Why choose Chalco Aluminum

By international classification societies

DNV - Det Norske Veritas

NK - Nippon Kaiji Kyokai

CCS - China Classification Society

ABS - American Bureau of Shipping

BV - Bureau Veritas

LR - Lloyd's Register

KR - Korean Register

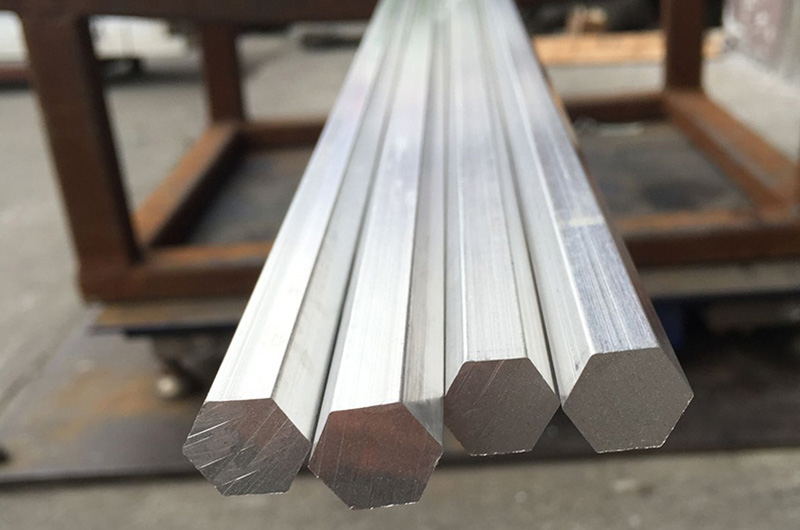

Standard specification for the production of 5454 5456 5754 aluminum hexagonal bars

ASTM B211/ASME SB211 - Specification for Aluminum and Aluminum-Alloy Rolled or Cold Finished Bar, Rod.

ASTM B565/ASME SB565 - Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Rods.

ASTM B316/ASME SB316 - Standard Specification for Aluminum and Aluminum-Alloy Rivet and Cold-Heading bars and Rods.

AMS 4102/ISO Al99.0Cu - Standard Specification for Aluminum and Aluminum-Alloy Cold / Hot Rolled Bars, Rods.

GBT 26006 - Evaluation of Machinability of Rolled Bars and Rods for Aluminum and Aluminum Alloy Products.

DIN EN 754-6 - Aluminium and aluminium alloys - Cold drawn rod/bar and tube - Part 6: Drawn round tube - Tolerances on dimensions and form.

BS EN 755-6 - Aluminium and aluminium alloys - Extruded rod/bar, tube and profiles - Part 6: Profiles, tolerances on dimensions and form.

Quality assurance

Chalco Aluminum employs a stringent ISO 14001 environmental management system and is also an ISO 9001 certified producer and supplier of high - quality specialty metals, including marine aluminum.

Delivering 5454 5456 5754 Aluminum Hexagon Bars to customers, we will test them to ensure the quality meets the requirements. We also provide copies of important documents, third-party test reports, etc. upon request.

