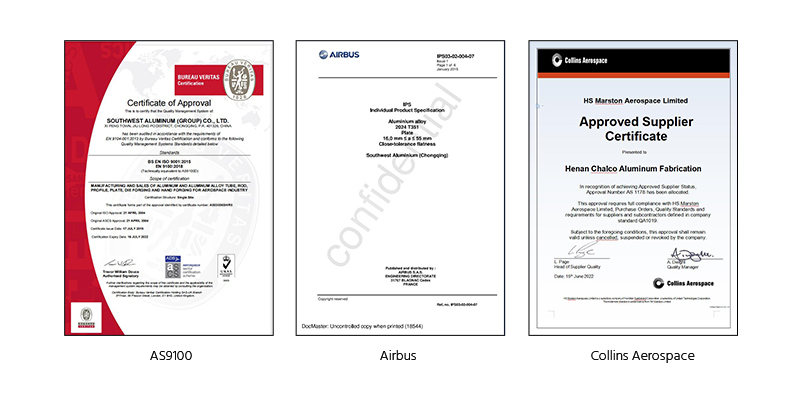

Aluminum alloy 7050 is a commercial aerospace grade aluminum with high strength, stress corrosion cracking resistance and toughness, Chalco can produce AMS 4342 UNS A97050 AMS QQ-A-225/9 7050 Aerospace aluminum rod bar has AS9100 Collin Aviation Certification.Quick Quote

Specifications of Chalco 7050 commercial aerospace alloy rod bars

Material temper: F, O, T6, T73511, T74511, T76511 etc.

Trade name: AMS 4108, AMS 4340, AMS 4341, AMS 4342, AMS 4201, UNS A97050, ASTM B247

Standards: AMS 4050, AMS 4201, DMS-2233, BMS 7-323, ASTM B221, EN3982

Round rod diameter: common diameters are 5mm to 350mm.

Round rod length: common lengths are 2000mm, 2500mm, 3000mm or 4000mm.

Hex rod diameter: from 1/4" (6.35mm) to 5" (127mm).

Hex rod height: from 1/4" (6.35mm) to 5" (127mm).

Other specifications: other specifications such as custom lengths or parts machined to desired shapes are available upon request.

7050 Aerospace Aluminum Round Bar and Square Bar Inventory Table

Inventory information is being updated in real-time, with hot selling inventory lengths of 6ft, 12ft, 24ft and other sizes available for cutting.

Welcome to click on the button to obtain the latest inventory information and lowest quotationQuick Quote

