Aluminum wire for electric traction is an aluminum alloy contact wire used in electrical transportation and lifting systems such as railways, mines, and urban transportation.

Why choose Chalco aluminum wire for electric traction?

Production standards

GB 12971.5-1991

Certification

Chalco products are manufactured in our advanced factory using a strict quality and environmental management system, and have passed ISO certification.

Production strength

Production and management comply with the international power quality system, ensuring the best quality with long service life, high mechanical strength, high conductivity, and high-temperature softening resistance.

Power customer reference

SIEMENS, ABB, TOSHIBA, LEGRAND, EATON, HITACHI.

Mechanical properties of trolley and contact wires for electric traction

| Section/mm2 | Tensile force/N | Elongation after fracture/(%) | Resistivity at 20℃/ (Ω*mm2/m) | 180° repeated twisting |

| 130 | ≥33130 | ≥4 | ≤0.328 | No breakage or cracking |

| 170 | ≥43310 | ≥4 | ≤0.328 | No breakage or cracking |

| 200 | ≥50960 | ≥4 | ≤0.328 | No breakage or cracking |

Specification of trolley and contact wires for electric traction

| Dimensions and deviations/mm | |||||

| Section/mm2 | 130 | 170 | 200 | ||

| Calculate cross-section/mm2 | 130.1 | 171.1 | 200.5 | ||

| Equivalent copper DC resistance cross-section/mm2 | 70 | 90 | 100 | ||

| A | (±2%) | 13.48 | 15.4 | 16.64 | |

| B | (±1%) | 13.48 | 15.4 | 16.64 | |

| C | (±2%) | 9.55 | 9.55 | 9.55 | |

| D | (+4%, -2%) | 7.27 | 7.27 | 7.27 | |

| E | (±2%) | 6.78 | 6.78 | 6.78 | |

| F | 2.67 | 3.97 | 4.93 | ||

| r | 0.38 | 0.38 | 0.38 | ||

| G | deviation±2° | 27° | 27° | 27° | |

| H | 51° | 51° | 51° | ||

| Weight/(kg/km) | 350 | 460 | 540 | ||

Alloys of aluminum wire for electric traction

In electric traction applications, commonly used aluminum alloys are aluminum magnesium alloy (Al Mg alloy) and aluminum manganese alloy (Al Mn alloy). These two alloys have good conductivity and mechanical strength, making them suitable for use in power transmission and traction systems.

Aluminum magnesium alloy has good strength and corrosion resistance, as well as high conductivity, making it a common choice in electric traction applications. The main components of this alloy are aluminum and a small amount of magnesium. Adding magnesium can improve the strength and hardness of aluminum while maintaining good conductivity. Represents alloy 5052.

Aluminum manganese alloy is another common alloy for electric traction applications. Its main components are aluminum and manganese. Aluminum manganese alloy has good conductivity and high mechanical strength. Compared to aluminum magnesium alloys, aluminum manganese alloys have higher strength, but their performance in corrosive environments may be slightly worse. Represents alloy 3003.

AA6101 (Aluminum Magnesium Silicon Alloy): this is an aluminum magnesium silicon alloy suitable for traction and power wires. It has good conductivity and strength, as well as good corrosion resistance.

AA6201 (Aluminum Magnesium Silicon Alloy): similar to AA6101, AA6201 is also an aluminum magnesium silicon alloy commonly used for traction wires and wires. It has high strength and good conductivity.

These aluminum alloy wire for electric traction widely used in electric traction due to their low density, good conductivity, mechanical strength, and lower cost compared to other metals such as copper.

Advantages of Chalco aluminum wires for electric traction

Lightweight and highly conductive: aluminum is a lightweight metal with a density of approximately one-third that of copper. In contrast, using aluminum wire can reduce the weight of the cable and reduce the load on the traction system. Although aluminum has a lower conductivity than copper, its lightweight properties can provide higher conductivity.

Good conductivity: although aluminum has a lower conductivity than copper, it still has good conductivity. Electric traction wire can effectively transmit electrical energy and reduce energy loss during the power transmission process.

Corrosion resistance: aluminum wire for electric traction has good corrosion resistance and can resist the corrosion of atmospheric environment and some chemical media. This makes aluminum wire more reliable for outdoor and humid environments.

Cost effectiveness: compared to copper wire, Aluminum wire for electric traction has lower manufacturing costs. Aluminum resources are relatively abundant and prices are relatively low, so using aluminum wires can reduce the construction and operation costs of traction systems.

Plasticity and workability: aluminum wire for electric traction has good plasticity and workability, and can be manufactured into various shapes and sizes of wire to meet different traction system requirements.

Environmental sustainability: the use of Aluminum wire for electric traction can reduce resource consumption and reduce its impact on the environment. Aluminum is a recyclable metal, and recycling aluminum wire can help reduce waste generation and energy consumption.

Precautions for purchasing aluminum wires for electric traction

Specifications and requirements: determine the required aluminum wire specifications and requirements, such as conductivity, current load, insulation level, etc. Ensure that the selected aluminum wire meets the requirements of the required power transmission and traction system.

Standards and certifications: ensure that the purchased aluminum wire meets relevant national or industry standards and has corresponding certifications. For example, the International Electrotechnical Commission (IEC) and national Standards organization (such as ASTM, GB, etc.) have formulated standard specifications for aluminum wires for electric traction.

Quality and reliability: choose suppliers or manufacturers with good quality and reliability. Understand its production process, quality control measures, and supply chain management. Refer to the evaluations and experiences of other users and choose reputable suppliers.

Corrosion resistance: for traction systems in outdoor or humid environments, ensure that the purchased aluminum wire has good corrosion resistance. Aluminum wire is usually improved in corrosion resistance through special surface treatment or coating.

Price and cost-effectiveness: compare the prices and cost-effectiveness of different suppliers. Consider the balance between quality, performance, and price of aluminum wire to ensure that the purchased aluminum wire has a reasonable price and performance ratio.

Service and support: understand the after-sales service and technical support provided by the supplier. Ensure timely technical consultation, after-sales service, and problem-solving support.

Logistics and delivery: negotiate delivery time and logistics arrangements with suppliers to ensure timely delivery of aluminum wires, and carry out appropriate packaging and transportation to prevent damage.

Regulations and safety: comply with relevant regulations and safety requirements. Ensure that the purchased aluminum wires comply with local safety standards for power transmission and traction systems, and follow safety operating guidelines.

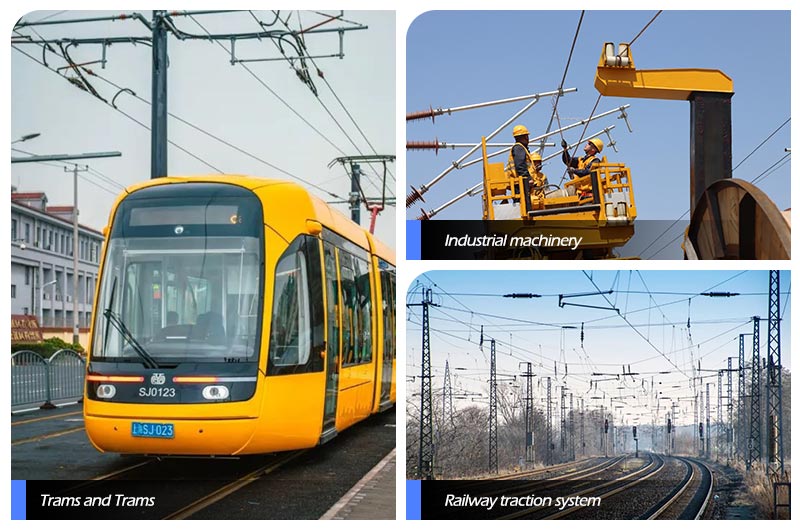

Applications of aluminum wires for electric traction

Railway traction system: aluminum wire for electric traction is widely used in railway traction systems, including urban rail transit (such as subways and light rail) and railway trains. Aluminum wires for electric traction are used for power transmission in power supply systems, including contact networks, traction cables, and contact rails.

Trams and trams: trolley and contact wires for electric traction is used for the traction line and contact network system of trams and trams, providing power and power transmission.

Electric motorcycles and scooters: aluminum electric traction wire for electric traction is used for the power transmission system of Electric motorcycles and scooters, including high-speed railway, freight train, Passenger train, etc.

Subway system: the power supply system in the subway system uses aluminum wires for power transmission and traction, including subway vehicles and platform areas.

Electric vehicles: in some electric vehicle systems, Aluminum wire for electric traction is used for power transmission and connection between electric motors and battery systems.

Port and terminal equipment: some port and terminal equipment (such as container cranes, stackers, etc.) use electric traction systems, with aluminum wires used for power transmission and supply.

Mines and quarries: some quarries and mines use electric traction equipment, such as electric forklifts, cranes, etc. Aluminum wire for electric traction is used for power transmission and supply.

Industrial machinery: aluminum wire for electric traction is used in some industrial machinery equipment, such as electric cranes, conveyor belt systems, etc., to provide power transmission.

These are some of the main application areas of aluminum wires for electric traction, among which aluminum wires are used for power transmission and power supply systems, providing power for different traction equipment and transportation vehicles. The lightweight, high conductivity, and cost-effectiveness of aluminum wire make it an ideal choice for these applications.