5052 aircraft aluminum bars, which have good corrosion resistance, high strength, excellent formability and weldability. It is usually used to manufacture aircraft fuselage, wings and other parts.

Why choose Chalco 5052 aviation aluminum bar

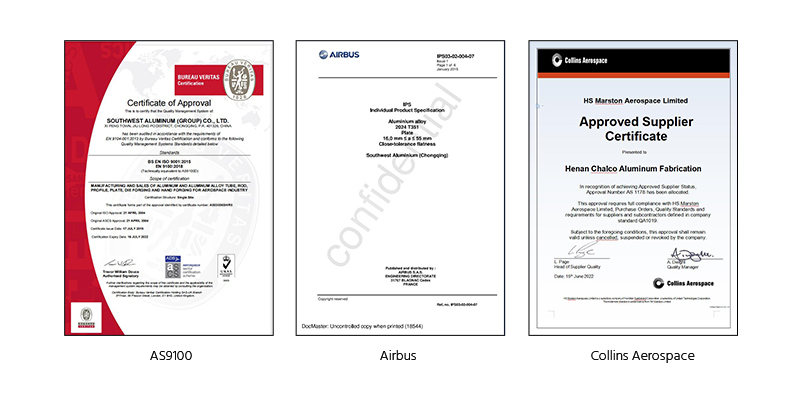

Chalco is a professional manufacturer of aviation materials. It has AS9100 aviation certification and strictly complies with the following AMS aviation standards.

Standards

AMS 4114, QQ-A-225/7, MIL-DTL-32262B, ASTM B221, AMS 4015, AMS 4016.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO 45001

ISO 9001

NADCAP HT

NADCAP NDT

IATP16949

The specification of 5052 aerospace aluminum round bars

| Alloy | 5052 aerospace aluminum round bars |

| Temper | F, H112, O, H111 |

| Out diameter (OD) | 3.0mm-600mm |

| Length(mm) | Common 1500/3000/5000/6000MM |

| Standard | AMS 4114, QQ-A-225/7, MIL-DTL-32262B, ASTM B221, AMS 4015, AMS 4016 |

Chemical composition of 5052 aircraft aluminum bar

| Element | Composition(%) |

| Al | REM |

| Si | ≤0.25 |

| Fe | ≤0.40 |

| Cu | ≤0.10 |

| Mn | ≤0.10 |

| Mg | ≤2.2-2.8 |

| Cr | ≤0.15-0.35 |

| Ni | / |

| Zn | ≤0.10 |

| Ti | / |

| Note: Each:≤0.05;Total:≤0.15 | |

Mechanical properties of 5052 aircraft grade aluminum square bar

| Alloy | Temper | Dimensions /mm | Room temperature Test Result | |||

| Tension strength/MPa | Yield strength/MPa | Elongation/% | ||||

| A50mm | A | |||||

| Not less than | ||||||

| 5052 | O H111 | All | 170-230 | 70 | 15 | 17 |

| H112 | All | 170 | 70 | 13 | 15 | |

| F | All | - | - | - | - | |

What are the advantages of Chalco 5052 aviation aluminum flat bus bar?

Good corrosion resistance

5052 aviation aluminum rod has strong oxidation resistance and corrosion resistance, and can maintain its surface smoothness and integrity in wet, salt fog and acid environment, reducing maintenance and repair costs.

High strength

The tensile strength of 5052 aviation aluminum metal bar can reach 210-230 MPa, and the yield strength can reach 110-130 MPa. The strength is high, and it can bear certain loads, ensuring the safety and reliability of the fuselage and parts.

Excellent formability

5052 aviation aluminum bar has good plasticity and machinability, and can be used for various forming processes, such as rolling, drawing, deep drawing, molding, etc., which can meet the forming requirements of complex parts.

Good welding performance

5052 aircraft aluminum bar has good welding performance, and can be connected by conventional welding processes, such as argon arc welding, resistance welding, laser welding, etc., which can make the structural components firmly spliced.

Lightweight

The 5052 aviation aluminum rod has a low density and is about one-third lighter than steel. The lightweight design can reduce the weight and fuel consumption of aircraft and improve fuel economy.

To sum up, 5052 aviation aluminum bar has corrosion resistance, high strength, excellent formability and weldability, and lightweight.

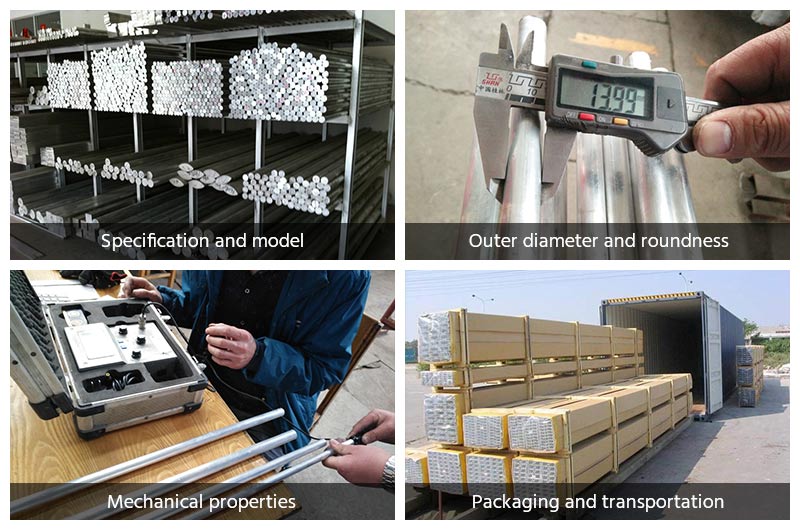

What are the precautions for purchasing 5052 aircraft aluminum metal bar?

Specification and model

It is very important to select the appropriate specifications and models. Different application fields have different requirements for aviation aluminum rods, and appropriate specifications and sizes need to be selected according to specific requirements.

It should be noted that the specifications and models of aviation aluminum rods are usually identified by diameter or cross-sectional area, and attention should be paid to distinguishing.

Quality standards

Products that meet relevant quality standards should be selected, such as ASTM, AMS and other standards, to ensure that the product quality is qualified and avoid quality problems.

Supplier reputation

It is very important to select reliable suppliers. You can evaluate the credibility of suppliers by querying their credibility and customer evaluation, and select trustworthy suppliers to ensure the quality and stability of products.

Quality inspection

Before purchasing, it is necessary to carry out product quality inspection to check whether there are defects, cracks, oxidation and other problems to ensure that the product conforms to relevant quality standards.

Packaging and transportation

After purchase, attention should be paid to the safety of packaging and transportation to avoid damage or deformation during transportation, which may lead to product quality degradation.

In short, the purchase of 5052 aircraft rectangular bars requires the selection of appropriate specifications and models, products that meet the quality standards, reliable suppliers, and the necessary quality testing, pay attention to the safety of packaging and transportation, and ensure the quality and stability of the products.

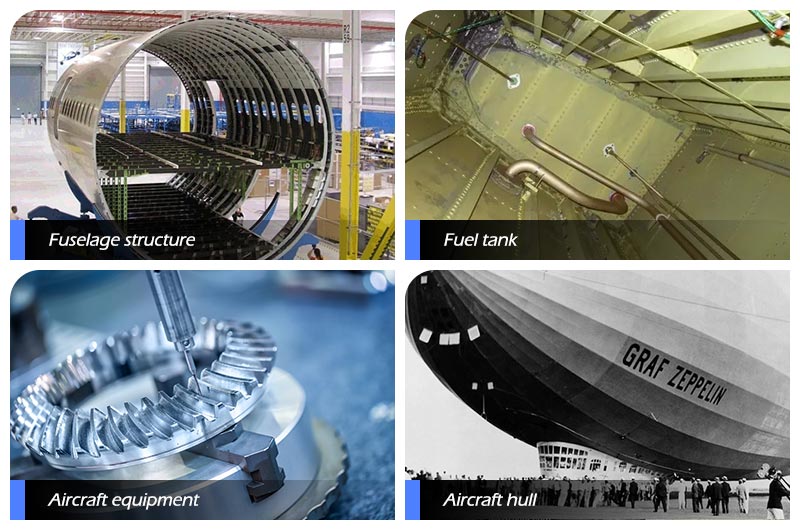

What are the applications of Chalco aircraft aluminium alloy 5052 round bars?

5052 aviation rectangular bars is a common aviation aluminum material, widely used in various fields of aviation industry, mainly including the following aspects:

Fuselage structure

5052 Aluminium Alloy Aerospace rod is usually used for the manufacture of structural parts, supports, connectors and other parts of aircraft fuselage. Its high strength and lightweight advantages can bear the load of the fuselage, reduce the weight of the aircraft and improve fuel economy.

Fuel tank

5052 aluminum aviation rod can be used to manufacture fuel tank, oil pump and other parts of fuel system. Its good corrosion resistance can resist fuel corrosion and prolong the service life of the fuel system.

Aircraft hull

5052 aviation aluminum rods are also widely used in the manufacture of aircraft hulls, such as the hull and chassis of small airships, helicopters and other aircraft, and have good corrosion resistance and strength.

Aircraft equipment

5052 aerospace flat bars can be used to manufacture parts of aircraft equipment and instruments, such as navigation instruments, remote control, landing gear and hatch, and can ensure the safety and stability of equipment.

In short, the 5052 ultralight aircraft aluminum square bar is widely used in the aviation industry, mainly in the fields of fuselage structure, fuel system, hull, equipment and instruments. It has advantages of good corrosion resistance, high strength, good formability and lightweight, and can meet the high requirements of the aviation industry for materials.