Chalco has AS9100 certification and produce 5083 aerospace aluminum sheet plate according to BS N8, AMS 4056, QQ-A-250/6 etc. standards. 5083 aluminum plate is a high-strength, corrosion-resistant aluminum alloy material widely used in the aerospace field, with excellent processing performance, welding performance, and corrosion resistance. It is commonly used in the manufacturing of aerospace structural components and containers.Welcome contact

Chalco high quality 5083 aerospace aluminum sheet plate

Chalco 5083 aerospace aluminum specification

BS N8, BS EN 573-3, BS EN 485-2, QQ-A-250/6, AMS 4056, AMS 4347, ASTM B928, ASTM B209, MIL-DTL-46027, MIL-DTL-32341A, MIL DTL46027

Chalco accreditations

AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Specification of Chalco 5083 aerospace aluminum sheet plate

| Hot selling temper | O, H111, H112, H321, H116, H131, H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38 | |

| Equivalent name | A95083, AlMg4, 5Mn, DIN 3.3547, EN AW-5083, GM41, Al Mg4.5 Mn0.7 | |

| 5083 aluminum sheet | thickness:0.01”-0.24”(0.2mm-6mm) | Width:35.4”-104”(900mm-2650mm) |

| 5083 aluminum plate | thickness:0.24”-9.84”(6mm-250mm) | Width:35.4”-104”(900mm-2650mm) |

| 5083 Ultra wide aluminum sheet | Thickness:0.24”-9.84”(6mm-250mm) | Width:35.4”-104”(900mm-4300mm) |

| 5083 cast aluminum plate | Thickness:0.24"-15.75"(6mm-400mm) | Width:52”-73.2”(1320mm-1860mm) |

| 5083 aluminum armor plate | Thickness:0.32”-9.84”(8mm-250mm) | Width:35.4”-104”(900mm-2650mm) |

| 5083 marine aluminum plate | Thickness:0.12"-9.84"(3mm-250mm) | Width:35.4”-104”(900mm-2650mm) |

| Surface treatment | Mill finish, Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

| Surface requirements | The surface is smooth, free of defects such as scratches and oxide skin to ensure that the aluminum plate will not be corroded or damaged during use | |

| Tolerance of flatness | On the longest side of the plate, the flatness tolerance is 3mm/m; On the shortest side of the plate, the flatness tolerance is 2mm/m. | |

For the hot selling stock, you can click the stock size list to check and other sizes can contact us to inquire.[Inventery list chart]

Chalco hot selling 5083 aluminum sheet plate products

5083-O aluminum plate sheet

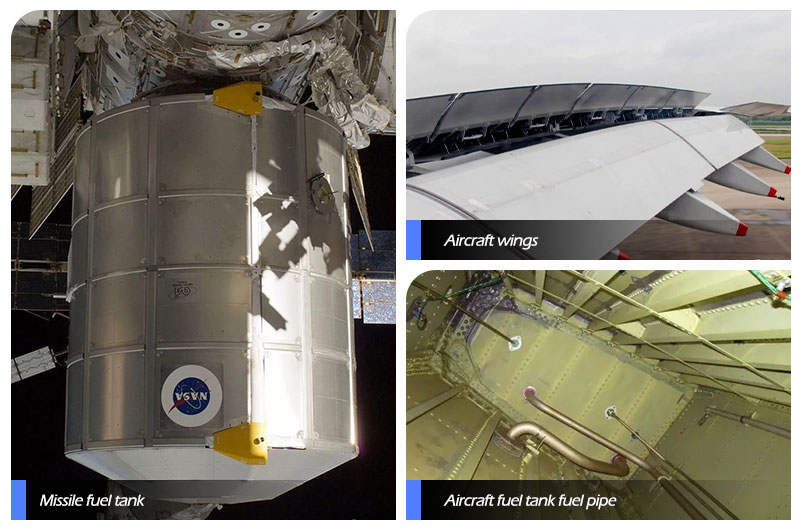

commonly used to manufacture components for various emergency purposes, such as emergency rescue equipment, fuel tanks, and fuel pipelines.

Contact us now

5083-H111 aluminum plate sheet

commonly used to manufacture aircraft reinforcements such as fuselage, wings, and tail wings.

Contact us now5083-H112 aluminum plate sheet

commonly used to manufacture structural components for high-speed aircraft, missiles, and rockets, such as fuselage, missile shells, and fuel tanks.

Contact us now

5083-H116 aluminum plate sheet

commonly used for manufacturing structural components on offshore ships and platforms, such as hulls, slipways, and ship internal structures.

Contact us now5083-H32 aluminum plate sheet

commonly used in the manufacture of aircraft stiffeners, skins, shells, and tail fins.

