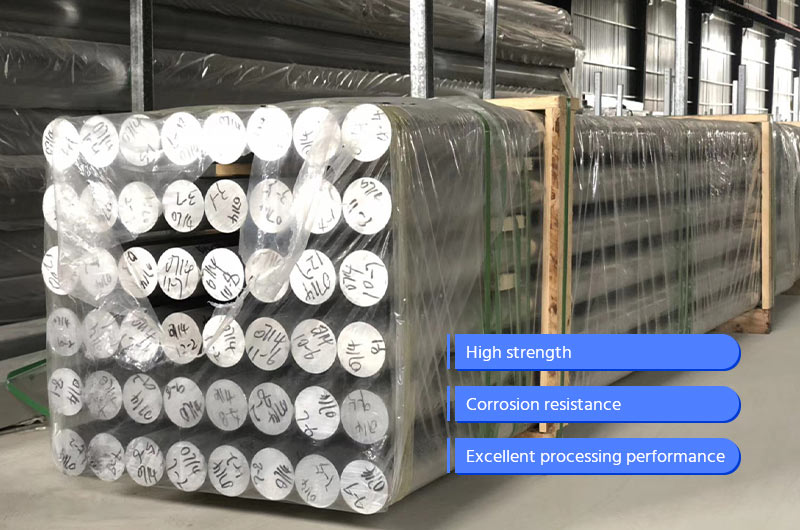

6082 aerospace aluminum rod is an aluminum alloy material with high strength, high corrosion resistance and good machinability, which is mainly used in the aerospace field.We offer 6082 Aluminum Alloy Round Rods in different sizes, thicknesses, standards and shapes as per the changing requirements provided by our clients.

This material has moderate strength, excellent corrosion resistance, good machinability, and anodizing performance. It has good weldability, although the overall strength around the weld area decreases. Machinability is particularly good in the T6 and T651 states, producing tight chip coils when using chip breakers.Quick Quote

The 6082 aerospace aluminum bar produced by Chalco Aluminum is applicable to the following standards: EN 573, EN 755, EN 754, ASTM B221, AMS 4156, EN 573-3, AMS QQ-A-200/9, AMS QQ-A-225/8, AS9100, NADCAP, JISQ 9100.

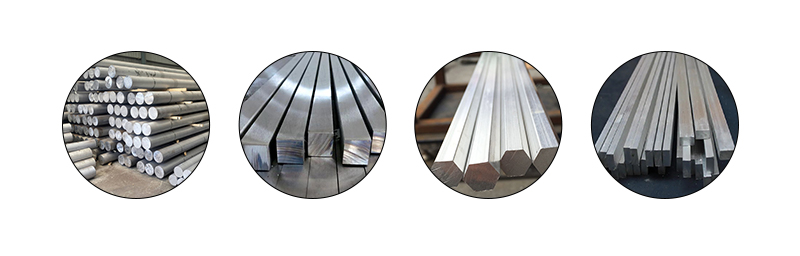

6082 aerospace aluminum bar

Round bar: 6082 aviation aluminum round bar is one of the most common shapes and is used in the manufacture of various mechanical parts and structural parts.

Square bar: 6082 aviation aluminum square rod is an aluminum rod with a quadrilateral cross section, which is usually used in architectural decoration, mechanical parts manufacturing and other fields.

Hexagonal bar: 6082 aviation aluminum hexagonal rod is an aluminum rod with a hexagonal cross-section, also known as a hexagonal rod, which is often used in the manufacture of mechanical parts.Quick Quote

Flat bar: 6082 aviation aluminum flat rod is a rectangular cross-section aluminum rod with a width greater than thickness, which is used to manufacture parts and components that require a flat shape.

