As the highest-strength alloy in the 6000 series, 6082 aluminum alloy is a medium-strength structural alloy known for its excellent corrosion resistance and superior mechanical properties.

The 6082 aluminum sheet is increasingly replacing the 6061 aluminum sheet in many applications.

Specifications of 6082 aluminum sheet

- ASTM B209

- ASME SB209

- BS EN 485-2

- BS EN 573

- ISO 6361

- GB/T 33227-2016

6082 T6 aluminum sheet plate stock sizes

We supply 6082 aluminum sheets in various sizes.Quick Quote

| Specification | Thickness (mm) | Width x Length (mm) |

| 1mm 6082 T6 Aluminum Sheet/Plate | 1mm | 1250 x 2500, 1550 x 3000 |

| 2mm 6082 T6 Aluminum Sheet/Plate | 2mm | 1250 x 2500, 1550 x 3000 |

| 3mm 6082 T6 Aluminum Sheet/Plate | 3mm | 1250 x 2500, 1550 x 3000 |

| 4mm 6082 T6 Aluminum Sheet/Plate | 4mm | 1250 x 2500, 1550 x 3000 |

| 5mm 6082 T6 Aluminum Sheet/Plate | 5mm | 1250 x 2500, 1550 x 3000 |

| 6mm 6082 T6 Aluminum Sheet/Plate | 6mm | 1250 x 2500, 1550 x 3000 |

| 8mm 6082 T6 Aluminum Sheet/Plate | 8mm | 1250 x 2500, 1550 x 3000 |

| 10mm 6082 T6 Aluminum Sheet/Plate | 10mm | 1250 x 2500, 1550 x 3000 |

| 12mm 6082 T6 Aluminum Sheet/Plate | 12mm | 1250 x 2500, 1550 x 3000 |

| 14mm 6082 T6 Aluminum Sheet/Plate | 14mm | 1250 x 2500, 1550 x 3000 |

| 15mm 6082 T6 Aluminum Sheet/Plate | 15mm | 1250 x 2500, 1550 x 3000 |

| 16mm 6082 T6 Aluminum Sheet/Plate | 16mm | 1250 x 2500, 1550 x 3000 |

| 18mm 6082 T6 Aluminum Sheet/Plate | 18mm | 1250 x 2500, 1550 x 3000 |

| 20mm 6082 T6 Aluminum Sheet/Plate | 20mm | 1250 x 2500, 1550 x 3000 |

| 22mm 6082 T6 Aluminum Sheet/Plate | 22mm | 1250 x 2500, 1550 x 3000 |

| 25mm 6082 T6 Aluminum Sheet/Plate | 25mm | 1250 x 2500, 1550 x 3000 |

| 28mm 6082 T6 Aluminum Sheet/Plate | 28mm | 1250 x 2500, 1550 x 3000 |

| 30mm 6082 T6 Aluminum Sheet/Plate | 30mm | 1250 x 2500, 1550 x 3000 |

| 32mm 6082 T6 Aluminum Sheet/Plate | 32mm | 1250 x 2500, 1550 x 3000 |

| 35mm 6082 T6 Aluminum Sheet/Plate | 35mm | 1250 x 2500, 1550 x 3000 |

| 40mm 6082 T6 Aluminum Sheet/Plate | 40mm | 1250 x 2500, 1550 x 3000 |

| 45mm 6082 T6 Aluminum Sheet/Plate | 45mm | 1250 x 2500, 1550 x 3000 |

| 50mm 6082 T6 Aluminum Sheet/Plate | 50mm | 1250 x 2500, 1550 x 3000 |

