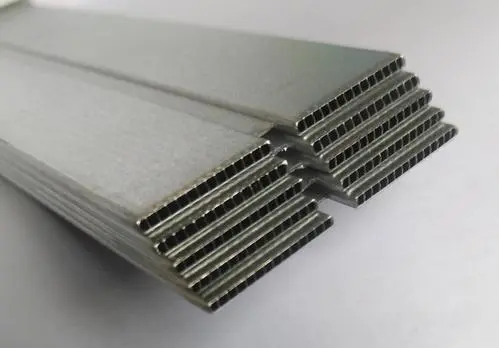

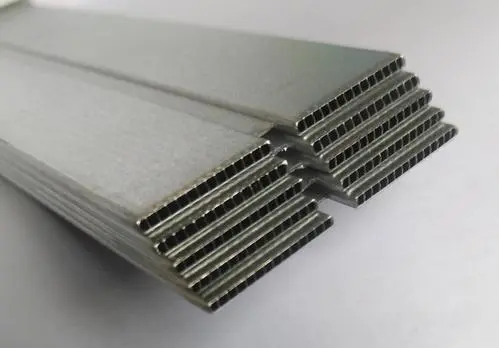

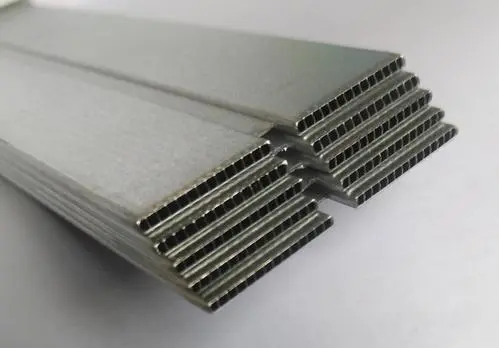

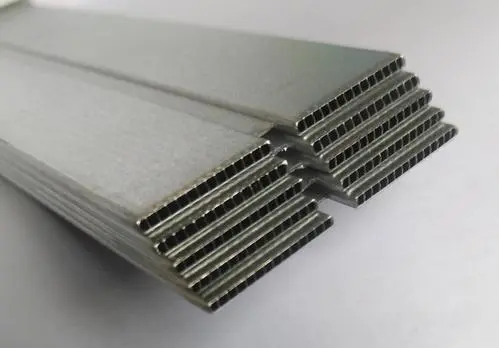

Aluminum microchannel tube is a thin-walled, porous, flat-shaped aluminum profile widely used in key components such as automotive air conditioning condensers. With the increasing demand for heat transfer efficiency, the design tends to increase the number of holes and reduce the wall thickness. Chalco's produced micro-channel aluminum tube can have up to 60 holes and a minimum wall thickness of 0.15mm, meeting the needs of most customers.Welcome to contact

Why choose Chalco parallel flow Micro-channel aluminum tube?

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.Purchase Now

Chalco Aluminum Microchannel Tube Hot Products

1050 Harmonica Aluminum Tube

Aluminum content 99%

Good ductility

Good processing performance

Contact us now

3003 aluminum microchannel tube

Aluminum-manganese alloy

Excellent corrosion resistance

Good welding performance

Contact us nowZinc-coated Aluminum Microchannel tube

Zinc powder spraying

Spray zinc thickness 5g/㎡-15g/㎡

Improve corrosion resistance

Contact us now

Pre-Flux Coated Aluminium Microchannel Tube

Flux (K1-3A1F46)

Flux thickness 8g/㎡-25g/㎡

Eliminate the soldering process

Contact us nowWhat are the characteristics of parallel flow aluminum tube?

High thermal conductivity: Due to the micro-channel structure, the Aluminum Radiator Flat Tube has a larger surface area and smaller fluid channels, enhancing its thermal conductivity and facilitating faster heat transfer.

Low fluid resistance: The micro-channel design reduces fluid resistance, minimizing pressure drop within the system and enhancing overall system efficiency.

Lightweight high strength: Aluminum material, known for its strength and hardness, combined with the micro-channel structure, results in lightweight yet durable Micro-channel tubes for heat exchangers.

High stability: Utilizing advanced manufacturing technology and materials, Micro-channel Aluminum Tubes withstand challenging environments, maintaining high stability and reliability.

Good controllability: Customizable micro-channel structure and internal design enable precise control of heat dissipation and transfer, meeting specific performance requirements.

Good corrosion resistance: Aluminum exhibits excellent corrosion resistance, ensuring prolonged use even in humid and corrosive environments.

Good security: Modular design minimizes safety issues like water leakage, ensuring user safety.

Energy saving and environmental protection: High-efficiency heat transfer properties reduce energy consumption, aligning with energy-saving and environmental protection goals.

