Why choose Chalco 5059 marine grade aluminum plate sheet?

Authentication

Chalco products are manufactured in our advanced factories using strict quality and environmental management systems, and have passed CCS, DNV, NK, CCS, ABS, BV, LR, KR certifications.

Production strength

Production and management comply with international marine quality system, to make sure best quality of super resistance to corrosion, good welding ability and strong impact-resistance.

Production standard

ASTM B928/B928M-15

ASTM B928/B928M-21

ISO 12215-5:2019

Mechanical properties of 5059 marine grade aluminum plate sheet

| Alloy | Temper | Thickness mm | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Elongation% | |

| A50 mm | A | |||||

| 5059 | O | 3.00-50.00 | 330-380 | ≥160 | ≥24 | ≥24 |

| H111 | 3.00-50.00 | 330-380 | ≥160 | ≥24 | ≥24 | |

| H116 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

| >20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

| H321 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

| 20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

| Anti-corrosion peeling performance | plate sheets in the state of H116 and H321 shall not have Class E exfoliation corrosion after exfoliation corrosion test; when the contract is marked as "used for sea-going hull shell" or "long-term direct contact with seawater", PB shall not appear after exfoliation corrosion test Exfoliation corrosion. Exfoliation corrosion resistance test shall be carried out according to the method specified in GB/T 22639. | |||||

| Intergranular corrosion performance | For plate sheets in the state of H116 and H321, the maximum depth of intergranular corrosion does not exceed grade 3 after the intergranular corrosion test. Carry out intergranular pitting corrosion test according to the method specified in GB/T 7998. | |||||

The specification of 5059 marine grade aluminum plate sheet

| Thickness (mm) | Width (mm) | Length (mm) |

| 3.00-20.00 | 1 000-2 400 | 1 000-11 000 |

| >20.00-50.00 | 1 000-3 500 | 1 000-20 000 |

| Plate thickness deviation (mm) | |||

| Thickness | The following widths correspond to the allowable deviation in thickness | ||

| ≤1500 | >1500-2000 | >2000 | |

| 3.00-4.00 | +0.10-0.10 | +0.17-0.15 | +0.23-0.15 |

| >4.00-8.00 | +0.20-0.20 | +0.23-0.20 | +0.28-0.25 |

| >8.00-12.00 | +0.38-0.25 | +0.51-0.25 | +0.58-0.25 |

| >12.00-20.00 | +0.50-0.35 | +0.60-0.40 | +0.65-0.50 |

| >20.00-50.00 | +0.65-0.45 | +0.75-0.50 | +0.90-0.65 |

Chemical composition of 5059 marine grade aluminum plate sheet

| Chemical composition (%) | |

| Al | Rest |

| Mg | 4.5-5.6 |

| Mn | 0.8-1.5 |

| Cr | 0.15-0.35 |

| Ti | 0.15-0.25 |

Advantages of Chalco 5059 marine grade aluminum plate sheet

Chalco 5059 ship plate sheet is a high-strength aluminum alloy material with the following advantages:

High strength: 5059 ship plate sheet has excellent strength characteristics, which can meet the strength requirements of ship structures. This high strength allows the plate sheet to withstand the loads and stresses of the ship in sailing and offshore environments.

Excellent anti-corrosion performance: 5059 ship plate sheet exhibits excellent anti-corrosion performance in marine environment. It resists the corrosive effects of salt water and humidity on materials, thereby increasing the durability and maintenance intervals of the hull.

Lightweight design: compared with traditional steel plate sheets, 5059 ship plate sheet has a lower density, so it contributes to light weight in ship design. It reduces the overall weight of the vessel, improving fuel efficiency and sailing performance.

Ease of processability: 5059 ship plate sheet has good processability and can be cut, bent, welded and shaped. This allows manufacturers to tailor the hull structure to specific needs, offering more flexible design options.

Good welding performance: 5059 ship plate sheet has good welding performance and can be connected by various welding methods. This makes the manufacturing process easier and ensures the strength and reliability of the welded joint.

In general, Chalco 5059 ship plate sheet has been widely used in the field of shipbuilding due to its high strength, excellent corrosion resistance and light weight characteristics. However, in specific applications, it is still necessary to evaluate the applicability and performance requirements of materials according to the ship design and service conditions.

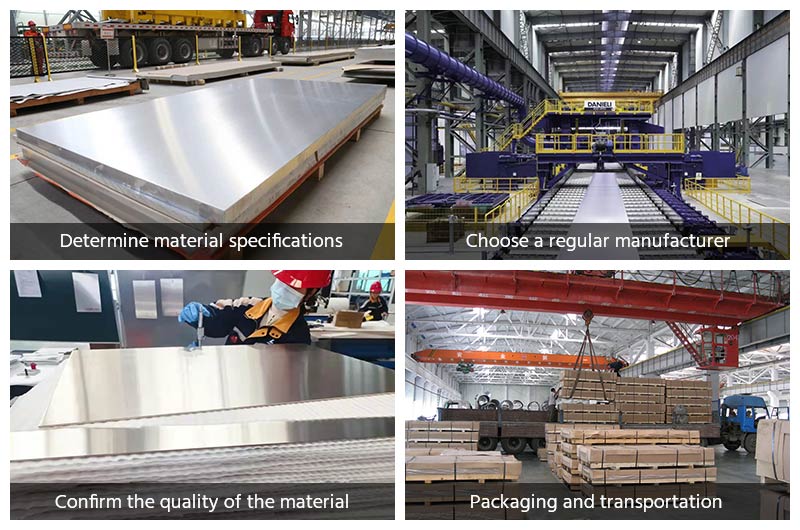

Precautions for purchasing 5059 marine grade aluminum plate sheet

Material certification: ensure that the purchased 5059 aluminum alloy material meets relevant standards and obtains a qualified material certification certificate.

Specification requirements: select the appropriate specification, size and shape according to actual needs to ensure that the purchased aluminum plate sheet can meet the specific ship plate sheet manufacturing requirements.

Surface quality: check whether the surface of the purchased aluminum plate sheet is smooth, free of cracks, wear, oxidation or other surface defects, to ensure that the surface quality of the aluminum plate sheet meets the requirements.

Supplier reputation: choose a reputable and experienced supplier to purchase to ensure that the purchased 5059 ship plate sheet is reliable in quality, reasonable in price and timely in delivery.

Storage requirements: pay attention to the storage requirements of the aluminum plate sheet, keep it dry, avoid moisture, mechanical impact or other damage.

In short, when purchasing 5059 ship plate sheets, you need to pay attention to material certification, specification requirements, surface quality, supplier reputation and storage requirements, etc., to ensure that the purchased aluminum plate sheets are reliable in quality and meet the requirements.

Applications of Chalco 5059 marine grade aluminum plate sheet

Chalco 5059 ship plate sheets are widely used in the field of shipbuilding. The following are some common application areas:

Hull structure: 5059 ship plate sheet can be used for structural components of the hull, including hull, deck, bulkhead, ship superstructure, etc. Its high strength and corrosion resistance allow ships to withstand loads and stresses in harsh marine environments.

Inside the ship: 5059 ship plate sheet can also be used for parts and equipment inside the ship, such as ship cargo warehouses, compartment partitions, steps, deck covers, etc. Its lightweight design helps to reduce overall weight and improve the vessel's fuel efficiency and payload capacity.

Ship deck equipment: because 5059 ship plate sheet has excellent strength and corrosion resistance, it is often used in ship deck equipment, such as gangway, porthole, ship crane, ship door, etc. These devices need to be able to withstand the challenges of the external environment and maintain structural integrity.

Marine storage tanks and fuel tanks: The corrosion resistance of 5059 Shipboard makes it an ideal material for marine storage tanks and fuel tanks. It can be used to store and transport various liquids such as fuel oil, fresh water and other chemicals.

It should be noted that specific application areas may vary depending on vessel type, design requirements and manufacturer's requirements. Boat builders and designers often choose the appropriate material and specification to meet the needs of a particular application based on specific needs and requirements.