6061 profile is an aluminum alloy with magnesium and silicon as the main alloy elements. It has good mechanical properties, processing properties, welding properties and corrosion resistance. Its commonly used standards include GB/T 5236-2019, DL/T 8117-2015, ASTM B221-18 and EN 755-2:2019.

6061 profile has also obtained various certifications, including aviation certification NADCAP, automotive certification IATF 16949, railway certification IRIS and ship certification ABS, CCS, BV, GL.Quick Quote

Aluminum profile production shipin

6061 aluminum profile shape & specification

6061 profiles refer to extruded products made from 6061 aluminum alloy. They can be classified into the following categories based on shape:

- Tubing: round tubing, square tubing, rectangular tubing, and special-shaped tubing. Tubing is commonly used in industries such as construction, transportation, machinery, and power.

- Rods: round rods, square rods, rectangular rods, etc. Rods are commonly used in mechanical manufacturing, mold making, instrumentation, and other industries.

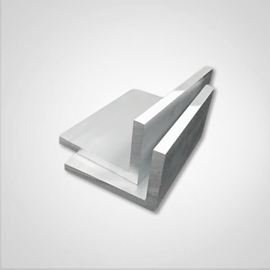

- Structural shapes: flat bars, round bars, angle bars, channel bars, I-beams, etc. Structural shapes are commonly used in construction, vehicles, ships, and other industries.Quick Quote

determined by national standards or industry standards. Common product specifications include:

- Tubing: diameter range from 6mm to 450mm, wall thickness range from 0.5mm to 12mm.

- Rods: diameter range from 6mm to 350mm.

- Structural shapes: thickness range from 0.5mm to 100mm, width range from 10mm to 1200mm.