Marine 5454 5456 5754 aluminum hex bar specifications

| Alloy | 5456 5454 | 5754 |

| Temper | O, H112 | H112 |

| Maximum inscribed circle diameter | 200mm | 200mm |

| Length | 1000-12000mm or as required | 1000-12000mm or as required |

| Remark | Can be customized | Can be customized |

Marine 5454 5456 5754 aluminum hex bar chemical composition

| Element | Composition (%) | ||

| 5454 | 5456 | 5754 | |

| Si | ≤0.25 | ≤0.25 | ≤0.40 |

| Fe | ≤0.40 | ≤0.25 | ≤0.40 |

| Cu | ≤0.10 | ≤0.10 | ≤0.10 |

| Mn | 0.50-1.00 | 0.50-1.00 | ≤0.50 |

| Mg | 2.40-3.00 | 4.70-5.50 | 2.60-3.60 |

| Sn | ≤0.05 | ≤0 .05 | ≤0.05 |

| Zr | ≤0.10 | ≤0.10 | ≤0.05 |

| Cr | ≤0.20 | 0.05-0.25 | ≤0 .30 |

| Ti | ≤0.20 | ≤0.25 | ≤0.15 |

| Al | Remainder | Remainder | Remainder |

Mechanical properties of marine 5454 5456 5754 aluminum hexagonal Bar

| Alloy | Temper | Inscribed circle diameter/mm | Tensile strength/(N/mm2 ) | Specified non-proportional tensile strength/(N/mm2 ) | Elongation after break/% | |

| A | A 50 mm | |||||

| not less than | ||||||

| 5456 | o | ≤12.50 | 285-365 | 130 | - | 14 |

| >12.50-150.00 | 285-365 | 130 | 12 | - | ||

| H112 | ≤12.50 | 300 | 130 | - | 12 | |

| >12.50-150.00 | 300 | 130 | 10 | - | ||

| 5454 | o | ≤12.50 | 200-275 | 85 | - | 16 |

| >12.50-200.00 | 200-275 | 85 | 18 | - | ||

| H112 | ≤12.50 | 180 | 80 | - | 12 | |

| >12.50-150.00 | 180 | 80 | 14 | - | ||

| >150.00-250.0 | 180 | 70 | 13 | - | ||

| 5754 | o | ≤ 150.00 | 180-250 | 8 0 | 1 7 | 1 5 |

| H112 | ≤1 50.00 | 180 | 80 | 1 4 | 12 | |

| >1 50 .0 0 - 20 0.00 | 180 | 7 0 | 1 3 | - | ||

Marine grade 5454 5456 5754 aluminum hex bar dimensional tolerance

Width tolerance

| Hex bar width | Allowable deviation of the width (or side length) of the following alloy hexagonal bars | |

| 5454 | 5456 5754 | |

| 10.00-18.00 | ±0.22 | ±0.30 |

| >18.00-25.00 | ±0.25 | ±0.35 |

| >25.00-40.00 | ±0.30 | ±0.40 |

| >40.00-50.00 | ±0.35 | ±0.45 |

| >50.00-65.00 | ±0.40 | ±0.50 |

| >65.00-80.00 | ±0.50 | ±0.70 |

| >80.00-100.00 | ±0.55 | ±0.90 |

| >100.00-120.00 | ±0.65 | ±1.0 |

| >120.00-150.00 | ±0.80 | ±1.2 |

| >150.00-180.00 | ±1.00 | ±1.4 |

| >180.00-220.00 | ±1.15 | ±1.7 |

Fillet tolerance

| width | Fillet (or chamfer) allowable deviation |

| 10.00-30.00 | ≤1.5 |

| >30.00-60.00 | ≤2.0 |

| >60.00-80.00 | ≤2.5 |

| >80.00-120.00 | ≤3.0 |

| >120.00-180.00 | ≤4.0 |

| >180.00-220.00 | ≤5.0 |

Curvature

| width | Curvature over any 300 mm length | Curvature ht on the full length (L meters) |

| 10.00-80.00 | ≤0.8 | ≤2×L |

| >80.00-120.00 | ≤1.0 | ≤2×L |

| >120.00-220.00 | ≤1.5 | ≤3×L |

Twist

| width | Twist per 1000 mm length | Twist over the entire length |

| 10.00-30.00 | ≤1 | ≤1.5 |

| >30.00-80.00 | ≤1.5 | ≤2.5 |

| >80.00-120.00 | ≤2 | ≤3 |

| >120.00-220.00 | ≤2.5 | ≤4 |

Length tolerance

| width | Permissible deviations in length on the following cut lengths | ||

| ≤2000 | >2000-5000 | >5000 | |

| ≤100.00 |

+5 0 |

+7 0 |

+10 0 |

| >100.00-200.00 |

+7 0 |

+9 0 |

+12 0 |

| >200.00-220.00 |

+8 0 |

+11 0 |

+14 0 |

Uses of marine grade 5454 5456 5754 aluminum hexagonal bars

5454 aluminum hex bars

5454 Aluminum Hex Bar include high strength, excellent corrosion resistance, and good formability and weldability.

Because 5454 aluminum alloy is a non-heat-treatable aluminum-magnesium alloy, it can only be hardened by cold working. Oil-based lubricants are recommended when machining, unless very light cuts can be done dry.

