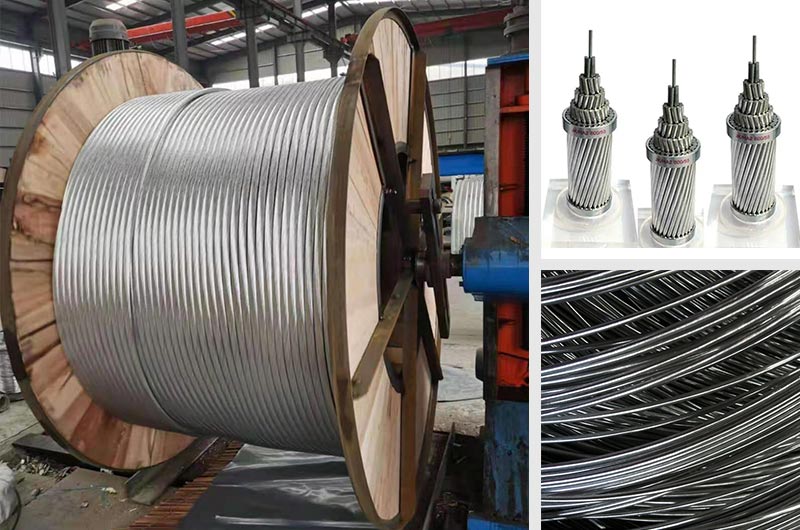

Aerial stranded wire is a type of wire used in power transmission and distribution systems to carry electricity while suspended from power poles. Heat-resistant aluminum alloy wire is a special stranded wire material with high heat resistance and electrical conductivity

Why choose Chalco Heat-resistant aluminum alloy wire for conductors?

Quality could full meet world wide cable wire standard: NBT, UL, CE, TUV, SAA, IEC etc.Quick Quote

Production and management comply with international cable wire quality system, to make sure specific intermediate strength advantage and resistance advantage.

Alloy and chemical composition of heat-resistant aluminum wires for overhead stranded wires

| Chemical composition | ||

| AA 6201-T81 | AA 1120-T81 | AA 6201-T63 |

| (Al): 97.4%-99.0% | (Al): 99.0%-99.5% | (Al): 97.4%-99.0% |

| (Fe): 0.7%-1.3% | (Fe): < 0.7% | (Fe): 0.7%-1.3% |

| (Si): 0.5%-0.9% | (Si): < 0.15% | (Si): 0.5%-0.9% |

| (Cu): 0.1%-0.3% | (Cu): 0.05%-0.2% | (Cu): 0.1%-0.3% |

| (Mn): 0.03%-0.1% | (Mn): < 0.05% | (Mn): 0.03% - 0.1% |

| Other: < 0.15% | (Zn): < 0.05% | Other: < 0.15% |

| (Ti): < 0.05% | ||

Diameter and tolerance of Chalco heat-resistant aluminum alloy wires for overhead stranded wires

| Diameter | Tolerance |

| ≤3.0 | ±0.03 |

| >3.0 | ±1% d |

Properties of heat-resistant aluminum alloy wires for overhead stranded wires

| Physical properties | ||||

| Type | NRLH1 | NRLH2 | NRLH3 | NRLH4 |

| 20℃ density/(kg/dm3) | 2.703 | 2.703 | 2.703 | 2.703 |

| Allowable continuous operating temperature (40 years)/℃ | 150 | 150 | 210 | 230 |

| 400h allowable operating temperature/℃ | 180 | 180 | 240 | 310 |

| Coefficient of linear expansion/(10-6/℃) | 23 | 23 | 23 | 23 |

| 20℃Temperature coefficient of resistance/(1/℃) | 0.0040 | 0.0036 | 0.0040 | 0.0038 |

| Mechanical properties | |||

| Type | Diameter/mm | Tensile strength/Mpa | Elongation(%) |

| NRLH1 | >2.90-3.50 | ≥162 | ≥1.7 |

| >3.50-3.80 | ≥1.8 | ||

| >3.80-4.00 | ≥159 | ≥1.9 | |

| >4.00-4.50 | ≥2 | ||

| NRLH2 | ≤2.60 | ≥218 | ≥1.5 |

| >2.60-2.90 | ≥245 | ≥1.6 | |

| >2.90-3.50 | ≥241 | ≥1.7 | |

| >3.50-3.80 | ≥1.8 | ||

| >3.80-4.00 | ≥238 | ≥1.9 | |

| >4.00-4.50 | ≥225 | ≥2 | |

| NRLH3 | ≤2.30 | ≥176 | ≥1.5 |

| >2.30-2.60 | ≥169 | ||

| >2.60-2.90 | ≥166 | ≥1.6 | |

| >2.90-3.50 | ≥162 | ≥1.7 | |

| >3.50-3.80 | ≥1.8 | ||

| >3.80-4.00 | ≥159 | ≥1.9 | |

| >4.00-4.50 | ≥2 | ||

| NRLH4 | ≤2.60 | ≥169 | ≥1.5 |

| >2.60-2.90 | ≥165 | ≥1.6 | |

| >2.90-3.50 | ≥162 | ≥1.7 | |

| >3.50-3.80 | ≥1.8 | ||

| >3.80-4.00 | ≥159 | ≥1.9 | |

| >4.00-4.50 | ≥2 | ||

| Heating duration and temperature for heat resistance | |||||

| Time | Temperature | NRLH1 | NRLH2 | NRLH3 | NRLH4 |

| 1 | heating temperature/℃ | 230 | 230 | 280 | 400 |

| Temperature tolerance/℃ |

+5 -3 |

+5 -3 |

+5 -3 |

+10 -6 |

|

| 400 | heating temperature/℃ | 180 | 180 | 240 | 310 |

| Temperature tolerance/℃ |

+10 -6 |

+10 -6 |

+10 -6 |

+10 -6 |

|

Characteristics of heat-resistant aluminum alloy wires for overhead stranded wires

Heat-resistant performance: heat-resistant aluminum alloy wire is made of special aluminum alloy material, which has excellent high-temperature resistance. It maintains stable electrical conductivity at high temperatures and is less susceptible to thermal expansion and softening. This makes heat-resistant aluminum alloy wires widely used in high-temperature areas or power transmission scenarios that need to withstand high-temperature loads.Quick Quote

Electrical conductivity: heat-resistant aluminum alloy wire has good electrical conductivity and can effectively transmit electric energy. Although the electrical conductivity of aluminum alloy is slightly lower than that of copper, due to its lightweight properties, heat-resistant aluminum alloy wire can carry the same current load with less weight, thereby reducing the weight and cost of the wire.

Corrosion resistance: heat-resistant aluminum alloy wire has strong corrosion resistance and can resist corrosion in environments such as atmosphere, soil and chemicals. This allows it to maintain a long service life in harsh weather conditions and highly corrosive environments.

Lightweight design: compared with traditional copper wires, heat-resistant aluminum alloy wires are lighter in weight. This makes the installation and suspension process more convenient, reduces the load on the power pole structure, and also reduces transportation costs.

Application of heat-resistant aluminum alloy wire for overhead stranded wire

Power transmission: heat-resistant aluminum alloy wires can be used in high-voltage transmission lines to transmit electrical energy generated in power stations to substations or other destinations. They can withstand high current loads and high temperature environments, maintain stable electrical conductivity, and ensure the efficiency and reliability of power transmission.

Distribution lines: after the power is transmitted to the substation, heat-resistant aluminum alloy wires can also be used to distribute power to different areas and users. They serve as distribution lines connecting substations to consumers, supplying electricity to homes, commercial buildings, and industrial facilities, among others.

Urban power grid: the use of heat-resistant aluminum alloy wires for overhead stranded wires can build a city's power grid system. They can be hung on power poles and cable supports to connect different transmission and distribution lines to provide a stable power supply to cities.

Application in high temperature environment: heat-resistant aluminum alloy wire is suitable for special occasions that need to withstand high temperature environment. For example, in industrial fields such as oil refineries, metallurgical plants and chemical plants, heat-resistant aluminum alloy wires can be used to transmit electricity because they can maintain good electrical conductivity under high temperature conditions.

Requirements for the use of heat-resistant aluminum alloy wires for overhead stranded wires

Power system standards: follow applicable power system standards and codes, such as national or regional power industry standards, International Electrotechnical Commission (IEC) standards, or Institute of Electrical and Electronics Engineers (IEEE) standards, etc. These standards define requirements and specifications for overhead stranded wires and conductors.

Electrical load and capacity: make sure that the electrical conductivity of the overhead stranded wire and heat-resistant aluminum alloy wire is sufficient for the required electrical load and capacity. According to the specific power transmission and distribution needs, select the appropriate parameters such as wire size, cross-sectional area and capacity.

Installation requirements: correctly install and hang the overhead stranded wire in accordance with relevant standards and specifications to ensure its stability, verticality and correct tension. Make sure that the spacing, lay length and suspension height of the wires meet the requirements to ensure the safety and reliability of power transmission.

Insulation protection: appropriate insulation protection materials or insulation sleeves are applied to the overhead strands as required to prevent contact with other objects or short circuits. This improves the insulation performance of the wire and protects the line from the external environment.

Environmental adaptability: considering the climatic conditions, environmental characteristics and use environment of the area, the heat-resistant aluminum alloy wire is selected to have appropriate heat resistance and corrosion resistance to ensure its long-term stable operation in harsh environments.

Inspection and maintenance: regular inspection and maintenance of overhead stranded wires and heat-resistant aluminum alloy wires, including surface cleaning, fastener inspection, wire tension inspection, insulation status inspection, etc. This helps keep the line in good working order and prolongs its life.