6082 aviation aluminum tube is a high-strength, corrosion-resistant aluminum alloy tube, usually used to manufacture aircraft and other aircraft parts.6082-T6 drawn tube is a medium-strength alloy, the strongest among the 6000 series alloys, and has excellent corrosion resistance.

Although 6082 is a relatively new alloy, its increased strength has allowed it to replace 6061 in many applications. In 6082 alloy, we are able to produce thin-walled, complex extruded and drawn tubes.Quick Quote

Introduction to 6082 T6 Aluminum Tube

| Shape | Aluminium Round Tube, Aluminium Hollow Box Section Profilc, Aluminium Rectangular Tube, Customization |

| Length | Can be cut according to customer requirements. |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Types | Seamless, Welded, Fabricated |

| Form | Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U” Shape, Pan Cake Coils, Hydraulic Tubes |

| End | Plain End, Beveled End, Treaded |

| Standard | BS L100, BS L114, BS1474, EN 573, EN 755, EN 754 |

| Related Specifications | AA6082, HE30, DIN 3.2315, EN AW-6082, ISO: Al Si1MgMn, A96082 |

| MOQ | One piece |

| Package | Wooden frame, wooden box packaging |

6082 aerospace aluminum tube stock size range

We stock 6082 aluminum tubing in a variety of sizes and conditions, including T4, T6 and O conditions.Quick Quote

| Description(mm) | OD(mm) | Wall (mm) | Length(mm) |

| 6 X 0.5 ALUMINIUM 6082 TUBE | 6 | 0.5 | 1000-6000 |

| 8 X 1 ALUMINIUM 6082 TUBE | 8 | 1 | 1000-6000 |

| 10 X 1 ALUMINIUM 6082 TUBE | 10 | 1 | 1000-6000 |

| 12 X 1 ALUMINIUM 6082 TUBE | 12 | 1 | 1000-6000 |

| 15 X 1 ALUMINIUM 6082 TUBE | 15 | 1 | 1000-6000 |

| 20 X 1 ALUMINIUM 6082 TUBE | 20 | 1 | 1000-6000 |

| 25 X 1.5 ALUMINIUM 6082 TUBE | 25 | 1.5 | 1000-6000 |

| 30 X 12ALUMINIUM 6082 TUBE | 30 | 2 | 1000-6000 |

| 35 X 2 ALUMINIUM 6082 TUBE | 35 | 2 | 1000-6000 |

| 40 X 2 ALUMINIUM 6082 TUBE | 40 | 2 | 1000-6000 |

| 45 X 2.5 ALUMINIUM 6082 TUBE | 45 | 2.5 | 1000-6000 |

| 50 X 2.5 ALUMINIUM 6082 TUBE | 50 | 2.5 | 1000-6000 |

| 55 X 2.5 ALUMINIUM 6082 TUBE | 55 | 2.5 | 1000-6000 |

| 60 X 3 ALUMINIUM 6082 TUBE | 60 | 3 | 1000-6000 |

| 8 X 1 ALUMINIUM 6082 TUBE | 65 | 3 | 1000-6000 |

| 70 X 3 ALUMINIUM 6082 TUBE | 70 | 3 | 1000-6000 |

If you want to see all 6082 aluminum tube stock sizes, please click on the corresponding image link.Quick Quote

Chemical composition of 6082 aviation aluminum tube

| Chemical composition | % |

| Al | 96.4%-98.8% |

| Cu | 0.6%-1.2% |

| Si | 0.7%-1.3% |

| Mg | 0.6%-1.2% |

| Mn | 0.4%-1.0% |

| Cr | 0.25%-0.35% |

| Zn | ≤0.2% |

| Ti | ≤0.1% |

Physical properties of 6082 aviation aluminum tube

| Physical properties | Value |

| Density | 2.70 g/cm3 |

| Elastic modulus | 70 GPa |

| Melting point | 555 °C |

| Coefficient of thermal expansion | 23.2×10-6/°C |

| Thermal conductivity | 180 W/mK |

| Conductivity | 33.0 MS/m |

| Tensile strength | 310 MPa |

| Yield strength | 260 MPa |

| Elongation | 8%-10% |

Advantages of 6082 aluminum tube

- Very good solderability

- Good formability

- Excellent corrosion resistance

- Highest strength 6xxx alloy

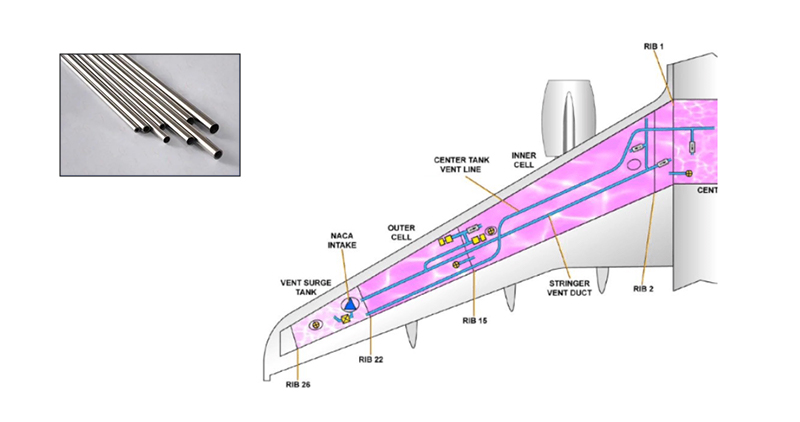

Application of 6082 aerospace aluminum tube

6082 aviation aluminum tube is a high-strength, corrosion-resistant aluminum alloy tube, usually used to manufacture aircraft and other aircraft parts. Some of these parts may include:

1. aircraft fuel tank pipe

It is usually used to create components that require high intensity and corrosion resistance, such as fuel tanks, fuel pipes, fuel tanks, and so on.Quick Quote

2. Fuselage structure

6082 aviation aluminum tubes can be used to manufacture support rods, support rods, connecting rods, counterweight rods and frames of aircraft fuselage structures.

3. Engine components

6082 aviation aluminum tubes can also be used to manufacture parts of aircraft engines, such as intake ducts, exhaust pipes, fuel delivery pipes and hydraulic pipes, etc.

4. Landing gear

6082 aviation aluminum tubes can be used to manufacture support rods and other parts of aircraft landing gear.Quick Quote

5. Auxiliary equipment

6082 aviation aluminum tube can also be used to manufacture components of aircraft auxiliary equipment, such as air conditioning, hydraulic system, fuel tank and fuel delivery system, etc.

The difference between 6082 and 6061 aluminum alloy

6082 alloy and 6061 alloy are two commonly used aluminum alloys. They have certain differences in chemical composition, mechanical properties, processing performance and application fields.

- 6082 alloy: It has good processing performance and weldability, and is suitable for occasions with high requirements on processing performance and weldability.

- 6061 alloy: It has high strength and good mechanical properties, and is suitable for occasions that require high strength and mechanical properties.

The exact alloy chosen depends on the specific application requirements.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote