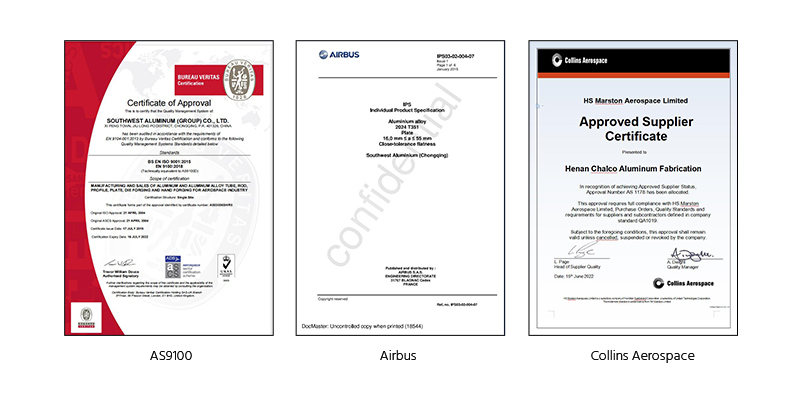

Why choose Chalco?

Certifications

AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Standard

AMS 4067; WW-T-700/2 3003

Production request

The production requirements for 3003 aerospace aluminum tube are governed by various standards and specifications to ensure that the material meets the necessary quality and performance standards. Here are some of the key production requirements for 3003 aluminum tube in aerospace applications.

Chemical composition: the aluminum alloy used to produce the tube must meet the required chemical composition, which includes a minimum of 1.0% manganese.

Heat treatment: The tube must undergo appropriate heat treatment to achieve the required temper and mechanical properties.

Dimensions and tolerances: the tube must be produced to meet the required dimensions and tolerances specified in the applicable standards, such as AMS 4067, ASTM B210, and MIL-T-7081.

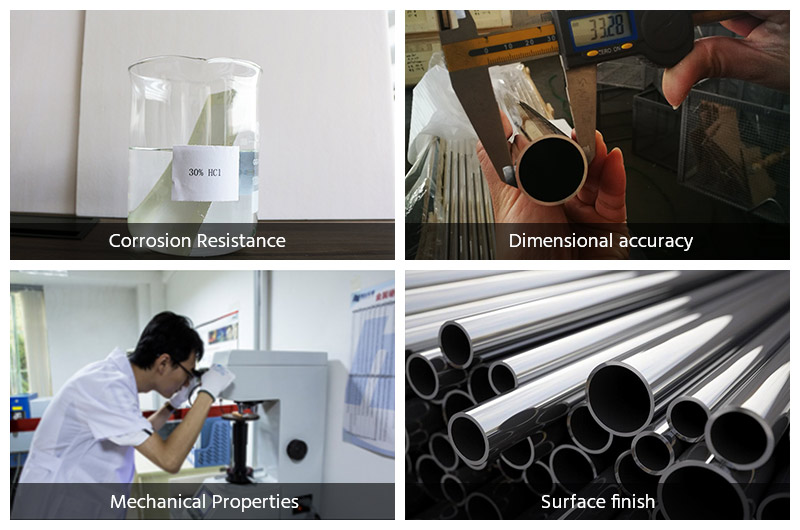

Surface finish: the tube must have a smooth and uniform surface finish, with no visible defects or surface irregularities that could affect its performance.

Mechanical properties: the tube must meet the required mechanical properties, such as strength, ductility, and hardness, as specified in the applicable standards.

Testing and quality control: the tube must undergo appropriate testing and quality control procedures to ensure that it meets the necessary performance and quality standards.

Overall, the production requirements for 3003 aerospace aluminum tube are designed to ensure that the material is reliable, durable, and meets the necessary performance standards for its specific application in the aerospace industry.

3003 aircraft aluminum tube size

Outside Diameter - 0.25mm (0.010") up to 16.00mm (0.625")

Wall - 0.05mm (0.002") up to 1.00mm (0.040")

Straight Lengths - 1.00mm (0.040") up to 5000.00mm (197")

People concern about 3003 aerospace aluminum tube

People in the aerospace industry may have several concerns related to 3003 aerospace aluminum tube. Here are a few possible concerns.

Mechanical properties

The mechanical properties of the 3003 aluminum alloy, including its strength, ductility, and toughness, may be a concern for some aerospace applications. Engineers and designers must carefully consider the specific requirements of the application and select the appropriate temper and thickness of the tube to ensure it meets the necessary performance standards.

Corrosion resistance

3003 aluminum is known for its excellent corrosion resistance, but it may not be suitable for all corrosive environments in aerospace applications. Engineers must consider the specific environmental factors that the tube will be exposed to, such as saltwater or acidic solutions, and select the appropriate material or coating to protect against corrosion.

Cost

The cost of 3003 aluminum may be a concern for some aerospace applications, especially for larger or more complex components. Engineers and designers must balance the cost of the material with the performance requirements of the application to ensure an optimal solution.

Manufacturing and production

The manufacturing and production of 3003 aluminum tube may present some challenges, such as achieving the required dimensions, tolerances, and surface finish. Quality control measures must be in place to ensure that the tube meets the necessary performance and quality standards.

Overall, concerns related to 3003 aerospace aluminum tube must be addressed through careful consideration of the specific application and requirements, along with appropriate selection of materials, manufacturing processes, and quality control measures.

3003 aerospace aluminum tube chemical composition

| Element | Composition % | |

| Al | Remainder | |

| Cu | 0.05-0.20 | |

| Si | 0.60 max | |

| Fe | 0.70 max | |

| Mn | 1.0-1.5 | |

| Zn | 0.10 max | |

| Others | 0.05 each | 0.15 total |

3003 aerospace aluminum tube mechanical property

The mechanical properties of 3003 aerospace aluminum tube can vary depending on the specific temper and thickness of the tube. Here are some general mechanical properties for the O (annealed) temper of 3003 aluminum tube.

Tensile strength: 90 MPa (13, 000 psi)

Yield strength: 35 MPa (5, 000 psi)

Elongation: 20%

Hardness (Rockwell B): 40

It's important to note that the mechanical properties of the 3003 aluminum tube can be influenced by several factors, including the thickness, diameter, and heat treatment process. Harder tempers, such as H14, H16, and H18, will have higher strength and stiffness values but lower ductility compared to the annealed (O) temper.

When selecting the appropriate temper and thickness of the 3003 aluminum tube for an aerospace application, it's important to carefully consider the specific mechanical requirements and ensure that the material meets the necessary performance standards.

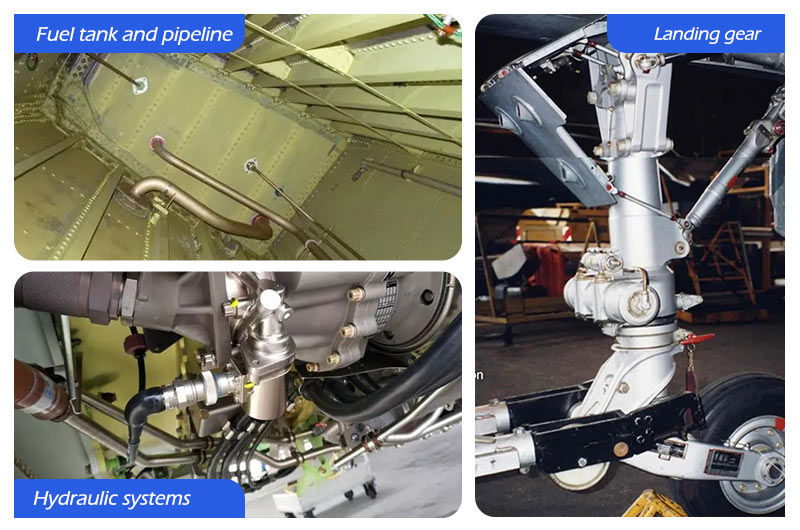

3003 aerospace aluminum tube application

3003 aerospace aluminum tube has a variety of applications in the aerospace industry. Here are some common examples.

Hydraulic and pneumatic systems: 3003 aluminum tube is commonly used in hydraulic and pneumatic systems for its excellent corrosion resistance, formability, and weldability. The tube is often used for fluid transfer and control in aircraft and aerospace vehicles.

Fuel lines: 3003 aluminum tube is also used for fuel lines in aircraft and aerospace vehicles due to its excellent corrosion resistance and lightweight properties. The tube can be used for both liquid and gas fuels, including hydraulic fluids, gasoline, and jet fuel.

Heat exchangers: the high thermal conductivity of 3003 aluminum makes it suitable for use in heat exchangers in aerospace applications. The tube can be formed into various shapes and sizes to optimize heat transfer efficiency and reduce weight.

Structural components: 3003 aluminum tube is used in some structural components of aircraft and aerospace vehicles due to its lightweight and high strength-to-weight ratio. The tube can be formed and welded into various shapes and sizes to meet the specific design requirements of the application.

Overall, the excellent corrosion resistance, formability, weldability, and lightweight properties of 3003 aluminum tube make it a versatile material for a variety of aerospace applications. The material must be carefully selected and engineered to meet the specific performance and mechanical requirements of the application.