| 55mm 6082 T6 Aluminum Sheet/Plate | 55mm | 1250 x 2500, 1550 x 3000 |

| 60mm 6082 T6 Aluminum Sheet/Plate | 60mm | 1250 x 2500, 1550 x 3000 |

| 65mm 6082 T6 Aluminum Sheet/Plate | 65mm | 1250 x 2500, 1550 x 3000 |

| 70mm 6082 T6 Aluminum Sheet/Plate | 70mm | 1250 x 2500, 1550 x 3000 |

| 75mm 6082 T6 Aluminum Sheet/Plate | 75mm | 1250 x 2500, 1550 x 3000 |

| 80mm 6082 T6 Aluminum Sheet/Plate | 80mm | 1250 x 2500, 1550 x 3000 |

| 85mm 6082 T6 Aluminum Sheet/Plate | 85mm | 1250 x 2500, 1550 x 3000 |

| 90mm 6082 T6 Aluminum Sheet/Plate | 90mm | 1250 x 2500, 1550 x 3000 |

| 95mm 6082 T6 Aluminum Sheet/Plate | 95mm | 1250 x 2500, 1550 x 3000 |

| 100mm 6082 T6 Aluminum Sheet/Plate | 100mm | 1250 x 2500, 1550 x 3000 |

| 120mm 6082 T6 Aluminum Sheet/Plate | 120mm | 1250 x 2500, 1550 x 3000 |

| 150mm 6082 T6 Aluminum Sheet/Plate | 150mm | 1250 x 2500, 1550 x 3000 |

| 160mm 6082 T6 Aluminum Sheet/Plate | 160mm | 1250 x 2500, 1550 x 3000 |

| 200mm 6082 T6 Aluminum Sheet/Plate | 200mm | 1250 x 2500, 1550 x 3000 |

| 300mm 6082 T6 Aluminum Sheet/Plate | 300mm | 1250 x 2500, 1550 x 3000 |

Chemical composition of 6082 aluminum sheet plate

| Chemical Element | % Present |

| Si | 0.70 - 1.30 |

| Fe | 0.0 - 0.50 |

| Cu | 0.0 - 0.10 |

| Mn | 0.40 - 1.00 |

| Mg | 0.60 - 1.20 |

| Cr | 0.0 - 0.25 |

| Zn | 0.0 - 0.20 |

| Ti | 0.0 - 0.10 |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Balance |

Physical properties of 6082 aluminum sheet plate

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 0.038 x10^-6 Ω.m |

| Electrical conductivity | 42% |

Mechanical properties of 6082 aluminum sheet plate

| Specification | Value |

| Proof Stress | 260 Min MPa |

| Tensile Strength | 310 Min MPa |

| Hardness (Brinell) | 94 HB |

Equivalent Grades of 6082 Aluminum Tube

| UNS | EN | DIN | ISO | BS (OLD) | USA | WNR |

| A96082 | AW-6082 | AlMgSi1 | Al Si1MgMn | HE30 | AA6082 | 3.2315 |

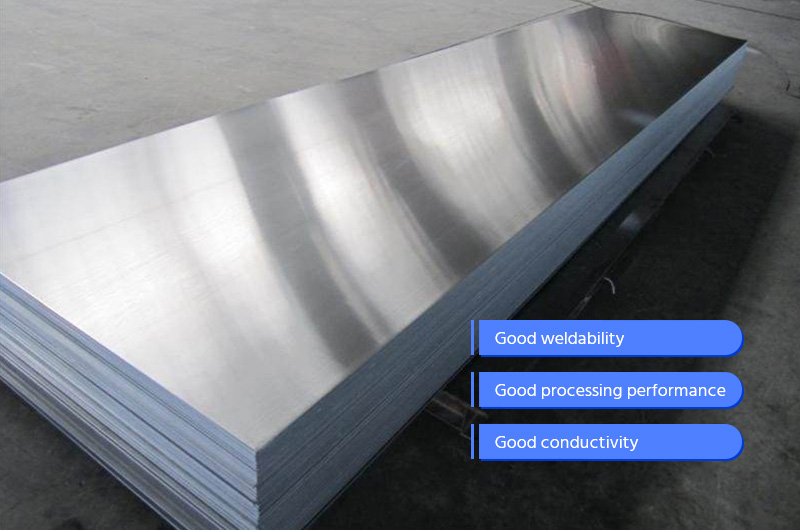

Features of 6082 aluminum sheet plate

6082 aluminum alloy is used in automobile manufacturing with the following characteristics:

Good weldability: 6082 aluminum alloy has good weldability and can be used to manufacture welded structural parts, such as automobile frames and chassis.

Good processing performance: 6082 aluminum alloy has good processing performance, and can be processed by forging, rolling, stretching, etc., and can meet the processing requirements of different structural parts in automobile manufacturing.

High strength and corrosion resistance: 6082 aluminum alloy has high strength and corrosion resistance, and can withstand large loads and complex environmental corrosion in automobile manufacturing.

Good conductivity: 6082 aluminum alloy has good conductivity and can be used to manufacture conductive components, such as automobile batteries, generators, engine radiators, etc.

Lightweight: 6082 aluminum alloy has a low density and can be used to manufacture lightweight structural parts, which can reduce the weight of the vehicle and improve fuel efficiency.

Recyclability: 6082 aluminum alloy has good recyclability, meets environmental protection requirements, and is conducive to the sustainable development of automobile manufacturing.

Uses of 6082 aluminum sheet plate

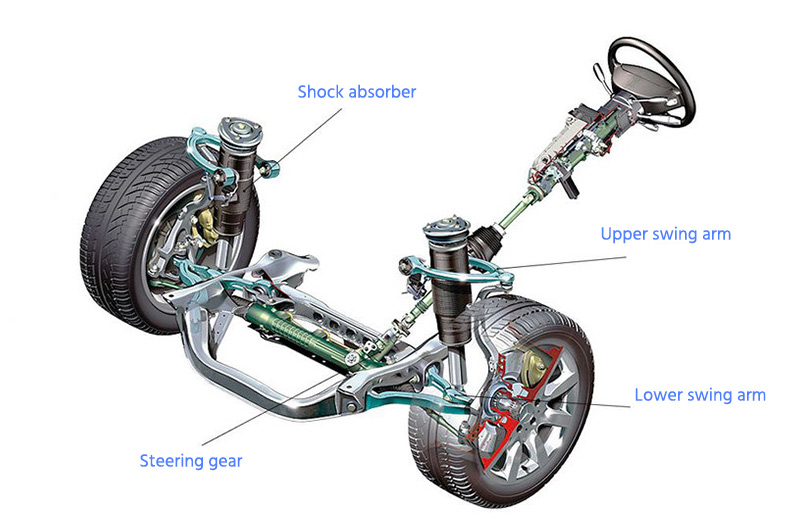

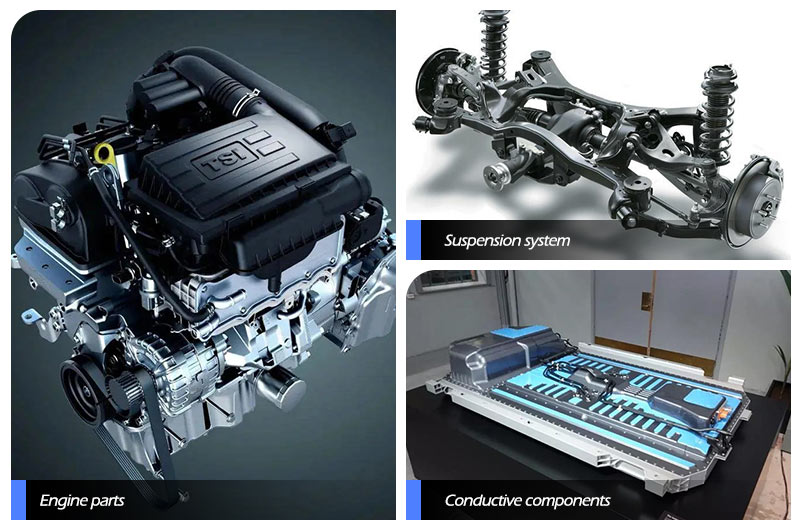

6082 aluminum sheets coils strips are widely used in the manufacture of structural parts in the automotive industry, mainly including:

Body frame: 6082 aluminum alloy has high strength and rigidity, and can be used to manufacture the body frame of a car to increase the strength and stability of the vehicle.

Engine parts: 6082 aluminum alloy has good high temperature resistance and fatigue resistance, and can be used to manufacture engine parts of automobiles to improve the power and reliability of the vehicle.