| Description | Temper | Diameter (in) |

| 1.5" (A)Aluminum Round Bar 7050-T74511 | T74511 | 1.5" |

| 2" (A)Aluminum Round Bar 7050-T74511 | T74511 | 2" |

| 2.5" (A)Aluminum Round Bar 7050-T74511 | T74511 | 2.5" |

| 3" (A)Aluminum Round Bar 7050-T74511 | T74511 | 3" |

| 3.5" (A)Aluminum Round Bar 7050-T74511 | T74511 | 3.5" |

| 4" (A)Aluminum Round Bar 7050-T74511 | T74511 | 4" |

| 0.5" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 0.5" |

| 0.625" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 0.625" |

| 0.75" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 0.75" |

| 0.875" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 0.875" |

| 1" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1" |

| 1.125" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1.125" |

| 1.25" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1.25" |

| 1.375" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1.375" |

| 1.5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1.5" |

| 1.625" (A)Aluminum Round Bar 7075-T651 | T6\T651 | 1.625" |

| 1.75" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 1.75" |

| 1.875" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 1.875" |

| 2" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 2" |

| 2.125" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 2.125" |

| 2.25" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 2.25" |

| 2.375" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 2.375" |

| 2.5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 2.5" |

| 2.75" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 2.75" |

| 3" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 3" |

| 3.25" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 3.25" |

| 3.375" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 3.375" |

| 3.5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 3.5" |

| 3.75" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 3.75" |

| 4" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 4" |

| 4.25" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 4.25" |

| 4.5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 4.5" |

| 4.75" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 4.75" |

| 5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 5" |

| 5.25" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 5.25" |

| 5.5" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 5.5" |

| 6" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 6" |

| 6.5" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 6.5" |

| 7" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 7" |

| 7.5" (A)Aluminum Round Bar 7050-T6\T651 | T6\T651 | 7.5" |

| 8" (A)Aluminum Round Bar 7050-T651 | T6\T651 | 8" |

| 0.5" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 0.5" |

| 0.75" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 0.75" |

| 0.875" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 0.875" |

| 1" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1" |

| 1.125" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.125" |

| 1.25" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.25" |

| 1.375" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.375" |

| 1.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.5" |

| 1.625" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.625" |

| 1.75" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 1.75" |

| 1.875" (A)Aluminum Round Bar 7050-T73\T735 | T73\T7351 | 1.875" |

| 2" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2" |

| 2.125" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.125" |

| 2.25" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.25" |

| 2.375" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.375" |

| 2.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.5" |

| 2.625" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.625" |

| 2.75" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 2.75" |

| 3" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 3" |

| 3.25" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 3.25" |

| 3.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 3.5" |

| 3.75" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 3.375" |

| 4" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 4" |

| 4.25" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 4.25" |

| 4.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 4.5" |

| 4.75" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 4.75" |

| 5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 5" |

| 5.25" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 5.25" |

| 5.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 5.5" |

| 6" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 6" |

| 6.25" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 6.25" |

| 6.5" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 6.5" |

| 7" (A)Aluminum Round Bar 7050-T7351 | T73\T7351 | 7" |

| 7.5" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 7.5" |

| 8" (A)Aluminum Round Bar 7050-T73\T7351 | T73\T7351 | 8" |

Note, customized sizes can be provided. Click to inquire about how to produce customized products with free mold fees.Quick Quote

Chemical composition of Chalco 7050 aerospace aluminum alloy

| 7050 alloy chemical | |

| Chemical element | % Present |

| Si | 0.12% |

| Fe | 0.15% |

| Cu | 2.0-2.6% |

| Mn | 0.1% |

| Mg | 1.9-2.6% |

| Ti | 0.06% |

| Cr | 0.04% |

| Zr | 0.08-0.15% |

| Zn | 5.7-6.7% |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of Chalco 7050 aerospace high quality aluminium rods

| Properties | |

| Mechanical property | Value |

| Tensile strength | 515MPa |

| Yield strength | 455 Min MPa |

| Elongation | A-11 Min % |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you

customized products. Precise quotation will be provided within 24 hours.

Get a quote

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteProduct features of Chalco 7050 aviation aluminum alloy rod bar

7050 aluminum is a heat treatable low temperature alloy known as a commercial aerospace aircraft alloy that is less quench sensitive than other aerospace aluminum alloys. This enables it to maintain its strength properties, stress corrosion cracking resistance and levels of fracture toughness.

- Strong corrosion resistance

- High tensile strength

- Brilliant polish

- Excellent machine strength

- High creep resistance

- High temperature strength

- Excellent mechanical properties

Application of Chalco 7050 industrial aerospace grade aluminium rod bars

7050 aluminum is the preferred aviation aluminum for applications such as fuselage frames, suitable for the manufacture of components that require high strength and light weight, such as fuselage frames for commercial and military aircraft applications, aircraft structural parts, structural parts in the aerospace field, aircraft shells, engines parts, aircraft bolts and wheels, etc.Quick Quote

Chalco 7050 Aluminum Rod related hot selling products in stock

7050-profile

7050-forging

7050-aluminum-shee-plate

7075-aluminum-tube

7075-aluminium-rod

7075-aluminum-plate

2024-round-bar

2618-bar-rod

6061-aluminum-bar

Production process of Chalco aluminum alloy 7050 (UNS A97050) bar

Aluminum ingot preparation: the production of 7050 aluminum alloy usually starts from aluminum ingots, which are processed by melting and casting, and generally have high purity and good crystallization properties.

Preheating and rolling: aluminum ingots are heat-treated in a preheating furnace, and then rolled into aluminum rods of required diameters through a rolling mill. During the rolling process, parameters such as rolling temperature and rolling speed need to be controlled to ensure the quality of the obtained aluminum rod.

Non-heat treatment: the aluminum rod is rolled through multiple passes and subjected to work hardening treatment to improve the strength, hardness and wear resistance of the aluminum rod.

Heat treatment: aluminum rods are heated under specific temperature and time conditions, so that the aluminum alloy material can obtain ideal properties and microstructure. Common heat treatment methods include aging treatment and solution treatment.Quick Quote

Cutting and processing: according to customer requirements, aluminum rods are cut and processed into parts of required length and shape.

Inspection: conduct various inspections on the manufactured 7050 aluminum rods, including tests on dimensions, mechanical properties, chemical composition, surface quality, etc., to ensure that they meet customer requirements and corresponding quality standards.

Packaging and transportation: pack the qualified 7050 aluminum rods, mark and record them, and then send them to customers.

Common Sizes of China Aluminum 7050 Aerospace Aluminum Round Bars and Square Bars

Round rod: Common diameters include 5mm, 6mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 70mm, 80mm, 90mm, 100mm, 120mm, 150mm, 200mm, etc.

Square rod: Common section sizes include 10mm×10mm, 12mm×12mm, 15mm×15mm, 20mm×20mm, 25mm×25mm, 30mm×30mm, 35mm×35mm, 40mm×40mm, 50mm×50mm, 60mm×60mm, 70mm×70mm, 80mm×80mm, 90mm×90mm, 100mm×100mm, 120mm×120mm, 150mm× 150 mm etc.

The length is usually between 2000mm, 2500mm, 3000mm, 4000mm, etc.

It should be noted that this is only one of the common dimensions of 7050 aviation aluminum round bars and square bars, and the actual inventory and supply may vary according to market demand.Quick Quote

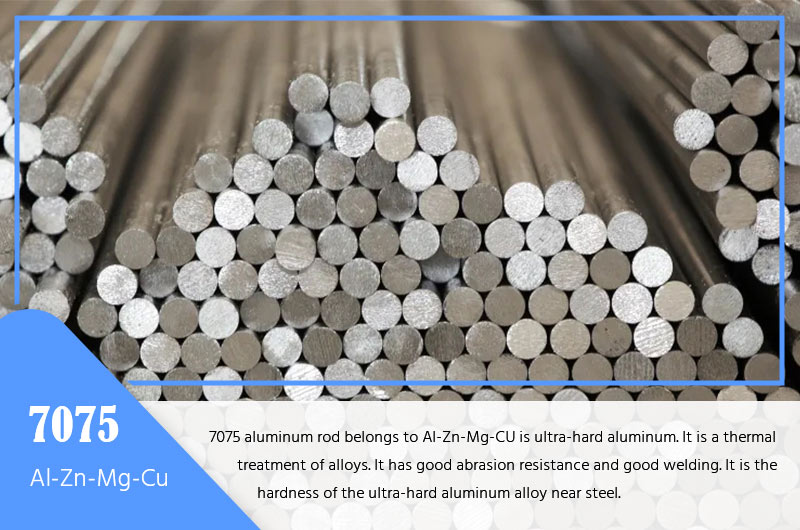

What is the difference between 7050 and 7075?

Alloy 7050 exhibits better toughness/corrosion resistance characteristics than alloy 7075. Because it is less quench sensitive than most aerospace aluminum alloys, 7050 retains its strength properties in thicker sections while maintaining good stress corrosion cracking resistance and fracture toughness levels.

7075 Aluminum Chalco is also available, please contact us for detailsQuick Quote

-

7050 Aluminum

7050 is known for its combination of high strength and toughness. It has slightly better stress corrosion cracking resistance than 7075.

High strength Corrosion resistance Strong resistance to stress -

7075 Aluminum

7075 is known for its exceptionally high strength-to-weight ratio and is often considered one of the strongest aluminum alloys available. It might not have the same level of toughness as 7050 but is still widely used in applications where high strength is crucial.

High strength High toughness Corrosion resistance

Why choose Chalco Aluminium as alloy 7050 aerospace bar aircraft materials manufacturer?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements. In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Colin Aviation certification, and produce according to the AMS 4342 UNS A97050 AMS QQ-A-225/9 standard required by customers, providing a strong guarantee for the quality of aerospace materials produced by our company.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.Quick Quote