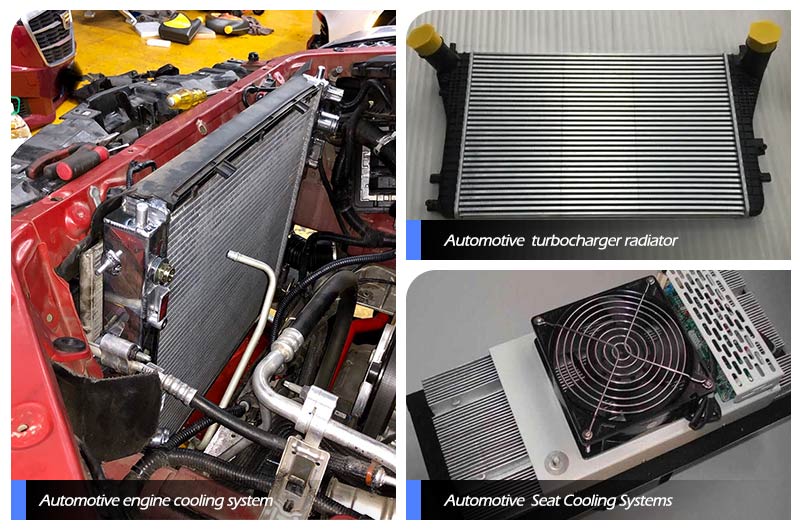

The usage of micro-channel aluminum tubes in the automotive field

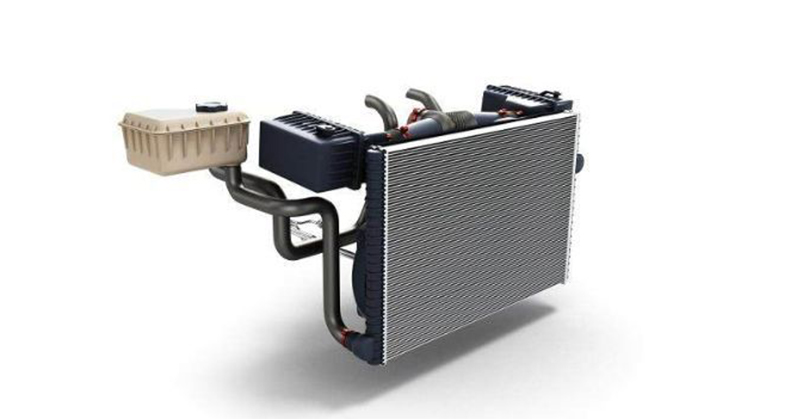

Car engine cooling system: aluminum microchannel flat tube can be used as radiators for car engines. Compared with traditional radiators, micro-channel radiators have a better heat dissipation effect and can achieve higher heat dissipation performance in the same size, thereby improving the fuel economy of the car, reducing emissions, and extending the service life of the engine.

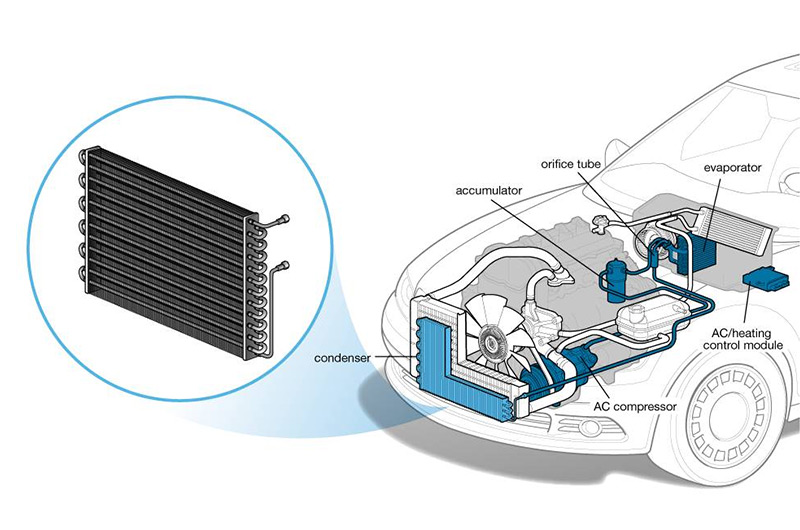

Automobile air-conditioning system: aluminum microchannel tube can be used in evaporators and condensers in automobile air-conditioning systems. In the air-conditioning system, the high-efficiency heat transfer characteristics of the micro-channel aluminum flat tube can improve the cooling effect, so that the interior of the car can be cooled more quickly and more evenly, and the efficiency of the air-conditioning system can be improved to reduce fuel consumption and emissions.

Car transmission radiator: the car transmission generates a lot of heat during long-term operation, so a radiator is needed to dissipate the heat. The Micro-channel tubes can be used in the radiator of the automobile transmission. Through its high-efficiency heat transfer characteristics, it can improve the heat dissipation effect and ensure the normal operation of the automobile transmission.

