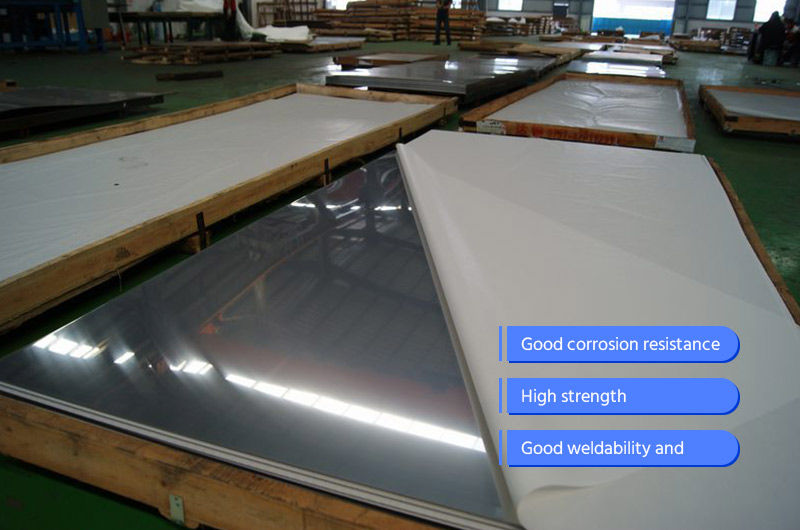

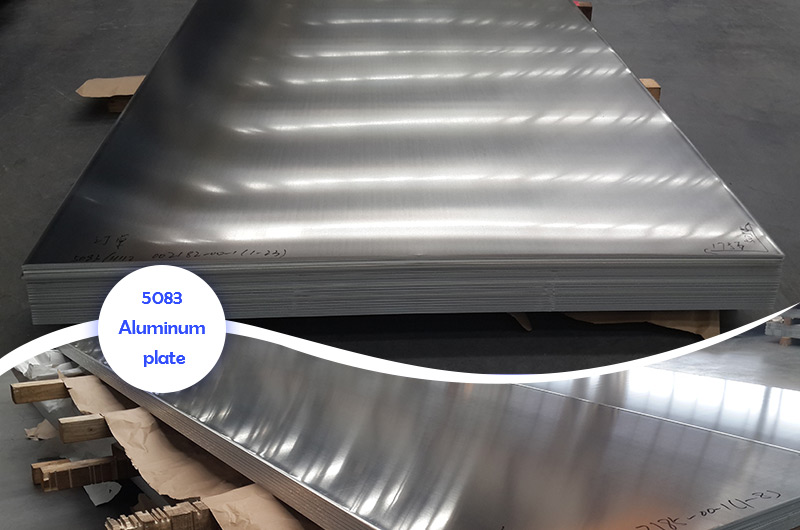

As an excellent automotive aluminum sheet material, 5083 Aluminum alloy Sheet has the characteristics of high strength, good corrosion resistance, good weldability and processability, and excellent heat resistance. It can be used to manufacture body structural parts (such as bumper), body panels, fuel tanks, wheel hubs, fenders, doors and other auto parts.Welcome contact

Why choose Chalco 5083 aluminum sheet for car body?

Automotive IATF16949 standard

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Well-known brand material certifications

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

The specification introduction of 5083 car body sheet material

Alloy: 5083 O H111 H32

ABS sheet dimension

Thickness: 0.70-1.50mm Width: 800-2400mm Length: 800-5500mm

ABS coil dimension

Thickness: 0.70-1.50mm Width: 800-2400mm

Specification: GB/T 33227-2016, JIS H4000, ASTM B209, EN 485

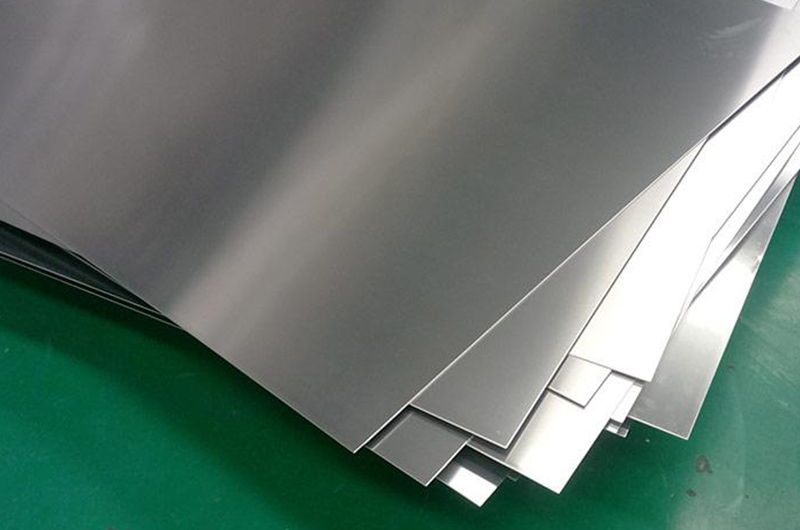

Chalco featured 5083 aluminum sheet plate for auto

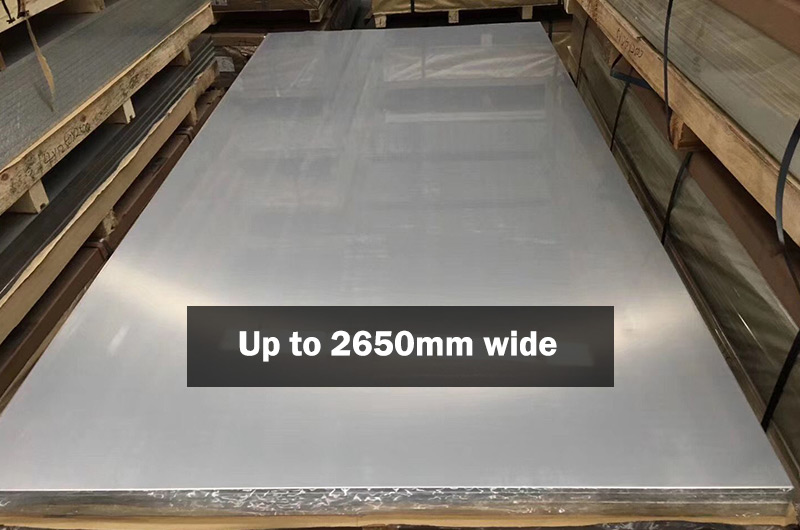

5083 aluminum ultra wide plate

Width:35.4”-104”(900mm-2650mm)

With large size, high strength, and lightweight characteristics, it is suitable for automotive body panels, fuel tanks, and vehicle structural components.

Contact us now

5083 aluminum treat checkered plate

Featuring a unique surface design that enhances slip resistance, it is commonly used for automotive floor panels, truck bodies, and other components requiring anti-slip functionality.

Contact us nowThis common size facilitates processing and application, suitable for automotive body panels, door panels, and more.

Contact us now

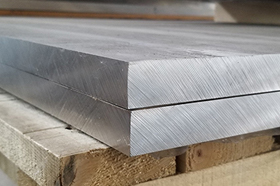

5083 aluminum cast plate

Thickness:0.24"-15.75"(6mm-400mm)

Width:52”-73.2”(1320mm-1860mm)

With high casting performance, it is suitable for automotive engine blocks, transmission system components, and other parts requiring high precision and strength.

5083 aluminum thick plate

With excellent mechanical properties and corrosion resistance, it is often used for automotive chassis and structural components that withstand high pressure and loads.

Contact us now

Chalco additional service——save time and costs for your automotive project

Deep Drawing, Cutting, and Other Additional Services

We provide deep drawing, cutting, and forming services to ensure aluminum sheet products meet the stringent requirements of automotive components during manufacturing.

Surface Processing: Enhancing Performance and Appearance

FM surface finish: provides a smooth base for further treatments

EDT: enhances paint adhesion with fine textured patterns

Ti/Zr:offers improved corrosion resistance and bonding for automotive parts

Surface Treatment: Adapting to Harsh Environments

NP(No Protection): leaves the surface untreated

P(Protection): adds a temporary protective layer

DO(Dry Oil): offers better corrosion resistance and uniform oil coverage for automotive applications

EO(Electrostatic Oil): high strength, corrosion resistance

Characteristics of 5083 automotive sheet metal panels

- 5083 Automotive sheet metal panels offer robust strength to meet industry demands.

- 5083 automobile body panels resist corrosion, extending part lifespan.

- 5083 automotive aluminum sheet welds seamlessly with other materials.

- 5083 automotive aluminum sheet enables versatile shaping methods.

- 5083 Aluminum alloy Sheet maintains properties in high-temperature environments.

- 5083 aluminum sheet for auto bodies allows diverse shaping methods.

- 5083 car body sheet metal ensures enduring properties over time.

- 5083 aluminum sheet for car bodies reduces vehicle weight, enhancing fuel efficiency and minimizing emissions.

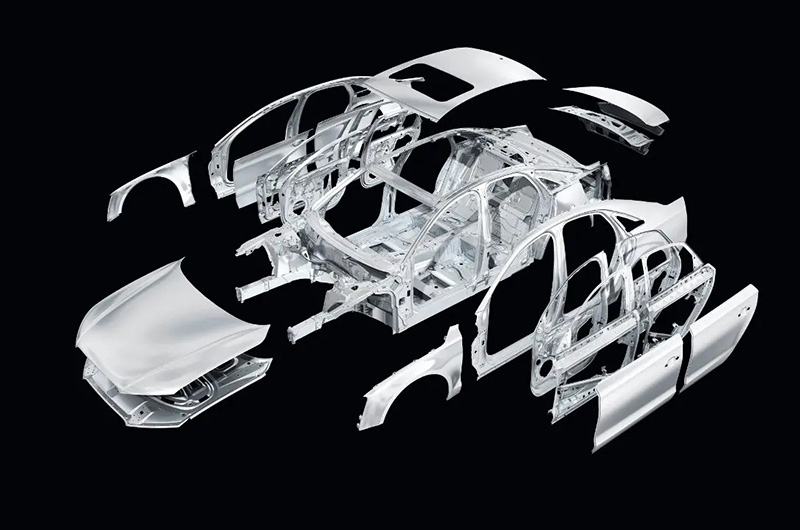

The usage of 5083 automotive aluminum sheet

- 5083 automotive body sheet metal have the characteristics of high strength, light weight, corrosion resistance, and fatigue resistance. They can be used in the manufacture of automotive body panels to improve the stability, safety and fuel consumption efficiency of the vehicle.

- 5083 aluminum for automotive body sheet panels can also be used in the manufacture of fuel tanks, which has excellent corrosion resistance and reliability, can effectively prevent fuel leakage and evaporation, and improve fuel economy.

- 5083 automotive sheet metal body panels can also be used in the manufacture of wheel hubs, with good strength and toughness, which can improve the load-bearing capacity and service life of the wheels.

- 5083 Automotive sheet metal panels can also be used in the manufacture of fender, which has excellent corrosion resistance and protection performance, and can effectively protect the body from stones, mud, etc. damage.

- 5083 automobile body panels can also be used in the manufacture of other auto parts, such as doors, roof, hood, chassis, etc., which can improve the overall performance and durability of the car.

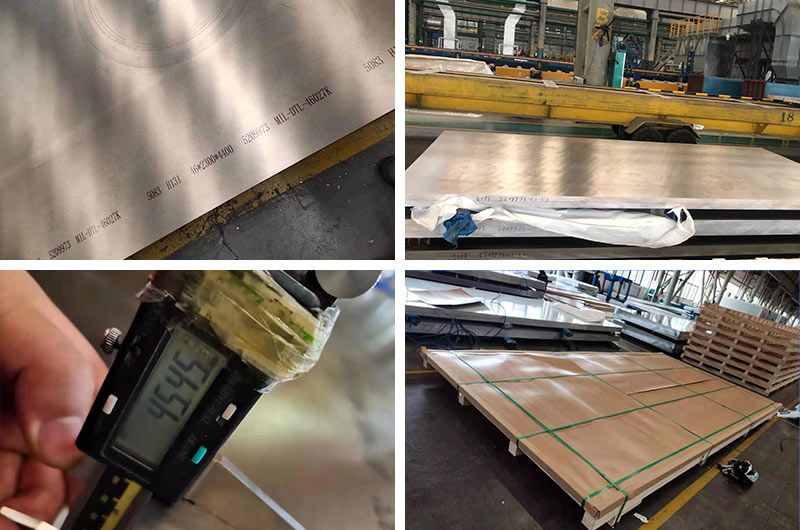

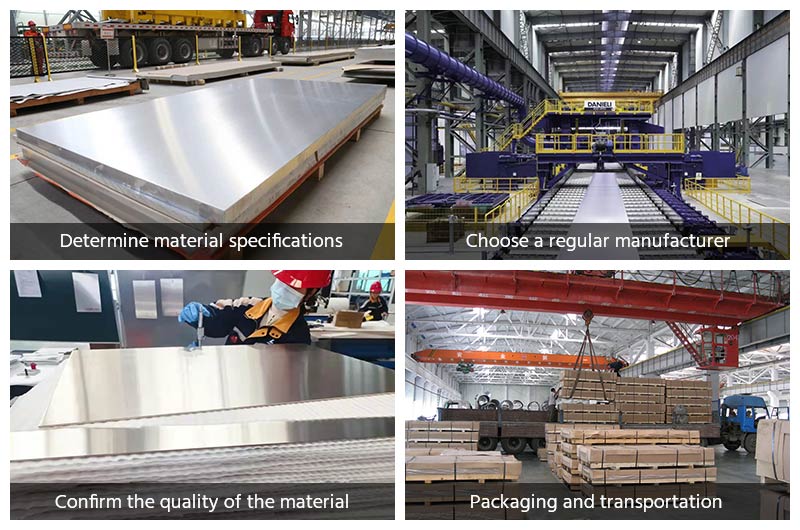

Chalco's quality control for 5083 automobile body panels

- Customize your 5083 automotive aluminum sheet according to your needs.

- Our 5083 car body sheet material boasts a smooth, flat surface without defects.

- Our 5083 automotive aluminum sheet offers reliable strength and hardness.

- We use advanced technology to ensure quality and performance.

- Our sheets come with corresponding inspection certificates to guarantee compliance with national or industry standards.

- We offer competitive pricing for 5083 auto body sheet metal.

- We prioritize safe packaging and shipping methods to prevent damage during transportation.

The chemical composition of 5083 aluminum for automotive body sheet panels

| Element | Composition (%) |

| Si | 0.40 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.40-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.15 |

| Al | Remainder |

The mechanical property of 5083 automotive sheet metal body panels

| Alloy Temper | Thickness mm | Tension Strength Rm N/mm2 | Yield Strength R p0.2 N/mm2 | Elongation A 50 min % |

| 5083 O H111 | 6.30-12.50 | 270-345 | 115 | ≥16 |

| 5083 H32 | 0.70-1.50 | 305-380 | 215 | ≥6 |

| Other requirements of aluminum car body sheet metal | |

| Flange performance | The grade of flanging of panels and strips for body panels is grade 1 or grade 2. If other products require flanging performance, it should be indicated in the order (or contract). |

| Paint brush line | The grade of paint brushing line for panels and samples of body panels is grade 1 or grade 2. When other products require the performance of paint wire, it should be indicated in the order (or contract). |

| Anti-dent performance | When the buyer has requirements on the dent resistance performance of the panels and strips used for body panels, the supplier shall provide relevant data on the dent resistance performance. |

| FLD performance | When the purchaser has FLD performance requirements for panels and strips used for body panels, the supplier shall provide relevant data on FLD performance. |

| High speed tensile properties | When the buyer has high-speed drawing performance requirements for the panels and strips used for body panels, the supplier shall provide relevant data on the high-speed drawing performance. |

| Microstructure | The microstructure of sheets and strips subjected to solution heat treatment is not allowed to be over-burned. |

| Oil amount | The oiling of the product is most determined through negotiation between the supplier and the buyer, and is indicated in the order form (or contract). |

| Passivation film thickness | The passivation film thickness of the product is determined through negotiation between the supplier and the buyer, and is specified in the order form (or contract). |

| Appearance Quality | Defects such as surface roughness, slight unevenness, scratches, color difference and small prints are allowed on the surface of panels and strips for inner panels of body panels and panels and strips for body structural parts, which do not affect the formability. |

| Defects such as cuts and marks that affect the use are not allowed on the outer surface of the panels and strips used for the outer panels of the body panels, and defects such as slight color difference, such as paint openings and cover-ups, are allowed. | |

Thickness deviation of 5083 O H111 H32 aluminum sheets and strips for body panels

| Thickness | Allowable thickness tolerance within the following width range | |||

| mm | ≤1500 | >1500-1700 | >1700-2000 | >2000-2400 |

| 0.30-0.50 | ±0.03 | ±0.04 | - | - |

| >0.50-0.80 | ±0.03 | ±0.04 | ±0.04 | - |

| >0.80-1.20 | ±0.04 | ±0.04 | ±0.05 | ±0.06 |

| >1.20-2.00 | ±0.05 | ±0.05 | ±0.06 | ±0.07 |

| >2.00-2.50 | ±0.06 | ±0.07 | ±0.07 | ±0.08 |

| >2.50-3.00 | ±0.07 | ±0.08 | ±0.08 | ±0.09 |

| >3.00-3.50 | ±0.08 | ±0.09 | ±0.10 | ±0.11 |

Width deviation of 5083 O H111 H32 aluminum sheets and strips for body structural parts

| Thickness mm | Width tolerances within the following width ranges | |||||||

| <100.0 | >100.0- 300.0 | >300.0 - 500.0 | >500.0- 800.0 | >800.0- 1 250.0 | >1 250.0-1 800.0 | >1 800.0-2 000.0 | >2 000.0- 2 400.0 | |

| 0.30—1.60 | + 0, 3 0 | + 0, 4 0 | + 1.0 0 | + 1.5 0 | + 2, 0 0 | + 3.0 0 | — | — |

| >1.60—3.50 | — | — | — | + 2.0 0 | 4-3.0 0 | + 4.0 0 | + 5.0 0 | + 6.0 0 |

Unevenness of 5083 O H111 H32 aluminum sheets and strips for body panel

| Thickness mm | The unevenness of sheets and strips within the following width ranges shall not be greater than | Termination area, warpage height | ||||

| <500.0 | >500.0-1 000.0 | >1 000.0-1 500.0 | >1 500.0-2 000.0 | >2 000.0 | ||

| 0.30-0.50 | 3 | 4 | 4 | 4 | — | ≤25 |

| >0.50-0.80 | 3 | 4 | 4 | 7 | 8 | |

| >0.80-1.60 | 3 | 4 | 4 | 6 | 8 | |

| >1.60-2.00 | 3 | 4 | 4 | 6 | 8 | |

| >2.00-3.50 | 3 | 4 | 4 | 6 | 8 | |