Contact us now

Chemical composition of Chalco 5083 aerospace aluminum plate

| Element | minimum value(BS N8) | Maximum(BS N8) |

| Al | Reminder | Reminder |

| Mg | 4.0% | 4.9% |

| Mn | 0.4% | 1.0% |

| Cr | 0.05% | 0.25% |

| Zr | 0.05% | below |

| Ti | 0.15% | below |

| Cu | 0.1% | below |

| Fe | 0.4% | below |

| Si | 0.4% | below |

Note: The above percentages are approximate and may vary depending on the specific composition of the alloy.

Physical properties of chalco 5083 aerospace aluminum sheet plate

| Property | Value |

| Density | ≤2.64 g/cm3 |

| Elastic modulus | ≥73 GPa |

| Coefficient of thermal expansion | ≤23.5×10-6 /°C |

| Thermal conductivity | ≥121 W/mK |

| Conductivity | ≥38.8 %IACS |

| Hardness | HB 95-120 |

Mechanical properties of Chalco 5083 aerospace aluminum plate hot selling products

| Temper | Specification | Yield strength | Tensile strength | Elongation | Fracture elongation |

| O | AMS 4056 required value | ≥85 MPa | ≥180 MPa | ≥25% | ≥30% |

| AMS 4056 typical value | 110-120 MPa | 220-240 MPa | 32-35% | 37-39% | |

| H32 | AMS 4056 required value | ≥240 MPa | ≥320 MPa | ≥5% | ≥10% |

| AMS 4056 typical value | 275-290 MPa | 335-350 MPa | 11-12% | 14-16% | |

| H111 | AMS 4056 required value | ≥145 MPa | ≥285 MPa | ≥10% | ≥15% |

| AMS 4056 typical value | 180-200 MPa | 320-340 MPa | 14-16% | 20-22% | |

| H112 | AMS 4056 required value | ≥190 MPa | ≥305 MPa | ≥8% | ≥12% |

| AMS 4056 typical value | 230-240 MPa | 330-350 MPa | 10-12% | 16-18% | |

| H116 | AMS 4056 required value | ≥240 MPa | ≥345 MPa | ≥10% | ≥15% |

| AMS 4056 typical value | 270-290 MPa | 380-400 MPa | 12-14% | 20-22% |

Other hot selling aerospace aluminum plate products in Chalco

2219 aerospace aluminum plate

2024 aerospace aluminum plate

2014 aerospace aluminum plate

2618 aerospace aluminum plate

7050 aerospace aluminum plate

7055 aerospace aluminum plate

7075 aerospace aluminum plate

5086 aerospace aluminum plate

6061 aerospace aluminum plate

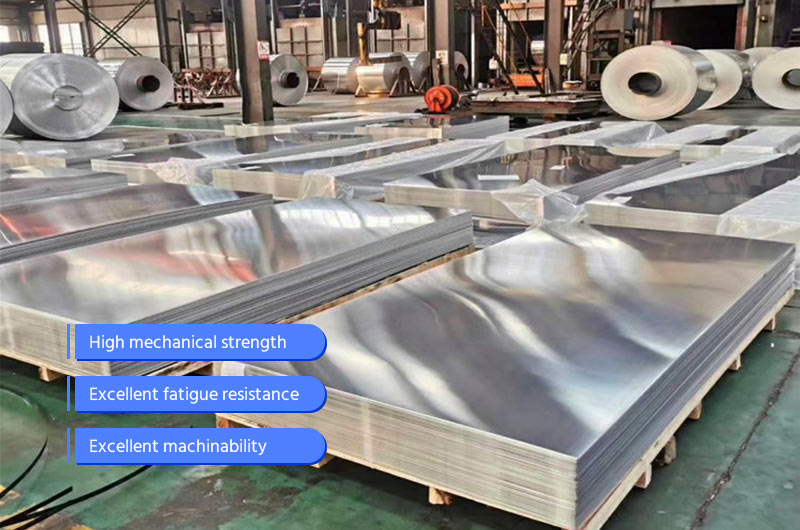

Performance advantages of Chalco 5083 aerospace aluminum sheet plate

- Good corrosion resistance

- High strength

- Good weldability and processability

- Good heat treatment performance

Application of 5083 aluminum sheet plate

Application of 5083 aluminum sheet in the aerospace field: 5083 aluminum sheet is used to make smaller and lighter aviation components like instruments, fasteners, cylinders, and tanks due to its strength and formability that meet the requirements for such parts.

Application of 5083 aluminum plate in the aerospace field: 5083 aluminum plate is used to make important aircraft structural components such as fuselage, wings, and tail wings due to its high strength and toughness. Its good welding performance allows for large structural component manufacturing.

