Chalco produces high-strength aluminum alloy wires for overhead aluminum stranded wires, high-strength 6101 aluminum alloy wires, 6201 aluminum alloy wires, 6061 aluminum alloy wires, 8006 aluminum alloy wires, 8030 aluminum alloy wires, 8176 aluminum alloy wires, etc. With high mechanical strength and electrical conductivity.

Chalco high-strength aluminum alloy wires are widely used in overhead lines to provide reliable power transmission and distribution, and are suitable for power transmission and communication fields.

Chalco can customize high-strength aluminum alloy wires of various sizes and supply them to one of the world-renowned power company suppliers such as SIEMENS, HITACHI (ABB), TOSHIBA, LEGRAND, and EATON.

Chalco high-strength aluminum alloy wire common specifications

| Alloy | 6061 6101 6021 8006 8030 8176 |

| Aluminum wire diameter range (mm) | 0.2-6.0 |

| Remark | Customizable diameter |

| Diameter tolerance |

Diameter d≤3.0 ±0.03mm Diameter d>3.00 ±1% |

| The production standard of aluminum alloy 6061 line | GB/T23308-2009/IEC 60104, ASTM B317,GB/T 3956, ASTM B398,ASTM B399 |

| Take-up spool size of Chalco high strength aluminum alloy wire |

Outer Diameter (OD): 200mm, 250mm, 300mm, 400mm, 500mm, 600mm Inner Diameter (ID): 50mm, 76mm, 100mm, 127mm, 150mm Height: 100mm, 150mm, 200mm, 250mm, 300mm In actual use, the appropriate size of the aluminum alloy reel should be selected according to the specific wire length, weight and handling requirements. At the same time, factors such as the load-bearing capacity, storage and transportation conditions of the wire reel need to be considered to ensure the safety and effectiveness of the wire. |

| Surface treatment of aluminum alloy wire |

Coated with industrial white oil. The surface of the high-strength aluminum alloy wire produced by Chalco is coated with industrial white oil, which is a special lubricant, which is usually used to reduce surface friction and prevent adhesion between wires. Coating industrial white oil can improve the surface quality of the aluminum alloy wire, make the surface smooth, reduce friction with the surrounding environment, and improve the smoothness of the wire. This is especially important for applications such as overhead stranded wires as it reduces the risk of back wires and keeps the wire in good condition. |

Chemical composition of Chalco high strength aluminum alloy wire

| Chemical composition | ||||||

| Alloy | 6061 | 6101 | 6021 | 8006 | 8030 | 8176 |

| Si | 0.4-0.8% | 0.30-0.6% | 0.9-1.2% | 0.4-0.8% | 0.7-1.3% | 0.6-1.0% |

| Mg | 0.8-1.2% | - | 0.8-1.3% | 0.8-1.3% | 0.8-1.5% | 0.8-1.4% |

| Fe | 0.7% max | 0.10% max | 0.7% max | 0.50% max | 0.7% max | 0.70% max |

| Cu | 0.15-0.4% | 0.03-0.05% | 0.10-0.30% | 0.10-0.30% | 0.10-0.30% | 0.10-0.25% |

| Mn | 0.15% max | 0.03% max | 0.50-1.1% | 0.20-0.60% | 0.10% max | 0.15% max |

| Zn | 0.25% max | 0.10% max | 0.25% max | 0.10% max | 0.10% max | 0.10% max |

| Cr | 0.04-0.35% | 0.03% max | 0.10% max | 0.10% max | 0.10% max | 0.10% max |

| Ti | 0.15% max | - | - | - | - | - |

| Other elements |

0.05% each 0.15% total |

0.05% each 0.15% total |

0.05% each 0.15% total |

0.05% each 0.15% total |

0.05% each 0.15% total |

0.05% each 0.15% total |

Mechanical properties of Chalco high strength aluminum alloy wire

| Alloy | Temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Conductivity (% IACS) |

| 6061 | T6 | 240 | 210 | 12 | 40-45 |

| 6101 | T61 | 180-250 | 130-190 | 8-20 | 52-55 |

| 6101 | T81 | 180-250 | 130-190 | 8-20 | 52-55 |

| 6021 | T4 | 180-220 | 120-180 | 8-12 | 50-52 |

| 6021 | T6 | 180-220 | 120-180 | 8-12 | 50-52 |

| 8006 | O | 160-220 | 150-200 | 4-8 | 53-55 |

| 8006 | H18 | 160-220 | 150-200 | 4-8 | 53-55 |

| 8030 | O | 160-220 | 150-200 | 4-8 | 53-55 |

| 8030 | H18 | 160-220 | 150-200 | 4-8 | 53-55 |

| 8176 | O | 160-220 | 150-200 | 4-8 | 53-55 |

| 8176 | H18 | 160-220 | 150-200 | 4-8 | 53-55 |

Please note that these values are general ranges and may vary depending on factors such as manufacturer, product specification and manufacturing process. In actual application, please refer to specific product specifications and data provided by suppliers.

Physical properties of aluminum-magnesium-silicon alloy round wire for overhead stranded wire

| Model | LHA1 | LHA2 |

| Conductivity | 52.5% IACS | 53% IACS |

| Density at 20℃/ (g/cm3 ) | 2.703 | 2.703 |

| Coefficient of linear expansion/ (10-6/℃) | 23 | 23 |

| Temperature Coefficient of Resistance at 20°C / (1/°C) | 0.0036 | 0.0036 |

Mechanical properties of aluminum-magnesium-silicon alloy round wire for overhead stranded wire

| Diameter d/mm | LHA1 | LHA2 | ||

| Tensile strength/Mpa | Elongation after break (%) | Tensile strength/Mpa | Elongation after break (%) | |

| ≤3.50 | 325 | 3.0 | 295 | 3.5 |

| >3.50 | 315 | |||

Application of high-strength aluminum alloy wire for overhead line conductors

6061 aluminum alloy wire has good mechanical properties and weldability, and is widely used in high-strength overhead aluminum stranded wire. It has excellent corrosion resistance and electrical conductivity.

6201 aluminum alloy wire is a special aluminum alloy in which copper is added as an alloying element. This alloy has higher strength and electrical conductivity and is suitable for overhead lines under high load conditions.

6101 aluminum alloy wire is a high-strength aluminum alloy wire with good electrical conductivity and oxidation resistance. It is commonly used in power transmission lines and electrical applications.

8006 aluminum alloy wire belongs to the 8000 series aluminum alloy wire, which contains alloy elements such as lithium and copper. It has good electrical conductivity and high mechanical strength, and is suitable for overhead lines under high load conditions.

8030 aluminum alloy wire also belongs to the 8000 series aluminum alloy, which contains lithium, copper and other alloying elements. It has high strength and good corrosion resistance and is often used in transmission lines and power applications.

8176 aluminum alloy wire is also a high-strength aluminum alloy in the 8000 series, which contains alloying elements such as lithium and copper. It has high electrical conductivity and mechanical strength, and is suitable for long-distance transmission lines and high-load conditions.

High strength aluminum alloy wire price

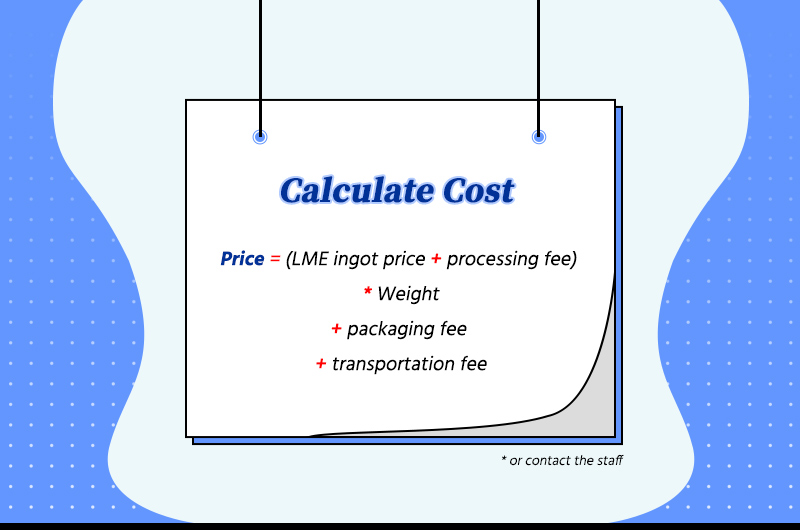

Price of high-strength aluminum alloy wire:

(LME ingot price + processing fee) x weight + packaging fee + transportation fee

The price of high-strength aluminum alloy wire will be affected by many factors, such as market supply and demand, raw material prices, processing costs, specifications, and other factors. Different manufacturers and suppliers may have different pricing strategies and price levels. In addition, it is also affected by factors such as currency exchange rate and international economic situation.

Therefore, please contact Chalco aluminum for inquiry, we will provide you with the best quotation and service.

Matters needing attention when purchasing high-strength aluminum alloy wire

Aluminum alloy wire material quality: ensure that the purchased aluminum alloy wire complies with relevant national or regional standards, and has good quality and reliability. High-quality aluminum alloy wire should have good strength, electrical conductivity and corrosion resistance.

Aluminum alloy wire specification and size: according to specific application requirements, select the appropriate specification and size of aluminum alloy wire. This includes considerations of wire diameter, cross-sectional area, conductor construction, etc. to ensure that the required current transfer and mechanical strength requirements are met.

Production standard of aluminum alloy wire: understand the production standard of the purchased aluminum alloy wire to ensure that it complies with relevant industry norms and requirements. Common production standards include national standards, ASTM standards, etc., which can be confirmed by checking the certificate or asking the supplier.

Aluminum alloy wire supplier reputation: choose a reputable and experienced supplier or manufacturer to purchase aluminum alloy wire to ensure product quality and supply stability. You can check the supplier's qualifications and customer testimonials, or ask other professionals or users for their experiences and opinions.

Aluminum alloy wire technical support: If necessary, ensure that the supplier can provide appropriate technical support and consulting services, including advice and guidance on aluminum alloy wire selection, installation and maintenance.

Cost-effectiveness of aluminum alloy wire: in addition to considering the quality and performance of aluminum alloy wire, cost-effectiveness should also be considered comprehensively. Compare the prices and delivery terms of different suppliers to choose reasonable prices and quality products.

Aluminum alloy wire safety certification: find out whether the aluminum alloy wire complies with relevant safety certification requirements, such as ISO certification or other industry standards. This helps ensure product reliability and compliance with safety requirements.

To sum up, when purchasing high-strength aluminum alloy wires for overhead aluminum wires, you need to pay attention to factors such as material quality, specifications, production standards, supplier reputation, technical support, cost-effectiveness, and safety certification to ensure that you choose the right one. products and meet specific application requirements.