7055 aluminum aircraft sheet has the characteristics of high strength, high corrosion resistance, high impact, widely used in the field of aerospace. Mainly used as wing, fuselage, engine housing, landing gear and engine room interior parts.

Why Choose Chalco's 7055 aviation sheet

Standard for aluminum 7055 aviation sheet

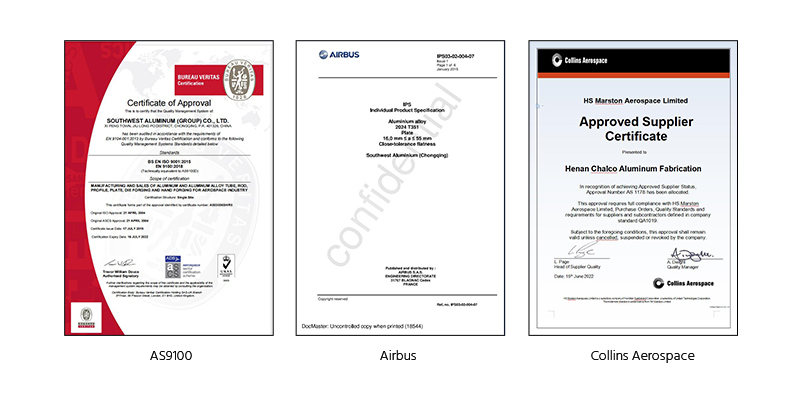

Chalco aluminum is a professional manufacturer of aluminium sheet for aviation, with AS9100 aerospace certification and strict compliance with the following aviation standards.

AMS (Aerospace Material Specification) is the acronym for the Aerospace Material Specification of the United States, which applies mainly to the aerospace industry. SAE AMS 4206 specifies the standard specification for 7055-T7751 aluminum alloy sheet, including the chemical composition, mechanical properties, machinability, corrosion properties and other requirements of the material.

MIL Standards: MIL (Military Standards) is an abbreviation of the United States Military Standards, including requirements for the design, production, and testing of military products. MIL-HDBK-5 is a manual on metal materials, including 7055-T7751 aluminum alloy sheet related specifications and test methods.

Chalco's accreditations

AS9100

OHSAS 18001

ISO14001

ISO 45001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

Specification of 7055 T7751 aluminum sheet

| Thickness(mm) | 0.5-600 |

| Width(mm) | <2650 |

| Length(mm) | <8000 |

| Standard | GB/T3880, GJB1541, GJB2662, STMB209, EN485, ASTM B209, AMS 4206, QQ-A-250, MIL-HDBK-5 |

Chemical composition of 7055 aluminum aerospace plate

| Element | Composition(%) |

| Al | Remainder |

| Si | ≤0.10 |

| Fe | ≤0.15 |

| Cu | 2.0-2.6 |

| Mn | ≤0.50 |

| Mg | 1.8-2.3 |

| Cr | ≤0.04 |

| Ni | / |

| Zn | 7.6-8.4 |

| Ti | ≤0.06 |

| Zr | 0.05-0.25 |

| Other | Single:≤0.05 Total:≤0.15 |

Mechanical properties of 7055 T7751 aluminum plate

7055 aviation aluminum alloy plate is a kind of high strength aluminum alloy material, its mechanical performance is excellent, the common mechanical property parameters include the following aspects:

Tensile strength: at room temperature, the tensile strength of 7055 aluminum plate is generally between 600 MPa and 680 MPa.

Yield strength: at room temperature, the yield strength of 7055 aluminum plate is generally between 480 MPa and 510 MPa.

Elongation: at room temperature, the elongation of 7055 aluminum plate is generally between 6% and 7%.

Impact toughness: 7055 aluminum plate impact toughness is better, can reach 45 J/cm2 above.

Advantages of Chalco high strength T7751 aircraft sheet

High strength

The strength of 7055 aluminium plate is about twice higher than that of traditional aviation aluminum alloy, which can withstand higher loads and more severe working conditions.

Good corrosion resistance

The corrosion resistance of 7055 aviation aluminum plate is several times that of ordinary aluminum alloy, and it can be used for a long time in harsh environment.

Good machinability

7055 aluminum aerospace alloy can adopt traditional metal processing technology, such as milling, drilling, cutting and bending, which is convenient for manufacturing and processing.

High impact resistance

The impact resistance of 7055 aluminum aircraft alloy is 30-50% higher than that of ordinary aluminum alloy.

Good weldability

7055 aluminum alloy plate can be connected by conventional welding methods, which is convenient for manufacturing and maintenance.

Lightweight

Although 7055 T7751 aluminum plates has very high strength, its density is still lighter than many other metals, which makes it an ideal material in the aviation and aerospace industry. It can reduce the weight of the entire aircraft or spacecraft, thus improving fuel efficiency and performance.

Selling points of Chalco 7055 aluminium plate for aviation

Lightweight design

7055 aircraft aluminum alloy plate has high strength and excellent machinability, which can make lighter, stronger and safer aircraft structural components, thus reducing the weight of the entire aircraft and improving fuel efficiency and performance.

Improve flight speed

7055 high -strength aluminum alloy plate has better tensile strength and elastic modulus, which can reduce the deformation of aviation structural components, thus improving flight speed and flight height.

Improve flight safety

The high strength and high impact resistance of 7055 aluminum aviation alloy plate can enhance the bearing capacity and durability of aircraft structural components and improve flight safety.

Improve flight economy

Aviation structural components made of China-Aluminum 7055 T7751 aluminum alloy plate can reduce the weight of the whole aircraft, thus reducing fuel consumption and improving flight economy.

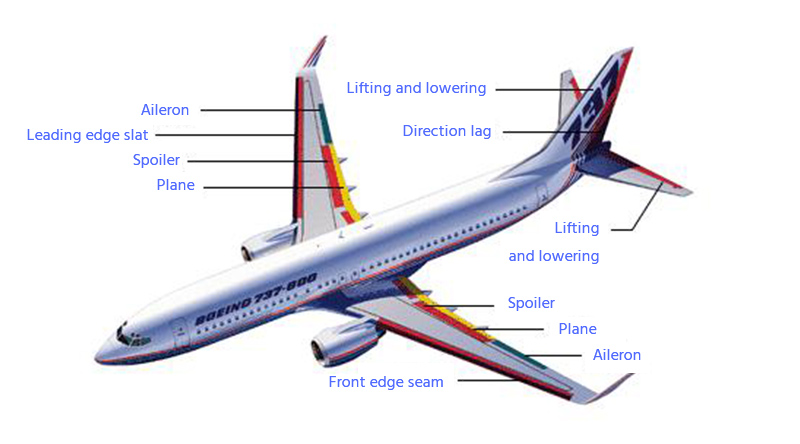

Applications of aluminum 7055 aviation plate

As a kind of high strength and corrosion resistant aluminum alloy material, 7055 aluminum aircraft plates are widely used in the aviation industry. The following are common applications of 7055 aluminum sheet in aircraft.

Aerospace structural components

7055 aluminium alloy is used in a wide range of aerospace structures, such as wings, fuselages, engine housings, landing gear and cabin interior parts.

Structural parts of fuselage

7055 aviation sheet can be used to manufacture structural parts of aircraft fuselage, such as fuselage shell, bottom cover plate, porthole frame, etc.

Wing body joints

7055 aluminum aerospace plates can be used to manufacture structural parts for wing body joints, such as those connecting the wing to the fuselage, and structural parts connecting horizontal and vertical stabilizers.

Landing gear

7055 high strength aluminum can be used to manufacture the structural components of landing gear, such as struts, connecting plates and protective covers.

Engine parts

High strength T7751 aircraft sheet can be used to manufacture aircraft engine parts such as hoods, intakes, fuel tanks and turbine blades.

In short, 7055 aluminum high strength aircraft sheet is widely used in the aviation industry manufacturing in a variety of structural components and fuselage shell and other fields to improve the strength and durability of the aircraft, while reducing the weight of the entire aircraft, improve its fuel efficiency and performance.

Other using fields

As a kind of high strength aluminum alloy, 7055 aluminum plate for aviation is also widely used in defense, shipbuilding and other fields.

Combat Vehicles: 7055 aluminum metal sheet is used in a wide range of military vehicles, including tanks, armored vehicles and military helicopters.

Shipbuilding: The high strength and corrosion resistance of 7055 aluminium sheets make it an ideal material for shipbuilding, such as hulls and ship plates.

Other applications: 7055 alloy aluminum plates can also be used to make high-speed trains, sports car bodies and electronic equipment casings.