- Specifications of Chinalco patterned aluminum plate

- Chalco hot selling patterned aluminum sheet

- Surface selection of patterned aluminum plate

- Thickness selection of patterned aluminum plate

- Precautions for purchasing patterned aluminum plate

- Technical Data Sheet (tolerance data)

Aluminum tread checkered plate, also known as Aluminium floor plate, Aluminium diamond plate, Aluminum anti-slip plate, Aluminum durbar plates, is a kind of metal plate with protruding diamonds or lines with regular patterns on one side and no features on the reverse side. The aluminum substrates of Chalco's aluminum tread checkered plates are all aluminum plates that meet national standards to ensure the durability of aluminum Diamond plate. The following is the production range of chalco checkered plate:

Specification of Chalco Aluminum tread checkered plate coil

| Name | Aluminum diamond plate, Aluminum checker plate, Aluminum chequered plate, Aluminum tread checkered plate, Aluminum durbar floor plate. |

| Alloy | 1050, 1060, 3003, 3103, 5026, 5052, 5083, 5086, 5754, 6082, 6061, 7020 |

| Temper | F, O, H111, H114, H116, H224, H244, T4, T6, T61 |

| Pattern Type | Lentil pattern diamond plate, 2 bar aluminium checker plate sheet, 3 bar aluminium checker plate sheet, 5 bar aluminium checker plate sheet, Needle pattern checker plate, Diamond checkered aluminum plate |

| Thickness | 1.2-8mm |

| Width | 100-1850 mm |

| Length | 500-16000 mm |

| Muscle high | Refer to the pattern height tolerance table |

| Production Process | Hot rolling, embossing. |

| Surface treatment | Mill finish, Bright finishClick to view detailed surface |

| Color | Black, sliver, blue, etc.(Customizable) |

| Delivery type | Plate, Roll |

| Surface protection | With membrane or without membrane, can be customized according to requirements |

| Package | Wooden frame/wooden box packaging, steel belt fixed |

| Standard | GB/T3618, Q/EL432, EN 1386, ASTM -B209 |

The production range in the above table is for your reference. If you have special needs or need to customize, please contact us for consultation.Quick Quote

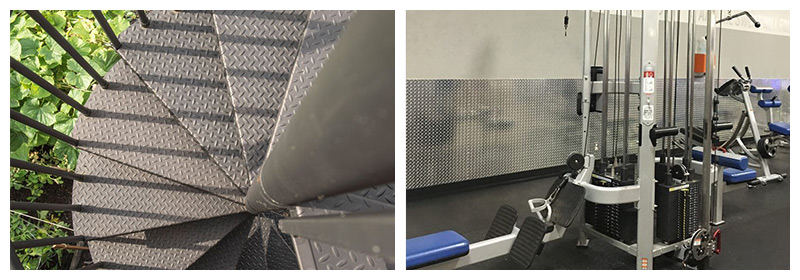

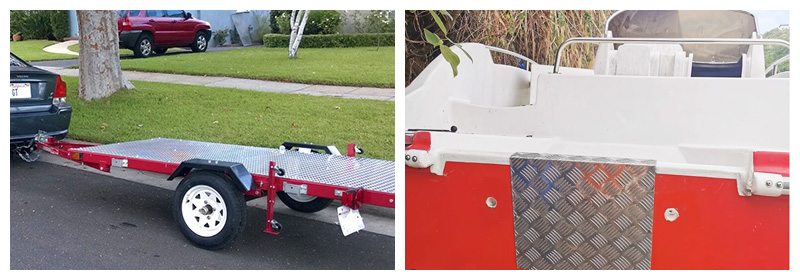

Chalco hot selling aluminum tread checkered plate

-

Aluminum diamond plate coil

The Aluminum diamond plate coil is also called 1 bar aluminium checker plate sheet or a aluminum checker plate. It has raised patterns on the surface and is often used as a non-slip aluminum plate or a decorative aluminum plate. It has good performance of beauty, wear resistance and corrosion resistance.

-

2, 3, 5 bar aluminium checker plate sheet

five-rib non-slip aluminum plate is also called willow-shaped pattern plate. Among them, the five-rib pattern plate can be divided into a large five-rib pattern plate and a small five-rib pattern plate according to the length of the pattern. The pattern lengths are 42mm and 34mm respectively. The patterns on the surface of the aluminum plate are arranged in parallel and present an angle of 60-80 degrees. This pattern has excellent anti-skid performance. It is mainly used for the interior of ambulance and fire truck pedal, truck compartment and trailer floor, etc.

-

Lentil pattern diamond plate

It is a commonly used style of anti-slip aluminum plate, with good anti-slip effect, mainly used for carriage, platform anti-slip, cold storage floor anti-slip, workshop floor anti-slip, elevator anti-slip.

1050 1060 pure aluminum tread checkered plate: aluminum alloy pattern plate processed with 1050 1060 aluminum plate as the base, which can adapt to the conventional environment and is cheap. Usually stair treads, cold storage, floors, and outer packaging use this kind of patterned aluminum sheet.

3003 3103 Al-Mn tread checkered plate :processed with 3003 3103 as the main raw material, this kind of aluminum plate is also called anti-rust aluminum plate, its strength is slightly higher than that of ordinary aluminum tread checkered plate, and it has certain anti-rust performance, but its hardness and corrosion resistance are not as good as the 5000 series aluminum tread checkered plate, so this product is used in rust-proof aspects that do not require strict requirements, such as truck models, refrigerated vehicles, and cold storage floors.

5052, 5083, 5754 Al-Mg tread checkered plate: processed from 5000 series aluminum plates such as 5052, 5083, etc., with good corrosion resistance, hardness, and rust resistance. It is usually used in special places, such as ships, carriages and other humid environments. This kind of aluminum plate has high hardness and has a certain load-bearing capacity.

6061, 6082 Al-Mg-Si tread checkered plate: processed from 6000 series aluminum plates such as 6061, 6082, etc., adding magnesium and silicon elements can further improve the corrosion resistance of the checkered plate, with high strength and good processing and welding performance. It is usually used in special places that need to be suspended in the air, such as places that need to be suspended in the air, stern anti-skid protection, shipping engineering, energy and chemical industry, etc., which are highly corrosive and prone to rust and corrosion.

Aluminum pattern plates of different alloys have different application fields and different processing costs. For details, please contact us.Quick Quote

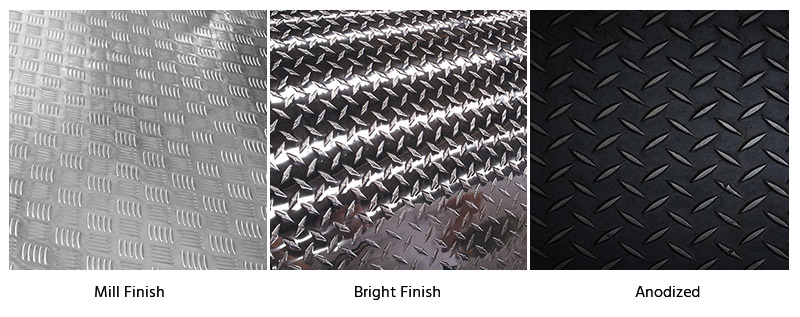

Surface selection of aluminum tread checker plate

Mill finish aluminum tread checker plate

Mill Finish Aluminum Tread Checker Plate is the natural appearance of aluminum as it comes out of the mill without any external mechanical or chemical treatment. It is an ordinary rolling surface with a certain degree of roughness, unlike a mirror surface. Mill Finish Aluminum Tread Checker Plate is suitable for walkways, platform pedals, cold storage floors, bus floors, etc.

Bright finish aluminum tread checker plate

The surface of Bright Finish Aluminum Tread Checker Plate is very smooth, just like mirror aluminum, but its strength is high, and the reflectivity of the aluminum surface is close to 90%, sometimes called polished surface, or mirror surface. Bright Finish Aluminum Tread Checker Plate has a high surface finish and has a certain decorative effect. It is suitable for decorative wall panels, automobile fenders, equipment bottom panels and other non-slip fields with certain decorative requirements.

Anodized aluminum tread checker plate

Anodizing is a process in which the oxide layer on the surface of aluminum is strengthened by electrolytic treatment, improving its corrosion resistance and hardness. The Aluminum Tread Checker Plate on the anodized surface has higher strength, stronger corrosion resistance, and can be oxidized into various colors, such as black, gold, silver, red...the color is bright and the decoration is stronger.

Thickness selection of aluminum tread checker plate

0.025” aluminum tread checker plate

Compared with other thickness checker boards, 0.025” checker board is a very unique material. It is thin, flexible, lightweight, easy to cut, easy to bend at corners, and can be rolled. If it is used as an aluminum pedal, 0.025” is generally not recommended, and it is generally embossed. It is suitable for refrigerator lining, decoration, wainscoting, ceiling and other decorative areas that do not require high thickness and hardness;

0.063” (1/16”) aluminum tread checker plate

0.063” thick aluminum diamond sheets are two layers thicker than our 0.025” and are commonly used to cover walls and floors where weight is not critical, subway skid plates, trailer side panels, car fenders, truck tool boxes, etc.

0.100” aluminum tread checker plate

The thickness of 0.100” is ideal for flooring and trailer decking. It is thick enough to withstand a lot of wear and tear. Choosing this thickness or above is more suitable for covering floors that often wear and tear, such as trucks, trailer floors, suspended stairs, etc.

Chalco can also provide aluminum Tread Checker plate with more thicknesses such as 0.125" and 0.25". Generally speaking, the choice of thickness depends on your budget and specific use. For more dimensions checkered plate, please contact us for consultation. Quick Quote

Precautions for purchasing aluminum tread checker plate

Size thickness and rib height: Determine the size and thickness of the aluminum Tread Checker plate you need, especially the rib height, if the rib height is too low, the anti-skid effect is not good, confirm in advance to ensure that it meets your project requirements, and choose the correct specification when purchasing.

Pattern type: Aluminum Tread Checker plates come in a variety of pattern and texture styles. Choose the right pattern type to suit your project's needs, taking into account appearance, functionality and adaptability.

Material and quality: Confirm the specific aluminum material of the purchased aluminum Tread Checker plate. Ordinary pure aluminum is enough, or you need anti-rust 3xxx, or 5, 6xxx aluminum plate with higher strength. The quality of the aluminum plate determines its durability and service life. Be sure to understand it before buying.

Finishes: Learn about finish options for aluminum Tread Checker plates such as rolled finish, gloss finish, and anodized finish. Generally, the bright surface has a certain decorative effect. Anodizing can be customized in different colors. Choose the appropriate surface treatment according to your needs to increase the weather resistance and decoration of the aluminum plate.

Export packaging: Packaging is crucial in ocean freight. Chalco can effectively protect the goods from moisture, scratches and damage during transportation through multiple steps such as moisture-proof paper, hard kraft paper covering, wooden frame/wooden box packaging and steel belt fixing.

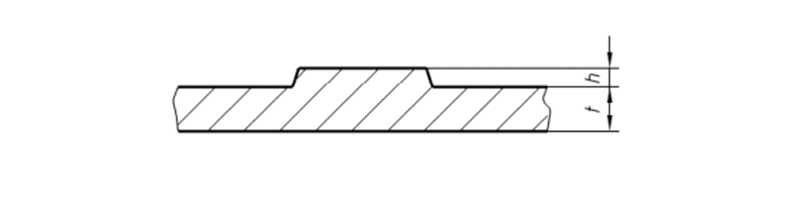

Detailed technical parameters of Chalco aluminum tread checker plate

Pattern height tolerance

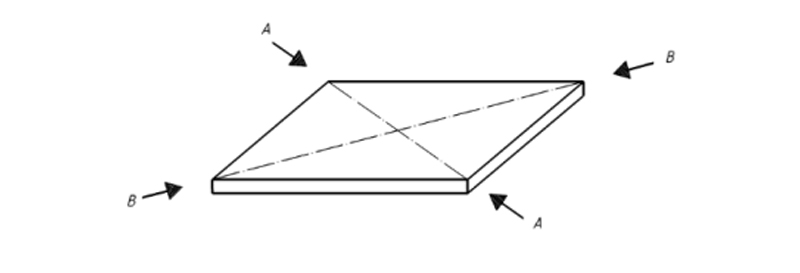

Key

- H: height of raised pattern

- t: nominal thickness

| Attern type | Range of thickness t | Raised pattern | |

| Nominal height /h | Maximum permissible deviation on nominal height /h | ||

| Figure 4 | 1.2-3.5 | 0.5 | ±0.2 |

| Figures 1.2 and 3 | 1.2-1.5 | 0.5 | ±0.3 |

| >1.5-2.5 | 1 | ±0.4 | |

| >2.5-20.0 | 1.5 | ±0.6 | |

| Figure 5 Standard height | 2.5-20.0 | 2.5 | ±0.6 |

| Figure 5 Reduced height | 2.5-20.0 | 1 | ±0.4 |

| Note for sheet of a thickness between 2 mm and 2.5 mm a height of the raised pattern of 1.5 mm±0.6 mm can be agreed between supplier and purchaser. | |||

Base plate thickness tolerance

| Range of nominal thickness/mm | Maximum permissible deviation for nominal width/mm | |

| ≤1600 | 1600 ≤ H < 2000 | |

| ≥1.2-2.5 | ±0.20 | ±0.30 |

| >2.5-3.5 | ±0.30 | ±0.40 |

| >3.5-6.5 | ±0.40 | ±0.50 |

| >6.5-12.5 | ±0.50 | ±0.60 |

| >12.5-20.0 | ±1.0 | ±1.0 |

Width length tolerance

| Nominal thickness t | Width/mm | Length | |||

| ≤1500 | 1500≤W<2500 | ≤2000 | 2000≤L<5000 | ≥5000 | |

| 1.2≤t≤3.0 | +8 | +8 | +8 | +10 | +12 |

| 3.0<t≤8.0 | +8 | +10 | +8 | +10 | +12 |

| t >8.0 | +5 | +8 | +6 | +8 | +10 |

Perpendicularity tolerance

| Nominal length | Squareness tolerance for nominal width | |||

| ≤1000 | 1000≤W<1500 | 1500≤W<2000 | 2000≤W<2500 | |

| 0-2000 | 6 | 7 | 8 | - |

| 2000-3000 | 7 | 7 | 9 | 10 |

| 3000-3500 | 7 | 8 | 10 | 10 |

| 3500-5000 | 8 | 10 | 10 | 12 |

| >5000 | 12 | 12 | 15 | 15 |