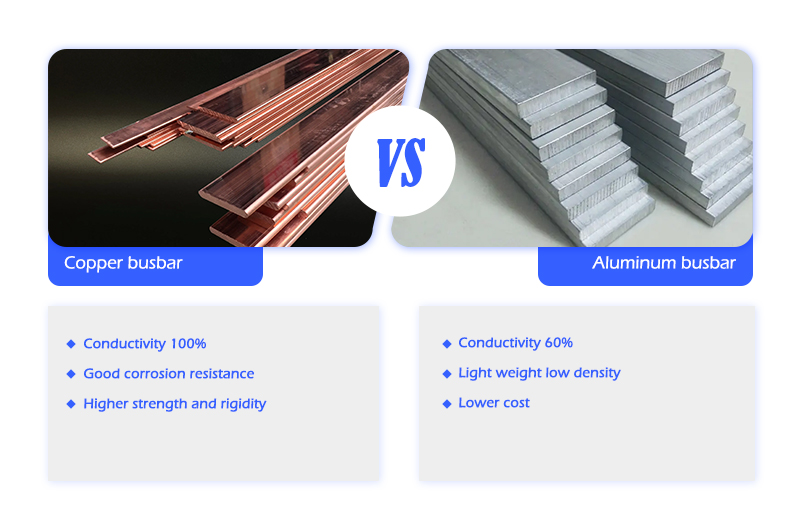

Busbars are typically made of conductive metals such as copper or aluminum. These materials are chosen due to their excellent electrical conductivity, mechanical strength, and relatively low cost. Copper is often preferred for its superior conductivity and thermal performance, while aluminum is favored in applications where weight and cost are significant considerations. In some cases, busbars may also be coated or plated with materials like tin or silver to enhance their conductivity and resistance to oxidation.

Chalco-reliable supplier of conductive aluminum busbar products

- Chalco's electrical busbar products are comprehensive, covering aluminum busbars, copper clad aluminum busbars, and copper busbars. Hot selling aluminum busbar products include 6101, 1050, 1060, 1070, 1100, 1350, 6061, 6063, 6082... Widely used in electrical conductors of distribution systems.

- Chalco EC grade aluminum busbar, complying with standards such as ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, EN 573-3, etc., is widely used in electrical conductors of distribution systems.

- Chalco specializes in providing various conductive aluminum busbar products and has established connections with a large number of manufacturers in transformers, switchgear, power capacitors, power tools, etc. fields.

Introduction of Chalco Aluminum conductive aluminum busbar

-

CCA bus or bimetallic conductive bus, it is the third generation of "new energy-saving conductor materials".

Conductivity Scalability Reliability -

6101 EC aluminum busbar T6, T61, T63, T64, T65

Containing magnesium and silicon, has high mechanical strength. Better anti creep than 1350.

Thermal stability Easy processing -

1060 EC aluminum busbar T3, T4, T5, T6, T8

It is usually formed by extrusion or rolling, and has good processing performance.

High conductivity Corrosion resistance -

1350 EC aluminum busbar H14, H16, H19

The minimum weight percentage is 99.5%, which is the material used for battery busbars.

Conductivity Thermal conductivity -

6060 EC aluminum busbar T4, T5, T6

It can effectively transmit and distribute electricity, reducing energy loss and line power loss.

Lightweight Processability -

6082 EC aluminum busbar T3, T4, T5, T6

It has high strength and hardness, while maintaining good conductivity.

Machinability High strength and rigidity -

6061 aluminum busbar has strong conductivity and is a universal material for most processing technologies.

Smooth surface Strong moisture resistance -

6063 EC aluminum busbar T4, T5, T6, T52, T66

In high-power applications, it can help effectively dissipate heat, and reduce the risk of equipment overheating.