6061 Popular profile products and stock sizes

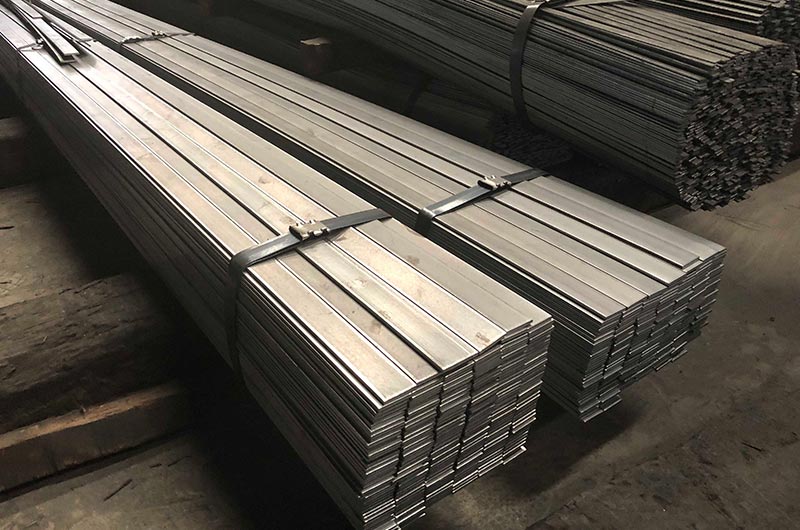

6061-aluminum-flat-bar

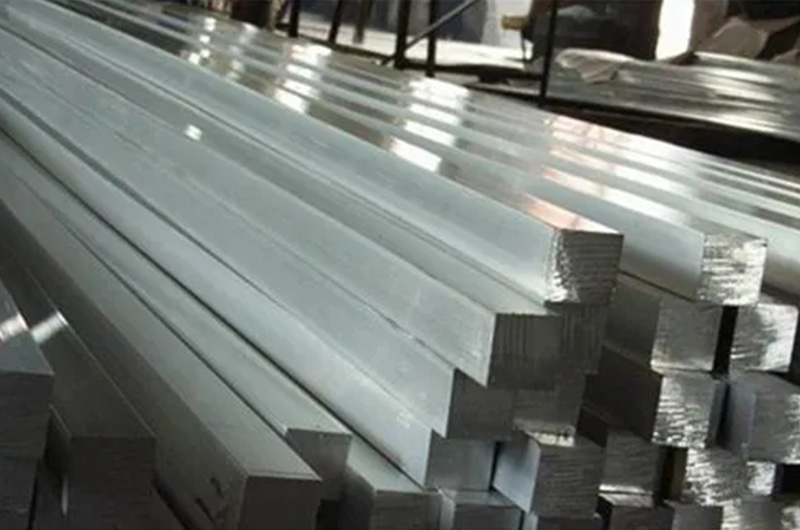

6061-aluminum-square-bar

6061-aluminum-hex-bar

6061-aluminum-tube

6061-aluminum-round-bar

6061-aluminum-square-tub

6061-aluminum-tube

| Description | ID (in) | Length |

| 1/2" ID X SCH 40 6061-T6 Aluminum pipe | 1/2" | Custom cutting available |

| 3/4" ID X SCH 40 6061-T6 Aluminum pipe | 3/4" | Custom cutting available |

| 1"ID X SCH 40 6061-T6 Aluminum pip | 1"ID | Custom cutting available |

| 1-1/4" ID X SCH 40 6061-T6 Aluminum pipe | 1-1/4" | Custom cutting available |

| 1-1/2" ID X SCH 40 6061-T6 Aluminum pipe | 1-1/2" | Custom cutting available |

| 2" ID X SCH 40 6061-T6 Aluminum pipe | 2" | Custom cutting available |

| 2-1/2" ID X SCH 40 6061-T6 Aluminum pipe | 2-1/2" | Custom cutting available |

| 3" ID X SCH 40 6061-T6 Aluminum pipe | 3" | Custom cutting available |

| 4" ID X SCH 40 6061-T6 Aluminum pipe | 4" | Custom cutting available |

| 6" ID X SCH 40 6061-T6 Aluminum pipe | 6" | Custom cutting available |

| 8" ID X SCH 40 6061-T6 Aluminum pipe | 8" | Custom cutting available |

| 10" ID X SCH 40 6061-T6 Aluminum pipe | 10" | Custom cutting available |

| 12" ID X SCH 40 6061-T6 Aluminum pipe | 12" | Custom cutting available |

| 3" ID X SCH 80 6061-T6 Aluminum pipe | 3" | Custom cutting available |

| 4" ID X SCH 80 6061-T6 Aluminum pipe | 4" | Custom cutting available |

| 6" ID X SCH 80 6061-T6 Aluminum pipe | 6" | Custom cutting available |

| 8" ID X SCH 80 6061-T6 Aluminum pipe | 8" | Custom cutting available |

| 10" ID X SCH 80 6061-T6 Aluminum pipe | 10" | Custom cutting available |

| 12" ID X SCH 80 6061-T6 Aluminum pipe | 12" | Custom cutting available |

6061 Aluminum Bar

| Description | ID (in) | Length |

| 6 mm 6061 Aerospace aluminum bar | 6 mm | Custom cutting available |

| 10 mm 6061 Aerospace aluminum bar | 10 mm | Custom cutting available |

| 12 mm 6061 Aerospace aluminum bar | 12 mm | Custom cutting available |

| 16 mm 6061 Aerospace aluminum bar | 16 mm | Custom cutting available |

| 20 mm 6061 Aerospace aluminum bar | 20 mm | Custom cutting available |

| 25 mm 6061 Aerospace aluminum bar | 25 mm | Custom cutting available |

| 30 mm 6061 Aerospace aluminum bar | 30 mm | Custom cutting available |

| 40 mm 6061 Aerospace aluminum bar | 40 mm | Custom cutting available |

| 50 mm 6061 Aerospace aluminum bar | 50 mm | Custom cutting available |

| 80 mm 6061 Aerospace aluminum bar | 80 mm | Custom cutting available |

| 100 mm 6061 Aerospace aluminum bar | 100 mm | Custom cutting available |

6061-T6 aluminum flat bar

| Description | Thickness mm | Size |

| 3 mm 6061 Aerospace flat bar | 3 mm | Custom cutting available |

| 4 mm 6061 Aerospace flat bar | 4 mm | Custom cutting available |

| 5 mm 6061 Aerospace flat bar | 5 mm | Custom cutting available |

| 6 mm 6061 Aerospace flat bar | 6 mm | Custom cutting available |

| 8 mm 6061 Aerospace flat bar | 8 mm | Custom cutting available |

| 10 mm 6061 Aerospace flat bar | 10 mm | Custom cutting available |

| 12 mm 6061 Aerospace flat bar | 12 mm | Custom cutting available |

| 15 mm 6061 Aerospace flat bar | 15 mm | Custom cutting available |

| 20 mm 6061 Aerospace flat bar | 20 mm | Custom cutting available |

| 30 mm 6061 Aerospace flat bar | 30 mm | Custom cutting available |

| 40 mm 6061 Aerospace flat bar | 40 mm | Custom cutting available |

| 45 mm 6061 Aerospace flat bar | 45 mm | Custom cutting available |

| 50 mm 6061 Aerospace flat bar | 50 mm | Custom cutting available |

| 60 mm 6061 Aerospace flat bar | 60 mm | Custom cutting available |

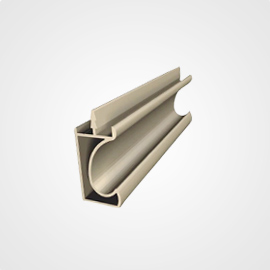

Chalco's hot-selling extruded profiles shapes

With decades of experience in the aluminum extrusion industry, Chalco has achieved an annual production capacity of 100, 000 tons. We also possess molds for 2000 standard aluminum extruded profiles. Take advantage of our latest promotional policy with waived mold fees.

Typically, 6063 is used for architectural applications, while 6061 is utilized for structural purposes. Chalco also offers various other alloy numbers such as the 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, and 7000 series. Our sales engineers can assist you in selecting the right alloy for your project.Quick Quote

Aluminum Angle

Aluminum T bar

Aluminum I Beam

Extruded Aluminum Channel

Aluminum Flat Bar

Aluminium G Profile

F-shaped-Aluminium-Extrusion

Aluminium J Profile

Square-Aluminum-Extrusion

Z-Aluminium-Extrusion

Oval Aluminum Extrusion

Y Section Aluminium Extrusion

Physical and mechanical properties of AMS 6061 aviation extruded aluminum profiles

| Physical and mechanical properties | |

| Density | 2.77 g/cm3 |

| Melting point | 580-650°C |

| Thermal expansion coefficient | 23.6 × 10-6/°C |

| Thermal conductivity | 170-200 W/mK |

| Conductivity | 43-47 MS/m |

| Elastic Modulus | 68.9 GPa |

| Hardness | 95 HRB |

| AMS 4150 6061-T6 extrusions mechanical property | |

| 0.2% yield strength | ≥35, 000 psi |

| ultimate tensile strength | ≥40, 000 psi |

| elongation at break | ≥8% |

| AMS 4160 6061-0 extrusion mechanical property | |

| 0.2% yield strength | ≥8, 000 psi |

| ultimate tensile strength | ≥14, 000 psi |

| elongation at break | ≥14% |

| AMS 4172 6061-T4511 extrusion mechanical property | |

| 0.2% yield strength | ≥45, 000 psi |

| ultimate tensile strength | ≥55, 000 psi |

| elongation at break | ≥10% |

| AMS 4173 6061-T6511 extrusion mechanical property | |

| 0.2% yield strength | ≥45, 000 psi |

| ultimate tensile strength | ≥60, 000 psi |

| elongation at break | ≥10% |

It should be noted that these values are only the minimum required values in the specification. In actual use, according to specific application requirements, higher mechanical performance requirements may be required, so stricter quality control and testing are required.Quick Quote

Chemical composition of 6061 aluminum profile

| Chemical composition Limits | |

| Weight% | Alloy 6061 |

| Si | 0.4~0.8 |

| Fe | ≤0.7 |

| Cu | 0.15~0.4 |

| Mn | 0.15 |

| Mg | 0.8~1.2 |

| Zn | ≤0.25 |

| Ti | 0.15~0.4 |

| Cr | 0.04~0.35 |

| Zn | 0.25 |

| Others | Each: 0.05 |

| Total: 0.15 | |

| Al | Bal |

Application of 6061 aluminum profiles in aircraft

6061 aluminum alloy profiles have a wide range of applications in the aviation field, the following are some common applications:

6061-T6 profiles and ring materials are commonly used in the manufacture of aircraft structural components, such as fuselage and wing structures, as well as aero engines and landing gear.

6061-O profiles are usually used in the manufacture of aircraft interiors and aircraft exterior parts.

6061-T4 profiles are suitable for manufacturing aircraft structural components that require high strength and good corrosion resistance, such as aircraft shells and spars.

6061-T4511 profiles are suitable for manufacturing aircraft structural components that require high strength and excellent corrosion resistance, such as support structures and chassis.

6061-T6511 profiles are also suitable for manufacturing aircraft structural components that require high strength and good corrosion resistance, such as wings and support structures.Quick Quote

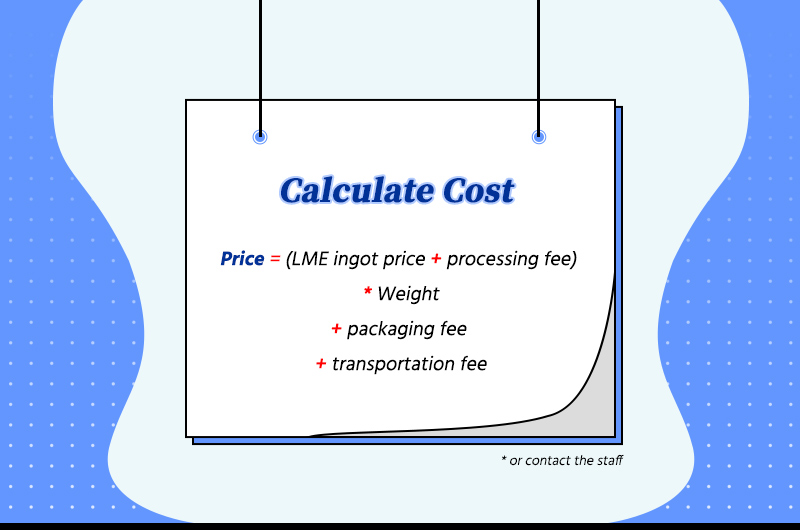

6061 aviation aluminum profile price

Price of 6061 aluminum profile: (LME ingot price + processing fee) × weight + packaging fee + transportation fee

The price of 6061 aluminum profiles will be affected by many factors, such as market supply and demand, raw material prices, processing costs, specifications and sizes, etc. Different manufacturers and suppliers may have different pricing strategies and price levels. In addition, it is also affected by factors such as currency exchange rate and international economic situation.Quick Quote

Therefore, please contact Chalco aluminum for inquiry, we will provide you with the best quotation and service.

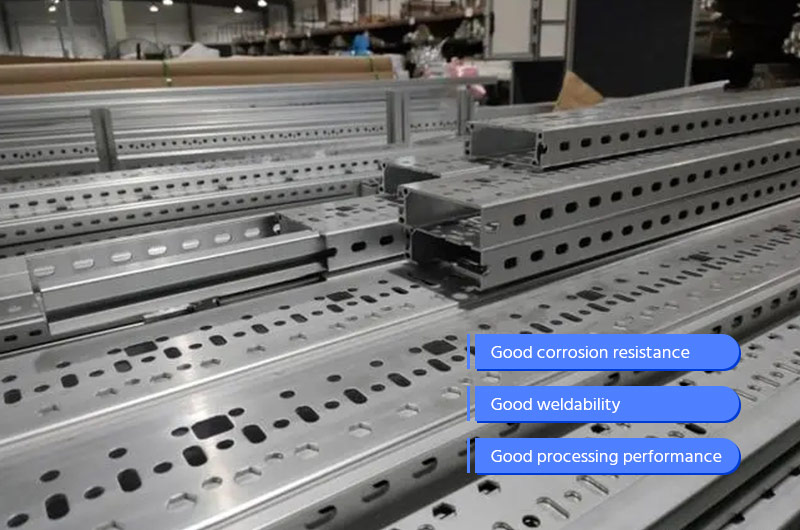

Characteristics of 6061 aviation aluminum profile material

High strength: 6061 aluminum profile has high strength after heat treatment, which can meet the application of strength requirements in the aviation field.

Good corrosion resistance: 6061 aluminum profile is added with appropriate amount of elements such as silicon and magnesium, which has good corrosion resistance, and can be used in applications that require corrosion resistance, such as aircraft shells and structural components.

Good weldability: 6061 aluminum profile has good weldability, which is convenient for the manufacture and maintenance of aircraft.

Good processing performance: 6061 aluminum profile has good processing performance, including milling, drilling, cutting and other processing methods.

Low density: 6061 aluminum profile has low density, which can be used to reduce the weight of the aircraft and improve the load capacity and fuel efficiency of the aircraft.

In summary, 6061 aluminum profile has the characteristics of high strength, good corrosion resistance, good weldability, good processability and low density, and is one of the widely used aluminum profile materials in the aviation field.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote