7050 aluminum sheet is one of the primary materials chosen for aerospace applications, particularly within the thickness range of 3-6 inches. Compared to the older, more mature 7075 alloy, 7050 alloy exhibits better toughness and corrosion resistance. Its lower sensitivity to quenching allows it to maintain its strength characteristics in thicker sections, while also possessing good resistance to stress corrosion cracking and fracture toughness. The common specification is AMS 4050, although individual manufacturers may have their own standards. 7050-T7451 sheet offers excellent stress corrosion and peel resistance, strength, and fracture toughness, even surpassing the more common 7075 aerospace aluminum alloy. Typical applications include fuselage frames, bulkheads, and wing components. Welding is not recommended as it may lead to weld cracks, porosity, and weak joints.

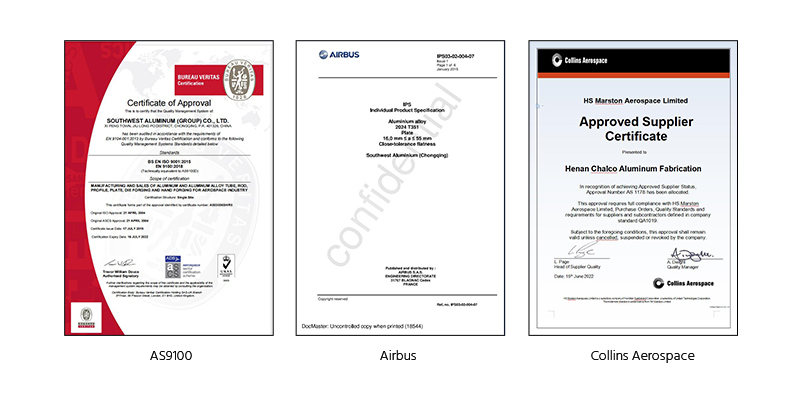

7050 aviation aluminum plate sheet has excellent corrosion resistance, weldability and formability, and has extremely high strength and hardness, Chalco can produce AMS 4050, AMS-STD-2154, EAC MS1004, EAC MS1005 QQ-A-430, EN 3982, 7050 Aerospace aluminum plate, has AS9100 Collin Aviation Certification.

Specifications of Chalco 7050 aerospace grade aluminum plate sheetQuick Quote

Alloy: 7050

Equivalent name: AA7050, EN AW-7050, A97050, JIS: A7050

Material temper: F, O, T6, T7351, T73, T7651, T7451, T7452, etc.

Specificationsr: AMS 4050; AMS STD 2154; ASTM B594; BAMS 516-003; BMS7-323 TY 1; BSS 7055; CLASS A; CMMP 025; DMS 2233; MEP 02 014; MMS 1420; MMS 1439; MMS 149; PS21271; BMS 7-323 TY 111; LMA-M7050; 299-947-530; OMS1-1270.

Thickness: 0.2mm-300mm

Width: 500mm-2600mm

Length: 500mm-12000mm

It should be noted that the specifications and dimensions of the 7050 aluminum sheet can be customized according to customer needs to meet different applications. At the same time, for some products with special shapes and processing requirements, special customization and processing are required to ensure the quality and performance of the products.

Stock of Chalco 7050 aerospace aluminum plate Sheet

Aluminum plates of different sizes in Chalco’s inventory can be cut, with fast delivery and competitive prices.Quick Quote

Regular stock specifications: 1525mm×3660mm, 1250mm×2550mm, 2020mm×4020mm

Regular stock thickness: 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm,

50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm, 85mm, 90mm, 100mm, 110mm

120mm, 150mm, 160mm, 180mm, 200mm, 250mm

| Products | Thickness | Length | Width |

| 0.25"*12"*12" 7050-T7451 Aluminum Plate | 0.25" | 12" | 12" |

| 0.25"*18"*12" 7050-T7451 Aluminum Plate | 0.25" | 18" | 12" |

| 0.25"*24"*12" 7050-T7451 Aluminum Plate | 0.25" | 24" | 12" |

| 0.25"*24"*24" 7050-T7451 Aluminum Plate | 0.25" | 24" | 24" |

| 0.25"*36"*12" 7050-T7451 Aluminum Plate | 0.25" | 36" | 12" |

| 0.25"*36"*24" 7050-T7451 Aluminum Plate | 0.25" | 36" | 24" |

| 0.25"*36"*36" 7050-T7451 Aluminum Plate | 0.25" | 36" | 36" |

| 0.25"*36"*48" 7050-T7451 Aluminum Plate | 0.25" | 36" | 48" |

| 0.375"*12"*12" 7050-T7451 Aluminum Plate | 0.375" | 12" | 12" |

| 0.375"*12"*18" 7050-T7451 Aluminum Plate | 0.375" | 12" | 18" |

| 0.375"*12"*24" 7050-T7451 Aluminum Plate | 0.375" | 12" | 24" |

| 0.375"*24"*24" 7050-T7451 Aluminum Plate | 0.375" | 24" | 24" |

| 0.375"*12"*36" 7050-T7451 Aluminum Plate | 0.375" | 12" | 36" |

| 0.375"*24"*36" 7050-T7451 Aluminum Plate | 0.375" | 24" | 36" |

| 0.375"*36"*36" 7050-T7451 Aluminum Plate | 0.375" | 36" | 36" |

| 0.375"*36"*48" 7050-T7451 Aluminum Plate | 0.375" | 36" | 48" |

| 0.5"*12"*12" 7050-T7451 Aluminum Plate | 0.5" | 12" | 12" |

| 0.5"*18"*12" 7050-T7451 Aluminum Plate | 0.5" | 18" | 12" |

| 0.5"*24"*12" 7050-T7451 Aluminum Plate | 0.5" | 24" | 12" |

| 0.5"*24"*24" 7050-T7451 Aluminum Plate | 0.5" | 24" | 24" |

| 0.5"*36"*12" 7050-T7451 Aluminum Plate | 0.5" | 36" | 12" |

| 0.5"*36"*24" 7050-T7451 Aluminum Plate | 0.5" | 36" | 24" |

| 0.5"*36"*36" 7050-T7451 Aluminum Plate | 0.5" | 36" | 36" |

| 0.5"*36"*48" 7050-T7451 Aluminum Plate | 0.5" | 36" | 48" |

| 0.625"*12"*12" 7050-T7451 Aluminum Plate | 0.625" | 12" | 12" |

| 0.625"*18"*12" 7050-T7451 Aluminum Plate | 0.625" | 18" | 12" |

| 0.625"*24"*12" 7050-T7451 Aluminum Plate | 0.625" | 24" | 12" |

| 0.625"*24"*24" 7050-T7451 Aluminum Plate | 0.625" | 24" | 24" |

| 0.625"*36"*12" 7050-T7451 Aluminum Plate | 0.625" | 36" | 12" |

| 0.625"*36"*24" 7050-T7451 Aluminum Plate | 0.625" | 36" | 24" |

| 0.625"*36"*36" 7050-T7451 Aluminum Plate | 0.625" | 36" | 36" |

| 0.625"*36"*48" 7050-T7451 Aluminum Plate | 0.625" | 36" | 48" |

| 0.75"*12"*12" 7050-T7451 Aluminum Plate | 0.75" | 12" | 12" |

| 0.75"*18"*12" 7050-T7451 Aluminum Plate | 0.75" | 18" | 12" |

| 0.75"*24"*12" 7050-T7451 Aluminum Plate | 0.75" | 24" | 12" |

| 0.75"*24"*24" 7050-T7451 Aluminum Plate | 0.75" | 24" | 24" |

| 0.75"*36"*12" 7050-T7451 Aluminum Plate | 0.75" | 36" | 12" |

| 0.75"*36"*24" 7050-T7451 Aluminum Plate | 0.75" | 36" | 24" |

| 0.75"*36"*36" 7050-T7451 Aluminum Plate | 0.75" | 36" | 36" |

| 0.75"*36"*48" 7050-T7451 Aluminum Plate | 0.75" | 36" | 48" |

| 1"*12"*12" 7050-T7451 Aluminum Plate | 1" | 12" | 12" |

| 1"*18"*12" 7050-T7451 Aluminum Plate | 1" | 18" | 12" |

| 1"*24"*12" 7050-T7451 Aluminum Plate | 1" | 24" | 12" |

| 1"*24"*24" 7050-T7451 Aluminum Plate | 1" | 24" | 24" |

| 1"*36"*12" 7050-T7451 Aluminum Plate | 1" | 36" | 12" |

| 1"*36"*24" 7050-T7451 Aluminum Plate | 1" | 36" | 24" |

| 1"*36"*36" 7050-T7451 Aluminum Plate | 1" | 36" | 36" |

| 1"*36"*48" 7050-T7451 Aluminum Plate | 1" | 36" | 48" |

| 1.25"*12"*12" 7050-T7451 Aluminum Plate | 1.25" | 12" | 12" |

| 1.25"*18"*12" 7050-T7451 Aluminum Plate | 1.25" | 18" | 12" |

| 1.25"*24"*12" 7050-T7451 Aluminum Plate | 1.25" | 24" | 12" |

| 1.25"*24"*24" 7050-T7451 Aluminum Plate | 1.25" | 24" | 24" |

| 1.25"*36"*12" 7050-T7451 Aluminum Plate | 1.25" | 36" | 12" |

| 1.25"*36"*24" 7050-T7451 Aluminum Plate | 1.25" | 36" | 24" |

| 1.25"*36"*36" 7050-T7451 Aluminum Plate | 1.25" | 36" | 36" |

| 1.25"*36"*48" 7050-T7451 Aluminum Plate | 1.25" | 36" | 48" |

| 1.5"*12"*12" 7050-T7451 Aluminum Plate | 1.5" | 12" | 12" |

| 1.5"*18"*12" 7050-T7451 Aluminum Plate | 1.5" | 18" | 12" |

| 1.5"*24"*12" 7050-T7451 Aluminum Plate | 1.5" | 24" | 12" |

| 1.5"*24"*24" 7050-T7451 Aluminum Plate | 1.5" | 24" | 24" |

| 1.5"*36"*12" 7050-T7451 Aluminum Plate | 1.5" | 36" | 12" |

| 1.5"*36"*24" 7050-T7451 Aluminum Plate | 1.5" | 36" | 24" |

| 1.5"*36"*36" 7050-T7451 Aluminum Plate | 1.5" | 36" | 36" |

| 1.5"*36"*48" 7050-T7451 Aluminum Plate | 1.5" | 36" | 48" |

| 1.75"*12"*12" 7050-T7451 Aluminum Plate | 1.75" | 12" | 12" |

| 1.75"*18"*12" 7050-T7451 Aluminum Plate | 1.75" | 18" | 12" |

| 1.75"*24"*12" 7050-T7451 Aluminum Plate | 1.75" | 24" | 12" |

| 1.75"*24"*24" 7050-T7451 Aluminum Plate | 1.75" | 24" | 24" |

| 1.75"*36"*12" 7050-T7451 Aluminum Plate | 1.75" | 36" | 12" |

| 1.75"*36"*24" 7050-T7451 Aluminum Plate | 1.75" | 36" | 24" |

| 1.75"*36"*36" 7050-T7451 Aluminum Plate | 1.75" | 36" | 36" |

| 1.75"*36"*48" 7050-T7451 Aluminum Plate | 1.75" | 36" | 48" |

| 2"*12"*12" 7050-T7451 Aluminum Plate | 2" | 12" | 12" |

| 2"*18"*12" 7050-T7451 Aluminum Plate | 2" | 18" | 12" |

| 2"*24"*12" 7050-T7451 Aluminum Plate | 2" | 24" | 12" |

| 2"*24"*24" 7050-T7451 Aluminum Plate | 2" | 24" | 24" |

| 2"*36"*12" 7050-T7451 Aluminum Plate | 2" | 36" | 12" |

| 2"*36"*24" 7050-T7451 Aluminum Plate | 2" | 36" | 24" |

| 2"*36"*36" 7050-T7451 Aluminum Plate | 2" | 36" | 36" |

| 2"*36"*48" 7050-T7451 Aluminum Plate | 2" | 36" | 48" |

| 2.25"*12"*12" 7050-T7451 Aluminum Plate | 2.25" | 12" | 12" |

| 2.25"*18"*12" 7050-T7451 Aluminum Plate | 2.25" | 18" | 12" |

| 2.25"*24"*12" 7050-T7451 Aluminum Plate | 2.25" | 24" | 12" |

| 2.25"*24"*24" 7050-T7451 Aluminum Plate | 2.25" | 24" | 24" |

| 2.25"*36"*12" 7050-T7451 Aluminum Plate | 2.25" | 36" | 12" |

| 2.25"*36"*24" 7050-T7451 Aluminum Plate | 2.25" | 36" | 24" |

| 2.25"*36"*36" 7050-T7451 Aluminum Plate | 2.25" | 36" | 36" |

| 2.25"*36"*48" 7050-T7451 Aluminum Plate | 2.25" | 36" | 48" |

| 2.5"*12"*12" 7050-T7451 Aluminum Plate | 2.5" | 12" | 12" |

| 2.5"*18"*12" 7050-T7451 Aluminum Plate | 2.5" | 18" | 12" |

| 2.5"*24"*12" 7050-T7451 Aluminum Plate | 2.5" | 24" | 12" |

| 2.5"*24"*24" 7050-T7451 Aluminum Plate | 2.5" | 24" | 24" |

| 2.5"*36"*12" 7050-T7451 Aluminum Plate | 2.5" | 36" | 12" |

| 2.5"*36"*24" 7050-T7451 Aluminum Plate | 2.5" | 36" | 24" |

| 2.5"*36"*36" 7050-T7451 Aluminum Plate | 2.5" | 36" | 36" |

| 2.5"*36"*48" 7050-T7451 Aluminum Plate | 2.5" | 36" | 48" |

| 2.75"*12"*12" 7050-T7451 Aluminum Plate | 2.75" | 12" | 12" |

| 2.75"*18"*12" 7050-T7451 Aluminum Plate | 2.75" | 18" | 12" |

| 2.75"*24"*12" 7050-T7451 Aluminum Plate | 2.75" | 24" | 12" |

| 2.75"*24"*24" 7050-T7451 Aluminum Plate | 2.75" | 24" | 24" |

| 2.75"*36"*12" 7050-T7451 Aluminum Plate | 2.75" | 36" | 12" |

| 2.75"*36"*24" 7050-T7451 Aluminum Plate | 2.75" | 36" | 24" |

| 2.75"*36"*36" 7050-T7451 Aluminum Plate | 2.75" | 36" | 36" |

| 2.75"*36"*48" 7050-T7451 Aluminum Plate | 2.75" | 36" | 48" |

| 3"*12"*12" 7050-T7451 Aluminum Plate | 3" | 12" | 12" |

| 3"*18"*12" 7050-T7451 Aluminum Plate | 3" | 18" | 12" |

| 3"*24"*12" 7050-T7451 Aluminum Plate | 3" | 24" | 12" |

| 3"*24"*24" 7050-T7451 Aluminum Plate | 3" | 24" | 24" |

| 3"*36"*12" 7050-T7451 Aluminum Plate | 3" | 36" | 12" |

| 3"*36"*24" 7050-T7451 Aluminum Plate | 3" | 36" | 24" |

| 3"*36"*36" 7050-T7451 Aluminum Plate | 3" | 36" | 36" |

| 3"*36"*48" 7050-T7451 Aluminum Plate | 3" | 36" | 48" |

| 3.25"*12"*12" 7050-T7451 Aluminum Plate | 3.25" | 12" | 12" |

| 3.25"*18"*12" 7050-T7451 Aluminum Plate | 3.25" | 18" | 12" |

| 3.25"*24"*12" 7050-T7451 Aluminum Plate | 3.25" | 24" | 12" |

| 3.25"*24"*24" 7050-T7451 Aluminum Plate | 3.25" | 24" | 24" |

| 3.25"*36"*12" 7050-T7451 Aluminum Plate | 3.25" | 36" | 12" |

| 3.25"*36"*24" 7050-T7451 Aluminum Plate | 3.25" | 36" | 24" |

| 3.25"*36"*36" 7050-T7451 Aluminum Plate | 3.25" | 36" | 36" |

| 3.25"*36"*48" 7050-T7451 Aluminum Plate | 3.25" | 36" | 48" |

| 3.5"*12"*12" 7050-T7451 Aluminum Plate | 3.5" | 12" | 12" |

| 3.5"*18"*12" 7050-T7451 Aluminum Plate | 3.5" | 18" | 12" |

| 3.5"*24"*12" 7050-T7451 Aluminum Plate | 3.5" | 24" | 12" |

| 3.5"*24"*24" 7050-T7451 Aluminum Plate | 3.5" | 24" | 24" |

| 3.5"*36"*12" 7050-T7451 Aluminum Plate | 3.5" | 36" | 12" |

| 3.5"*36"*24" 7050-T7451 Aluminum Plate | 3.5" | 36" | 24" |

| 3.5"*36"*36" 7050-T7451 Aluminum Plate | 3.5" | 36" | 36" |

| 3.5"*36"*48" 7050-T7451 Aluminum Plate | 3.5" | 36" | 48" |

| 3.75"*12"*12" 7050-T7451 Aluminum Plate | 3.75" | 12" | 12" |

| 3.75"*18"*12" 7050-T7451 Aluminum Plate | 3.75" | 18" | 12" |

| 3.75"*24"*12" 7050-T7451 Aluminum Plate | 3.75" | 24" | 12" |

| 3.75"*24"*24" 7050-T7451 Aluminum Plate | 3.75" | 24" | 24" |

| 3.75"*36"*12" 7050-T7451 Aluminum Plate | 3.75" | 36" | 12" |

| 3.75"*36"*24" 7050-T7451 Aluminum Plate | 3.75" | 36" | 24" |

| 3.75"*36"*36" 7050-T7451 Aluminum Plate | 3.75" | 36" | 36" |

| 3.75"*36"*48" 7050-T7451 Aluminum Plate | 3.75" | 36" | 48" |

| 4"*12"*12" 7050-T7451 Aluminum Plate | 4" | 12" | 12" |

| 4"*18"*12" 7050-T7451 Aluminum Plate | 4" | 18" | 12" |

| 4"*24"*12" 7050-T7451 Aluminum Plate | 4" | 24" | 12" |

| 4"*24"*24" 7050-T7451 Aluminum Plate | 4" | 24" | 24" |

| 4"*36"*12" 7050-T7451 Aluminum Plate | 4" | 36" | 12" |

| 4"*36"*24" 7050-T7451 Aluminum Plate | 4" | 36" | 24" |

| 4"*36"*36" 7050-T7451 Aluminum Plate | 4" | 36" | 36" |

| 4"*36"*48" 7050-T7451 Aluminum Plate | 4" | 36" | 48" |

| 4.25"*12"*12" 7050-T7451 Aluminum Plate | 4.25" | 12" | 12" |

| 4.25"*18"*12" 7050-T7451 Aluminum Plate | 4.25" | 18" | 12" |

| 4.25"*24"*12" 7050-T7451 Aluminum Plate | 4.25" | 24" | 12" |

| 4.25"*24"*24" 7050-T7451 Aluminum Plate | 4.25" | 24" | 24" |

| 4.25"*36"*12" 7050-T7451 Aluminum Plate | 4.25" | 36" | 12" |

| 4.25"*36"*24" 7050-T7451 Aluminum Plate | 4.25" | 36" | 24" |

| 4.25"*36"*36" 7050-T7451 Aluminum Plate | 4.25" | 36" | 36" |

| 4.25"*36"*48" 7050-T7451 Aluminum Plate | 4.25" | 36" | 48" |

| 4.5"*12"*12" 7050-T7451 Aluminum Plate | 4.5" | 12" | 12" |

| 4.5"*18"*12" 7050-T7451 Aluminum Plate | 4.5" | 18" | 12" |

| 4.5"*24"*12" 7050-T7451 Aluminum Plate | 4.5" | 24" | 12" |

| 4.5"*24"*24" 7050-T7451 Aluminum Plate | 4.5" | 24" | 24" |

| 4.5"*36"*12" 7050-T7451 Aluminum Plate | 4.5" | 36" | 12" |

| 4.5"*36"*24" 7050-T7451 Aluminum Plate | 4.5" | 36" | 24" |

| 4.5"*36"*36" 7050-T7451 Aluminum Plate | 4.5" | 36" | 36" |

| 4.5"*36"*48" 7050-T7451 Aluminum Plate | 4.5" | 36" | 48" |

Chemical composition of Chalco 7050 aerospace aluminum alloy

| Element | Composition(%) |

| Si | 0.12% |

| Fe | 0.15% |

| Cu | 2.0-2.6% |

| Mn | 0.1% |

| Mg | 1.9-2.6% |

| Ti | 0.06% |

| Cr | 0.04% |

| Zr | 0.08-0.15% |

| Zn | 5.7-6.7% |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of Chalco 7050 aerospace aluminium plate

| Mechanical Property | Value |

| Tensile Strength | 496 MPa |

| Proof Stress | 427 Min MPa |

| Elongation | A-9 Min % |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteProduct features of Chalco 7050 aerospace aluminum plate sheet

7050 aerospace aluminum plate has excellent mechanical properties, its strength is higher than ordinary steel, and its weight is much lighter, which makes it the material of choice for many high-end applications. 7050 aluminum has higher corrosion resistance and better toughness. Alloy 7050 is required in thicker sections because it is less quench sensitive than other aerospace aluminum alloys. This enables it to maintain its strength properties, stress corrosion cracking resistance and levels of fracture toughness.

