Environmentally friendly lead-free easy-cutting aluminum alloy bars, using elements from the 2000 or 6000 series aluminum alloys, with either Sn, Bi, or both replacing lead in the alloy.

They offer cutting performance comparable to lead-containing easy-cutting aluminum alloys while avoiding the adverse environmental effects associated with lead in traditional aluminum alloys.Welcome contact

Specification of Chalco Aluminum easy machining aluminum bar

| Alloy |

Pb free: 2011B 6262A 6012A 6021 6023 Conventional: 2017 2007 6026 6043 6065 |

| Diameter | Φ4mm~Φ400mm |

| Length | 1000mm-6000mm |

| Production specification | ASTM B211 AMS B211 EN755 |

Chalco Pb free easy-machining aluminum bar products

2011B Pb free easy machining aluminum barQuick Quote

Temper: T3, T351, T4, T451, T6, T651, T6511, T7351

2011 is a top easy-cutting alloy with high strength. To meet eco-demands, Chalco created 2011B rods, using Sn and Bi instead of Pb. This keeps 2011's machining prowess while going greener.

6262A Pb free easy machining aluminum barQuick Quote

Temper: T4, T6

Easily machinable with excellent mechanical properties, ideal for various cutting processes. It's mainly used in making precise aluminum components for automotive and electronic equipment.

6021 Pb free easy machining aluminum barQuick Quote

Temper: T4, T6

Easy to machine with excellent mechanical properties, ideal for various cutting processes. Mainly used for precise aluminum components needing high precision and surface finish.

6023 Pb free easy machining aluminum barQuick Quote

Temper: T4, T6

It has moderate mechanical properties but high corrosion resistance, good weldability, hot forging, and anodizing properties.

Chalco hot-selling easy machining aluminum bar products

2017 easy machining aluminum barQuick Quote

Temper: T3, T351, T4, T451, T6, T651, T6511, T7351

2017 is a hard aluminum alloy with heat resistance, ideal below 150°C, and excels over 7075 above 125°C. It boasts high mechanical strength, superb fatigue resistance, and good forging and machining abilities.

2007 easy machining aluminum barQuick Quote

Temper: T3, T351, T4, T451, T6, T651, T6511, T7351

Excel in machining, ideal for high-speed cutting, offering high strength and corrosion resistance. Widely used in aerospace and automotive manufacturing for high-strength, precision components.

6026 easy machining aluminum barQuick Quote

Temper: T4, T6

With excellent corrosion resistance, suitable for anodizing treatment, providing decorative and hard anodizing options. The extruded bars share the same minimum tensile strength as alloys 2011 and 2030.

6043 easy machining aluminum barQuick Quote

Temper: T4, T6

Though not as strong as 2000 or 7000 series, 6026 aluminum alloy boasts excellent machinability, superior welding, plating, and corrosion resistance due to its Mg and Si alloy properties.

6065 easy machining aluminum barQuick Quote

Temper: T4, T6

High toughness, no deformation after processing, dense and defect-free material, easy to polish, excellent oxidation effect, etc.

Advantage of Chalco easy machining aluminum bar

- Straightness <0.3m/2.5m, ensuring rotational speed requirements >8000 rpm, with no material vibration.

- Coarse grain ring <0.5mm, reducing turning volume, increasing efficiency, and lowering costs.

- Easy to machine, significantly improving machining efficiency.

- Lead-free easy-cutting aluminum rods meet environmental requirements, being green, non-toxic, and harmless.

- Chips are easy to break, non-sticky to the knife, do not wrap around the knife, and are easy to remove.

- Clean and tidy surface with good smoothness.

- High precision, widely used in various high-precision parts.

- High strength with good corrosion resistance.

- Uniform color and bright appearance in hard anodizing.

Cooperative field of Chalco free cutting aluminum bar

- Mechanical parts

- Precision instruments

- Electronic components

- Pistons

- Mold manufacturing

- Screw and rivet manufacturing

- Construction structural components manufacturing

- Aircraft, ship, and transportation equipment manufacturing

Chemical components of Chalco easy machining aluminum bar

Chalco's lead-free easy-cutting aluminum rods utilize Sn and Bi elements as substitutes for Pb, ensuring environmental friendliness while maintaining excellent machining and cutting properties.

When using either Sn or Bi, the content of Sn or Bi in the aluminum alloy ranges from 0.1% to 2%. When using both Sn and Bi, the combined content of Sn and Bi in the aluminum alloy ranges from 0.2% to 4%.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Bi (Pb) Sn | Ti | Al |

| 2011B | 0.05 | ≤0.4 | ≤5.01 | 0.01 | 0.01 | - | - | Bi: 0.4-0.5 Sn: 0.26-0.3 | ||

| 6262A | 0.4-0.8 | ≤0.7 | 0.15-0.4 | ≤0.15 | 0.8-1.2 | 0.04-0.14 | ≤0.25 | Bi: 0.4-0.9 Sn: 0.4-1.0 | ≤0.1 | Re |

| 6012A | 0.6-1.4 | ≤0.5 | ≤0.4 | 0.2-1.0 | 0.6-1.2 | ≤0.3 | ≤0.3 | Bi: 0.7 Sn: 0.4-2.0 | ||

| 6021 | 0.6-1.5 | ≤0.4 | ≤0.2 | 0.4-1.0 | 0.8-1.5 | 0.25 | 0.2 | Sn: 0.6-1.5 | Re | |

| 6023 | 0.6-1.4 | ≤0.5 | 0.2-0.5 | 0.2-0.6 | 0.4-0.9 | - | - | Bi: 0.3-0.8 Sn: 0.6-1.2 | - | Re |

| 2017 | 0.2-0.8 | ≤0.7 | 3.5-4.5 | 0.4-1.0 | 0.4-0.8 | ≤0.1 | ≤0.25 | Bi: - Pb: - Sn: - | ≤0.15 | |

| 2007 | 0.8 | ≤0.8 | 3.3-4.6 | 0.5-1.0 | 0.4-1.8 | 0.1 | 0.8 | Bi: 0.2 Pb: 0.8-1.5 Sn: 0.2 | ≤0.2 | |

| 6026 | 0.6-1.4 | ≤0.7 | 0.2-0.5 | 0.2-1.0 | 0.6-1.2 | ≤0.3 | ≤0.3 | Bi: 0.5-1.5 Pb: 0.4 Sn: 0.05 | ≤0.2 | Re |

| 6065 | 0.4-0.8 | ≤0.7 | 0.15-0.4 | ≤0.15 | 0.8-1.2 | ≤0.15 | ≤0.25 | Bi: 0.5-1.5 Pb: 0.05 | ≤0.1 | Re |

Mechanical properties of Chalco easy machining aluminum bar

| Alloy | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) |

| 2011B | 486.1 MPa | 421.5 MPa | 10.4% |

| 6262A | ≥370 | ≥300 | ≥8 |

| 6012A | ≥220 | ≥110 | ≥9.1 |

| 6023 | ≥320 | ≥270 | ≥10 |

| 2017 | ≥360 | ≥220 | ≥7 |

| 2007 | ≥370 | ≥240 | ≥5.6 |

| 6026 | ≥370 | ≥300 | ≥8 |

| 6065 | ≥260 | ≥240 | ≥10 |

FAQ for purchasing easy machining aluminum bar

How to calculate the weight of free cutting aluminum bar?

The density of 2000 Series aluminum alloy is 2.85 g/cm3.

The density of 6000 series aluminum alloy is 2.70 g/cm3.

Weight calculation of aluminum round bar: π R2× Height×0.0000027 (3.1415 * radius square of aluminum bar * length of aluminum bar * density, radius length in mm)

Weight calculation of aluminum square bar: side A * side B * 0.0027 * H (side length * side length * density * aluminum bar length), unit: mm.

Price of Chalco Aluminum free cutting aluminum bar

Extruded aluminum bars FOB price:

[(SMM Shanghai aluminum ingot price+processing fee)×weight+transportation fee]/exchange rate

FOB price can be USD price, Euro price, or RMB price according to customer requirements.

We can customize according to requirements, but also have stock for small or urgent customers to choose.

How to choose the supplier for easy machining aluminum bar?

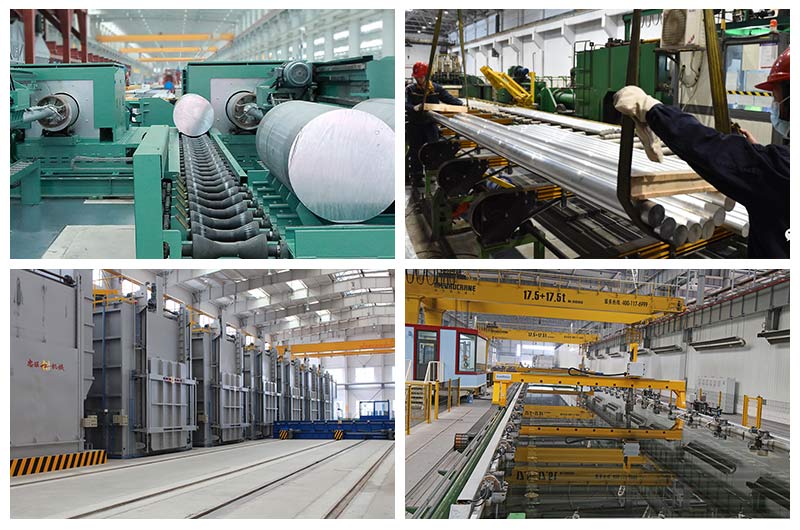

China Aluminum Corporation is a comprehensive aluminum processing enterprise with modern equipment such as 12500 ton horizontal extruder, 2800mm cold and hot rolling mill, 6000 ton stretching straightening machine, etc.

Equipped with the first domestic "1+4" hot rolling production line, equipped with multiple imported cutting machines, fully automatic feeding sawing machines, vertical large automatic feeding machines, and other equipment.

Chalco provides customized material services to meet different processing needs, including aluminum rod inspection, sawing, milling and other services. Feel free to contact you at any time.

Packaging of Chalco Aluminum free cutting aluminum bar

Chalco Aluminum uses pearl cotton to separate each aluminum rod, neatly stack it, and then wrap it with moisture-proof kraft paper. The outermost layer is wrapped with thickened moisture-proof film, and then coated with steel tape or fiber tape. It shall be packed in export fumigation wooden cases or wooden pallets. It can also be customized according to customer requirements.