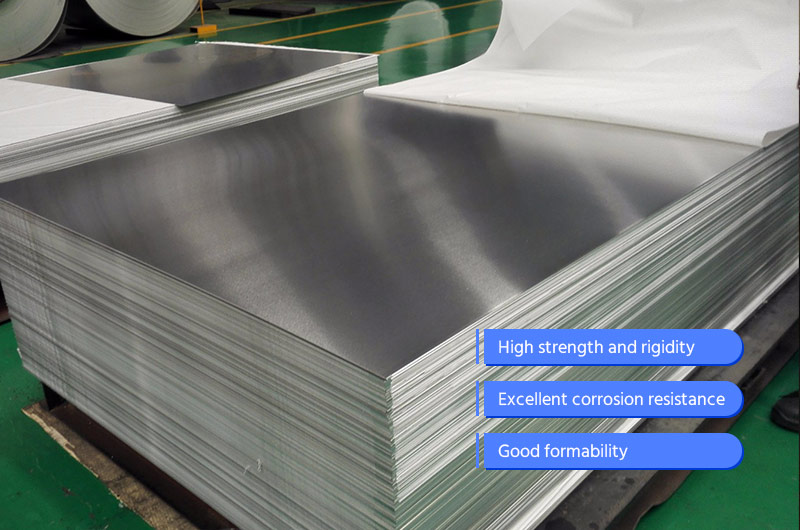

The strength of 5086 aluminum alloy plate is even higher than that of 5052 or 5083. This alloy can be easily welded while retaining most of its mechanical strength.

5086 aluminum plate is known as "marine-grade aluminum" due to its excellent corrosion resistance in seawater, making it highly popular for marine applications.

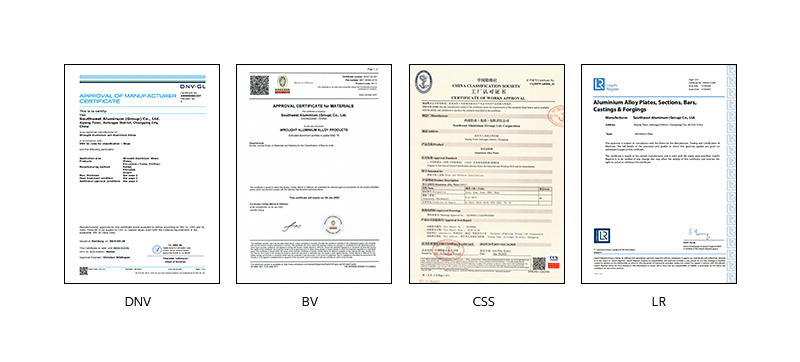

5086 aluminum plate certification and standards

- ASTM B928

- QQ-A-250/7

- ASTM B209

- EN 573-3

- EN 485-2

The 5086 aluminum plate has certifications from the following classification societies: LR, BV, DNV, CCS, KR, and ClassNK.

Popular stock sizes of 5086 aluminum plate

Our 5086 aluminum plates are available in H32 and H116 temper, as well as 5086 H244 aluminum checker plate.Quick Quote

Popular stock sizes of 5086 aluminum H32 plate

| Description | Temper | Thickness |

| 5086-H32 Aluminum Sheet 0.032" | H32 | 0.032" |

| 5086-H32 Aluminum Sheet 0.040" | H32 | 0.040" |

| 5086-H32 Aluminum Sheet 0.050" | H32 | 0.050" |

| 5086-H32 Aluminum Sheet 0.063" | H32 | 0.063" |

| 5086-H321 Aluminum Sheet 0.063" | H32 | 0.063" |

| 5086-H32 Aluminum Sheet 0.090" | H32 | 0.090" |

| 5086-H32 Aluminum Sheet 0.125" | H32 | 0.125" |

| 5086-H32 Aluminum Sheet 0.190" | H32 | 0.190" |

| 5086-H32 Aluminum Sheet 0.250" | H32 | 0.250" |

| 5086-H32 Aluminum Plate 0.375" | H32 | 0.375" |

| 5086-H32 Aluminum Plate 0.500" | H32 | 0.500" |

| 5086-H32 Aluminum Plate 0.625" | H32 | 0.625" |

Popular stock sizes of 5086 aluminum H116 plate

| Description | Temper | Thickness |

| 5086-H116 Aluminum Sheet 0.080" | H116 | 0.080" |

| 5086-H116 Aluminum Sheet 0.100" | H116 | 0.100" |

| 5086-H116 Aluminum Sheet 0.125" | H116 | 0.125" |

| 5086-H116 Aluminum Sheet 0.160" | H116 | 0.160" |

| 5086-H116 Aluminum Sheet 0.190" | H116 | 0.190" |

| 5086-H116 Aluminum Plate 0.250" | H116 | 0.250" |

| 5086-H116 Aluminum Plate 0.313" | H116 | 0.313" |

| 5086-H116 Aluminum Plate 0.375" | H116 | 0.375" |

| 5086-H116 Aluminum Plate 0.500" | H116 | 0.500" |

| 5086-H116 Aluminum Plate 0.625" | H116 | 0.625" |

| 5086-H116 Aluminum Plate 0.750" | H116 | 0.750" |

| 5086-H116 Aluminum Plate 1.000" | H116 | 1.000" |

| 5086-H116 Aluminum Plate 1.250" | H116 | 1.250" |

| 5086-H116 Aluminum Plate 1.500" | H116 | 1.500" |

| 5086-H116 Aluminum Plate 2.000" | H116 | 2.000" |

Popular stock sizes of 5086 aluminum checker plate

| Description | Temper | Finish |

| 5086 Aluminum Checker Plate 3mmx2431.9mmx10195.95mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mmx2431.9mmx10805.95mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mmx2431.9mmx6715.95mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mmx2431.9mmx7935.95mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mmx2431.9mmx9280.95mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mm x 2438.4mm x 9448.8mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mm x 2438.4mm x 10972.8mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate 3mm x 2438.4mm x 11582.4mm | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate .118" x 8' x 31' | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate .118" x 8' x 36' | H244 | Rice Grain Pattern |

| 5086 Aluminum Checker Plate .118" x 8' x 38' | H244 | Rice Grain Pattern |

In addition to these sizes, we can also custom produce.Quick Quote

Chemical elements of 5086 aluminum plate

| Chemical Composition Limits (WT %) | |

| Silicon | 0.4 |

| Iron | 0.5 |

| Copper | 0.1 |

| Manganese | 0.20-0.70 |

| Magnesium | 3.5-4.5 |

| Chromium | 0.05-0.25 |

| Zinc | 0.25 |

| Titanium | 0.15 |

| Others, each | 0.05 |

| Others, total | 0.15 |

| Aluminum | Balance |

Mechanical properties of 5086 aluminum plate

| Temper | H32 | H116 |

| Tensile Strength | 300 MPa | 300 MPa |

| Yield Strength | 210 MPa | 210 MPa |

| Elongation (%) | 11 | 11 |

| Brinell Hardness | 80 | 81 |

| Fatigue Strength | 170 MPa | 150 MPa |

| Shear Strength | 180 MPa | 180 MPa |

These values are typical characteristics and may not meet your needs. If you have special needs, pleaseContact Us

Physical properties of 5086 aluminum plate

| Physical Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 640 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 31 % IACS |

Click to view Aerospace Aluminum Sheet Properties.

5086 Aluminium Sheet Equivalent Grades

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

| AW-AlMg4 | AG4MC | 3.3545 | A95086 | AlMg4 | 5086 | AlMg4Mn |

Advantages of 5086 aluminum plate

- High Strength: Offers greater strength compared to 5052 or 5083.

- Corrosion Resistance: Exceptional resistance to corrosion.

- Dimensional Accuracy: Maintains precise dimensions.

- High Pressure and Temperature Tolerance: Capable of withstanding high-pressure and high-temperature loads.

- Rust Resistance Treatment: Enhanced protection against rust.

- Perfect Transition:Ensures a smooth transition from flange thickness to piping.

- Excellent Stress Distribution: Guarantees outstanding stress distribution.

- Variable Mechanical Properties: Mechanical performance may significantly change with hardening and temperature.

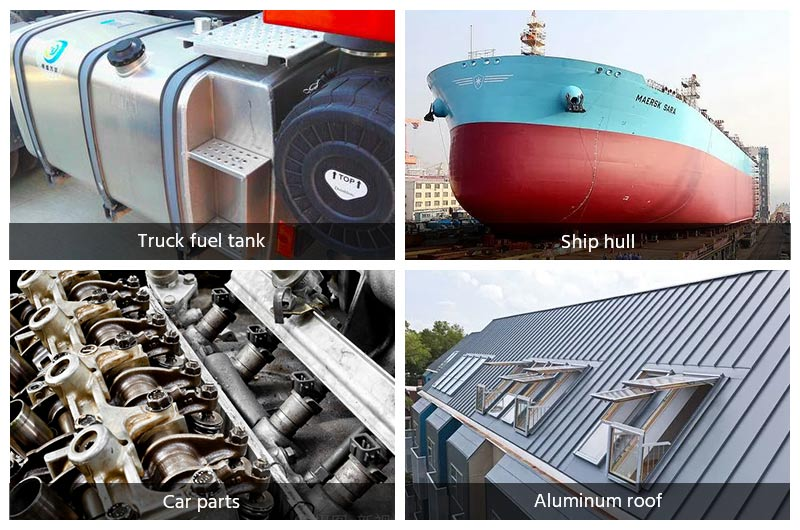

5086 Aluminum Sheet Application

- Shipbuilding: Used for hulls, bulkheads, and decks due to its excellent corrosion resistance and strength.

- Automotive Industry: Applied in body structures and components to enhance lightweight and strength.

- Pressure Vessels: Suitable for storing high-pressure gases and liquids.

- Building Structures: Used in frames and supports, especially in marine environments.

- Piping: Employed for transporting corrosive liquids, ensuring safety and durability.

Quality inspection report – traceable

Our products undergo strict quality control and come with a complete set of quality inspection reports.

- Chemical Composition Analysis: Complies with industry standards

- Mechanical Performance Testing: Validates product strength

- Non-Destructive Testing: Comprehensive hazard detection

- Appearance Inspection: Pursuing excellence

- Traceability Records: Fully traceable

Welding and machining recommendations for 5086 aluminum alloy

Welding: This alloy is easily welded using conventional methods, with excellent results achieved particularly through arc welding.

Machining: Strain-hardened tempers (H34, H36, H38) offer good machinability, while annealed (O temper) machining is more challenging but feasible with the use of lubricants. Cold working is excellent in the O state, but slightly less effective in H36 and H38 states.

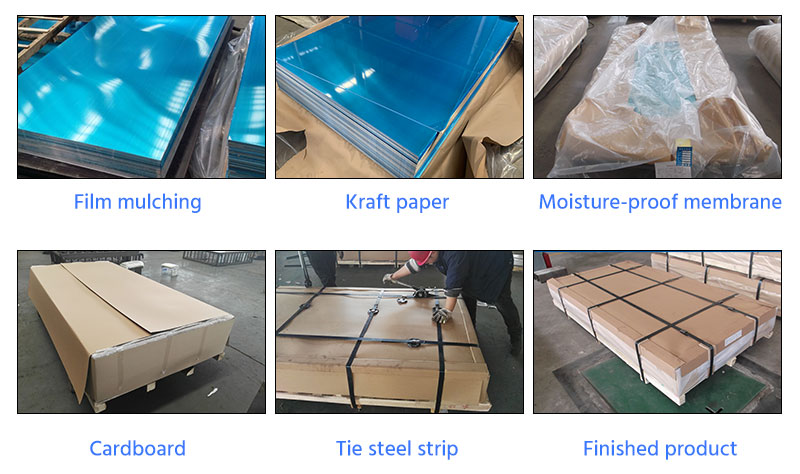

Packaging for 5086 H32 H116 Aluminum Sheet

- Apply interleaving paper or film to protect the aluminum sheet.

- Wrap with plastic or kraft paper (ensuring each package has a moisture-absorbing desiccant).

- Add protective corners or edge protection materials to prevent damage.

- Reinforce with wooden pallets and secure with steel straps to prevent collisions during transportation.

- For export, package the products in wooden boxes and pallets marked with fumigation signs.

- Packaging can be customized according to additional requirements from the customer.

Feel to leave your requirements below, and we will respond to you as quickly as possible.Quick Quote

The main differences between 5086 and 5083 aluminum alloys

- Strength: 5086 has generally higher strength than 5083, making it suitable for applications requiring greater strength.

- Corrosion Resistance: 5083 offers better corrosion resistance in certain environments, especially in marine applications.

- Weldability: 5086 is easier to weld, particularly with arc welding; 5083 can also be welded but may require more specialized techniques.

- Thickness: 0.5mm-25mm