Application of Chalco 7050 aviation aluminum plate

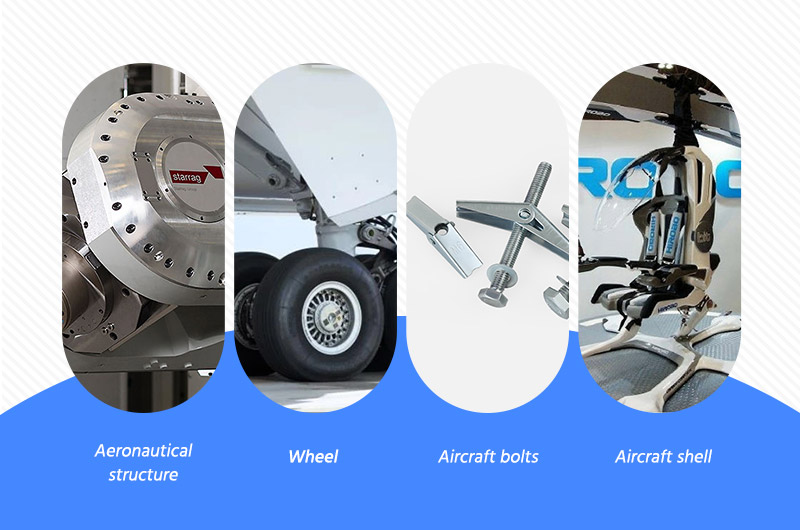

It is suitable for the manufacture of components requiring high strength and light weight, such as structural parts in the aerospace field, aircraft casings, engine parts, aircraft bolts and wheels, etc.

Applications commonly used for 7050 aluminum alloy include bulkheads and fuselage frames requiring section thicknesses between 2 and 6 inches. Another common application is wing skinning. Most applications this metal is used for require thicknesses greater than two inches.

Production process of Chalco 7050 aluminum aerospace plate sheet

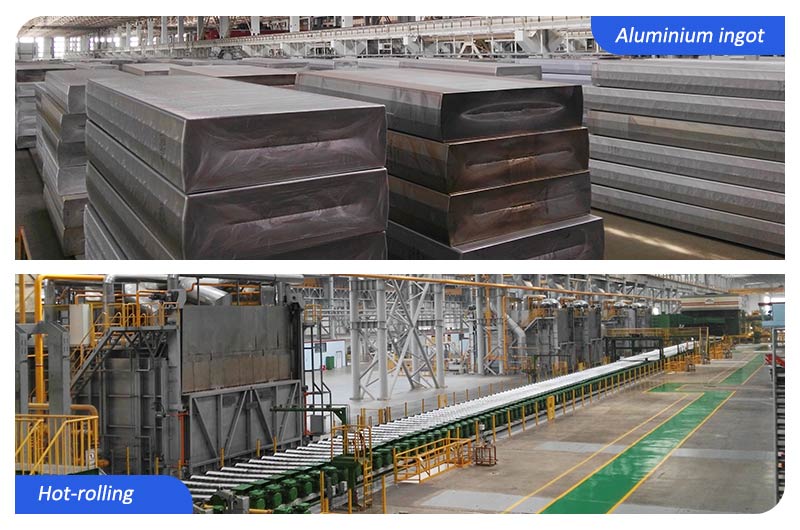

Material preparation: prepare a sufficient quantity of 7050 aluminum alloy raw materials, and conduct strict chemical composition and physical performance tests on them to ensure that the materials meet the corresponding quality standards.

Casting: the aluminum alloy raw materials are melted and poured into casting molds, and then formed into ingots through solidification, cooling and other processes.

Preheating: preheating the ingot to bring it to a suitable processing temperature, while helping to improve the plasticity and toughness of the material.

Hot rolling: the preheated ingot is rolled through a hot rolling mill to make a plate of specified thickness.

Area cutting: cut the rolled aluminum plate into areas of different sizes and shapes according to customer needs.

Surface treatment: according to the need, carry out surface treatment on the aluminum plate, including oxidation, anodic treatment, spraying, etc.

Heat treatment: heat treatment of aluminum plate to adjust its properties, such as improving its strength, hardness, corrosion resistance and fatigue resistance, etc.

Inspection: conduct various inspections on the finished 7050 aluminum plate, including tests on size, mechanical properties, chemical composition, surface quality, etc., to ensure that it meets customer requirements and corresponding quality standards.

Packaging and transportation: package the qualified 7050 aluminum plate, mark and record it, and then send it to the customer.

Why choose Chalco 7050 aviation aluminum alloy plate sheet?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Colin Aviation certification, and produce according to the AMS-QQ-A-430 AMS 4050 EN 3982 standard required by customers, providing a strong guarantee for the quality of aerospace materials produced by our company.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.