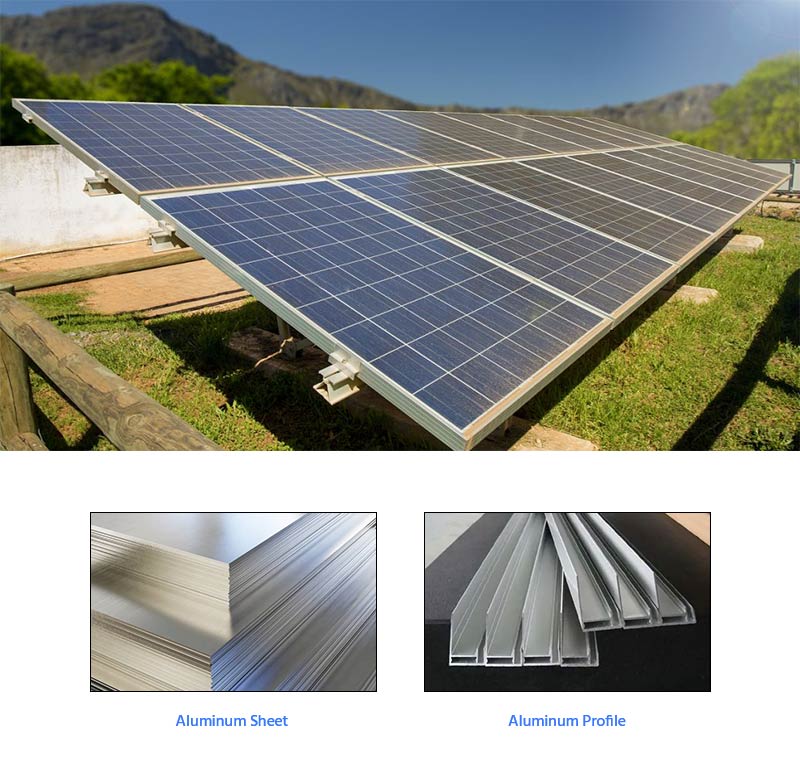

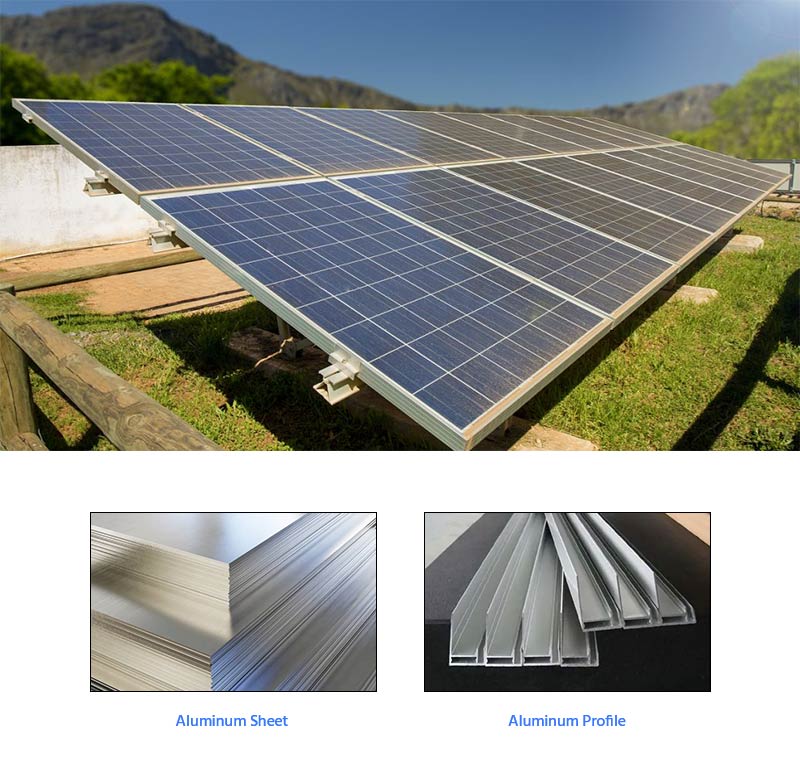

With its advantages of light weight, high strength, corrosion resistance and durability, aluminum is widely used in building solar panel frames and photovoltaic supports. Research shows that aluminum is the most widely used material in solar photovoltaic (PV) applications, accounting for more than 85% of most solar PV modules. Products conform to CEE AAMA, GB, BS, En; CE, DNV, ISO9001 certifications and can provide the TUV and other certifications.Welcome contact

Specification of Chalco aluminum products for solar panel

Alloy: 6061 6063 6082 6060 6005 6463 [click to check the Alloy Performance Parameter Table]

Product type: aluminum profile, aluminum sheet, aluminum strip, aluminum flat bar, etc.

Deep processing: drilling, bending, welding, precision cutting, punching, etc.

Surface treatment: mill finish, powder coating, anodizing, wooden grain, electrophoresis, PVDF painting, sanding blasting, polishing, etc.

Anodizing: smooth, frosted; Layer code: AA10, AA15, AA20, AA25

Electrophoretic coating: glossy or dull transparent paint film; Paint film code: EA21, EB16

Standard and certification: CEE, TUV, GB 5237-2008, JISH, AAMA, GB, BS, En; CE, DNV, ISO9001

Solar panel sizes: [click to check the Refernce Table]

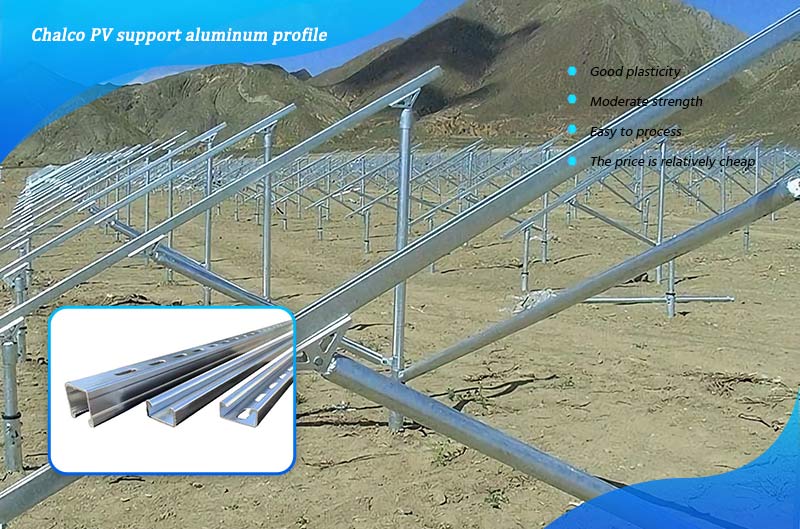

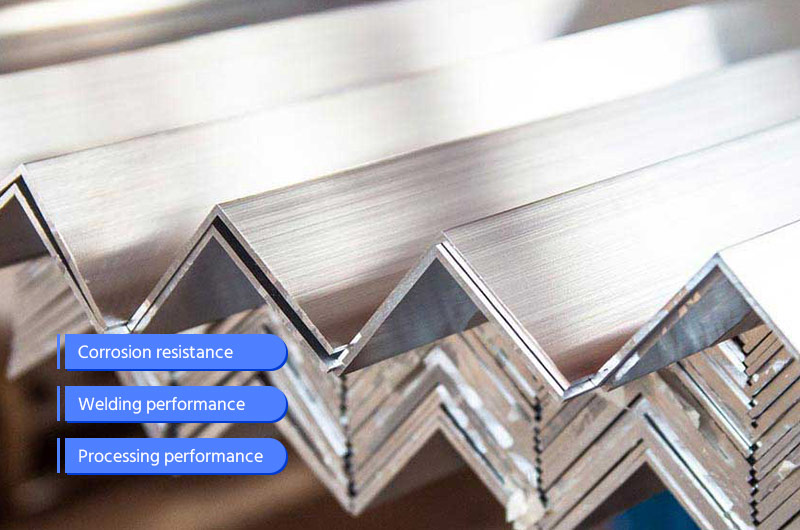

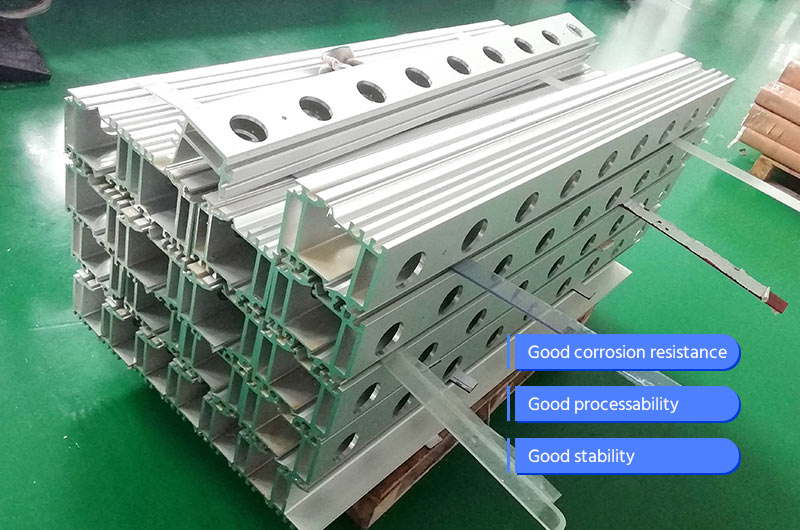

Extruded aluminum profile for the solar panel frame system

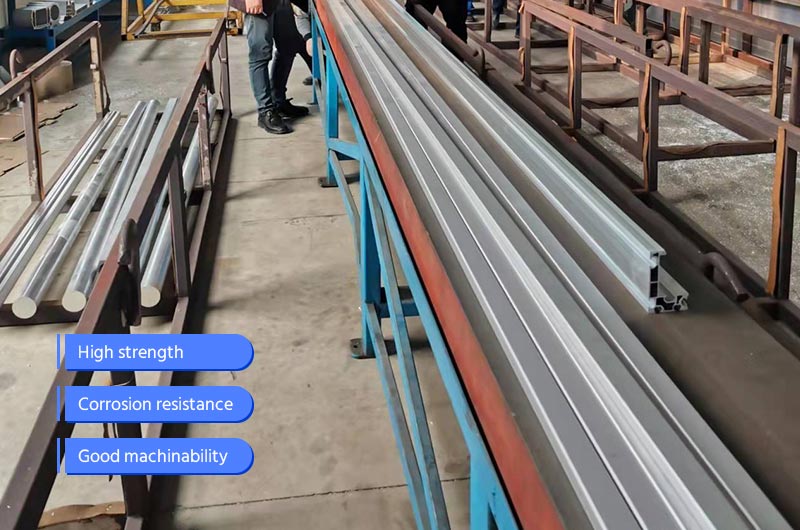

Extruded aluminum profiles are usually used for solar panel frames and solar mounting system, because aluminum extrusions have high strength, light weight and strong corrosion resistance. The aluminum frame seals and secures the solar cell module between the glass cover and back plate, ensuring structural stability and extending battery lifespan. Aluminum alloy, with its moderate price, strength, processability, corrosion and weather resistance, and recyclability, is an ideal material for solar panel support in solar mounting system, requiring no maintenance over the 25-year operation period.Quick Quote

Extruded aluminum profile for solar panel frame

T-profile: capability to offer both support and stability.

L-profile: providing edge protection for panels.

U-channel: used for cable management in panel system, ensuring efficient installation.

Extruded aluminum profile for solar mounting system

H profile:construct the frames and supports of solar panels.

Z-profile:used to attach the mounting frame to roofs.

T-slot:primary structural component in solar panel supports with flexible design options.

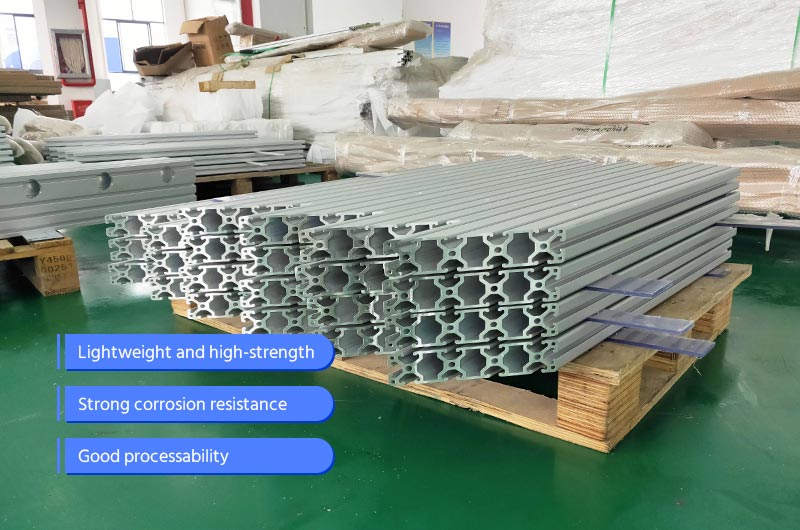

6061 aluminum profile

6063 aluminum profile

6082 aluminum profile

6060 aluminum profile

6005 aluminum profile

6463 aluminum profile

Properties of Chalco aluminum profile

| Alloy | Temper | Wall thickness | Tensile strength Rm(MPa) | Yield strength RP0.2(MPa) | elongation % |

| 6005 | T5 | ≤5.00 | ≥260 | ≥240 | ≥8 |

| 6060 | T5 | ≤5.00 | ≥160 | ≥120 | ≥6 |

| T6 | ≤3.00 | ≥190 | ≥150 | ≥6 | |

| T66 | ≤3.00 | ≥215 | ≥160 | ≥8 | |

| 6061 | T6 | ≤5.00 | ≥265 | ≥245 | ≥8 |

| 6063 | T5 | ≤5.00 | ≥160 | ≥110 | ≥8 |

| T6 | ≤3.00 | ≥205 | ≥180 | ≥8 | |

| T66 | ≤3.00 | ≥245 | ≥200 | ≥6 | |

| 6463 | T5 | ≤5.00 | ≥150 | ≥110 | ≥6 |

| T6 | ≤5.00 | ≥195 | ≥160 | ≥8 |

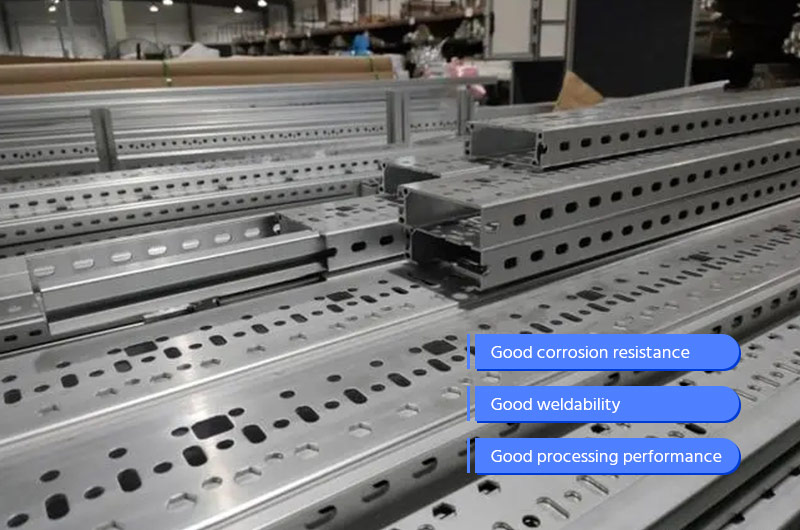

- Anodized aluminum alloy with transparent coating, high corrosion resistance and oxidation resistance.

- High tensile strength performance, improving snow load resistance, rain resistance, wind impact resistance and so on.

- The excellent mold reduces the machining allowance to 0.02mm while ensuring the accuracy to ensure smooth installation.

- The aluminum alloy photovoltaic support is generally in the form of long rod, and the stress is tensile stress and compressive stress, which is easy to buckle and deform, so the design wall thickness is generally not less than 1.5 mm.

- The commonly used aluminum alloy series for solar photovoltaic brackets need to undergo aging heat treatment to achieve the required strength.

- China Aluminum strictly controls the solution treatment and aging heat treatment process to ensure the required strength of the aluminum alloy brackets.

- The oxide film thickness is generally AA15, but in humid or heavily polluted areas, AA20 or AA25 can be chosen to improve corrosion resistance.

Aluminum sheet, strip, flat bar for solar panel

The cooling speed of aluminum is fast compared to the traditional materials, which has a significant advantage in solar PV system because the increase of PV cell temperature will reduce the power generation efficiency. And with is good conductivity, aluminum has gradually replaced the position of silver, copper and stainless steel in the solar panels.

Compared with traditional materials, aluminum cooling speed is fast, which has a significant advantage in solar PV, because the increase of PV cell temperature will reduce the power generation efficiency. And because of its good conductivity, aluminum has gradually replaced silver, copper and stainless steel in the position of solar panels.Quick Quote

Aluminum strip and flat bar for solar cell interconnection

Solar cell chips, typically silicon-based, are mainly linked using aluminum. Aluminum strips and ribbons facilitate efficient current flow between the cell chips.

Hot selling: 6101 aluminum flat bar

Aluminum sheet for solar reflector panel

Aluminum is also employed as reflector panels in solar panels, guiding sunlight to enhance energy absorption efficiency in certain solar heating systems.

Hot selling: 1100, 3003 aluminum sheet

-

6101 aluminum busbar

used in solar cell connections to link solar cell chips together, ensuring efficient current transmission.

-

1100 aluminum sheet

employed on solar cell reflector panels to guide sunlight and enhance energy absorption efficiency.

-

3003 aluminum sheet

Provide effective reflective performance while also offering lightweight and weather resistance.

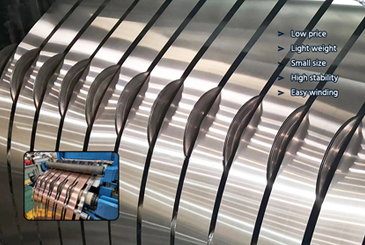

Aluminum transformer strip for solar photovoltaic circuit systems

In solar energy, transformers convert and regulate electrical energy from photovoltaic systems, ensuring efficient operation and grid connectivity. Their design directly impacts solar system efficiency and reliability, crucial across the industry chain.Quick Quote

Aluminum transformer strip for solar photovoltaic circuit systems

1050: better than 60% IACS

1060: better than 61.5% IACS

1070: better than 62.7% IACS

1350: better than 62% IACS

- Power converters: solar photovoltaic panels generate direct current, which needs to be converted into alternating current via inverters for grid supply or direct use in residential and commercial applications. Transformers within inverters perform voltage conversion and power adaptation, ensuring output voltage and frequency meet requirements.

- Interconnecting transformers: in solar power plants, multiple PV panel arrays are typically interconnected using interconnecting transformers to integrate energy from different arrays into a unified output, enhancing overall system efficiency and energy transmission effectiveness.

- Distributed transformers: in distributed energy systems like solar microgrids or distributed generation systems, transformers manage and optimize energy flow from solar PV systems to the grid, ensuring efficient energy transmission and supply stability.

- Battery storage systems: solar power systems with battery storage typically require transformers to manage voltage and current during battery charging and discharging, ensuring efficient energy utilization and safe system operation.

Other applications of aluminum profiles in the field of solar frame

Aluminum has become a feasible solution in the energy field due to its properties of light weight, efficient installation capacity and low price. In addition to the application of the above frame and battery panel in the solar energy field, aluminum is also applied to the following solar systems:

- Wind turbine structure and components

- Module framework and components

- Concentrated solar collector

- Thermal management solution

- Inverter housing and components

Why choose Chalco solar energy aluminum products

Chalco stock various aluminum extruded solar panel frames and photovoltaic support aluminum alloys, with a variety of finishes to choose from. If the existing products are not suitable for your needs, we can also customize them according to customer requirements.

All extrusion parts can be cut, drilled or machined according to customer specifications. As a professional aluminum profile supplier, Chalco operates the latest CNC drilling and processing center, which can provide accurate processing and cost-effective parts in a short cycle time.

Because the panel frame is exposed to the natural environment, it has high requirements for corrosion resistance. Chalco provides anodized aluminum profiles to further enhance the corrosion resistance of solar aluminum alloy frames.

After the production of aluminum profiles, we will provide strict product quality inspection and precise product film pasting, packaging and transportation. Ensure product quality at any link of production and delivery.Quick Quote

Solar panel sizes reference table

| Power (w) | Number of cells(pcs) | Size of cells(mm) | Solar panel frame size(mm) | Weight (Kg) |

| 5 | 2*18 | 78*12 | 280x190x17 | 0.7 |

| 10 | 4*9 | 52*31.2 | 250x350x17 | 1.2 |

| 20 | 4*9 | 78*39 | 420x360x17 | 2.3 |

| 30 | 2*18 | 156*26 | 360x550x20 | 2.5 |

| 40 | 4*9 | 156*39 | 670*420×25 | 3.2 |

| 50-60 | 4*9 | 156*52 | 540x670x25 | 4.2 |

| 80-90 | 4*9 | 156*78 | 780x670x30 | 6.6 |

| 100 | 4*9 | 156*104 | 1000x670x30 | 8 |

| 110-120 | 4*18 | 156*52 | 1020x670x35 | 8.8 |

| 130 | 4*9 | 156*117 | 1120*670*35 | 10.5 |

| 140 | 4*9 | 156*63 | 1200*670*35 | 10.5 |

| 150-180 | 4*9 | 156.75*156.75 | 1480x670x35 | 12 |

| 190-200 | 6*12 | 125*125 | 1580x808x35 | 15.5 |

| 210-230 | 6*8 | 156.75*156.75 | 1320x992x35 | 17 |

| 250-270 | 6*9 | 156.75*156.75 | 1482x992x40 | 18 |

| 280-310 | 6*10 | 156.75*156.75 | 1640x992x40 | 18 |

| 340-380 | 6*12 | 156.75*156.75 | 1956x992x40 | 23 |

| 460-500 | 8*12 | 156.75*156.75 | 1956x1310x45 | 29 |