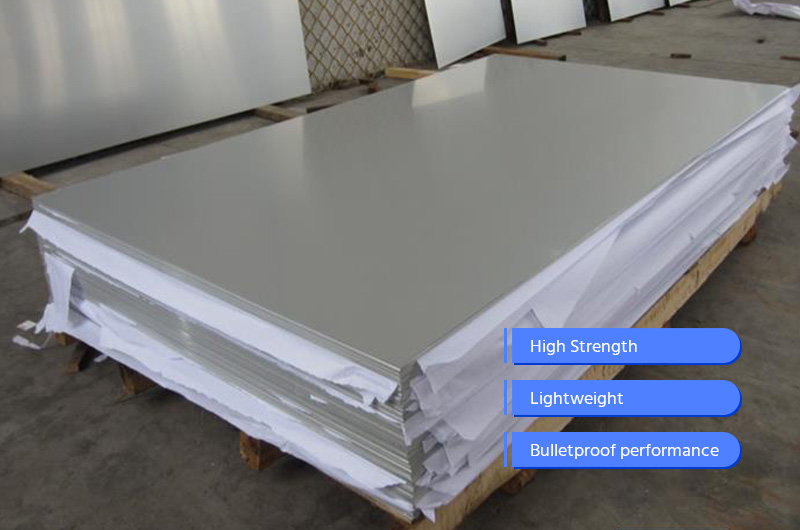

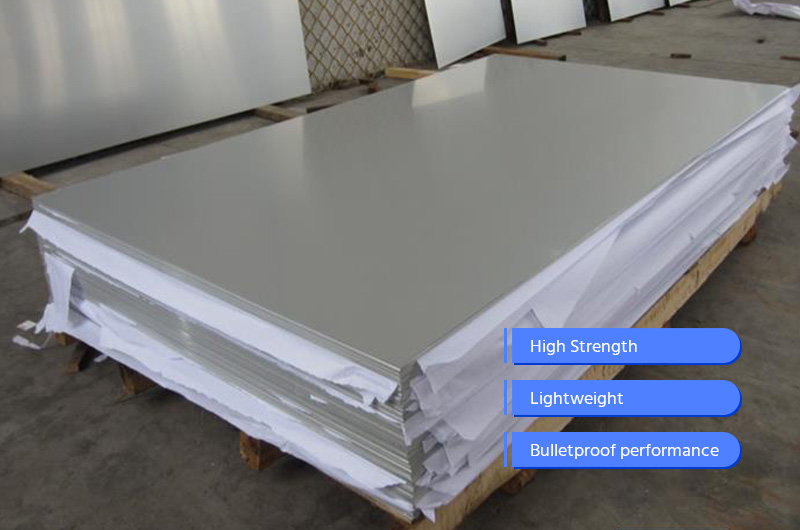

Chalco produces 5083 5456 5059 H131 H136 H116 H321 Aluminum Armor Plate for armored vehicles, diving equipment and military armored vehicles, tanks and bulletproof vehicles, etc. The use of alloy armor plates can provide excellent protection against threats from explosions, impacts and shrapnel , while having the advantage of lighter weight.

The aluminum alloy armor plates and bulletproof plates produced by CHALCO are supplied to world-renowned military equipment manufacturers such as SUKROBORONPROM, ASELSAN HEAVY INDUSTRIES TAXILA, Raytheon Company, and SF Engineering.Quick Quote

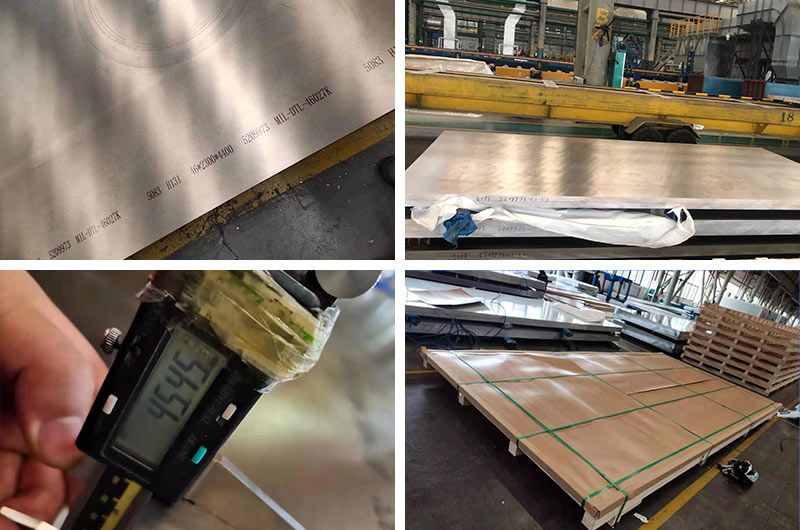

5083 5456 5059 Aluminium armor plate specification

| Aluminum alloy | 5083 5456 5059 |

| Temper | H131 H136 H116 H321 |

| Production standards | MIL-DTL-46027, ASTM B209, EN 485-2, SAE AMS4027 |

| Thickness (mm) | 0.250 to 3.000 inch |

| Width (mm) | ≤100inch |

| Length (mm) | ≤236inch |

| Remark | The above specifications are for reference, special specifications can be customized. And Certificates with a traceable lot number are available for these products. |

5083 5456 5059 Aluminium armor plate Stock Size

| Description | Temper | Thickness | Width * Length |

| Aluminum Armor Sheet 5083-H131 0.25"(t) | H131 | 0.25" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 0.375"(t) | H131 | 0.375" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 0.5"(t) | H131 | 0.5" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 0.75"(t) | H131 | 0.75" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 1"(t) | H131 | 1" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 1.25"(t) | H131 | 1.25" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 1.5"(t) | H131 | 1.5" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 1.75"(t) | H131 | 1.75" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 2"(t) | H131 | 2" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 2.25"(t) | H131 | 2.25" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 2.5"(t) | H131 | 2.5" | 72" * 144" |

| Aluminum Armor Sheet 5083-H131 3"(t) | H131 | 3" | 72" * 144" |

| Aluminum Armor Sheet 5083-H32 0.25"(t) | H32 | 0.25" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 0.375"(t) | H32 | 0.375" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 0.5"(t) | H32 | 0.5" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 0.75"(t) | H32 | 0.75" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 1"(t) | H32 | 1" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 1.25"(t) | H32 | 1.25" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 1.5"(t) | H32 | 1.5" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 1.75"(t) | H32 | 1.75" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 2"(t) | H32 | 2" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 2.25"(t) | H32 | 2.25" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 2.5"(t) | H32 | 2.5" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 3"(t) | H32 | 3" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 3.25"(t) | H32 | 3.25" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 3.5"(t) | H32 | 3.5" | 48" * 144" |

| Aluminum Armor Sheet 5083-H32 4"(t) | H32 | 4" | 48" * 144" |

| Aluminum Armor Sheet 5456-H116 0.125"(t) | H116 | 0.125" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.156"(t) | H116 | 0.156" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.190"(t) | H116 | 0.190" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.250"(t) | H116 | 0.250" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.313"(t) | H116 | 0.313" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.375"(t) | H116 | 0.375" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.500"(t) | H116 | 0.500" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.625"(t) | H116 | 0.625" | Can be cut |

| Aluminum Armor Sheet 5456-H116 0.750"(t) | H116 | 0.750" | Can be cut |

| Aluminum Armor Sheet 5456-H116 1.250"(t) | H116 | 1.250" | Can be cut |

| Aluminum Armor Sheet 5456-H116 1.500"(t) | H116 | 1.500" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.125"(t) | H131 | 0.125" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.156"(t) | H131 | 0.156" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.190"(t) | H131 | 0.190" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.250"(t) | H131 | 0.250" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.313"(t) | H131 | 0.313" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.375"(t) | H131 | 0.375" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.500"(t) | H131 | 0.500" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.625"(t) | H131 | 0.625" | Can be cut |

| Aluminum Armor Sheet 5059-H131 0.750"(t) | H131 | 0.750" | Can be cut |

| Aluminum Armor Sheet 5059-H131 1.250"(t) | H131 | 1.250" | Can be cut |

| Aluminum Armor Sheet 5059-H131 1.500"(t) | H131 | 1.500" | Can be cut |

Can't find the size? It doesn't matter, we can customize any specifications you wantQuick Quote

5083 5456 5059 Aluminium armor plate chemical composition

| ELEMENTS | Composition (%) | ||

| 5083 CLASS 1 | 5456 >CLASS 2 | 5059 CLASS 3 | |

| Silicon | 0.40 | 0.25 | 0.45 |

| Iron | 0.40 | 0.40 | 0.50 |

| Copper | 0.10 | 0.10 | 0.25 |

| Manganese | 0.40 - 1.0 | 0.50 - 1.0 | 0.6 - 1.2 |

| Magnesium | 4.0 – 4.9 | 4.7 – 5.5 | 5.0 – 6.0 |

| Chromium | 0.05 – 0.25 | 0.05 – 0.20 | 0.25 |

| Zinc | 0.25 | 0.25 | 0.40 – 0.9 |

| Titanium | 0.15 | 0.20 | 0.20 |

| Other, max. Each | 0.05 | 0.05 | 0.05 |

| Other, max. Total 3/ | 0.15 | 0.15 | 0.15 |

| Aluminum | Remainder | Remainder | Remainder |

5083 5456 5059 Aluminium armor plate minimum mechanical properties

| Thickness, inches | Tensile Strength, Ksi | Yield Strength, 0.2% Offset, Ksi | Elongation percent | ||||||

| 5083 | 5456 | 5059 | 5083 | 5456 | 5059 | 5083 | 5456 | 5059 | |

| 0.250 to 0.499, incl. | 45.0 | 45.0 | 53.0 | 35.0 | 35.0 | 39.0 | 8 | 8 | 8 |

| 0.500 to 2.000, incl. | 45.0 | 45.0 | 52.0 | 37.0 | 37.0 | 39.0 | 8 | 8 | 7 |

| 2.001 to 3.000, incl. | 44.0 | 44.0 | 47.0 | 35.0 | 35.0 | 39.0 | 9 | 9 | 8 |

5083 5456 5059 Aluminium armor plate minimum mechanical properties for each class of alloy

| 5083 | Tensile Strength, Ksi | Yield Strength, 0.2% Offset, Ksi | Elongation percent | ||||||

| Thickness, inches | H131 | H136 | H321 H116 | H131 | H136 | H321 H116 | H131 | H136 | H321 H116 |

| 0.250 to 0.499, incl. | 45.0 | 44.0 | 44.0 | 35.0 | 31.0 | 31.0 | 8 | 10 | 10 |

| 0.500 to 2.000, incl. | 45.0 | 41.0 | 41.0 | 37.0 | 29.0 | 29.0 | 8 | 10 | 10 |

| 2.001 to 3.000, incl. | 44.0 | 41.0 | 41.0 | 35.0 | 29.0 | 29.0 | 9 | 10 | 10 |

| 5456 | Tensile Strength, Ksi | Yield Strength, 0.2% Offset, Ksi | Elongation percent | ||||||

| Thickness, inches | H131 | H321 H116 | H24 | H131 | H321 H116 | H24 | H131 | H321 H116 | H24 |

| 0.250 to 0.499, incl. | 45.0 | 46.0 | 53.7 | 35.0 | 33.0 | 40.6 | 8 | 10 | 13 |

| 0.500 to 2.000, incl. | 45.0 | 41.0 | 53.7 | 37.0 | 29.0 | 40.6 | 8 | 12 | 13 |

| 2.001 to 3.000, incl. | 44.0 | 41.0 | 53.7 | 35.0 | 29.0 | 40.6 | 9 | 12 | 13 |

| 5059 | Tensile Strength, Ksi | Yield Strength, 0.2% Offset, Ksi | Elongation percent | ||||||

| Thickness, inches | H131 | H136 | H321 H116 | H131 | H136 | H321 H116 | H131 | H136 | H321 H116 |

| 0.250 to 0.499, incl. | 57.0 | 53.0 | 44.0 | 44.0 | 43.0 | 31.0 | 8 | 10 | 10 |

| 0.500 to 2.000, incl. | 57.0 | 52.0 | 41.0 | 43.0 | 42.0 | 29.0 | 7 | 10 | 10 |

| 2.001 to 3.000, incl. | 50.0 | 50.0 | 41.0 | 42.0 | 42.0 | 29.0 | 8 | 10 | 10 |

Nominal design thickness for Ballistic test 5083 5456 5059 armor plate

| 5083 | 5456 | Projectile to be used |

| 0.705-1.100 | 0.705-1.100 | Cal. .50 FSP |

| 1.101-1.700 | 1.101-1.700 | Cal. .30 APM2 |

| 1.101-1.700 | 1.101-1.700 | 20mm FSP |

| 1.701-3.000 | 1.701-3.000 | Cal. .50 APM2 |

5083 5456 5059 aluminum alloy armor plate related hot selling recommendations

5083 aluminum has high strength, light weight and excellent corrosion resistance, making it a very valuable material for military applications, including armor plating. To ensure the success of any armor plate products and solutions, it is important to work with an experienced material supplier. At Chalco, a team of sales professionals is dedicated to partnering with customers every step of the purchasing process. Contact a friendly and knowledgeable service representative today.Quick Quote

5083-aluminum-plate

5083-aluminum-round-bar

5083-aluminum-pipe

5083-armored-vehicle-forging

armored-vehicle-extruded

2139-armored-vehicle-sheet

7039-armored-vehicle-sheet

7b52-armored-vehicle-sheet

7a52-armored-vehicle-sheet

5083 5456 5059 aluminum alloy armor plate application field

One of the core components of bulletproof vests is the 5083 and 5456 armored plates. These plates are designed to provide bulletproof and protective functions, effectively shielding individuals and critical equipment from enemy firepower and explosions.

Another crucial application area is turret armor, where high-strength armor plates such as 5083 and 5456 are employed. These armor plates play a critical role in tanks, self-propelled artillery, and armored vehicle turrets, delivering outstanding protection to ensure the safety of gunners and fire control equipment in combat.

Chassis armor is utilized for various sections of armored vehicle chassis, providing additional strength to safeguard against landmines, bombs, and other bottom-based attacks. This reinforcement enhances the durability and survivability of the chassis, making it more reliable on the battlefield.

Reinforcing side armor contributes to an overall increase in the vehicle's protection level, considering that the sides are one of the vulnerable areas susceptible to attacks. By using forged armor plates, the side structures can be strengthened, offering superior resistance to impact and explosive forces, thereby enhancing the vehicle's survivability under enemy attacks.Quick Quote

Points to note when purchasing 5083 5456 5059 aluminum alloy armor plates

Standards and specifications: ensure that the selected aluminum alloy panels comply with applicable standards and specifications, such as the MIL-DTL-46027K standard or other relevant industry standards. These standards specify the performance and quality requirements for alloy plates.

Strength and hardness: the armor plate needs to have sufficient strength and hardness to provide effective protection. Check the strength parameters of the selected alloy plate, such as yield strength and tensile strength, to ensure that it meets the requirements of the armor plate.

Protection performance: different alloy plates have different capabilities for different levels of protection. According to the required level of protection and application scenarios, select the appropriate aluminum alloy plate, considering its anti-explosion, anti-ballistic and anti-penetration properties.

Thickness and size: determine the appropriate thickness and size of the selected aluminum alloy plate according to actual needs. Consider the weight of the armor plate, workability and installation requirements to select the appropriate plate size.

Plate supplier and quality certification: choose a reputable aluminum alloy plate supplier and ensure that the selected plate has relevant quality certification, such as ISO 9001 certification, to ensure the quality and reliability of the plate.

Cost-effectiveness: comprehensively consider the price and performance of the selected aluminum alloy plate, and choose an armor plate with reasonable cost-effectiveness to meet the budget and needs.Quick Quote