6061 aluminum alloy is a commonly used aerospace grade aluminum alloy with high strength, excellent corrosion resistance and good machinability making 6061 aluminum alloy the best choice for automotive body panel applications.Welcome contact

Why choose Chalco 6061 automotive body sheet metal?

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF 16949 standard audited by BSI (British Standards Institute), providing quality compliance for continued expansion of the automotive product market and high quality development.

Well-known brand material certifications

Chalco Aluminum serves top new energy vehicle manufacturers like Tesla, Ford, Shanghai Auto, Azera Auto, BAIC New Energy, Changan Auto, and more. We've certified automotive panels for plants including BAIC New Energy and Azera Auto.

The specification introduction of 6061 auto body sheet

Alloy: 6061 O, T4, T451, T6, T651

ABS sheet dimension

Thickness: 0.30-3.5MM Width: 52.0-2400.0MM Length: 500.0-10000.0MM

ABS coil dimension

Thickness: 0.30-3.5MM Width: 52.0-2400.0MM

Specification: GB/T 33227-2016, JIS H4000, ASTM B209, EN 485

Chalco featured 6061 aluminum plate product for auto

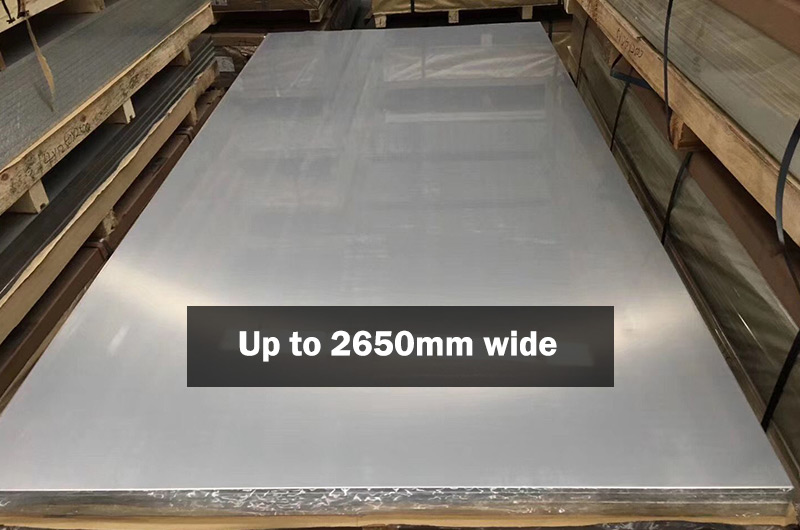

6061 aluminum ultra wide plate

Width:35.4”-104”(900mm-2650mm)

The width exceeds 2 meters, which can meet the needs of large-scale automotive component manufacturing, such as Body frames, roofs, floors, etc.

Contact us now

The surface has anti-slip patterns, which increases friction and is suitable for places that require anti-slip, widely used in vehicle pedals, floors, cargo boxes, etc.

Contact us nowThe size is 4 feet x 8 feet (approximately 1.2 meters x 2.4 meters), which is a common aluminum sheet size with a wide range of applications, such as body parts, interior parts, components, etc.

Contact us now

6061 aluminum ultra flat plate

Thickness: 0.24"-15.75"(6mm-400mm)

Width: 52”-73.2”(1320mm-1860mm)

The surface flatness is high, which can meet the application requirements with high surface finish requirements, widely used in automotive interior parts, decorative panels, etc.

6061 aluminum thick plate

The thickness exceeds 50 mm, which can meet the application requirements of high strength and stiffness, wide used in body structural parts, load-bearing parts, etc.

Contact us now

Chalco additional service——save time and costs for your automotive project

Deep Drawing, Cutting, and Other Additional Services

We provide deep drawing, cutting, and forming services to ensure aluminum sheet products meet the stringent requirements of automotive components during manufacturing.

Surface Processing: Enhancing Performance and Appearance

FM surface finish: provides a smooth base for further treatments

EDT: enhances paint adhesion with fine textured patterns

Ti/Zr:offers improved corrosion resistance and bonding for automotive parts

Surface Treatment: Adapting to Harsh Environments

NP(No Protection): leaves the surface untreated

P(Protection): adds a temporary protective layer

DO(Dry Oil): offers better corrosion resistance and uniform oil coverage for automotive applications

EO(Electrostatic Oil): high strength, corrosion resistance

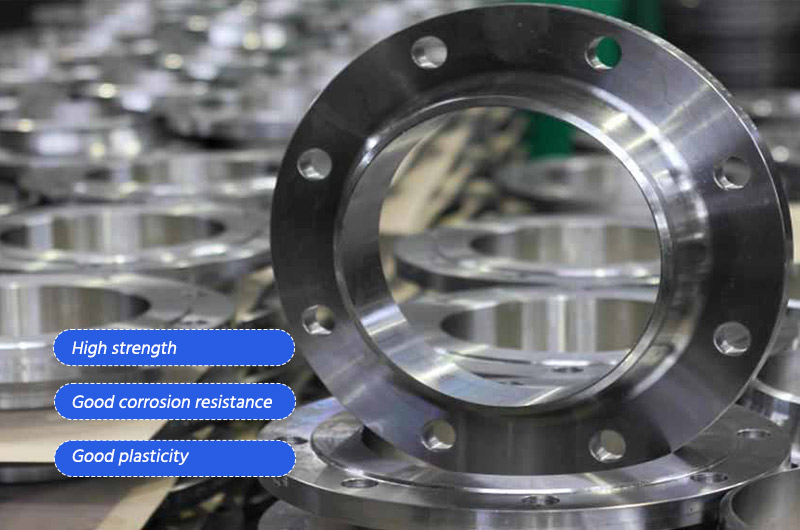

Advantages of 6061 aluminum for automotive body sheet metal panels

- 6061 aluminum alloy has the right amount of alloying elements added to it, which has high strength and hardness and can meet certain strength requirements for parts in automobile manufacturing.

- 6061 aluminum alloy has a certain amount of silicon and iron added to it, which has good corrosion resistance and is suitable for use in harsh working environment.

- 6061 aluminum alloy has good plasticity and workability, and can be used in various molding and processing operations.

- 6061 aluminum alloy is suitable for various welding methods, such as argon arc welding, resistance welding, etc. The strength of the welded joints is high.

- compared with traditional steel materials, aluminum alloy has lighter weight, which can reduce the overall weight of the car and improve the fuel economy of the vehicle.

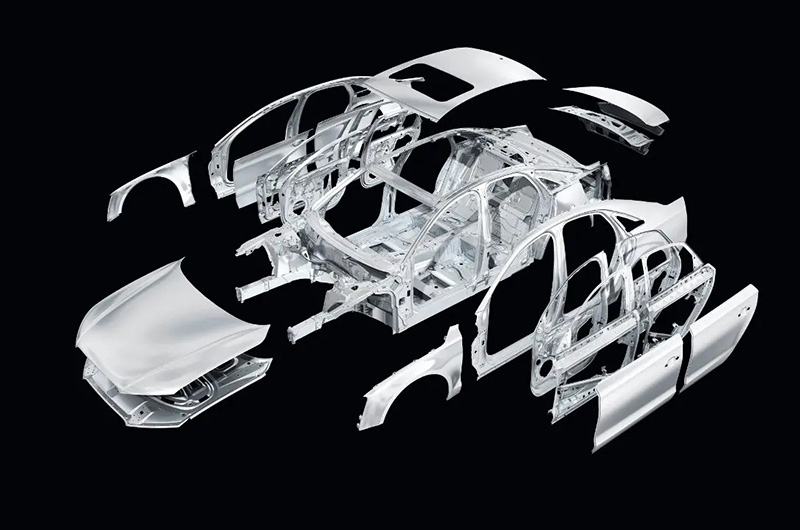

The usage of 6061 automotive sheet metal panels

6061 aluminum alloy automotive aluminum sheet is widely used in various parts and structures in automobile manufacturing, including but not limited to the following aspects:

Body structure parts: such as body skeleton, roof, floor and other parts, aluminum alloy materials can improve the strength and stiffness of the body, and can reduce the weight of the whole car and improve fuel economy.

Interior decoration parts: such as door panels, central control panel, steering wheel, seats and other parts, aluminum alloy materials can improve the texture and beauty of the interior, and can reduce the weight of the whole car.

Wheels: aluminum alloy wheels have better strength and stiffness, and have good thermal conductivity and aesthetics, which can improve the performance and appearance quality of the vehicle.

Hood and chassis cover: aluminum alloy material can improve the strength and stiffness of the hood and has good corrosion resistance, which can protect the engine and chassis.

Other parts: such as door handles, mirrors, exhaust pipes and other parts, aluminum alloy materials can improve their strength and corrosion resistance, as well as improve the lightness of the whole vehicle.

In summary, 6061 aluminum alloy automotive aluminum sheet has a wide range of applications in automobile manufacturing, which can improve the performance and quality of the whole vehicle, and reduce the weight of the vehicle and improve fuel economy.

The chemical composition of 6061 car body sheet metal

| Element | Composition (%) |

| Si | 0.4-0.8 |

| Fe | 0.7 |

| Cu | 0.15-0.4 |

| Mn | 0.15 |

| Mg | 0.8-1.2 |

| Zr | 0.08 |

| Ti | 0.15 |

| Al | Remainder |

The mechanical properties of automobile body panels at room temperature

| Temper | Tensile Strength | Yield Strength | Elongation in 2" (%) | Hardness |

| 6061-O | ≥45 | ≥20 | ≥25 | ≥40 |

| 6061-T4 | ≥180 | ≥110 | ≥16 | ≥70 |

Thickness deviation of 6061 O T4 automotive body sheet metal

| Thickness mm | Thickness tolerances within the following width ranges | |||

| ≤1500 | >1500.0-1700.0 | >1700 - 2000.00 | >2000-2400.00 | |

| 0.70—1.00 | ±0.03 | ±0.04 | - | - |

| >0.50—0.80 | ±0.03 | ±0.04 | ±0.04 | - |

| >0.80—1.20 | ±0.04 | ±0.04 | ±0.05 | ±0.06 |

| >1.20—2.00 | ±0.05 | ±0.05 | ±0.06 | ±0.07 |

| >2.00—2.50 | ±0.06 | ±0.07 | ±0.07 | ±0.08 |

| >2.50—3.00 | ±0.07 | ±0.08 | ±0.08 | ±0.09 |

| >3.00—3.50 | ±0.08 | ±0.09 | ±0.10 | ±0.11 |

Width deviation of 6061 T4 automotive body sheet metal

| Thickness mm | Width tolerances within the following width ranges | ||

| 800.0-1600.0 | >1600.0-1800.0 | >1800-2400.0 | |

| 0.70—1.50 |

+ 0, 3 0 |

+ 5, 0 0 |

+ 6, 0 0 |

Width deviation of 6061 O automotive body sheet metal

| Thickness mm | Width tolerances within the following width ranges | |||||||

| ≤100 | >100-300 | >300-500 | >500-800 | >800-1250 | >1250-1800 | >1800-2000 | >2000-2400 | |

| 0.3-1.6 | +0.30 | +0.40 | +1.00 | +1.50 | +2.00 | +3.00 | - | - |

| >1.60-3.5 | - | - | - | +2.00 | +3.00 | +4.00 | +5.00 | +6.00 |

Unevenness of 6061 T4 automotive body sheet metal

| Thickness mm | Width tolerances within the following width ranges | |||||

| ≤500 | >500-1000 | >1000-1500 | >1500-2000 | >2000 | End part Warp height | |

| 0.30-0.50 | - | - | - | - | - | ≤25 |

| >0.50-0.80 | 4 | 5 | 6 | 7 | 8 | |

| >0.80-1.60 | 4 | 4 | 5 | 7 | 8 | |

| >1.60-2.00 | 4 | 4 | 5 | 7 | 8 | |

| >2.00-3.50 | 4 | 5 | 6 | 7 | 8 | |

| The end part is the entire surface of the end contained within a length of 300.0 mm at both ends of the product in the length direction. If the sheet is square, the end The end part is the surface of the square circle contained within 300.0 mm around the edge. | ||||||

Unevenness of 6061 O automotive body sheet metal

| Thickness mm | Width tolerances within the following width ranges | |||||

| ≤500 | >500-1000 | >1000-1500 | >1500-2000 | >2000 | End part Warp height | |

| 0.30-0.50 | 3 | 4 | 4 | 4 | - | ≤25 |

| >0.50-0.80 | 3 | 4 | 4 | 7 | 8 | |

| >0.80-1.60 | 3 | 4 | 4 | 6 | 8 | |

| >1.60-2.00 | 3 | 4 | 4 | 6 | 8 | |

| >2.00-3.50 | 3 | 4 | 4 | 6 | 8 | |

| The end part is the entire surface of the end contained within a length of 300.0 mm at both ends of the product in the length direction. If the sheet is square, the end The end part is the surface of the square circle contained within 300.0 mm around the edge. | ||||||

Related recommendation of Chalco 6061 aluminum alloy

6061 aerospace forging

6061 aerospace plate

6061 auto profile

6061 oil tanker tube

6061 aluminum square tube

6061 aluminum bar

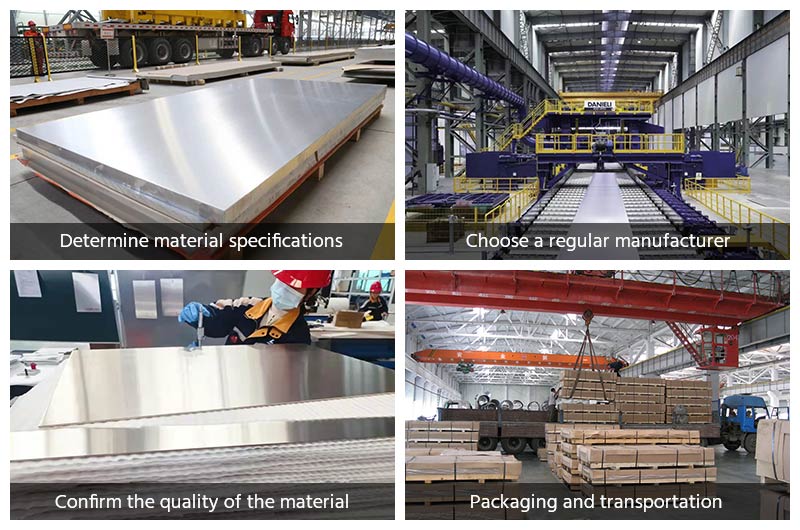

What items should be paid attention to when purchasing 6061 automotive sheet metal body panels?

Specifications and sizes: choose the right specifications and sizes according to your needs. The specification and size of the aluminum sheet have a great influence on the subsequent processing and use.

Surface quality: surface quality is an important indicator of the quality of aluminum sheet. 6061 automotive aluminum sheet produced by Chalco Aluminum has a smooth and flat surface without cracks, bubbles and other surface defects.

Strength and hardness: strength and hardness are important performance indicators of aluminum sheet materials. 6061 automotive aluminum sheet produced by Chalco Aluminum has sufficient strength and hardness to ensure that it will not cause problems in use.

Production process: production process is an important factor that affects the quality of aluminum sheet. 6061 automotive aluminum sheet produced by Chalco Aluminum uses advanced process to produce aluminum sheet to ensure its quality and performance.

Supplier reputation and service: the supplier's reputation and service quality are also factors you need to consider. chalco aluminum is a supplier with good reputation and perfect after-sales service to ensure your purchasing experience is pleasant and smooth.

Test certificates: test certificates are an important measure of the quality of aluminum sheet, and Chalco Aluminum can provide the appropriate test certificates to ensure that the sheet meets national or industry standards.

Price: considering the cost of 6061 automotive aluminum sheet, Chalco Aluminum's prices are moderate and popular with automotive parts manufacturers.

Packaging and shipping: Chalco Aluminum takes full consideration of how the aluminum sheets are packaged and shipped to ensure they are not damaged during transit.