Chalco Aluminum 7175 aluminum profile is an aluminum profile made of 7175 aluminum alloy. The common ones are round tube, square tube, rectangular tube, angle bar, T profile, U profile, etc. The size can vary according to different application requirements.

7175 aluminum profiles have high strength, toughness and corrosion resistance, and are widely used in aerospace, transportation, machinery manufacturing, electronics industry and other fields. In the field of aviation, 7175 aluminum profiles are often used in aircraft structural parts, wings, flaps, fuel tanks, support frames and other fields.Quick Quote

Aluminum profile production shipin

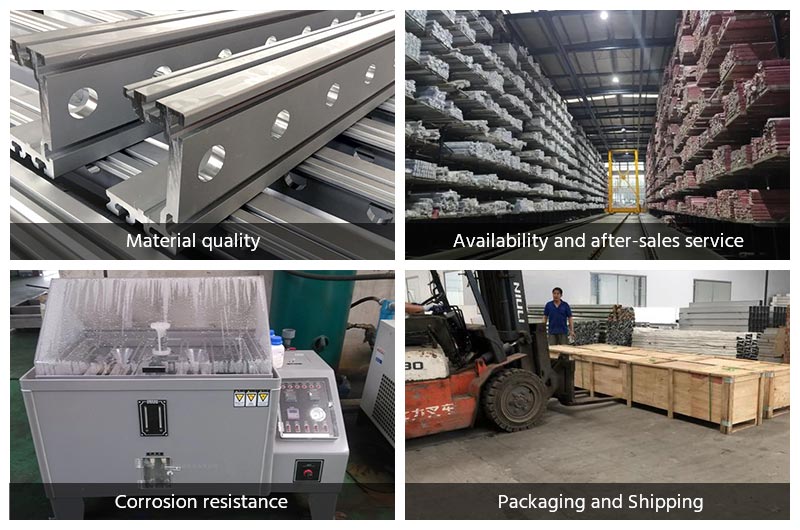

Why choose Chalco 7175 aviation aluminum profile?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Standard

A97050, AMS 4344, AMS 4341, AMS 4342 etc.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

Chalco's hot-selling extruded profiles shapes

With decades of experience in the aluminum extrusion industry, Chalco has achieved an annual production capacity of 100, 000 tons. We also possess molds for 2000 standard aluminum extruded profiles. Take advantage of our latest promotional policy with waived mold fees.

Typically, 6063 is used for architectural applications, while 6061 is utilized for structural purposes. Chalco also offers various other alloy numbers such as the 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, and 7000 series. Our sales engineers can assist you in selecting the right alloy for your project.Quick Quote

Aluminum Angle

Aluminum T bar

Aluminum I Beam

Extruded Aluminum Channel

Aluminum Flat Bar

Aluminium G Profile

F-shaped-Aluminium-Extrusion

Aluminium J Profile

Square-Aluminum-Extrusion

Z-Aluminium-Extrusion

Oval Aluminum Extrusion

Y Section Aluminium Extrusion

Chemical composition of 7175 aluminum alloy profiles

| Element | Percentage |

| Al | 88.6-90.6% |

| Zn | 5.0-6.0% |

| Mg | 1.9-2.6% |

| Cu | 1.4-2.0% |

| Fe | 0.5% max |

| Mn | 0.3% max |

| Si | 0.20-0.80% |

| Cr | 0.18-0.28% |

| Ti | 0.06-0.20% |

Physical properties of 7175 aluminum alloy profiles

| Property | Value |

| Density | 2.70 g/cm3 |

| Melting point | 582-652°C |

| Tensile strength | 90-120 MPa |

| Yield strength | 50-80 MPa |

| Elongation | 15-25% |

| Hardness (Brinell) | 25-45 HB |

| Thermal conductivity | 180-210 W/mK |

| Electrical conductivity | 34-40 MS/m |

| Coefficient of thermal expansion | 23.1×10-6 /°C |

Dimensions of 7175 aluminum alloy profiles

| Extrusion type | Dimension range (inches) | Wall thickness range (inches) |

| Round Tube | 1-10 | 0.125-0.75 |

| Square Tube | 1-8 | 0.125-0.5 |

| Rectangular Tube | 1*2-8*12 | 0.125-0.5 |

| Angle | 1*1-8*8 | 0.125-0.5 |

| T-Profile | 1*1-6*6 | 0.125-0.5 |

| U-Profile | 1*0.5-6*2 | 0.125-0.5 |

Chalco 7175 aluminum alloy profile hot-selling products

7175-T6 temper is obtained by heat treatment (T6) at room temperature, has excellent strength and toughness, and is usually used in aerospace applications that require high strength and corrosion resistance, such as aircraft fuselage, landing gear, etc.

7175-T73511 temper is based on the T6 temper, obtained by molding or extrusion forming processes, which can obtain higher mechanical properties and fatigue strength, and are widely used in structural parts, frames and supports in the aerospace field.

Characteristics of 7175 aluminum profiles in the aviation field

High strength: 7175 aluminum alloy profiles have high strength, can withstand high loads in extreme environments, and can be used in high-speed aircraft and high-altitude aircraft.Quick Quote

Corrosion resistance: 7175 aluminum alloy profiles have good corrosion resistance in high temperature, high humidity and corrosive environments.

Good processability: 7175 aluminum alloy profiles can be formed through a variety of processing techniques, such as extrusion, rolling, stretching, die forging, etc.

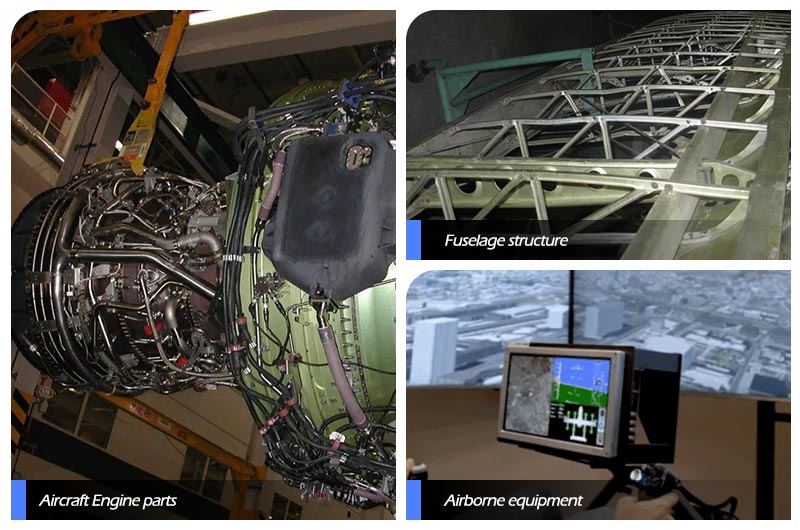

Application of 7175 aluminum alloy profiles in aviation field

Fuselage structure: 7175 aluminum profiles can be used to manufacture wings, webs, ribs, brackets, supports, etc. in aircraft fuselage structures.

Engine parts: 7175 aluminum profiles can be used to manufacture aircraft engine parts, such as blades, guides, air intakes, etc.

Airborne equipment: 7175 aluminum profiles can be used to manufacture housings and brackets for avionics equipment.

7175 aluminum profiles need to pay attention to the following matters when using

Anti-corrosion: 7175 aluminum alloy profiles can be used in high-temperature, high-humidity, and corrosive environments, but still need to pay attention to prevent corrosion. When using, avoid direct contact with other metals, avoid the use of corrosive cleaning agents and solvents, and avoid prolonged exposure to high humidity.

Operating temperature: the high strength of 7175 aluminum alloy profile mainly comes from its solid solution strengthening phase, which will fail at high temperature, so pay attention to avoid overheating and keeping it in a high temperature environment for a long time when using it at high temperature.

Processing: 7175 aluminum alloy profiles are prone to deformation and cracks in processing processes such as extrusion, rolling, stretching, and die forging. Therefore, it is necessary to pay attention to selecting appropriate processing parameters and processes to avoid over-processing.Quick Quote

Softening: when performing local heating, care should be taken to avoid softening the 7175 aluminum alloy profile, so as not to affect its strength and toughness.

When purchasing 7175 aluminum profiles, you need to pay attention to the following points

Material standard: the performance and service life of 7175 aluminum alloy profiles are closely related to their material quality. When purchasing, it is necessary to confirm that the material meets international or industry standards, such as American ASTM standards or aviation standards.

Product quality: it is necessary to confirm that the supplier's products are of good quality, including surface finish, dimensional accuracy, chemical composition, physical properties, etc.

Dimensions and specifications: Confirm whether the purchased 7175 aluminum alloy profile size and specifications meet your needs, such as length, width, thickness, etc.

Supplier reputation: it is necessary to choose a reputable and professional supplier to ensure the quality and service quality of the purchased 7175 aluminum alloy profiles.Quick Quote

Price: the price of 7175 aluminum alloy profiles is generally relatively high, and market research is required to compare the prices of different suppliers and choose suppliers with reasonable prices.