Strong plasticity Excellent heat dissipation

For more alloy products or customized requirements, please contact us

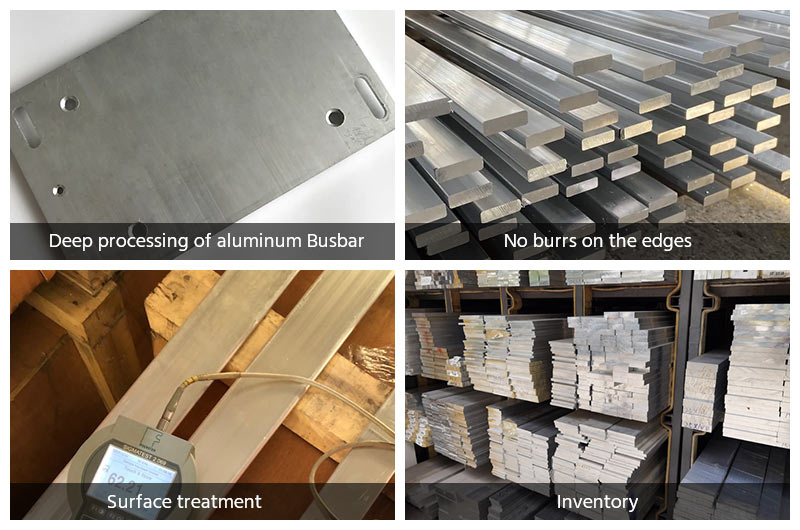

Production capacity of Chalco Aluminum electrical busbar

Chalco can provide complete design, including machining, forming, and brazing. Cutting, stamping, bending, drilling and other processing can be completed according to the specific requirements of customers for current capacity and bending degree.

Chalco conducts size, weld seam, and appearance quality inspections on the processed conductive aluminum busbar. Ensure that the surface of the product is free of burrs and other defects, and that its performance meets the requirements and standards.

Chalco can provide surface coating and insulation processing for conductive aluminum busbars according to customer requirements to improve product corrosion resistance, aesthetics, and avoid short circuits and other issues.

Surface treatment: anodizing, electroplating, spraying, etc.; Usually aluminum is plated with silver, tin, and nickel.

Insulation treatment:

Insulation coating (powder coating, epoxy resin coating or insulation paint coating, etc.)

Insulating sleeve (PVC, heat shrink tubing, or silicone rubber, etc.)

Copper vs aluminum-choose the correct material for your project

There is debate over whether aluminum or copper is more suitable for busbars, as both have been successfully used. In the past 50 years, busbars have evolved beyond traditional distribution, with recent innovations shifting demand from copper to aluminum. Despite some misconceptions about aluminum, both materials can meet requirements if manufactured and installed correctly.

There is debate over whether aluminum or copper is more suitable for busbars, as both have been successfully used. In the past 50 years, busbars have evolved beyond traditional distribution, with recent innovations shifting demand from copper to aluminum. Despite some misconceptions about aluminum, both materials can meet requirements if manufactured and installed correctly.

If you have an electrical project and want to find the most suitable material for it, please feel free to contact Chalco. We will address all your questions regarding copper and aluminum busbars.Quick Quote

Service field and cooperative partner of Chalco electrical busbar

Power transmission and distribution system: can be used in high-voltage transmission lines, substations, distribution transformers, and other power equipment.

Industrial power applications: such as factories, mines, and manufacturing facilities.

Buildings and building facilities: can be located in the distribution room and power box inside the building.

New energy systems: such as solar and wind power generation systems. They are used to convert new energy into electrical energy and transmit it to the power grid or energy storage equipment.

New energy electric vehicles: with the popularization of new energy electric vehicles, conductive aluminum busbars are also widely used in electric vehicle drive systems and charging stations. The high conductivity and lightweight performance of aluminum can not only meet the requirements of reaching the point, but also meet the requirements of automotive lightweight.