Suspension system: 6082 aluminum alloy has high strength and toughness, and can be used to manufacture the suspension system of automobiles to improve the stability and comfort of the vehicle.

Other structural parts: 6082 aluminum alloy can also be used to manufacture other structural parts of automobiles to improve the safety and aesthetics of the vehicle.

Conductive components: due to the good conductivity and machinability of 6082 aluminum alloy, it is often used in the manufacture of conductive components in automobile manufacturing, such as generators, batteries, engine radiators, etc.

Welding recommendations for 6082 aluminum sheet plate

6082 has very good weldability, but the strength of the welded area is lower. When welding 6082 itself, it is recommended to use alloy 4043 filler wire. If welding 6082 to 7005, alloy 5356 filler wire should be used.

Thickness tolerance range of 6082 aluminum sheet plate

| Thickness mm | Thickness tolerances within the following width ranges mm | ||||

| ≤1500.00 | ˃1500.0-1700.0 | >1700.0-2000.0 | >2000-2400.00 | ||

| 0.30-0.50 | ±0.03 | ±0.04 | — | — | |

| >0.50-0.80 | ±0.03 | ±0.04 | ±0.04 | — | |

| >0.80-1.20 | ±0.04 | ±0.04 | ±0.05 | ±0.06 | |

| >0.80-1.20 | ±0.04 | ±0.04 | ±0.05 | ±0.06 | |

| >1.20-2.00 | ±0.05 | ±0.05 | ±0.06 | ±0.07 | |

| >2.00-2.50 | ±0.06 | ±0.07 | ±0.07 | ±0.08 | |

| >2.50-3.00 | ±0.07 | ±0.08 | ±0.08 | ±0.09 | |

Width tolerance range of 6082 aluminum sheet plate

| Thickness |

Width tolerances within the following width ranges |

|||||||

| ≤100.00 | ˃100-300.00 | >300.0-500.0 | >500.0-800.0 | >800.0-1250.0 | >1250.0-1800.0 | >1800.0-2000.0 | >2000.0-2400.0 | |

| 0.30-1.60 | + 0, 3 0 | + 0, 4 0 | + 1.0 0 | + 1.5 0 | + 2.0 0 | + 3.0 0 | | |

| >1.60-3.50> | — | — | — | + 2.0 0 | + 3.0 0 | + 4.0 0 | + 5.0 0 | + 6.0 0 |

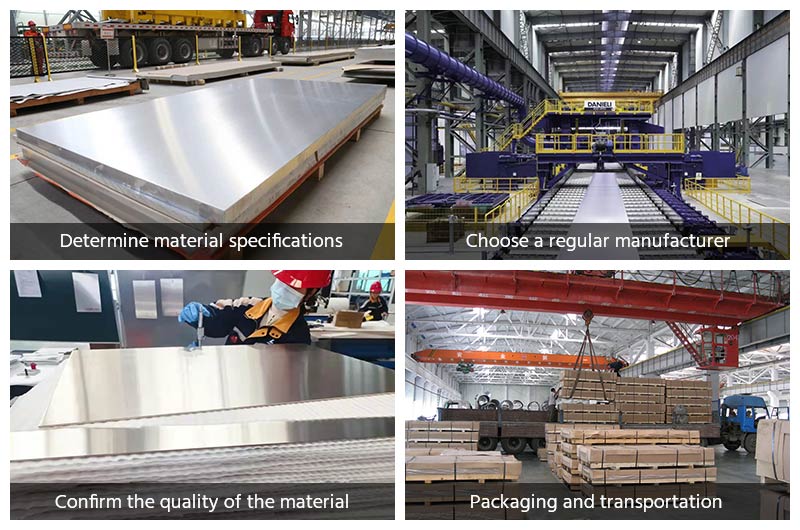

Quality inspection report — traceable

Our products undergo strict quality control, providing a complete set of quality inspection reports.

- Ultrasonic Testing: Ensures no internal defects.

- Chemical Composition Analysis: Complies with industry standards.

- Mechanical Performance Testing: Verifies product strength.

- Non-Destructive Testing: Comprehensive hazard assessment.

- Visual Inspection: Striving for perfection.

- Traceability Records: Fully traceable throughout the process.