6082 aerospace aluminum bar stock dimensions

6082 Aluminum Rod is in stock in a variety of shapes, sizes and conditions including T4, T6, T6510 and T6511 conditions.Quick Quote

| Specification | Diameter(inch) | Length(feet) | Size(Can be cut) |

| 1/8" Dia 6082 Aluminium bar | 1/8" | 12-20(Can be cut) | round |

| 1/4" Dia 6082 Aluminium bar | 1/4" | 12-20(Can be cut) | round |

| 1/2" Dia 6082 Aluminium bar | 1/2" | 12-20(Can be cut) | round |

| 3/4" Dia 6082 Aluminium bar | 3/4" | 12-20(Can be cut) | round |

| 1" Dia 6082 Aluminium bar | 1" | 12-20(Can be cut) | round |

| 1-1/4" Dia 6082 Aluminium bar | 1-1/4" | 12-20(Can be cut) | round |

| 1-1/2" Dia 6082 Aluminium bar | 1-1/2" | 12-20(Can be cut) | round |

| 2" Dia 6082 Aluminium bar | 2" | 12-20(Can be cut) | round |

| 2" Dia 6082 Aluminium bar | 2" | 12-20(Can be cut) | round |

| 2 1/4" Dia 6082 Aluminium bar | 2 1/4" | 12-20(Can be cut) | round |

| 2 1/2" Dia 6082 Aluminium bar | 2 1/2" | 12-20(Can be cut) | round |

| 3" Dia 6082 Aluminium bar | 3" | 12-20(Can be cut) | round |

| 3 1/2" Dia 6082 Aluminium bar | 3 1/2" | 12-20(Can be cut) | round |

| 4" Dia 6082 Aluminium bar | 4" | 12-20(Can be cut) | round |

| 4 1/2" Dia 6082 Aluminium bar | 4 1/2" | 12-20(Can be cut) | round |

| 5 1/2" Dia 6082 Aluminium bar | 5 1/2" | 12-20(Can be cut) | round |

| 1/4" Dia 6082 Aluminium bar | 1/4" | 12-20(Can be cut) | square |

| 1/2" Dia 6082 Aluminium bar | 1/2" | 12-20(Can be cut) | square |

| 3/4" Dia 6082 Aluminium bar | 3/4" | 12-20 | square |

| 1" Dia 6082 Aluminium bar | 1" | 12-20(Can be cut) | square |

| 1/2" Dia 6082 Aluminium bar | 1/2" | 12-20(Can be cut) | hexagon |

| 1" Dia 6082 Aluminium bar | 1" | 12-20(Can be cut) | hexagon |

| 1-1/2" Dia 6082 Aluminium bar | 1-1/2" | 12-20(Can be cut) | hexagon |