Ampacity chart of copper and aluminum busbar

| Converting Copper to Aluminum using an Ampacity Chart | ||||||||||||

| Ampacity Conversion Chart | Copper C110 | 30° C Rise | 50° C Rise | 65° C Rise | Aluminum 6101 | 30° C Rise | 50° C Rise | 65° C Rise | ||||

| Flat Bar Size in Inches | Sq. In | Circ Mils Thousands | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp* | Weight Per Ft in Lb. | DC Resistance at 20° C, Microhms/Ft | 60 Hz Ampacity Amp** | ||||

| 1/2*1 | 0.5 | 637 | 1.93 | 16.5 | 620 | 820 | 940 | 0.585 | 31 | 347 | 459 | 526 |

| 1/2*1 1/2 | 0.75 | 955 | 2.9 | 11 | 830 | 1100 | 1250 | 0.878 | 21 | 465 | 616 | 700 |

| 1/2*2 | 1 | 1270 | 3.86 | 8.23 | 1000 | 1350 | 1550 | 1.17 | 15 | 560 | 756 | 868 |

| 1/2*2 1/2 | 1.25 | 1590 | 4.83 | 6.58 | 1200 | 1600 | 1850 | 1.463 | 12 | 672 | 896 | 1036 |

| 1/2*3 | 1.5 | 1910 | 5.8 | 5.49 | 1400 | 1850 | 2150 | 1.755 | 10 | 784 | 1036 | 1204 |

| 1/2*3 1/2 | 1.75 | 2230 | 6.76 | 4.7 | 1550 | 2100 | 2400 | 2.048 | 9 | 868 | 1176 | 1344 |

| 1/2*4 | 2 | 2550 | 7.73 | 4.11 | 1700 | 2300 | 2650 | 2.34 | 8 | 952 | 1288 | 1484 |

| 1/2*5 | 2.5 | 3180 | 9.66 | 3.29 | 2050 | 2750 | 3150 | 2.925 | 6 | 1148 | 1540 | 1764 |

| 1/2*6 | 3 | 3820 | 11.6 | 2.74 | 2400 | 3150 | 3650 | 3.51 | 5 | 1344 | 1764 | 2044 |

| 1/2*8 | 4 | 5090 | 15.5 | 2.06 | 3000 | 4000 | 4600 | 4.68 | 4 | 1680 | 2240 | 2576 |

| 1/4*1/2 | 0.125 | 159 | 0.483 | 65.8 | 240 | 315 | 360 | 0.146 | 123 | 134 | 176 | 202 |

| 1/4*3/4 | 0.188 | 239 | 0.726 | 43.8 | 320 | 425 | 490 | 0.220 | 82 | 179 | 238 | 274 |

| 1/4*1 | 0.25 | 318 | 0.966 | 32.9 | 400 | 530 | 620 | 0.293 | 62 | 224 | 297 | 347 |

| 1/4*1 1/2 | 0.375 | 477 | 1.450 | 21.9 | 560 | 740 | 880 | 0.439 | 41 | 314 | 414 | 482 |

| 1/4*2 | 0.5 | 637 | 1.930 | 16.5 | 710 | 940 | 1100 | 0.585 | 31 | 398 | 526 | 616 |

| 1/4*2 1/2 | 0.625 | 796 | 2.410 | 13.2 | 850 | 1150 | 1300 | 0.731 | 25 | 476 | 644 | 728 |

| 1/4*3 | 0.75 | 955 | 2.900 | 11 | 990 | 1300 | 1550 | 0.878 | 21 | 554 | 728 | 868 |

| 1/4*3 1/2 | 0.875 | 1110 | 3.380 | 9.4 | 1150 | 1500 | 1750 | 1.024 | 18 | 644 | 840 | 980 |

| 1/4*4 | 1 | 1270 | 3.860 | 8.23 | 1250 | 1700 | 1950 | 1.170 | 15 | 700 | 952 | 1092 |

| 1/4*5 | 1.25 | 1590 | 4.830 | 6.58 | 1500 | 2000 | 2350 | 1.463 | 12 | 840 | 1120 | 1316 |

| 1/4*6 | 1.5 | 1910 | 5.800 | 5.49 | 1750 | 2350 | 2700 | 1.755 | 10 | 980 | 1316 | 1512 |

| 1/8*1/2 | 0.0625 | 79.6 | 0.241 | 132 | 153 | 205 | 235 | 0.073 | 247 | 86 | 115 | 132 |

| 1/8*3/4 | 0.0938 | 119 | 0.362 | 87.7 | 215 | 285 | 325 | 0.110 | 164 | 120 | 160 | 182 |

| 1/8*1 | 0.125 | 159 | 0.483 | 65.8 | 270 | 360 | 415 | 0.146 | 123 | 151 | 202 | 232 |

| 1/8*1 1/2 | 0.188 | 239 | 0.726 | 43.8 | 385 | 510 | 590 | 0.220 | 82 | 216 | 286 | 330 |

| 1/8*2 | 0.25 | 318 | 0.966 | 32.9 | 495 | 660 | 760 | 0.293 | 62 | 277 | 370 | 426 |

| 1/8*2 1/2 | 0.312 | 397 | 1.210 | 26.4 | 600 | 800 | 920 | 0.365 | 49 | 336 | 448 | 515 |

| 1/8*3 | 0.375 | 477 | 1.450 | 21.9 | 710 | 940 | 1100 | 0.439 | 41 | 398 | 526 | 616 |

| 1/8*3 1/2 | 0.438 | 558 | 1.690 | 18.8 | 810 | 1100 | 1250 | 0.512 | 35 | 454 | 616 | 700 |

| 1/8*4 | 0.5 | 636 | 1.930 | 16.5 | 900 | 1200 | 1400 | 0.585 | 31 | 504 | 672 | 784 |

| 1/16*1/2 | 0.0312 | 39.7 | 0.121 | 264 | 103 | 136 | 157 | 0.037 | 494 | 58 | 76 | 88 |

| 1/16*3/4 | 0.0469 | 59.7 | 0.181 | 175 | 145 | 193 | 225 | 0.055 | 327 | 81 | 108 | 126 |

| 1/16*1 | 0.0625 | 79.6 | 0.242 | 132 | 187 | 250 | 285 | 0.073 | 247 | 105 | 140 | 160 |

| 1/16*1 1/2 | 0.0938 | 119 | 0.362 | 87.7 | 270 | 355 | 410 | 0.110 | 164 | 151 | 199 | 230 |

| 1/16*2 | 0.125 | 159 | 0.483 | 65.8 | 345 | 460 | 530 | 0.146 | 123 | 193 | 258 | 297 |

| Source: Copper Development Organization; Aluminum Association | ||||||||||||

| Note: Ratings depend upon configuration, air flow, ambient temp, etc. The values depicted are an approximation. Controlled testing is always required to validate. | ||||||||||||

| Other considerations Forming the busbar (aluminum has a tendency to crack with very tight radius) Electroplating the busbar (white rust on aluminum, oxidation is an issue with aluminum) Configuration of the busbar (vertical or horizontal configuration) | ||||||||||||

Conductive aluminum busbar size reference table

| Square angle aluminum bar | ||||||||||

| 2mm | 2*30 | 2*40 | 2*67 | 2*70 | 2.5* 25 | |||||

| 3mm | 3*10 | 3*15 | 3*20 | 3*25 | 3*30 | 3*40 | 3*50 | 3*60 | 3*67 | 3*75 |

| 3*110 | ||||||||||

| 4mm | 4*10 | 4*15 | 4*20 | 4*25 | 4*30 | 4*40 | 4*45 | 4*50 | 4*60 | 4.6*60 |

| 4.8*9.8 | ||||||||||

| 5mm | 5*15 | 5*20 | 5*25 | 5*30 | 5*35 | 5*40 | 5*50 | 5*60 | 5*80 | 5*100 |

| 6mm | 6*20 | 6*25 | 6*30 | 6*40 | 6*50 | 6*54 | 6*55 | 6*60 | 6*65 | 6*70 |

| 6*75 | 6*80 | 6*100 | 6*120 | 6*150 | 6*160 | |||||

| 6.3mm | 6.3*50 | 6.3*63 | 6.3*63.5 | 6.3*80 | 6.35*50.8 | 6.35*76.2 | ||||

| 7mm | 7.6*80 | 7*150 | 7*4*20*4 | |||||||

| 8mm | 8*11 | 8*30 | 8*40 | 8*50 | 8*51 | 8*60 | 8*63 | 8*63.5 | 8*65 | 8*70 |

| 8*80 | 8*90 | 8*100 | 8*120 | 8*125 | 8.8*28.6 | |||||

| 9mm | 9*170 | 9*125 | 9. 2*64 | |||||||

| 10mm | 10*20 | 10*25 | 10*30 | 10*40 | 10*45 | 10*50 | 10*60 | 10*63 | 10*65 | 10*70 |