Car turbocharger radiator: a turbocharger is a device that boosts engine output through supercharging, and generates a lot of heat when it runs inside. The Ultra Precision Micro-channel Aluminum Flat Tubes can be used in the radiator of the automobile turbocharger, and through its high-efficiency heat transfer characteristics, the temperature of the turbocharger can be reduced to ensure its normal operation.

Car seat cooling systems: some high-end cars have cooling systems on the seats to provide more comfort in hot weather. The Extra wide Parallel Flow Aluminum Flat Tube can be used in the car seat cooling system, through its high-efficiency heat transfer characteristics, it can improve the cooling effect and ensure the comfort of passengers.

In addition, the Parallel Flow Aluminium Flat Tube can also be used in automotive battery radiators, hydraulic system radiators and other fields to ensure the efficient operation and safety performance of the car.

Key items for purchasing automotive micro-channel aluminum flat tubes

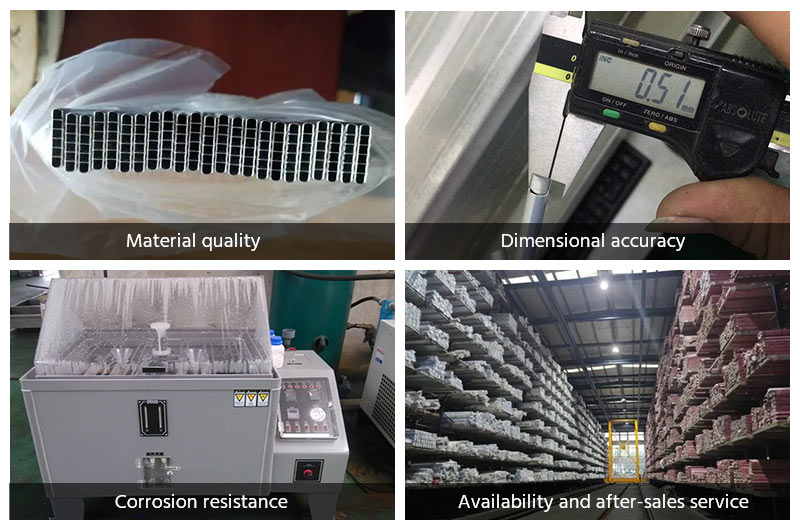

Material: the material of the Parallel Flow Aluminum Tube is usually 1xxx pure aluminum or 3xxx aluminum manganese alloy, and the appropriate material should be selected according to the actual application requirements.

Dimensional specifications: attention should be paid to the dimensional parameters such as the length, width, thickness and internal channel diameter of the Extra wide Parallel Flow Aluminum Flat Tube to ensure compliance with the use requirements.

Appearance quality: the surface of the Parallel Flow Aluminium Flat Tube produced by Chalco Aluminum is flat and free of defects such as oxidation, scratches, and dents.

Material quality: the micro-channel aluminum flat tube produced by Chalco Aluminum adopts strict quality and environmental management system to ensure that it meets ISO 9001 and ISO 14001 certification, IATF16949 certification, etc., and can meet your application needs.

Packaging and shipping: Chalco Aluminum has fully considered the packaging and shipping methods of micro-channel aluminum flat tubes to ensure that they will not be damaged during shipping.

Learn more about automotive radiator aluminum

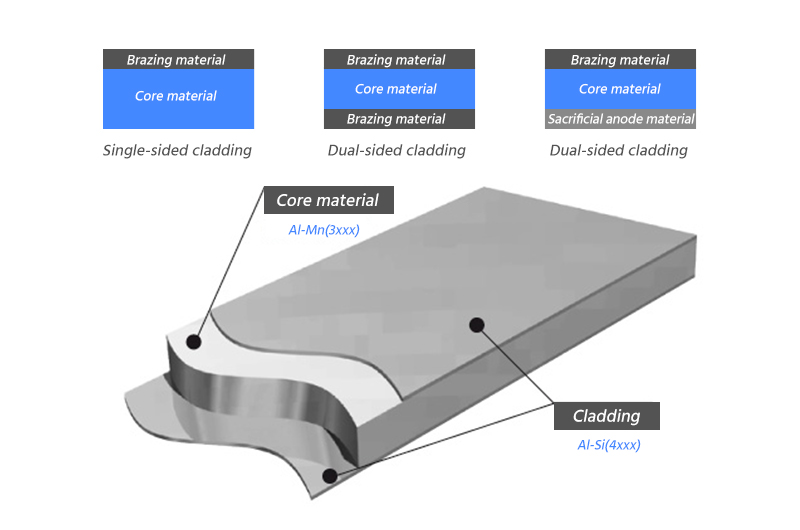

Brazing Sheet in Auto

Brazing sheet is a layered aluminum alloy with a lower……

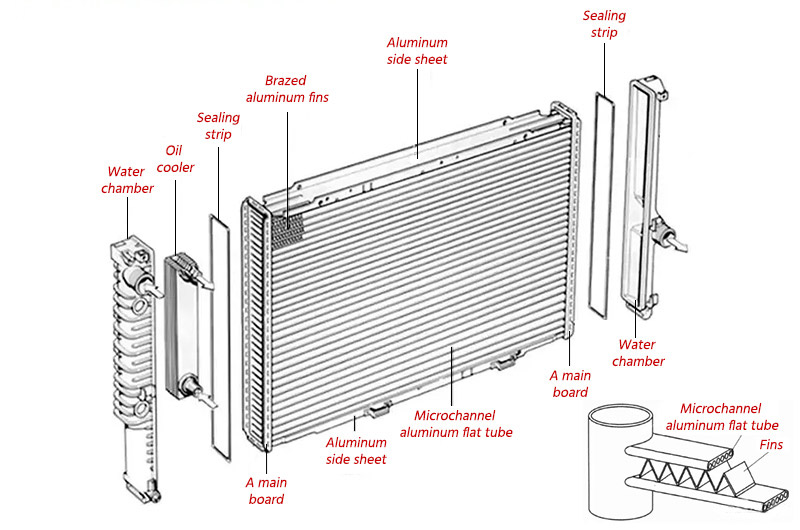

Alu tubes for heat exchangers

The aluminum heat exchanger is composed of aluminum tubes……

Auto Brazing Clad Foil

Brazing composite foil for automobiles is mainly used in pipelines……

Alu Brazing Welding Material

Aluminum brazing welding material are usually used to wet……

Auto Brazing Clad Alu Coil

Chalco Aluminum produces Automotive Brazing Composite Aluminum Coil……

Non-clad Brazing Alu Strip

4104 4004 4047 6951 4045 Non clad brazing aluminum strip……

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

The specification introduction of micro-channel tubes for heat exchanger

| Alloy | Temper | Supply type | Dimensions | |

| Size name | Size range mm | |||

| 1050, 1100, 1197, 3003, 3102, 3026 | H12 | Straight plate (neck, no neck) | Length L | 50.0-6000.0 |

| Coil | Coil ID | 400-550 | ||

| Coil OD | 700-1500 | |||

| Coil Width | 300-1000 | |||

| Cross Section Dimensions | |||||

| Width w | Height H | Plane wall thickness t1 | Thick ribs t2 | Side wall thickness t3 | Hydraulic diameter De |

| 6.00-60.00 | ≤3.50 | 0.15-0.45 | 0.15-0.45 | 0.30-0.80 | 1.0 |

The mechanical properties of automobile aluminum radiator flat tube

| Alloy | Temper | Tensile Strength Rm MPa | Yield Strength Rp0.2 MPa | Elongation A50mm % |

| not less than | ||||

| 1050 | H112 | 60 | 20 | 23 |

| 1100 | 75 | 20 | 20 | |

| 3102 | 75 | 30 | 22 | |

| 3003 | 95 | 35 | 20 | |

| 3026 | 85 | 35 | 20 | |

| Burst pressure of heat exchangers for automotive air conditioners | ||

| non electric vehicle | electric car | |

| condenser | Evaporator | |

| ≥11.5 | ≥5.5 | ≥11.5 |

The dimensional deviation of micro channel condenser aluminum flat tubes

| Cross-sectional dimension deviation | ||||

| Width | Height | Plane wall thickness | Thick ribs | Side Wall Thickness |

| ±0.05 | ±0.02 | ±0.05 | ±0.08 | ±0.08 |

| Supply length of straight flat tube and its shrinkage size deviation | |||

| category | size | Allowable deviation | |

| Length L | ≤1 000.0 | ±0.5 | |

| >1 000.0-2 000.0 | ±1.5 | ||

| >2 000.0-6 000.0 | ±2.0 | ||

| end necking | For positioning | Width W1 | ±0.05 |

| Height H1 | ±0.03 | ||

| Neck length L1 | ±0.3 | ||

| Non-positioning | Width W1 | ±0.1 | |

| Height H1 | ±0.03 | ||

| Neck length L1 | ±0.5 | ||

| Longitudinal curvature and longitudinal side curvature of flat tubes | |

| Curvature at the following lengths | |

| Every 300 mm length | Overall length (L m) |

| ≤0.3 | ≤1.0×L |

| Twist degree of straight flat tube | |

| Twist on the following overall length (L meters) | |

| L≤1 | L>1 |

| ≤1.0×L | ≤1.0 |