Other applications of 5083 aluminum plate sheet: 5083 treat checkered aluminum plate, 5083 marine aluminum plate, 5083 automotive aluminum plate, 5083 tank car aluminum plate, 5083 armor plate, 5083 jig tooling plate.

Purchase guide for Chalco 5083 aerospace aluminum sheet plate

Price of Chalco 5083 aerospace aluminum sheet plate

Chalco relies on its own production and delivery capabilities to ensure the delivery of primary supplies to customers. Provide customers with the best quality products while ensuring the most competitive prices. Contact our customer service personnel for free samples and quotes.

Production capacity of Chalco 5083 aerospace aluminum sheet plate

Chalco's production capacity has also been fully recognized by customers. With a large production workshop and professional production team, sufficient inventory and large batch production capacity, it can meet any batch requirements of customers. At the same time, we can also provide fast delivery services to ensure that customers' production plans are not affected. Customized services can be provided for plate thickness, dimensions, surface treatment, etc.

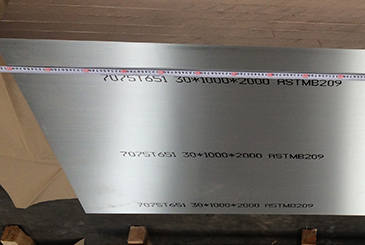

Chalco 5083 aluminum plate stock list

| Description | temper | Thickness/in | Width/in | Length/in |

| 0.25(t) 5083 H32 Aluminum Plate ASTM B928 48x96 | H32 | 0.25 | 48 | 96 |

| 0.25(t) 5083 H32 Aluminum Plate ASTM B928 48x144 | H32 | 0.25 | 48 | 144 |

| 0.25(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 96x240 | O | 0.25 | 96 | 240 |

| 0.375(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 60x144 | O | 0.375 | 60 | 144 |

| 0.375(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x240 | O | 0.375 | 72 | 240 |

| 0.375(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 96x288 | O | 0.375 | 96 | 288 |

| 0.5(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x240 | O | 0.5 | 72 | 240 |

| 0.5(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x240 | O | 0.5 | 72 | 240 |

| 0.75(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x240 | O | 0.75 | 72 | 240 |

| 0.75(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 96x288 | O | 0.75 | 96 | 288 |

| 1(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x240 | O | 1 | 72 | 240 |

| 1(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 96x288 | O | 1 | 96 | 288 |

| 1.25(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 60x144 | O | 1.25 | 60 | 144 |

| 1.5(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 120x240 | O | 1.5 | 120 | 240 |

| 2(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 72x144 | O | 2 | 72 | 144 |

| 2(t) 5083 O Aluminum Plate AMS4056, QQ-A-250/6 96x288 | O | 2 | 96 | 288 |

| 0.25(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 60x120 | H116 | 0.25 | 60 | 120 |

| 0.375(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 60x120 | H116 | 0.375 | 60 | 120 |

| 0.375(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 96x288 | H116 | 0.375 | 96 | 288 |

| 0.5(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 60x120 | H116 | 0.5 | 60 | 120 |

| 0.75(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 48x144 | H116 | 0.75 | 48 | 144 |

| 0.75(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 60x120 | H116 | 0.75 | 60 | 120 |

| 1(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 48x144 | H116 | 1 | 48 | 144 |

| 1(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 60x120 | H116 | 1 | 60 | 120 |

| 1.25(t) 5083 H116 Aluminum Plate ASTM B209, ASTM B928 48x144 | H116 | 1.25 | 48 | 144 |

| 0.25(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 0.25 | 48 | 144 |

| 0.375(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 0.375 | 48 | 144 |

| 0.5(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 0.5 | 48 | 144 |

| 0.75(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 0.75 | 48 | 144 |

| 1(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 1 | 48 | 144 |

| 2.5(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 2.5 | 48 | 144 |

| 2.875(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 2.875 | 48 | 144 |

| 3(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 3 | 48 | 144 |

| 3.25(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 3.25 | 48 | 144 |

| 3.5(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 3.5 | 48 | 144 |

| 4.25(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 4.25 | 48 | 144 |

| 6(t) 5083 H321 Aluminum Plate ASTM B209, ASTM B928 48x144 | H321 | 6 | 48 | 144 |

| 1.25(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 1.25 | 48.5 | 144.5 |

| 1.5(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 1.5 | 48.5 | 144.5 |

| 1.75(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 1.75 | 48.5 | 144.5 |

| 2(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 2 | 48.5 | 144.5 |

| 2.25(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 2.25 | 48.5 | 144.5 |

| 2.5(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 2.5 | 48.5 | 144.5 |

| 3(t) 5083 H131 Aluminum Plate MIL DTL46027 48.5x144.5 | H131 | 3 | 48.5 | 144.5 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote