Aluminum foil in Chalco Aluminum is a kind of aluminum foil directly rolled into thin sheets with a thickness of less than 0.2mm. The rolling of Chalco Aluminum aluminum foil is divided into three processes: rough rolling, intermediate rolling and finishing rolling. From the process point of view, it can be roughly divided from the thickness of the rolling outlet: generally, the thickness of the outlet is greater than or equal to 0.05mm is rough rolling; the thickness of the outlet is between 0.013mm and 0.05mm is medium rolling; the finished products of single sheet and double rolling with the outlet thickness less than 0.013mm are finish rolling.

Advantages of aluminum foil products in Chalco Aluminum

- The surface of the aluminum foil is uniform in color, clean and flat, without obvious roll marks, pits, pinholes and corrosion marks.

- There are no rolling defects such as creases, mottles, bright lines on the surface of the aluminum foil.

- There is no color difference on the surface of aluminum foil.

- No oil on the surface, no serious oil odor, no visible oil spots.

Classification of aluminum foil in Chalco Aluminum

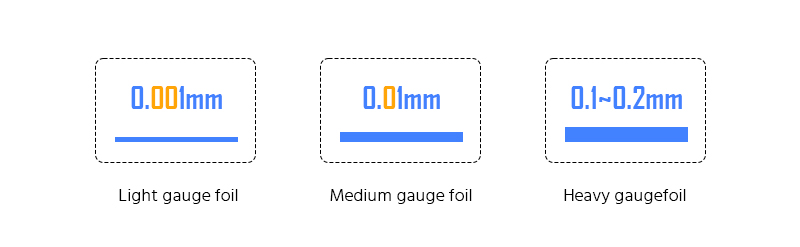

Classification according to the thickness difference

Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the thickness difference.

| Thick foil (heavy gaugefoil) | foil with a thickness of 0.1 to 0.2 mm |

| Single zero foil (medium gauge foil) | foil with a thickness of 0.01mm and less than 0.1mm |

| Double zero foil (light gauge foil) | 0.005~0.009mm (less than 0.01) |

Classification according to the temper

Aluminum foil can be divided into rigid foil, semi-hard foil and soft foil according to the temper.

Hard foil:

The aluminum foil that has not been softened (annealed) after rolling, and has no residue on the surface when it is not degreasing. Therefore, the hard foil must be degreased before printing, lamination, and coating, and it can be used directly if it is used for forming.

Semi-hard foil:

aluminum foil whose hardness (or strength) is between hard foil and soft foil, usually used for forming.

Soft foil:

Aluminum foil that has been fully annealed and softened after rolling. The material is soft and there is no residual oil on the surface. Most applications, such as packaging, lamination, electrical materials use flexible foils.

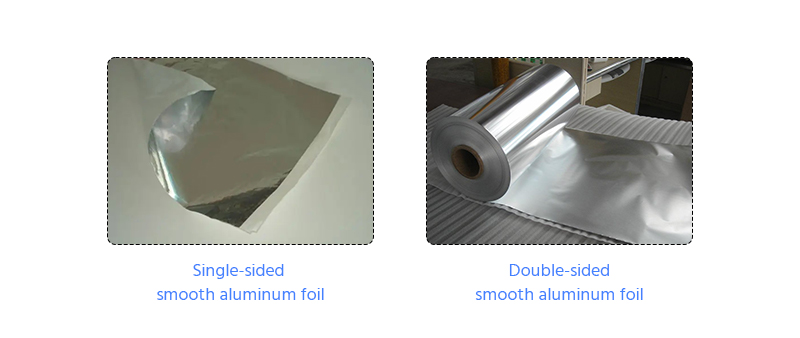

Classification according to the surface state

Aluminum foil can be divided into single sided smooth aluminum foil and both sided smooth aluminum foil according to the surface state.

Single-sided smooth aluminum foil:

double-rolled aluminum foil, one side is bright after sub-rolling, and the other side is black, such aluminum foil is called single-sided smooth aluminum foil. The thickness of one side light aluminum foil is usually not more than 0.025mm.

Double-sided smooth aluminum foil:

single rolled aluminum foil, both sides are in contact with the roll, and the two sides of the aluminum foil are divided into mirror two-sided smooth aluminum foil and ordinary two-sided smooth aluminum foil due to the different surface roughness of the roll. The thickness of the two-sided glossy aluminum foil is generally not less than 0.01mm.

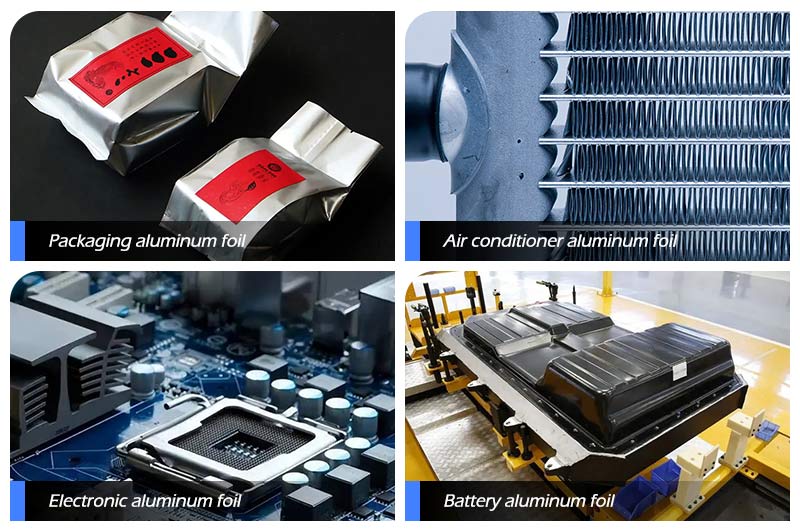

The application of aluminum foil in Chalco Aluminum

Packaging aluminum foil: Aluminum foil has outstanding properties of impermeability (especially for oxygen and water vapor) and light-shielding properties. It also has the characteristics of shape retention and rigidity. Packaging food with aluminum foil can prevent air from entering the food packaging bag.

Air conditioning Aluminum foil: Aluminum is widely used due to its advantages of low density, good thermal conductivity, easy processing, odorless, environmental protection and low price. The use of aluminum foil to make thermal conductive fins for air conditioning heat exchangers is one of the representatives.

Electronic aluminum foil: refers to the light foil, which is the key raw material for the production of aluminum electrolytic capacitors. Due to the sequence of the production process, it is divided into electronic aluminum foil and electrode foil.

The electrode foil includes corrosion foil and chemical foil.

Capacitor foil is a corrosive material that works under polar conditions, and has high requirements on the structure of the foil. There are three types of aluminum foils used: cathode foil with a thickness of 0.015-0.06mm, high-voltage anode foil with a thickness of 0.065-0.1mm, low voltage anode foil with a thickness of 0.06-0.1mm. The anode foil is made of industrial high-purity aluminum, and the mass fraction should be greater than or equal to 99.93%, while the purity of aluminum used for high-voltage anodes should be greater than or equal to 4N.

Battery Aluminum Foil: this kind of aluminum foil is used as a current collector for Li-ion batteries. Typically, the lithium-ion battery industry uses rolled aluminum foil as the positive current collector. Rolled foil thicknesses vary from 10 to 50 microns. The pure aluminum foil commonly used for lithium battery has various alloy grades such as 1060, 1050, 1145, 1235 and has states such as -O, H14, -H24, -H22, -H18.

Common aluminum foil alloy grades in Chalco Aluminum

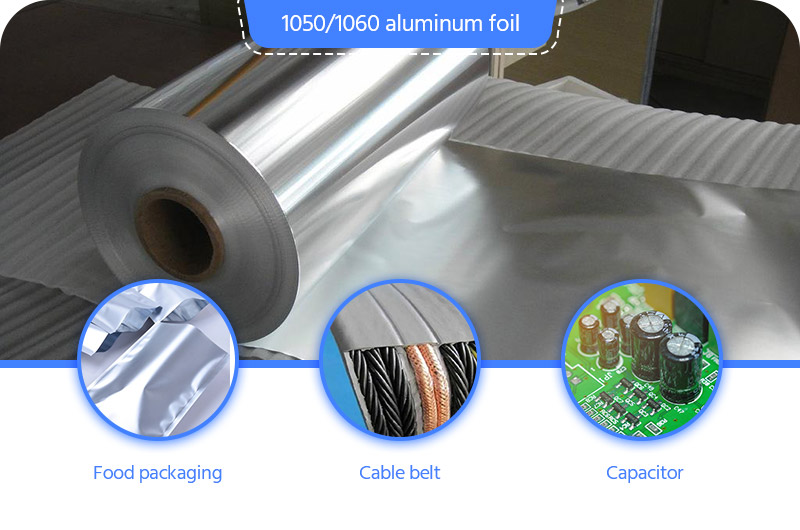

1050/1060 Aluminum Foil

| Thickness | 0.03mm-0.2mm |

| Width | 300mm-1650mm |

| Temper | HO/H22/H24/H18 etc |

Mainly used in food packaging, cable tapes, capacitors, etc.

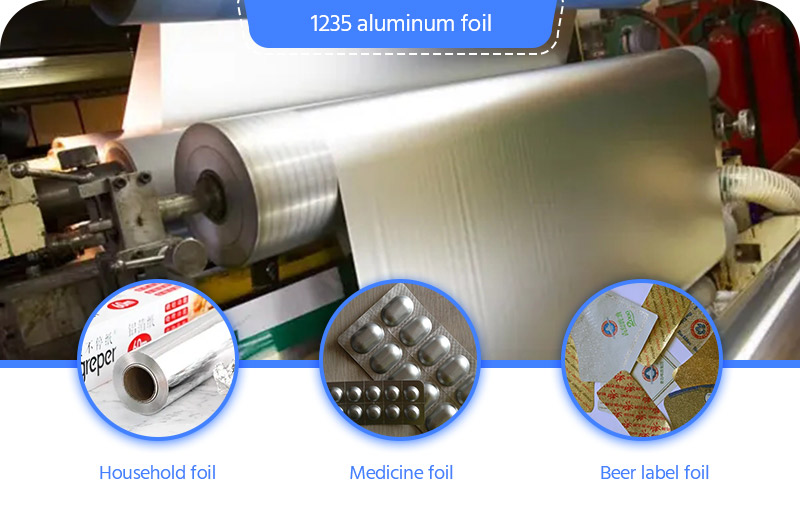

1235 aluminum foil

| Thickness | 0.006mm-0.2mm |

| Width | 250mm-1650mm |

| Temper | HO/H22/H24/H18/H26/H19 etc |

Chalco Aluminum ALLOY 1235 has mature production technology, stable quality, and excellent mechanical properties such as elongation and tensile strength. It is mainly used in household foils, container foils, medicine foils, soft packs, heat sealing, beer standard single and double zero foil blank, cable tape blanks, bottle caps, aluminum-plastic panels, curtain wall panels, etc.

3003 3004 aluminum foil

| Thickness | 0.03mm-0.2mm |

| Width | 300mm-1650mm |

| Temper | HO/H22/H24/H14/H26/H18 etc |

Chalco Aluminum ALLOY 3003 3004 is the most widely used anti-rust aluminum, with moderate strength, good corrosion resistance, good weldability, and excellent product characteristics such as ductility changes with cold processing and heat treatment. They have been mainly used in container lunch boxes, food packaging foils, electronic foils as well as roofing color coatings, deep-drawing wafers, glass spacers, curtain wall panels, battery shells, high-frequency welded pipe materials, etc.

3004 aluminum foil is a kind of Al-Mn alloy, adding the strengthening element magnesium. It has the advantages of 3003 alloy, and at the same time has higher strength than 3003 alloy, and has good formability, solubility and corrosion resistance.

5052 aluminum foil

| Thickness | 0.03mm-0.2mm |

| Width | 300mm-1650mm |

| Temper | HO/H24/H32/H34 etc |

Chalco Aluminum ALLOY 5052 aluminum foil belongs to Al-Mg alloy, which is widely used and is a promising aluminum alloy. It has the advantage of high strength, especially high fatigue strength, high plastic rust and corrosion resistance, good weldability, poor machinability, and polishability. 5052 aluminum foil is mainly used in container lunch boxes, cans, umbrella frames, trolley cases, door handles, high-end signs, etc.

8006 8011 aluminum foil

| Thickness | 0.08mm-0.2mm |

| Width | 250mm-1650mm |

| Temper | HO/H22/H24/H18/H26 etc |

Chalco Aluminum ALLOY 8006 8011 alloy aluminum foil products have the characteristics of high strength, excellent elongation and rolling performance. The product is smooth, flat, not easy to deform and has extremely high moisture resistance, fresh-keeping performance. It is the quality materials used for making lunch boxes, egg tart trays, etc. 8006 8011 aluminum foil is mainly used in household foil, container foil, medicine foil, food packaging, etc.

8079 aluminum foil

| Thickness | 0.006mm-0.2mm |

| Width | 250mm-1650mm |

| Temper | HO/H22/H24/H18/H26 etc |

Chalco Aluminum ALLOY 8079 alloy aluminum foil products have the characteristics of high strength, excellent elongation and rolling performance, high moisture resistance, fresh-keeping performance, and not easy to deform. 8079 aluminum foil is mainly used in medicine foil, food packaging, household foil, container foil, etc.