| 10*80 | 10*90 | 10*100 | 10*110 | 10*114 | 10*120 | 10*125 | 10*140 | 10*150 | 10*160 | |

| 12mm | 12*30 | 12*40 | 12*45 | 12*50 | 12*60 | 12*70 | 12*76 | 12*80 | 12*100 | 12*120 |

| 12*125 | 12*130 | 12*140 | 12*150 | 12*160 | ||||||

| 12.5mm | 12.5*90 | 12.5*100 | 12.5*125 | 12.5*127 | 12.7*101.6 | 12.7*160 | ||||

| 13mm | 13*125 | 13*130 | 13*160 | |||||||

| 14mm | 14*100 | 14*120 | 14.5*80 | |||||||

| 15mm | 15*30 | 15*35 | 15*50 | 15*60 | 15*80 | 15*100 | 15*120 | 15*125 | 15*150 | |

| 16mm | 16*30 | 16*90 | 16*100 | 16*110 | 16*125 | 16*130 | 16*140 | 16*150 | 16*160 | |

| 20mm | 20*76 | 20*100 | 20*120 | 20*130 | ||||||

| Square bar | 19*19 | 30*45 | 15*15 | |||||||

| Round bar | Φ6 | Φ8 | Φ10 | Φ11 | Φ12 | Φ14 | Φ15 | Φ15.6 | Φ16 | Φ18 |

| Φ20 | Φ21 | Φ22 | Φ23 | Φ25 | Φ27 | Φ28 | Φ30 | Φ32 | Φ35 | |

| Φ38 | Φ40 | Φ45 | Φ50 | Φ55 | Φ60 | |||||

| Round angle aluminum bar | |||||||||

| 2mm | R2*20 | R2.5* 50 | |||||||

| 3mm | R3*30 | R3*40 | R3*50 | R3*60 | R3*80 | R3*100 | R3*120 | R3*160 | |

| 4mm | R4*25 | R4*30 | R4*35 | R4*40 | R4*50 | R4*60 | R4.1*44.1 | R4.7*151 | |

| 5mm | R5*30 | R5*35 | R5*40 | R5*45 | R5*50 | R5*60 | R5*70 | R5*75 | R5*80 |

| R5*90 | R5*100 | R5*120 | |||||||

| 6mm | R6*40 | R6*50 | R6*60 | R6*70 | R6*80 | R6*100 | R6*120 | R6*140 | R6*160 |

| R6.3*63 | R6.35*76.5 | ||||||||

| 7mm | R7*70 | ||||||||

| 8mm | R8*40 | R8*50 | R8*60 | R8*80 | R8*100 | RS*120 | |||

| 10mm | R10*20 | R10*40 | R10*50 | R10*60 | R10*75 | R10*80 | R10*100 | R10*120 | R10*125 |

| R10*150 | R10*160 | R10*170 | R10.4*25 | ||||||

| 12mm | R12*80 | R12*100 | R12*110 | R12*120 | R12*125 | R12*150 | R12*160 | ||

| 12.5mm | R12.5*80 | R12.5*125 | R12.7*90 | R12.7*127 | |||||

| 13mm | R13*120 | R13*125 | |||||||

| 14mm | R14*100 | R14*120 | R14*150 | ||||||

| 15mm | R15*100 | R15*120 | R15*130 | R15*150 | |||||

| 16mm | R16*150 | R16*160 | |||||||

| 19mm | R19.05*101.6 | R19.05*127 | |||||||

| 20mm | R20*80 | R20*120 | R20*130 | ||||||

| Special-shaped hypotenuse | *4*50 | *5*50 | *5*60 | *6*40 | *6*50 | *6*60 | *6*80 | *8*60 | *8*80 |

| *8*100 | *8*120 | *10*40 | *10*80 | *10*100 | *10*120 | *12*80 | *12*100 | *12*120 | |

| *15*120 | *20*130 | *28*60 | |||||||

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote