7014 aluminum alloy profile is a high-strength, corrosion-resistant aluminum alloy material with good weldability and machinability. It is often used in the manufacture of structural parts and components in the aerospace field.

Why choose Chalco Aluminum's 7014 T4/T6 aluminum profile extrusion?

Quality could full meet world wide aviation standard

DTD 5044 7014 Bars and Section

Production and management comply with international aviation quality system certification

AS9100

OHSAS 18001

ISO14001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Specs of 7014 T4 T6 aluminum profile extrusion

| Specification | |

| Alloy | 7014 |

| Temper | T4, T6, T6511 |

| Open profile dimensions | Min 4mm*3mm, Max.850mm*50mm. |

| Closed profiles dimension | Min. 6.35mm*1mm, Max. 573mm*10mm. |

| Weight per meter | Min. 0.03kg/m, Max. 124kg/m |

| Profile length | Maximum 28m(standard 6000mm) |

| Standard | DTD 5044 7014 Bars and Section |

Chemical composition of 7014 aluminum alloy

| 7014 Alloy % | |

| Si | 0.50 |

| Fe | 0.50 |

| Cu | 0.30-0.70 |

| Mn | 0.30-0.70 |

| Mg | 2.20-3.20 |

| Cr | - |

| Ni | 0.10 |

| Zn | 5.20-6.20 |

| Ti+Zr | 0.20 |

| Al | Remainder |

Mechanical property of 7014 T4/T6 aluminum profile extrusion

| Alloy Temper | Tension strength | Yield strength | Elongation | Hardness |

| T4 | 480 MPa | 360 MPa | 11% | 130 HV |

| T6 | 510 MPa | 470 MPa | 10% | 145 HV |

| T6511 | 510 MPa | 470 MPa | 10% | 145 HV |

Features of 7014 T4 T6 aluminum profile extrusion

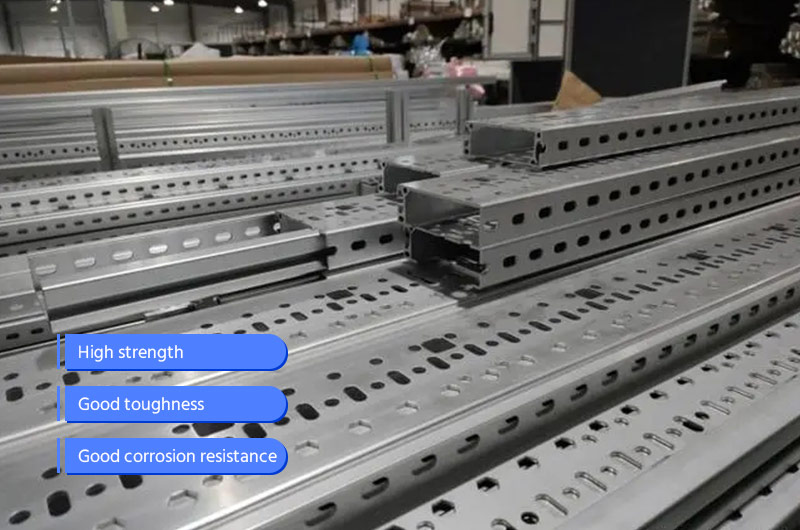

High strength: 7014 aviation aluminum alloy profiles have high strength and can be used in the manufacture of aircraft parts, vehicle components, bridge construction and other fields that require high strength.

Good toughness: 7014 aviation aluminum alloy profile not only has high strength, but also has good toughness, which is not easy to break or deform when impacted or squeezed, so it has a good performance in applications such as aircraft and automobiles that are impacted.

Good corrosion resistance: The surface of 7014 aviation aluminum alloy profiles has good corrosion resistance, and can be used in harsh environments for a long time without being damaged by corrosion.

Good machinability: 7014 aviation aluminum alloy profiles have good machinability, easy to stamping, stretching, bending, deep drawing, etc., so they can meet the needs of different shapes and sizes.

Low density: 7014 aviation aluminum alloy profile has a low density, about 1/3 lighter than ordinary steel, so it has a good performance in applications requiring light weight.

Types and uses of 7014 T4 T6 aluminum profile extrusion

7014 T4 aluminum profile

This is an aluminum profile after natural aging treatment. With medium strength and good toughness, it is suitable for aerospace structures that require high stability, such as fuselage structures, wings and empennages.

7014 T6 aluminum profile

It after artificial aging treatment. It has high strength and hardness, but low toughness. It is suitable for aerospace structures that require high strength and rigidity, such as fuselage ribs and wing ribs.

7014 T6511 aluminum profile

It is an aluminum profile after artificial aging and stretching processing. It has high strength and hardness, and retains a certain degree of toughness. It is suitable for aerospace structures that require high strength and good processing performance, such as fuselage ribs and wing ribs.

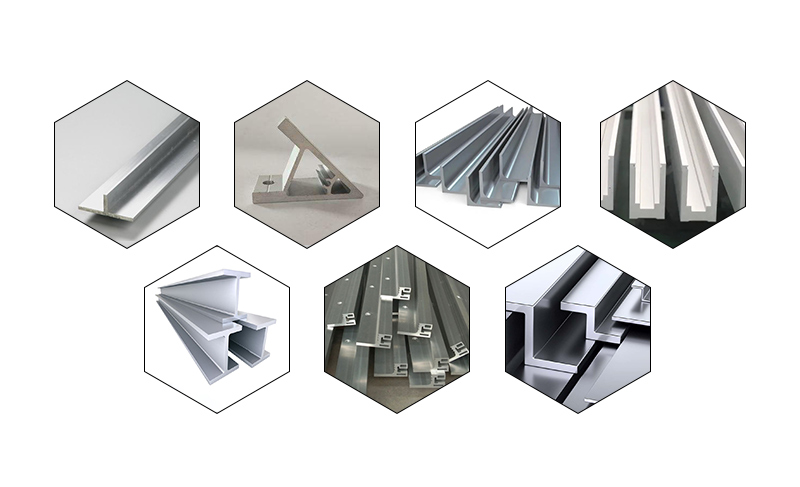

7014 L-shaped aluminum extrusion

It is a profile with an L-shaped cross-section, which is usually used to manufacture components such as frames, supports, and corner connections. It is characterized by being relatively firm and able to withstand greater weight and pressure.

7014 I-shaped aluminum profile

It is a profile with an I-shaped cross-section, which is usually used to manufacture components such as load-bearing structures. It is characterized by good stability and high tensile strength.

7014 U-shaped aluminum profile

It is a profile with a U-shaped cross-section, which is usually used to manufacture parts such as guardrails and decorative materials. It is characterized by beautiful shape and easy installation.

7014 Aluminum round bar

It is a round aluminum profile of uniform diameter that is commonly used to manufacture components such as aircraft parts. It is characterized by high strength, light weight and strong corrosion resistance.

7014 aluminum pipe

It is a hollow cylindrical aluminum material, commonly used in the manufacture of piping systems for conveying gases, liquids and powders. It is characterized by light weight, corrosion resistance and easy processing.

What precautions should I take when purchasing 7014 T4/T6 aluminum profile extrusion?

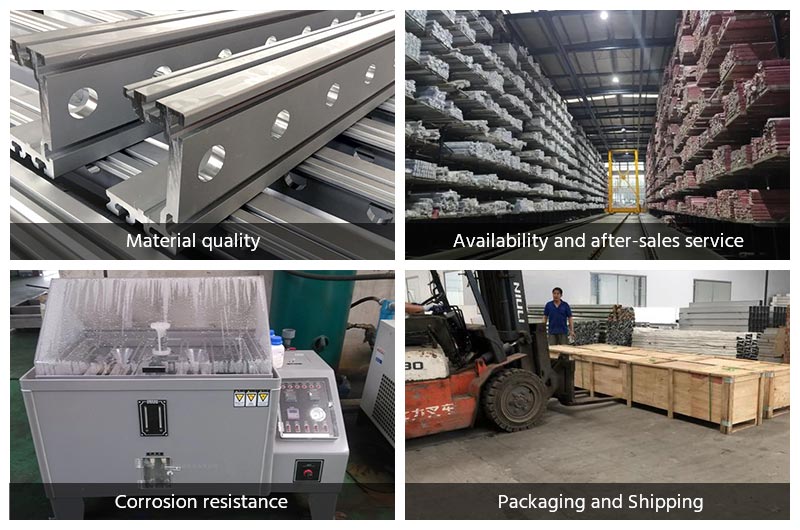

Material certification: ensure that the purchased aluminum alloy profile materials comply with relevant national and industry standards, such as aerospace material standards, etc. It is best to choose a supplier with ISO, CE or other relevant certifications.

Specification requirements: aluminum alloy extrusion of corresponding specifications and sizes should be purchased according to needs, such as length, width, thickness, etc. According to different applications, it is also necessary to consider the cross-sectional shape, strength and other indicators of the profile.

Surface treatment: it is necessary to choose different surface treatment methods according to actual needs, such as anodizing, sandblasting, chemical cleaning, etc. Surface treatment can not only improve the corrosion resistance of aluminum alloy profiles, but also beautify the surface effect.

Manufacturer's reputation: choose a reputable manufacturer and supplier to ensure product quality and after-sales service.

Price comparison: compare prices according to market conditions and choose products with high cost performance. But don't just look at the price, but also consider factors such as quality and after-sales service.