3003, 3005, 7072 | O | 0.300-0.600 | ≥7.00 |

| >0.600-1.000 | ≥8.00 | |||

| >1.000-1.300 | ≥9.00 | |||

| >1.300-6.000 | ≥10.00 | |||

| 4004, 4045, 4104, 4343 | 6A02, 6060, 6063, 6951 | O | 0.300-6.000 | ≥6.00 |

The specification of brazed composite aluminum sheet, brazed deep-drawn sheet

| Composite plate grades | Temper | Size | ||

| Thickness | Width | Length | ||

| 4004/3003 |

O H12 H22 H14 H24 H16 H26 H18 |

0.21-5.00 | ≤1600 | ≤10000 |

| 4004/3005 | ||||

| 4004/3003/4004 | ||||

| 4004/3A11/4004 | ||||

| 4004/3003/7072 | ||||

| 4004/6063 | ||||

| 4004/6060 | ||||

| 4004/6A02 | ||||

| 4104/3003 | ||||

| 4104/3003/4104 | ||||

| 4104/7A11/4104 | ||||

| 4104/6063 | ||||

| 4104/6063/4104 | ||||

| 4104/6060 | ||||

| 4104/6A02 | ||||

| 4A13/3003 | ||||

| 4A13/3003/4A13 | ||||

| 4A13/3A11/4A13 | ||||

| 4A13/7A11/4A13 | ||||

| 4A17/3003/4A17 | ||||

| 4A17/3A11/4A17 | ||||

| 4A17/7A11/4A17 | ||||

| 4343/3003 | ||||

| 4343/7A11/4343 | ||||

| 4343/7A11 | ||||

| 4343/3003/7072 | ||||

| 4343/3003/4343 | ||||

| 4343/3003/1100 | ||||

| 4343/3A11/4343 | ||||

| 4343/7A11/7072 | ||||

| 4343/7A11/1100 | ||||

| 4343/6951/4343 | ||||

| 4A43/3003 | ||||

| 4A43/3003/7072 | ||||

| 4A43/3003/4A43 | ||||

| 4A43/3A11/4A43 | ||||

| 4045/3003 | ||||

| 4045/3003/7072 | ||||

| 4045/7A11 | ||||

| 4045/3003/4045 | ||||

| 4045/7A11/7072 | ||||

| 4045/3A11/4045 | ||||

| 4045/6951/4045 | ||||

| 4A45/3A11/4A45 | ||||

| 4A45/3003/4A45 | ||||

| 4047/3003 | ||||

Allowable deviation of brazed composite aluminum sheet, brazed deep-drawn sheet

| Allowable deviation of brazing layer cladding rate | |

| Wrap rate | Allowable deviation of covering rate |

| 3.0-6.0 | ±1.2 |

| >6.0-8.0 | ±1.5 |

| >8.0-13.0 | ±2.0 |

| >13.0-25.0 | ±3.0 |

| Thickness | Composite plates width allowable deviation on the following widths | ||

| ≤1000.0 | >1000.0-1320.0 | >1320.0-1600.0 | |

| >0.200-3.000 | ±2.0 | ±3.0 | 4 |

| 3.000-6.000 | ±3.0 | ±4.0 | ±5.0 |

| Thickness | Composite plates length allowable deviation on the following widths | |

| ≤3000 | >3000 | |

| >0.200-6.000 | ±4 | ±6 |

| Width | Composite plates lateral curvature | ||||

| ≤1000 | >1000-2000 | >2000-3500 | >3500-6000 | >6000-10000 | |

| ≤1 000.0 | ≤2 | ≤3 | ≤4 | ≤7 | ≤10 |

| >1 000.0-1 320.0 | - | ≤ | ≤4 | ≤7 | ≤8 |

| >1 320.0-1 600.0 | - | - | ≤3 | ≤6 | ≤8 |

| Width | Diagonal deviation of composite plates | |

| The diagonal difference in the following lengths is not greater than | ||

| ≤3700 | >3700 | |

| ≤1000.0 | 2.4*W/300 | 3.6*W/300 |

| >1000.0 | 2.0*W/300 | 2.8*W/300 |

| Note: When the width W is not an integer multiple of 300.0 mm, the deviation is determined by adding 1 to its integer multiple. For example, if the width W is 1220.0 mm and the length is 2000 mm, the diagonal difference is 2.0*(4+1) mm=10.0 mm. | ||

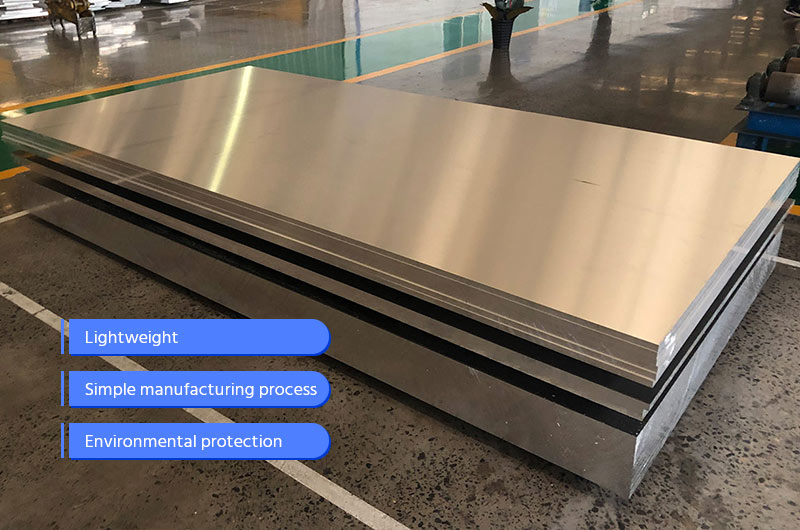

Advantages of Chalco brazed composite aluminum sheet, brazed deep-drawn sheet

Alcoa brazed composite aluminum plate and brazed deep-drawn plate are both lightweight and high-strength aluminum alloy materials made by brazing process, and they have the following advantages:

Light weight: compared with steel materials, composite aluminum plates and brazed deep-drawn plates are less dense and lighter in weight, which can greatly reduce the weight of the whole product and improve the fuel efficiency and operational efficiency of the product.

High strength: due to the brazing process used for these aluminum plates, a strong connection is formed between the aluminum alloy layers, which improves the strength and durability of the entire aluminum plate.

Excellent corrosion resistance: the aluminum alloy material has excellent corrosion resistance and can maintain stable performance in harsh environments for a long time.

Simple manufacturing process: the brazing process does not require a large amount of equipment and large machines and can be used for mass production, thus reducing production costs.

Good plasticity: aluminum has good plasticity and can be made into various shapes, which can be widely used in different products and industries.

Environmental protection: aluminum has good recyclability and will not cause pollution to the environment, which meets the requirements of environmental protection.

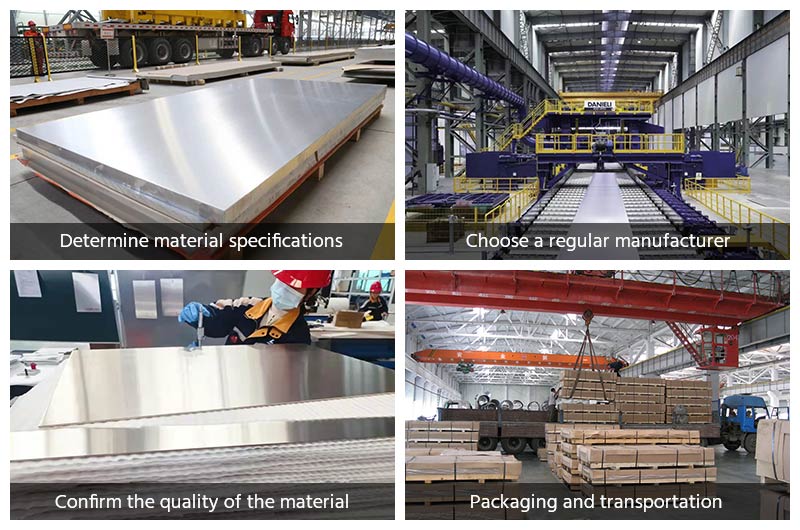

Precautions for purchasing brazed composite aluminum sheet, brazed deep-drawn sheet

Material certification

Ensure that the purchased brazed composite aluminum sheet, brazed deep-drawn sheet meets relevant standards and obtains a qualified material certification certificate.

Specification requirements

Select appropriate specifications, sizes, and shapes based on actual needs to ensure that the purchased aluminum profiles can meet specific automotive component manufacturing requirements.

Surface quality

Check whether the surface of the purchased aluminum profile is flat, free from cracks, wear, oxidation, or other surface defects, to ensure that the surface quality of the aluminum profile meets the requirements.

Supplier reputation

Choose reputable and experienced suppliers to purchase to ensure reliable quality, reasonable price, and timely delivery of 7129 automotive aluminum profiles.

Storage requirements

Pay attention to the storage requirements of aluminum profiles, keep them dry, avoid moisture, and avoid mechanical impact or other damage.

In summary, when purchasing 7129 automotive aluminum profiles, it is necessary to pay attention to material certification, specification requirements, surface quality, supplier reputation, and storage requirements to ensure that the purchased aluminum profiles are of reliable quality and meet the requirements.

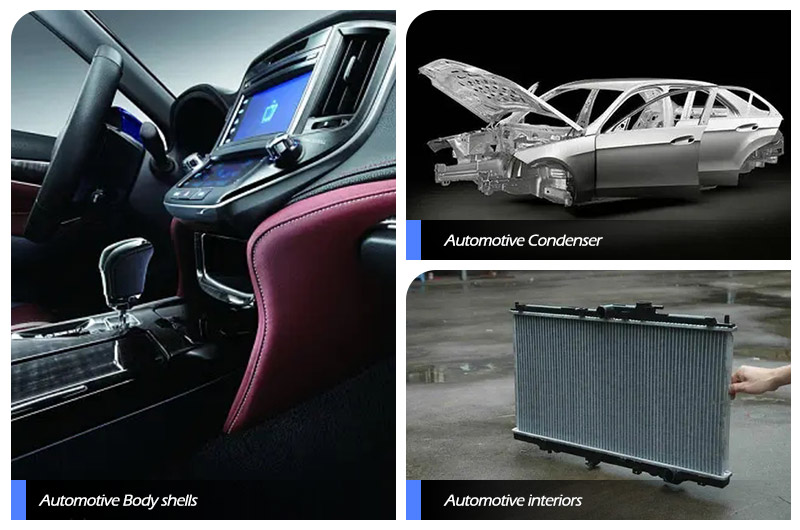

Applications of Chalco brazed composite aluminum sheet, brazed deep-drawn sheet

Aluminized brazed composite aluminum sheets and brazed deep-drawn sheets have a wide range of applications in the automotive manufacturing industry, of which the following are some examples:

Body shells: aluminized brazed composite aluminum sheet can be used for body shells of automobiles because of its high strength and corrosion resistance, while allowing for lightweighting and thus reducing fuel consumption and emissions.

Radiator: brazed deep-drawn sheet can be used for the radiator of automobiles because it has good thermal conductivity and corrosion resistance, which can effectively dissipate heat and extend service life.

Condenser: aluminized brazed composite aluminum sheet can be used for the condenser of automobiles because it has good thermal conductivity and strength to withstand high pressure and high temperature environment.

Automotive interiors: aluminized brazed composite aluminum sheet can be used for automotive interiors, such as door panels and instrument panels, because it has good surface quality and plasticity, allowing for a variety of complex shapes and surface textures.

In general, the application of Aluminim brazed composite aluminum sheet and brazed deep-drawn sheet in the automotive manufacturing industry can help achieve the goals of light weight, energy saving and environmental protection, safety and reliability.