If you need a full stock size chart, please contact us.Quick Quote

Alloy temper of 6082 aerospace aluminum bar

| Temper | Tensile strength(MPa) | Field strength(MPa) | Elongation(%) |

| T6 | 295-390 | 240-330 | 8-10 |

| T6511 | 290-380 | 240-330 | 8-10 |

| T651 | 290-380 | 240-330 | 8-10 |

Physical properties of 6082 aerospace aluminum bar

| Physical properties | Value |

| Density | 2.70 g/cm3 |

| Elastic modulus | 70 GPa |

| Melting point | 555 °C |

| Coefficient of thermal expansion | 23.2×10-6/°C |

| Thermal conductivity | 201-218 W/mK |

| Conductivity | 30-36 MS/m |

| Tensile strength | 310 MPa |

| Yield strength | 260 MPa |

| Elongation | 8%-10% |

Popular products related to 6082 aluminum rods

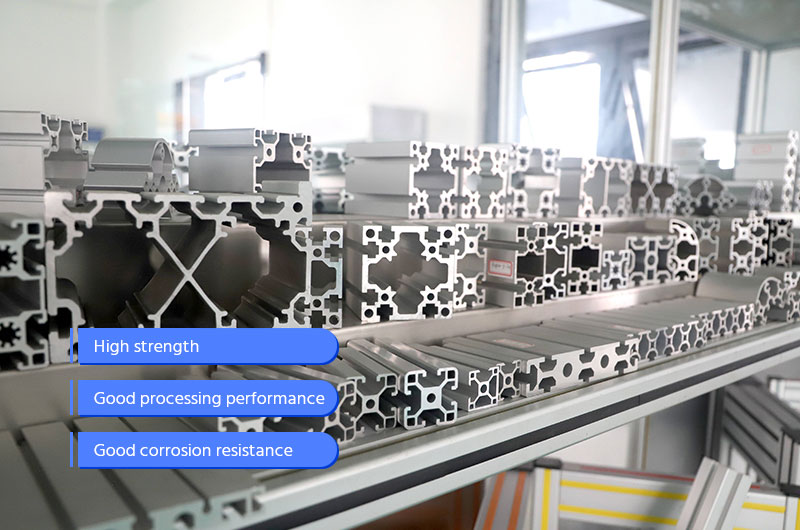

6082-profile

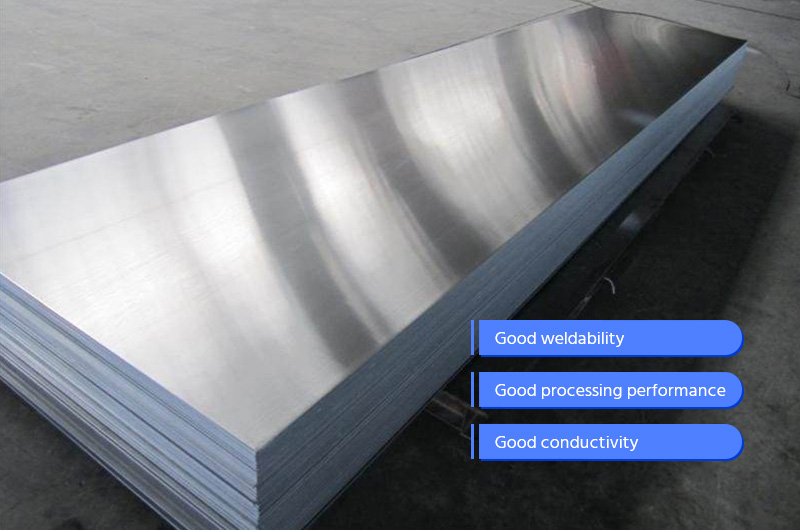

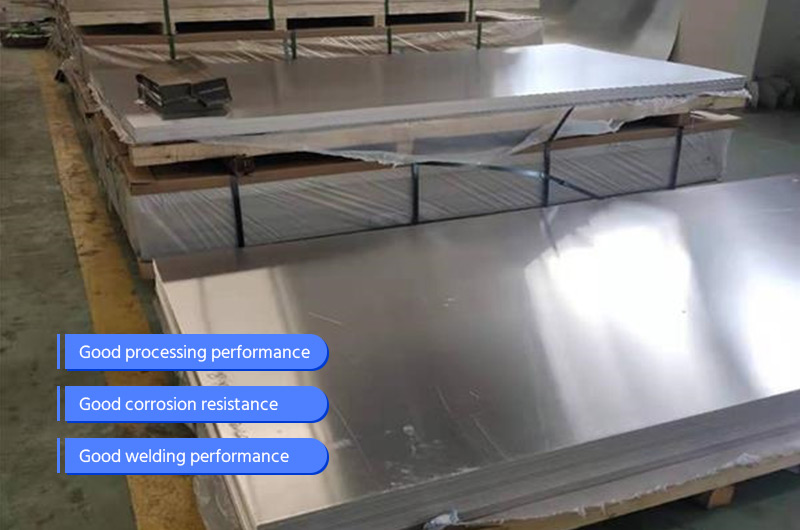

6082-sheet

6082-forging

6082-aerospace-aluminum-tube

6082-aluminium-tube

6082-T6 aluminum

Chemical composition of 6082 aerospace aluminum bar

| Chemical composition | % |

| Al | 96.4%-98.8% |

| Cu | 0.6%-1.2% |

| Si | 0.7%-1.3% |

| Mg | 0.6%-1.2% |

| Mn | 0.4%-1.0% |

| Cr | 0.25%-0.35% |

| Zn | ≤0.2% |

| Ti | ≤0.1% |

6082 aluminum Related Specifications

- AA6082

- HE30

- DIN 3.2315

- EN AW-6082

- ISO: Al Si1MgMn

- A96082

Usage of 6082 aerospace aluminum bar

Aircraft structural parts: 6082 aerospace aluminum bars have excellent strength and rigidity, and can be used in the manufacture of aircraft fuselage, airfoils, flaps, propellers and other components.Quick Quote

Aviation engine components: 6082 aerospace aluminum bars have excellent high temperature resistance and can be used to manufacture aircraft engine blades, turbine disks and other components.

Aerospace electronic devices: 6082 aerospace aluminum bars have good electrical conductivity and can be used to manufacture casings and radiators for aerospace electronic devices.

Aerospace equipment: 6082 aerospace aluminum bars can be used to manufacture various aerospace equipment, such as satellites, missiles, rockets, etc.

In general, 6082 aerospace aluminum bar has the characteristics of high strength, light weight, corrosion resistance and high temperature resistance, making it one of the commonly used materials in the aerospace field, and is widely used in various aerospace equipment and parts.

Features of Chalco Aluminum 6082 aerospace aluminum bar

High strength: the tensile strength of 6082 aerospace aluminum bars in the T6 state can reach more than 320MPa, stronger than ordinary structural steel, and can meet the demand for high-strength materials in the aerospace field.

Corrosion resistance: 6082 aerospace aluminum bar has good corrosion resistance and can be used in various harsh environments.

Excellent processing performance: 6082 aerospace aluminum bar has good processing performance and can be processed by various processing methods, such as cutting, drilling, milling, welding, etc.

Lightweight: the density of 6082 aerospace aluminum bar is 2.7g/cm3, which is about 1/3 lighter than ordinary structural steel, which can help reduce the weight of aircraft, spacecraft, etc., and improve load capacity and flight efficiency.

Recyclability: 6082 aerospace aluminum bar is a recyclable and environmentally friendly material, which is conducive to reducing resource waste and environmental pollution.Quick Quote

Certification and standards of Chalco Aluminum 6082 aerospace aluminum bar

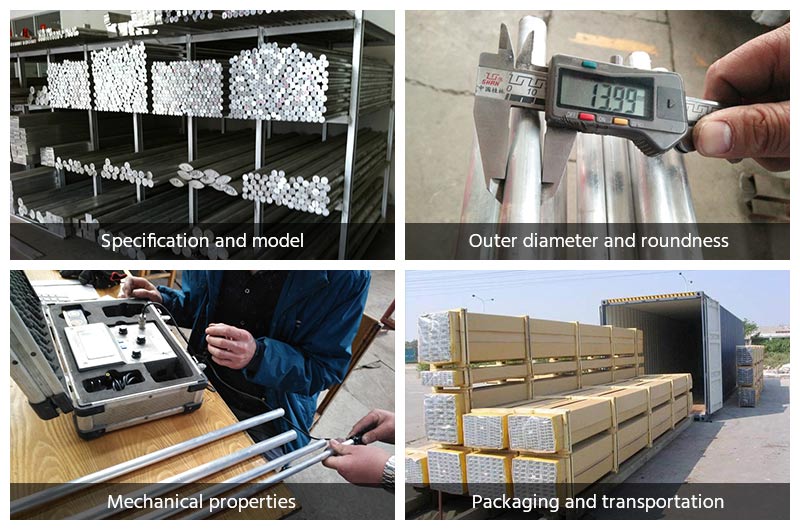

Quality certification: 6082 aerospace aluminum bar has ISO 9001:2015 quality management system certification and AS9100D aerospace quality management system certification to ensure the standardization and effectiveness of the quality management system in the production and sales process.

Standard: 6082 aerospace aluminum bar complies with international standards and industry standards, such as ASTM B221, AMS 4156, EN 573-3, etc., to ensure that its chemical composition, physical properties, dimensions, etc. meet the standard requirements.

Testing and certification: 6082 aerospace aluminum bars undergo strict testing, including ultrasonic testing, dimensional testing, tensile testing, hardness testing, chemical composition analysis, etc., to ensure that its quality and performance meet the requirements.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote