Why choose Chalco 5083 5456 7039 2219 extruded weldable aluminium alloy armor

Production standards

MIL-DTL-46083E

Production ability

5083 5456 7039 2219 ALUMINUM ALLOY ARMOR, EXTRUDED, WELDABLE are manufactured in our state-of-the-art factory under strict quality and environmental management systems, ISO certified. Production and management comply with the quality system of aluminum profiles for armor, ensuring high strength and mechanical properties, as well as the best quality in corrosion resistance.

customer reference

UKROBORONPROM, ASELSAN, HEAVY INDUSTRIES TAXILA, Raytheon Company, SF Enginnering etc.

The Specs of 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

| Alloy | 5083 5456 7039 2219 |

| Thickness | 0.75-2.0 inches |

| Width | 500MM-3000MM |

| Length | 500MM-3000MM |

| Standard | MIL-DTL-46083E /ASTM B577/ASTM E716 |

The chemical composition of 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

| Elements | Composition (%) | |||

| 5083 | 5456 | 7039 | 2219 | |

| Silicon | 0.40 | 0.25 | 0.30 | 0.20 |

| Iron | 0.40 | 0.40 | 0.40 | 0.30 |

| Copper | 0.10 | 0.10 | 0.10 | 5.8-6.8 |

| Manganese | 0.40-1.0 | 0.50-1.0 | 0.10-0.40 | 0.20-0.40 |

| Magnesium | 4.0-4.9 | 4.7-5.5 | 2.3-3.3 | 0.02 |

| Chromium | 0.05-0.25 | 0.05 – 0.20 | 0.15-0.25 | - |

| Zinc | 0.25 | 0.25 | 3.5-4.5 | 0.10 |

| Titanium | 0.15 | 0.20 | 0.10 | 0.02-0.10 |

| Vanadium | - | - | - | 0.05-0.15 |

| Zirconium | - | - | - | 0.10-0.25 |

| Other, max. Each | 0.05 | 0.05 | 0.05 | 0.05 |

| Other, max. Total 3/ | 0.15 | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder | Remainder |

The mechanical properties of 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

| Alloy | Thickness Inches | Tensile Strength, Ksi | Yield Strength, 0.2% Offset, Ksi | Elongation percent A |

| No less than | ||||

| 5083 5456 | 0.75-2.0 inches | 45 | 35 | 9 |

| 2219 7039 | 0.75-2.0 inches | 57 | 48 | 8 |

Minimum ballistic limits (protection at 0 o obliquity) for using 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable caliber .50 fsp.

| Thickness inches | Required BL(P) fps | Thickness inches | Required BL(P) fps | ||

| Class I | Class II | Class I | Class II | ||

| 0.720 | 1689 | 1700 | 0.800 | 1919 | 2017 |

| 0.725 | 1702 | 1718 | 0.805 | 1934 | 2039 |

| 0.730 | 1716 | 1737 | 0.810 | 1950 | 2060 |

| 0.735 | 1730 | 1756 | 0.815 | 1965 | 2082 |

| 0.740 | 1743 | 1774 | 0.820 | 1981 | 2105 |

| 0.745 | 1757 | 1794 | 0.825 | 1997 | 2127 |

| 0.750 | 1771 | 1813 | 0.830 | 2013 | 2150 |

| 0.755 | 1786 | 1832 | 0.835 | 2029 | 2173 |

| 0.760 | 1800 | 1852 | 0.840 | 2045 | 2196 |

| 0.765 | 1814 | 1872 | 0.845 | 2062 | 2219 |

| 0.770 | 1829 | 1892 | 0.850 | 2078 | 2243 |

| 0.775 | 1844 | 1912 | 0.855 | 2095 | 2267 |

| 0.780 | 1858 | 1933 | 0.860 | 2112 | 2291 |

| 0.785 | 1873 | 1954 | 0.870 | 2129 | 2315 |

| 0.790 | 1888 | 1975 | 0.875 | 2163 | 2365 |

| 0.795 | 1904 | 1996 | 0.880 | 2180 | 2390 |

Acceptance ballistic test extrusions 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

| Class | Ordered Thickness, Inches | Projectile | Angle of Obliquity in Degrees | Table |

| I | 0.750-1.000 | Cal. .50 FSP | 0 | A-I |

| I | 1.001-2.000 | Cal. .30 APM2 | 0 | A-II |

| I | 1.001-1.700 | 20mm FSP | 0 | A-III |

| II | 0.750-0.950 | Cal. .50 APM2 | 0 | A-I |

| II | 0.951-1.500 | Cal. .30 APM2 | 0 | A-II |

| II | 0.951-1.500 | 20mm FSP | A-III | |

| II | 1.501-2.000 | Cal. .50 APM2 | A-IV |

Features of 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

High strength: extruded aluminum alloy armor usually has excellent strength properties, which enable it to effectively resist external impacts and cope with different defense requirements.

Lightweight: aluminum alloy is a lightweight material that weighs less than other armor materials such as steel. This allows the armor structure to provide protection while reducing overall weight, which benefits the vehicle's mobility and fuel efficiency.

Corrosion resistance: aluminum alloys generally have good corrosion resistance, especially for use in marine environments and high humidity environments, which is one of the reasons for their widespread use in ships and naval equipment.

Thermal conductivity: aluminum alloy has good thermal conductivity, which helps to transfer and dissipate heat quickly when impacted or exploded, thereby reducing the temperature of the armor.

Weldability: a distinguishing feature of weldable extruded aluminum alloy armor is its ease of welding. Aluminum alloy is easy to melt and fuse during welding, and the weld can achieve relatively high strength. This makes it easier to manufacture, repair and improve armor.

Plasticity: the extrusion process enables aluminum alloys to be produced in complex shapes and cross-sections, which provides more design freedom to suit the requirements of different armor structures.

Recyclable: aluminum alloys are recyclable materials that help reduce environmental pollution and promote sustainable development.

Application of 5083 5456 7039 2219 aluminum alloy armor, extruded, weldable

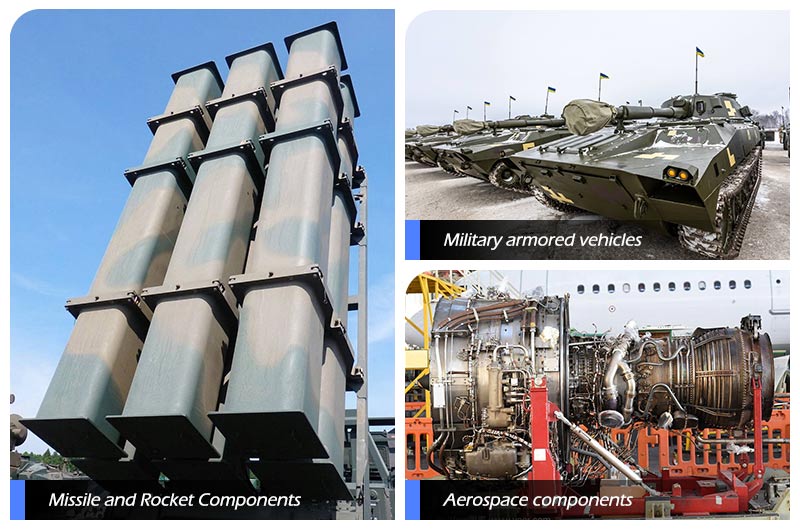

Military armored vehicles: weldable extruded aluminum alloy armor is widely used in military armored vehicles such as infantry fighting vehicles, wheeled armored vehicles and armored personnel carriers. These vehicles require high-strength, lightweight armor for occupant protection and some mobility.

Aerospace components: extruded aluminum alloy armor is also used in the aerospace field, such as aircraft shields and structural parts. Lightweight aluminum alloys can provide aircraft weight reduction and fuel efficiency improvements.

Marine ships: for ships in marine environments, such as warships, patrol boats, and fishing boats, extruded aluminum alloy armor with good corrosion resistance is an ideal choice because it can effectively resist the corrosion of seawater.

Ballistic panels and protective structures: weldable extruded aluminum alloy armor is used to manufacture ballistic panels and protective structures to provide protection for buildings, vehicles or other facilities.

Missile and rocket components: certain aluminum alloy armor types are used in structural parts of missiles and rockets to provide impact and armor-penetration resistance.

Safety equipment and protective equipment: in the civilian sector, weldable extruded aluminum alloy armor can be used to manufacture safety equipment and protective equipment, such as bulletproof vests and armored vehicles.

Armored vehicle improvement: in the modern warfare environment, the improvement of military armored vehicles is of paramount importance. By updating the armor of existing vehicles to make them lighter, stronger and easier to maintain, their survivability on the battlefield can be improved.