The 1050 aluminum sheet is known for its high purity, typically above 99.5%, and offers moderate strength with excellent workability.

It is renowned for its outstanding corrosion resistance, high ductility, and high reflectivity. While it can be strengthened through cold working, it is not suitable for heat treatment.Welcome to Contact

Chalco 1050 aluminum sheet plate In-stock inventory

- All stock products are available for retail with no minimum order. Orders are cleared and shipped within a week.

- As a leading manufacturer with one-stop production, we offer aluminum plates at 10% below market price.

- Our reputable brand ensures strict quality inspections, giving you peace of mind about product quality.

If you need to make a bulk purchase, you can first check our available stock, which is updated in real-time…… If we don't have the size you need, please contact us for custom orders.Click to order

1050 Aluminum sheet Hot Selling Size Table (Metric)

| Description | Metric Thickness/ | Imperial Thickness/in | size | Specifications |

| 1050 H14/H24 aluminum sheet | 0.5 | 0.0197 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 0.7 | 0.0276 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 0.8 | 0.0315 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 0.9 | 0.0354 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 1 | 0.0394 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 1.2 | 0.0472 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 1.5 | 0.0591 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 2 | 0.0787 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 2.5 | 0.0984 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 3 | 0.1181 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 4 | 0.1575 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 5 | 0.1969 | 1500*3020 | EN485, ASTM B209 |

| 1050 H14/H24 aluminum sheet | 6 | 0.2362 | 1500*3020 | EN485, ASTM B209 |

1050 Aluminum sheet Hot Selling Size Table (Imperial)

| Description | Dimensions | Standard |

| 0.020" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.028" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.031" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.035" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.039" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.047" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.059" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.079" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.098" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.118" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.157" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.197" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

| 0.236" 1050 H14 aluminum sheet | 48" x 144" | EN485, ASTM B209 |

If the above inventory does not meet your specifications, you can contact us directly for customization.Quick Quote

Specifications of aluminium sheet alloy 1050

| Alloy | 1050 |

| Equivalent Names | Aluminium 1050-O; UNS A91050; NF A5 (France); DIN Al99.5; AA1050-O, ASTM B491; BS 1B (UK); CSA 9950 (Canada); ASTM B491; Al1050-O |

| Temper | O, H14 |

| Thickness | 0.2-260mm |

| Width | 500-2650mm |

| Hot Selling Sizes | 1250x2500, 1500x3000, 1520x3020, 1525x3660 |

Product categories of 1050 aluminum plate

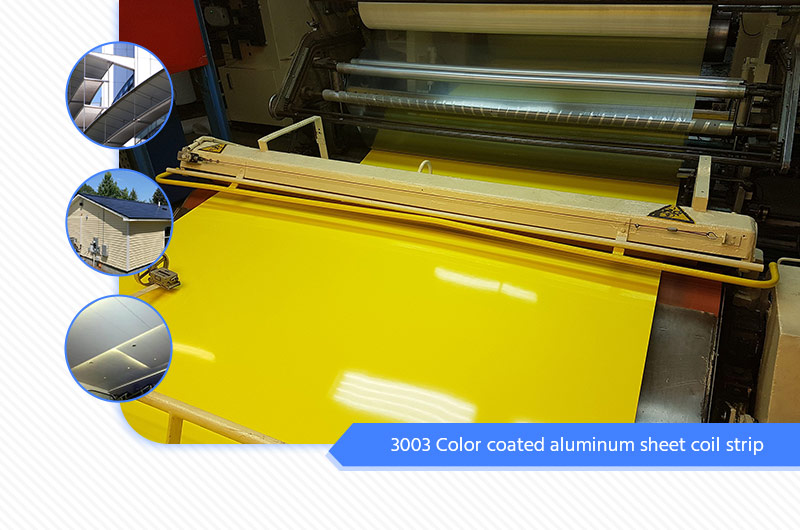

1050 color coated aluminum sheet

Thickness: 0.2-6mm

Coating thickness: 5-25UM

1050 color coated aluminum sheet is widely used in caps, bottle caps, cans, cosmetic caps, etc.

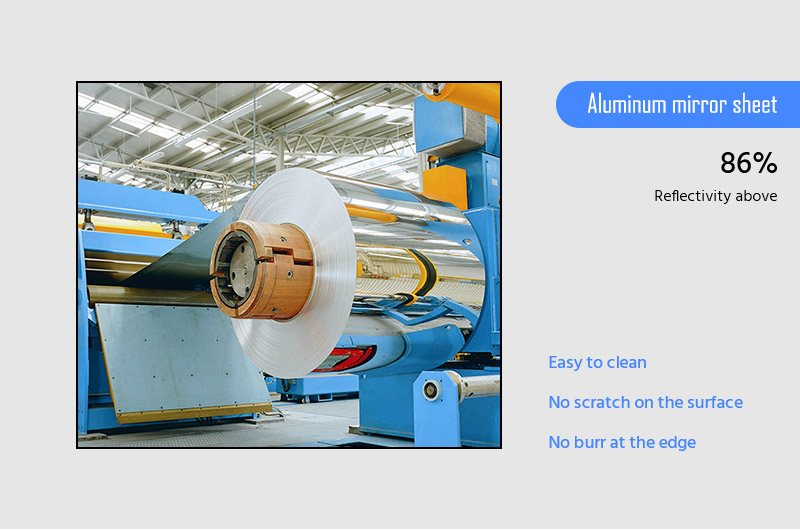

Contact us nowThickness: 0.1-3.5mm

Reflectivity: 80%, 86%, 95%

Used in building decoration, lighting fixtures, solar reflectors, electronic product casings, etc.

Contact us now1050 Aluminum Tread Checkered Plate

Common Thickness: 0.025", 0.063", 0.100"

It is commonly used in stair treads, wall panels, industrial anti-slip walkways and other fields.

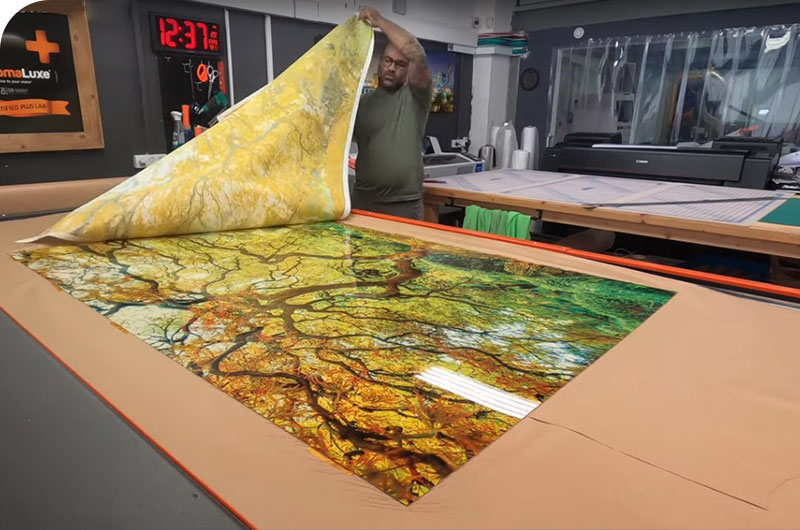

Contact us now1050 Sublimation Aluminum Sheet

Thickness: 0.22-1.1mm, common( 0.45, 0.55, 1.0mm)

Dimensions: 1200x600mm, 600x400mm, 600x300mm

Widely used in signs, furniture, electronic equipment housings and curtain walls.

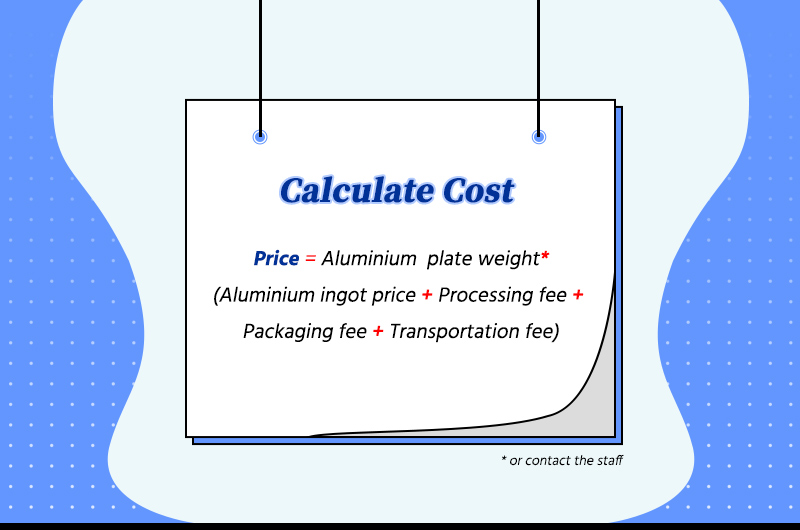

Contact us nowPrice composition and weight calculation of 1050 aluminum plate

FOB price of 1050 aluminum sheet = SMM A00 aluminum ingot price on the day of inquiry + processing fee / exchange rate

Notes: Aluminum ingot price is SMM A00 aluminum ingot price

FOB price can be US dollar price, Euro price, or Renminbi price, according to customer requirements.

We can customize on demand, some products are in stock, and they will be shipped immediately after placing an order. We look forward to cooperating with you!Quick Quote

Aluminum plate weight calculation: length (mm) * width (mm) * density 2.7g/cm3

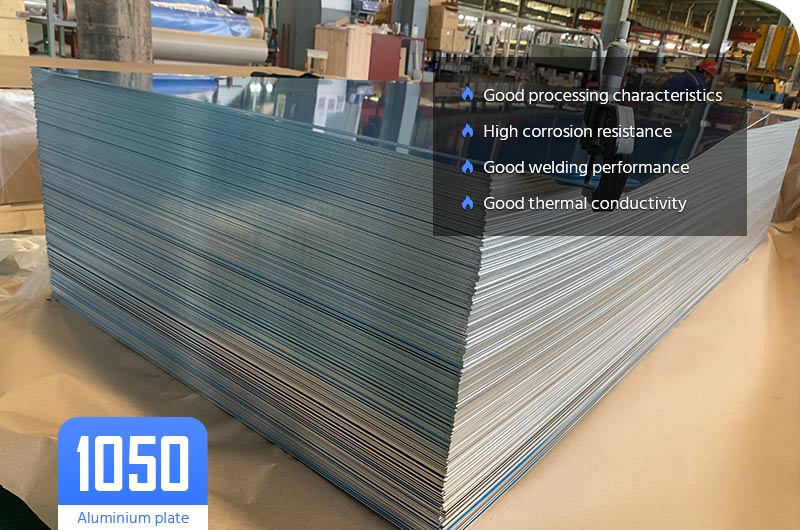

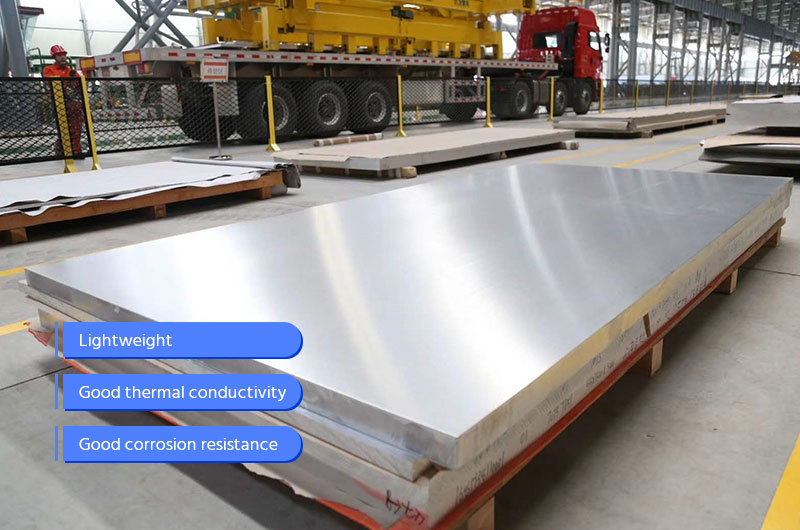

Advantages of 1050 aluminum plate

- 1050 aluminum alloy is formed by adding a small amount of copper element to pure aluminum. It has excellent forming and processing characteristics, high corrosion resistance and good weldability.

- It is easy to weld by MIG or TIG process, and has good electrical conductivity and thermal conductivity. It is an ideal choice for chemical and electrolytic whitening, with very good anodizing quality and high reflective effect.

- It has long service life, low cost, and high recycling value.

- The processing technology of 1050 aluminum plate is mature, and the price has a great advantage compared with other series of alloy aluminum plates.

- Since it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries.

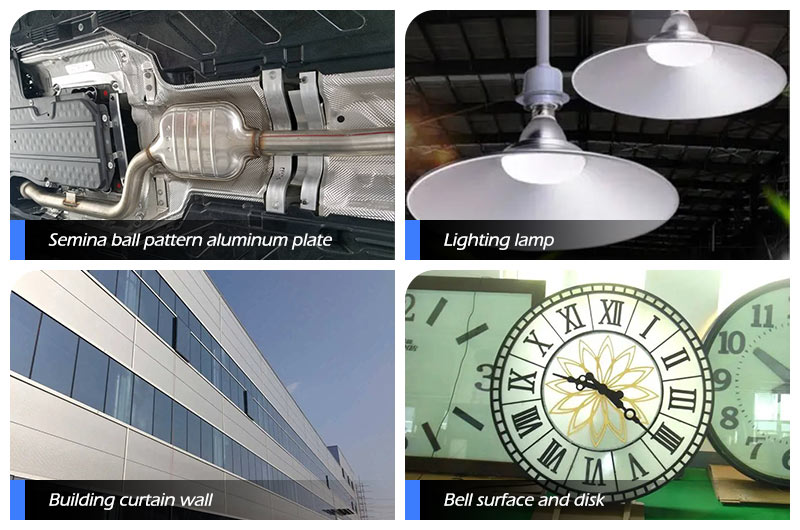

Application of Chalco hot sale 1050 aluminum sheet series

- 1050 O aluminum plate is often used in pressing hemispherical pattern aluminum plate, embossed aluminum coil, embossed aluminum plate.

- Extrusion coil stampings for the food, chemical and brewing industries.

- Daily necessities, lighting fixtures, reflectors, decorations, lamps, electrical appliances, and other products.

- Building decoration components and transport panels, building waterproof board, curtain walls, oxides.Customized alu sheet

- 1050 aluminum plate is corrosion-resistant, highly formable, and used in chemical equipment, PS plate base, lithium battery soft connections, valves, signs, electronics, and thin plate processing parts. It is also used in deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surfaces, kitchen utensils, hollow vessels, chemical containers, food and beverage packaging, cable sheaths, and general sheet metal parts.

Related recommendation of Chalco 1050 aluminum plate

1050 Pre-Sensitized Plate

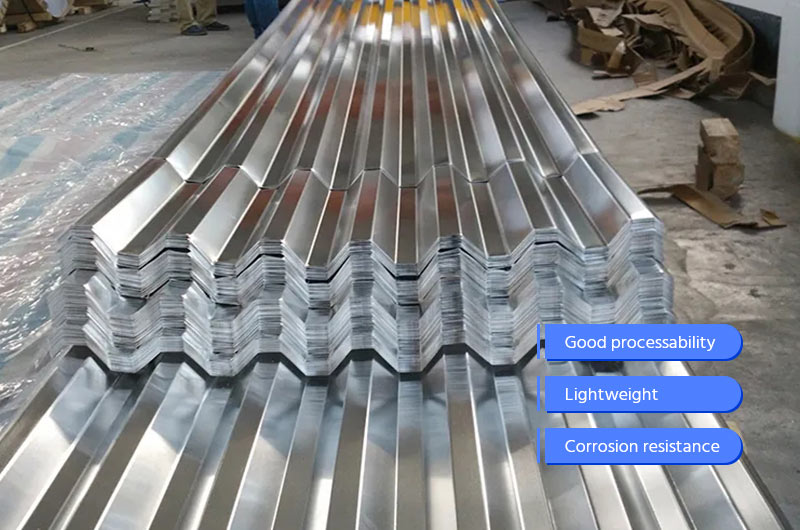

1050 Aluminum Corrugated Metal

1050 CTP Sheet Aluminum Substrate for Printing

1050 Aluminum Sheet for Power Battery Shell

1050A Aerospace Aluminum Sheet

1050 Automotive Insulation Aluminum Sheet

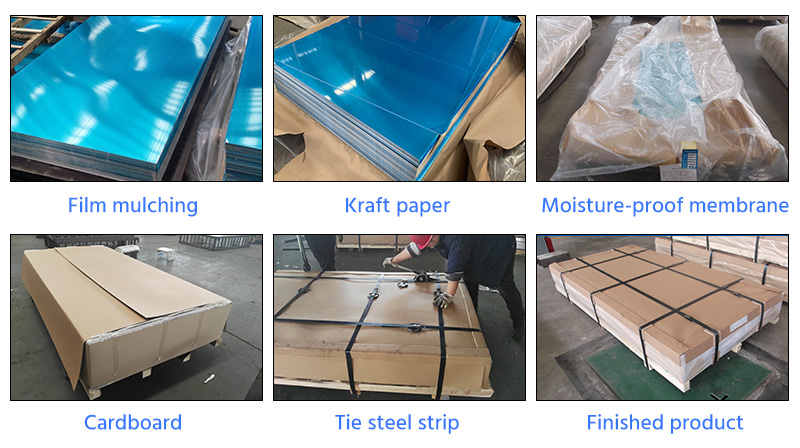

Packaging and transportation of the 1050 aluminum plate

- Carry out paper clipping or film coating on the 1050 aluminum plate to ensure that the surface of the aluminum plate is intact without scratches.

- To transport 1050 aluminum plates, pack them in plastic or kraft paper with a desiccant to keep them clean and dry. Ship them in a closed compartment, ship warehouse, or gondola car and cover them with rain-proof and snow-proof tarpaulins to prevent water, rain, and snow from entering.

- Install wooden pallets and reinforce them with steel strips to avoid collisions during transportation and ensure that the geometric shape of the 1050 aluminum plate remains unchanged.

- Export products are packed in wooden boxes and brackets with fumigation marks, and fumigation certificates are provided.

- Pack it according to other packaging requirements of the customer. If it is covered with a rain cloth during transportation, it is necessary to avoid water ingress of the aluminum plate packaging due to weather, and avoid bumping during loading and unloading, so that the aluminum plate can be safely transported to the user's hands.

Why choose Chalco as a1050 aluminum sheet supplier

- More than 12 years of 1050A aluminum sheet plate manufacturing, inventory and supply experience.

- Best price for AL1050 aluminum sheet plate-available worldwide with shortest delivery time.

- Exporting 1050A aluminum sheet plate conforming to ASTM and EN standards is our specialty.

- We can handle the logistics for you-we can provide FOB, CIF delivery to any port.

- The documents we provide include-Certificate of Origin, Chamber of Commerce certified invoice and PL, test certificate according to EN 10204 3.1, and other test reports as our clients may require.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Chemical composition of aluminium sheet type 1050

| Chemical Element | % Present |

| Si | 0.25 |

| Fe | 0.4 |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Zn | 0.05 |

| Ti | 0.03 |

| Other (Each) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

Physical characteristics of aluminium sheet alloy 1050

| Physical Property | Value |

| Density | 2.71g/cm3 |

| Melting Point | 650°C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 71GPa |

| Thermal Conductivity | 222W/m.K |

| Electrical Resistivity | 0.0282 x10^-6 Ω.m |

| Mechanical Property | Value |

| Tensile Strength | 105 - 145 MPa |

| Proof Stress | 85 Min MPa |

| Hardness Brinell | 34HB |

| Elongation | A - 12 Min % |