Why choose Chalco Aluminum

By international classification societies

DNV - Det Norske Veritas

NK - Nippon Kaiji Kyokai

CCS - China Classification Society

ABS - American Bureau of Shipping

BV - Bureau Veritas

LR - Lloyd's Register

KR - Korean Register

Standard specification for the production of 6060 6005A 6082 6061 aluminum hexagonal bars

ASTM B211/ASME SB211 - Specification for Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod.

ASTM B565/ASME SB565 - Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Rods.

ASTM B316/ASME SB316 - Standard Specification for Aluminum and Aluminum-Alloy Rivet and Cold-Heading bars and Rods.

AMS 4102/ISO Al99.0Cu - Standard Specification for Aluminum and Aluminum-Alloy Cold / Hot Rolled Bars, Rods.

GBT 26006 - Evaluation of Machinability of Rolled Bars and Rods for Aluminum and Aluminum Alloy Products

DIN EN 754-6 - Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 6: Drawn round tube - Tolerances on dimensions and form

BS EN 755-6 - Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 6: Profiles, tolerances on dimensions and form

Quality assurance

Chalco Aluminum employs a stringent ISO 14001 environmental management system and is also an ISO 9001 certified producer and supplier of high - quality specialty metals, including marine aluminum.

delivering the 6060 6005A 6082 6061 Aluminum Hexagon Rods to customers, we will test them to ensure the quality meets the requirements. We also provide copies of important documents, third-party test reports, etc. upon request.Quick Quote

Marine 6060 6005A 6082 6061 aluminum hex bar specifications

| Alloy | 6060 | 6005A | 6082 6061 |

| Temper | T4, T3511, T5, T6, T8511 | T6 | O, T4, T3511, T6, T8511 |

| Maximum inscribed circle diameter | 120 mm | 120 mm | 120 mm |

| Length | 1000-12000 (mm) or as required | 1000-12000 (mm) or as required | 1000-12000 (mm) or as required |

| Remark | Can be customized | Can be customized | Can be customized |

Marine 6060 6005A 6082 6061 aluminum hex bar chemical composition

| Element | Composition (%) | |||

| 6060 | 6005A | 6082 | 6061 | |

| Si | 0.35-0.60 | 0.50-0.90 | 0.70-1.3 | 0.40-0.80 |

| Fe | ≤0.10 | ≤0.35 | ≤0.50 | ≤0.70 |

| Cu | ≤0.10 | ≤0.30-0.60 | 0.10-0.40 | 0.15-0.40 |

| Mn | ≤0.10 | ≤0.50 | 0.40-1.00 | 0.15-0.40 |

| Mg | 0.45-0.90 | 0.40-0.70 | 0.60-1.20 | 0.80-1.20 |

| Sn | - | ≤0 .10 | - | ≤0.20 |

| Zn | ≤0.10 | ≤0.20 | ≤0.20 | ≤0 .25 |

| Ti | ≤0 .10 | ≤0 .10 | ≤0 .20 | ≤0 .15 |

| Cr | ≤0 .10 | ≤0 .10 | 0.25-0.35 | 0.04-0.35 |

| B | - | ≤0 .10 | - | - |

| Al | Remainder | Remainder | Remainder | Remainder |

Mechanical properties of marine 6060 6005A 6082 6061 aluminum hexagonal bar

| Alloy | Temper | Inscribed circle diameter/mm | Tensile strength/(N/mm2 ) | Specified non-proportional tensile strength/(N/mm2 ) | Elongation after break/% | |

| A | A 50 mm | |||||

| not less than | ||||||

| 6060 | T4, T3511 | ≤12.50 | 120 | 60 | - | 16 |

| >12.50-150.00 | 120 | 60 | 16 | - | ||

| T5 | ≤12.50 | 160 | 120 | - | 8 | |

| >12.50-150.00 | 160 | 120 | 8 | - | ||

| T6, T8511 | ≤12.50 | 190 | 150 | - | 8 | |

| >12.50-150.00 | 190 | 150 | 8 | - | ||

| 6005A | T6 | ≤12.50 | 270 | 225 | - | 8 |

| >12.50-25.00 | 270 | 225 | 10 | - | ||

| >25.00-50.00 | 270 | 225 | 8 | - | ||

| >50.00-100.00 | 260 | 215 | 8 | - | ||

| 6082 | O | ≤12.50 | ≤160 | ≤110 | - | 12 |

| ≥12.50-150.00 | ≤160 | ≤110 | 14 | - | ||

| T4, T3511 | ≤12.50 | 205 | 110 | - | 14 | |

| >12.50-150.00 | 205 | 110 | 14 | - | ||

| T6, T8511 | ≤5.00 | 295 | 250 | - | 6 | |

| >5.00-12.50 | 310 | 260 | - | 10 | ||

| >12.50-150.00 | 310 | 260 | 8 | - | ||

| >150.00-200.00 | 280 | 240 | 6 | - | ||

| >200.00-250.0 | 270 | 200 | 6 | - | ||

| 6061 | O | ≤12.50 | ≤150 | ≤110 | - | 14 |

| >12.50-200.00 | ≤150 | ≤110 | 16 | - | ||

| T4, T3511 | ≤12.50 | 180 | 110 | - | 15 | |

| >12.50-200.00 | 180 | 110 | 15 | - | ||

| T6, T8511 | ≤12.50 | 260 | 240 | - | 10 | |

| >12.50-200.00 | 260 | 240 | 8 | - | ||

Marine 6060 6005A 6082 6061 aluminum hex bar size tolerance

Width tolerance

| Hex bar width | The width (or side length) tolerance of the hexagonal bar |

| 10.00-18.00 | ±0.22 |

| >18.00-25.00 | ±0.25 |

| >25.00-40.00 | ±0.30 |

| >40.00-50.00 | ±0.35 |

| >50.00-65.00 | ±0.40 |

| >65.00-80.00 | ±0.50 |

| >80.00-100.00 | ±0.55 |

| >100.00-120.00 | ±0.65 |

| >120.00-150.00 | ±0.80 |

| >150.00-180.00 | ±1.00 |

| >180.00-220.00 | ±1.15 |

Fillet Tolerance

| width | Fillet (or chamfer) allowable deviation |

| 10.00-30.00 | ≤1.5 |

| >30.00-60.00 | ≤2.0 |

| >60.00-80.00 | ≤2.5 |

| >80.00-120.00 | ≤3.0 |

| >120.00-180.00 | ≤4.0 |

| >180.00-220.00 | ≤5.0 |

Curvature

| width | Curvature over any 300 mm length | Curvature ht on the full length (L meters) |

| 10.00-80.00 | ≤0.8 | ≤2×L |

| >80.00-120.00 | ≤1.0 | ≤2×L |

| >120.00-220.00 | ≤1.5 | ≤3×L |

Twist

| width | Twist per 1000 mm length | Twist over the entire length |

| 10.00-30.00 | ≤1 | ≤1.5 |

| >30.00-80.00 | ≤1.5 | ≤2.5 |

| >80.00-120.00 | ≤2 | ≤3 |

| >120.00-220.00 | ≤2.5 | ≤4 |

length tolerance

| width | Permissible deviations in length on the following cut lengths | ||

| ≤2000 | >2000-5000 | >5000 | |

| ≤100.00 |

+5 0 |

+7 0 |

+10 0 |

| >100.00-200.00 |

+7 0 |

+9 0 |

+12 0 |

| >200.00-220.00 |

+8 0 |

+11 0 |

+14 0 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteFeatures and uses of marine 6060 6005A 6082 6061 aluminum hexagonal bars

6060 aluminum hex bar

6060 aluminum is a medium strength alloy with excellent corrosion resistance, weldability and machinability. It has excellent extrusion properties and can be easily formed into complex profiles, making it ideal for marine applications. It is very similar to 6063 aluminum alloy, the only difference is the content of magnesium.

6005A aluminum hex bar

6005A aluminum alloy is a medium strength heat treatable alloy with excellent corrosion resistance. Its properties are between 6061 and 6082 aluminum alloys, and it is often used interchangeably with these two alloys, but 6005A has a better grinding surface, and has better extrusion properties than 6082 , it still has some difficulties in producing thin-walled or complex extrusions. 6005A is more suitable for producing solid or hollow extrusions in standard and custom shapes.

6082 aluminum hex bar

6082 aluminum hex bar is very easy to machine and can make complex parts quickly. Suitable for DIY processing such as drilling and cutting. Because of its light weight, high strength-to-weight ratio, good corrosion resistance and easy processing, it is widely used in precision parts, fasteners, machine parts, etc. in ships. Also features a modular exterior finish for a shiny and attractive look.

6061 aluminum hex bar

6061 aluminum alloy has good strength to weight ratio, high corrosion resistance and machinability, suitable for welding. Commonly used in the manufacture of corrosion-resistant marine components. The machinability is good in the T4 and T6 states, but it is more difficult in the annealed and tempered states. Can be processed by cold working and forming, such as stamping, bending, spinning, deep drawing.

Applicable to various welding techniques, argon arc welding can be used for thin sections , and gas shielded electric welding can be used for thick sections . Aluminum alloy 4043 gives the best results as filler wire, but will reduce T6 performance.

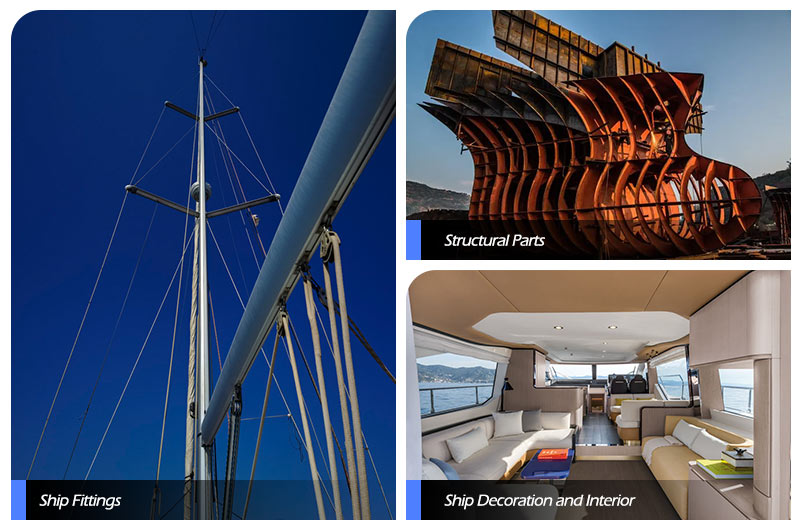

Applications in ships

Structural parts: these Aluminum Hexagon Bars can be used to manufacture hull structural parts such as hull frames, bilge beams, deck beams, etc. They provide strength and stability and help build the skeleton of the hull.

Ship fittings: aluminum hex bars can be used to manufacture various ship fittings, such as porthole frames, ship hatches, deck railings, etc. They are able to provide a comfortable and safe ship environment.

Ship decoration and interior: these aluminum alloy hex bars can be used for decoration and interior decoration of ships, such as ship stair railings, cabin partitions, display shelves, etc. They have good appearance and decorative effect.

Ship mechanical equipment support: aluminum hexagonal bars can be used to support ship mechanical equipment, such as engine bed frames, pump brackets, conveying equipment, etc. They are strong and rigid enough to support vital mechanical components.

Ship electrical equipment brackets: these aluminum alloy hexagon bars can be used to make ship electrical equipment brackets, such as cable trays, electric control cabinet brackets, etc. They provide stable support and protect electrical equipment.

FAQ

Do you accept small batch production?

We accept small batch production, please contact us.

Before mass production?

If you need samples, please contact us. You only need to pay postage to get product samples for free.

Is there stock in stock?

Chalco Aluminum 's stock is available in different specifications, standards, and diameters. If you need customization, welcome to consult.

Can I visit and inspect the goods?

sure. contact us, We have the best service and try our best to meet all your needs.

Packaging and shipping details

We provide standard export packaging (inner: waterproof paper, outer: steel belt and pallet). It can also be packed according to your requirements, but please explain in advance.

Payment and delivery method

Payment<=USD 1000, 100% in advance.

Payment>=USD 1000, 30% deposit and balance before shipment pay by TT.

Delivery methods include: FOB, CFR, CIF, EXW, DHL door to door, and Air express.

More payment methods depend on your choice.