Aluminum brazing welding material are usually used to wet and spread on the surface of the base metal, fill the gap between the base metal, and form metallurgical connections after cooling and solidification.

Chalco hot selling aluminum brazing welding material including clad aluminum brazing material and self-brazing aluminum material.Welcome contact

Chalco clad aluminum brazing welding material

Typical alloy composition of clad aluminum brazing materials

4045/3003/4045 4045/3003/7072 4045/3A11/4045 4045/7A11/7072 4045/6951/4045

Thickness: 0.05mm-6mm Width: 5mm -2200mm

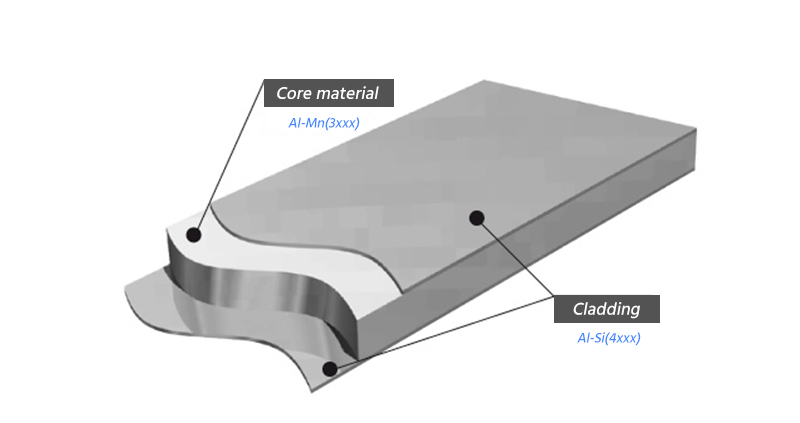

Clad aluminum brazing composite material, also known as Al Si brazing material, is the most widely used aluminum based brazing material. The form of clad aluminum brazing materials is clad aluminum plate, strip, foil, etc. Generally composed of core material and clad layer:

- Core materials are generally composed of aluminum manganese 3 series aluminum alloy, which plays the role of intensity support and heat dissipation.

- The cladding layer is composed of aluminum-silicon 4000 series alloy 4343, 4045, 4047 or other aluminum alloy, which plays a role in welding or improving the performance of the overall material.

Chalco hot selling clad aluminum brazing products

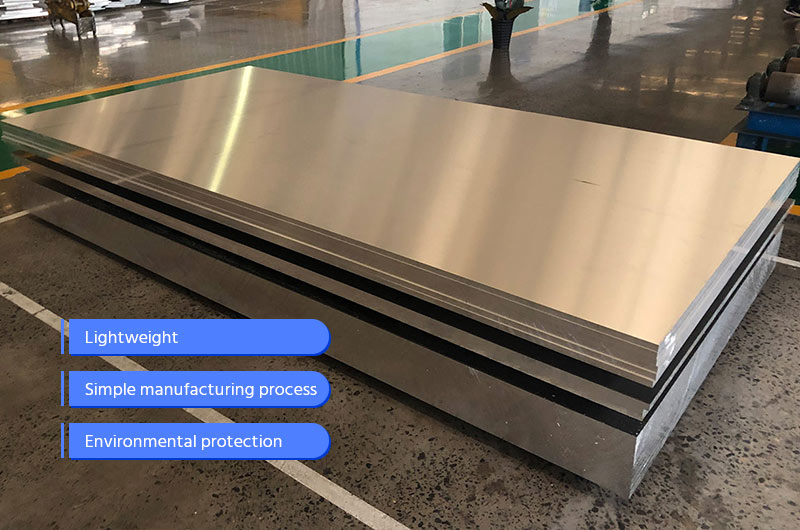

Clad aluminum brazing sheet

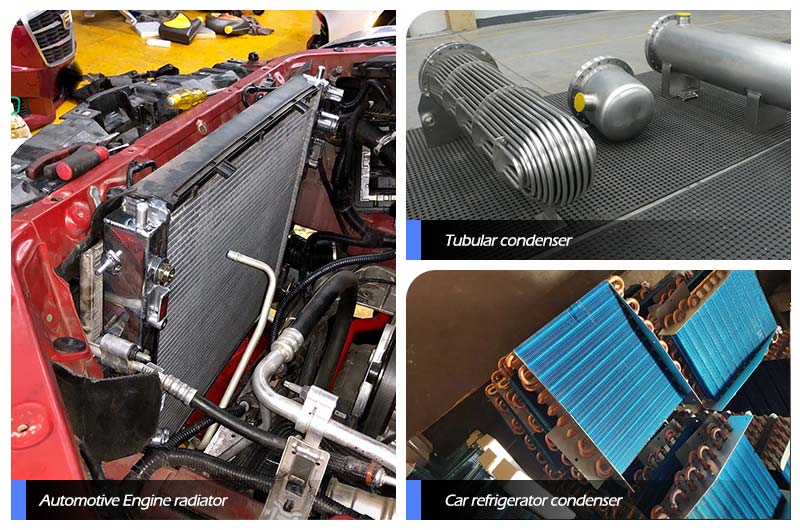

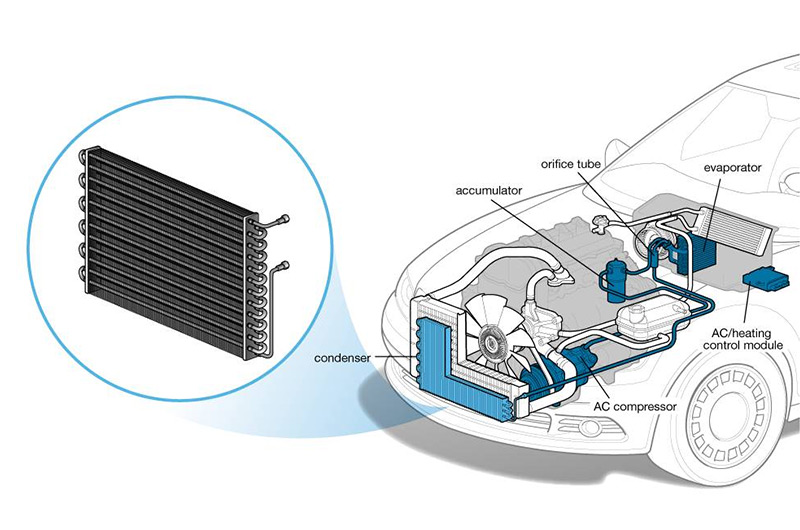

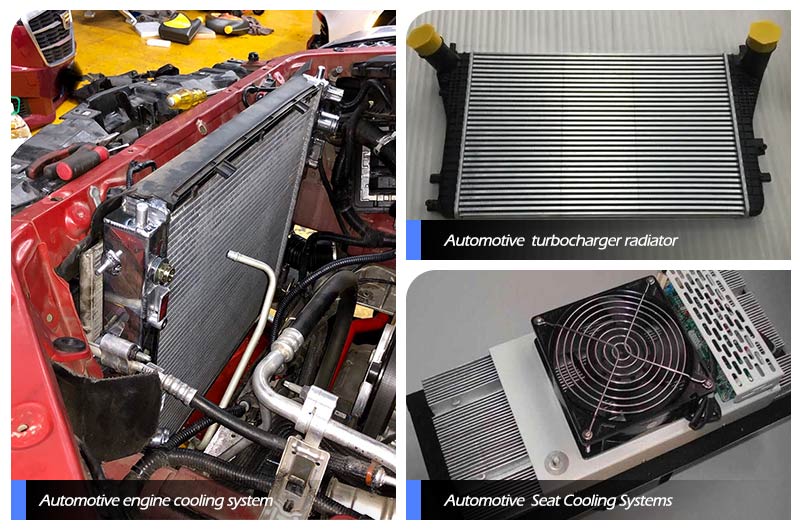

For automotive radiators, air conditioners, other heat exchangers...

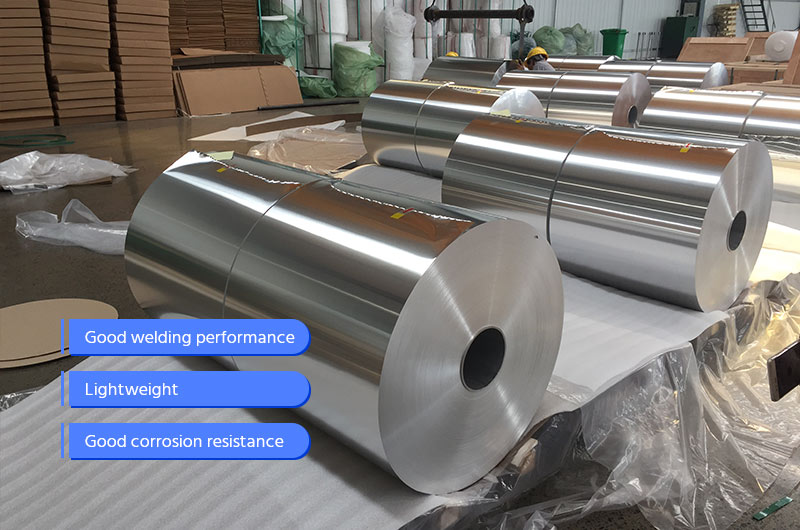

Clad aluminum brazing coil

Suitable for automotive air conditioners, refrigerator condensers...

Clad aluminum brazing foil

Used in battery, electronic device cooling, and aerospace applications...

The characteristics of brazing aluminum sheet foil coil strip

- The Aluminum Cladding Fin and Sheet have advantages of compact structure, high heat dissipation efficiency, and good collapse resistance;

- Aluminum brazing composite materials have good wettability and flowability;

- Aluminum Brazing Fin and Sheet have good corrosion resistance;

- Clad aluminum brazing sheet has good machinability.

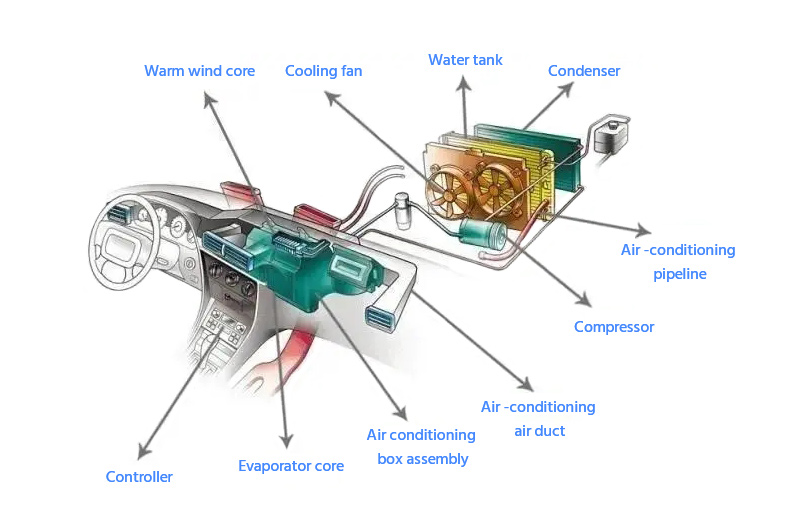

The application of brazing aluminum sheet foil coil strip

The brazing aluminum sheet foil coil strip are widely used in automotive heat exchange systems, such as engine radiators, engine oil radiator, medium refrigerator, air -conditioning condenser and evaporator etc.

Chalco hot selling aluminum products of brazing welding material

Utilizes induction or resistance heating to weld steel strips or plates, often requiring welding materials for seam filling to ensure quality.

Contact us now

Aluminum brazing welding fin

Used in radiators or coolers, produced via rolling and forming processes. Consideration for connections with other components may involve welding, using aluminum alloy brazing materials for filler and connection strength.

Contact us nowComposite microchannel aluminum round tube

Clad material: 4343/3003/7072

Application: typically used in the manufacture of automotive radiators and air conditioners, among other products requiring high strength and corrosion resistance.

Contact us now

-

4032 aluminum sheet coil block bar

Low coefficient of thermal expansion, excellent wear and corrosion resistance, and high temperature strength.

-

4043 brazing aluminum sheet foil coil strip

Good fluidity and less susceptibility to welding hot cracks; often used in welding wires for aluminum silicon alloys.

-

4343 brazing aluminum sheet coil block bar

Outstanding brazing, corrosion resistance, excellent thermal conductivity, suitable for high temperatures.

-

4004 brazing aluminum sheet foil coil strip

Used as the coating layer, often rolled together with 3003 aluminum to form composite materials.

-

4045 brazing aluminum sheet foil coil strip

Excellent welding performance and is often used as cladding layer for composite plates and composite fins.

-

4047 brazing aluminum sheet foil coil strip

Used as welding filler wire and fusion welding material; widely used in automobiles, air conditioning...

-

4A11 brazing aluminum sheet coil block bar

Malleability, castability, low coefficient of thermal expansion, good thermal strength and wear resistance.

-

4A13 brazing aluminum sheet foil coil strip

Commonly used as a hard solder for sheet and strip materials, and for the brazing layer of radiator.

-

4A17 brazing aluminum sheet foil coil strip

Good brazing performance and a lower melting point. Used for welding radiators and brazing layers.

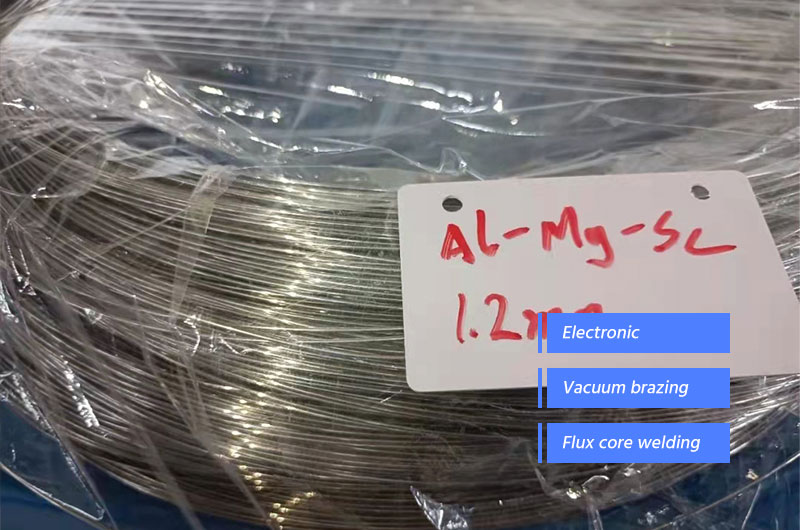

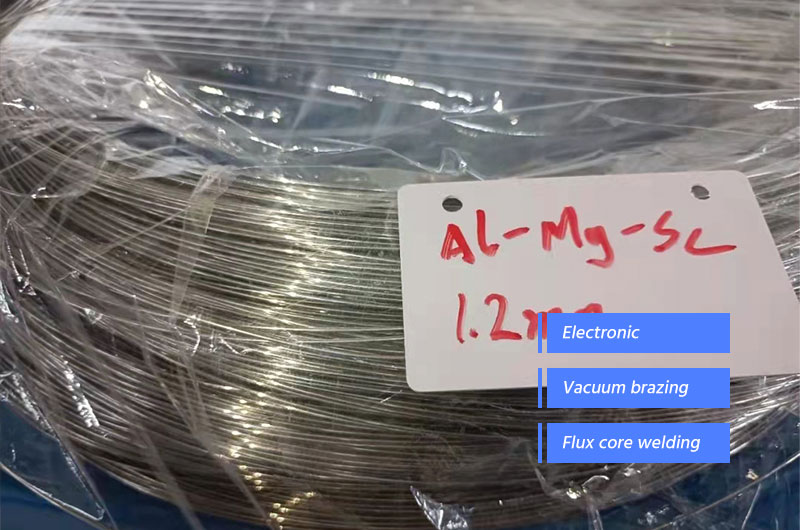

Chalco hot selling welding wire rod products

Aluminum welding wire rod

Welding wire rod is a filler material used in welding processes, supplied typically in the form of wire. It melts during welding to fill the weld joint and bond metal components together securely.

Contact us now

4043 4047 Aluminium Welding Wire Rod

ER5183 ER5356 Aluminum Welding Wire Rod

5556 5556A Aluminum Welding Wire Rod

Chalco self-brazing aluminum solder

Hot selling alloy of Chalco self-brazing aluminum solder

1060, 1100, 3003, 3026, 5052, 6061, 6063

Aluminum self brazing filler metal can be made into wire, ring, sheet, etc. with a diameter of 1.4-2.5.

Self-brazing aluminum solder are mainly used in welding of aircraft engine groups, automotive air -conditioning heat exchangers, refrigerated air-conditioning all-aluminum evaporator, condenser, refrigerator freezer, electric aluminum bar and aluminum alloy tubes etc. This product has the following three features:

- There is no need for welding paste and welding flux during welding, with the advantage of environmentally friendly and efficient.

- Easily docking the current automation production process requirements.

- There is no corrosive residue after welding, no need to clean.

Production capacity of Chalco aluminum brazing welding material

- The raw material for Clad Aluminum Sheet production is aluminum ingot or large flat ingot. The use of large flat ingots can save the aluminum ingot melt. The production links mainly include four processes: melting, hot rolling, cold rolling, and refinement.

- In the melting and casting process, the aluminum ingot and other trace metals are matched and purified, and heated in the melting and casting furnace to reach the melting temperature, and then combined and purified to form aluminum alloy.

- The final form of the product is aluminum cladding brazing sheet plate, aluminum cladding brazing Coil strip, aluminum brazing foil. These products are then sent to downstream customers for stamping and welding processes. Finally, various heat exchangers are formed.

Choose Chalco as the aluminum brazing welding material supplier

We have more than 30 years of experience in supplying clad aluminum brazing material, self-brazing Aluminum solder and aluminum soldering paste powder for brazed heat exchangers, intercoolers, air conditioner condensers and evaporators etc. and today we have Rolled aluminum for appliances and other niche markets to become a global player.

We have a complete set of domestic advanced aluminum brazing materials research and development, testing and analysis instruments, which guarantees the efficiency of new product research and development and accelerates the transformation of scientific and technological achievements. In addition, our R&D & innovation and validation capabilities can help enhance our customers' competitiveness by saving time and costs in new product development and marketing.

We have passed the IATF16949 certification required by the automotive industry, the AS9100 certification required by the aviation industry, and the DNV BV LR ABS RINA CCS certification required by the shipbuilding industry etc.

The Chalco brand stands for quality, delivery and a strong reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.