Additionally, all welding methods can be adapted to AL 5454. But if TIG (argon arc welding) or MIG (metal inert gas welding) with AL 5554 or 5356 electrodes The process effect will be particularly good.

5456 aluminum hex bars

5456 Aluminum Hex Bar is ideal for processes such as extrusion, rolling, and forging. It can be made stronger by cold working, but the process reduces its ductility.

The arc welding process is best suited for welding this alloy, which together with its excellent corrosion resistance makes it widely used in marine structural applications.

5754 aluminum hex bars

Because of its superior corrosion resistance , 5454 aluminum hexagon bar is very suitable for marine industry and other industrial applications with corrosive operating environment. And because of its high strength, it is also suitable for ship interior floor structure, skeleton application.

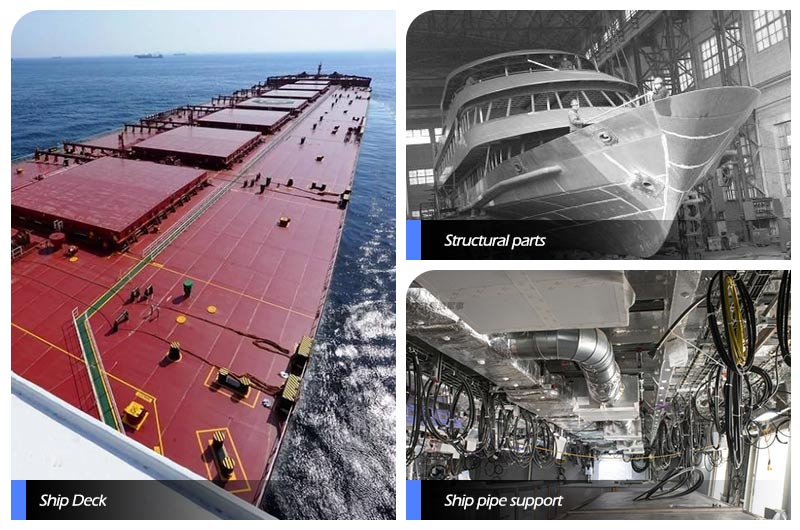

Applications in ships

Structural parts: such as hull frames, support rods, connectors, etc. Its high strength and corrosion resistance make it an ideal material for building strong hulls.

Ship deck: it can be used to make support bars, handrails and railings on ship decks. Its corrosion resistance and lightweight properties make it an alternative to traditional materials such as steel, helping to reduce hull weight and improve fuel efficiency.

Ship equipment bracket: it can be used to manufacture equipment brackets on ships, such as support structures for marine machinery and electrical equipment. Its high strength and weldability make it a reliable choice for supporting and securing equipment.

Ship pipe support: it can be used to make supports and fixtures for ship pipes. Its corrosion resistance and lightweight properties make it an alternative to traditional materials, helping to reduce hull loads and improve piping system reliability.

FAQ

Do you accept small batch production?

We accept small batch production, please contact us.

before mass production?

If you need samples, please contact us. You only need to pay postage to get product samples for free.

Is there stock in stock?

Chalco Aluminum 's stock is available in different specifications, standards, and diameters. If you need customization, welcome to consult.

Can I visit and inspect the goods?

sure. contact us, We have the best service and try our best to meet all your needs.

Packaging and shipping details

We provide standard export packaging (inner: waterproof paper, outer: steel belt and pallet). It can also be packed according to your requirements, but please explain in advance.

Payment and delivery method

Payment<=USD 1000, 100% in advance.

Payment>=USD 1000, 30% deposit and balance before shipment pay by TT.

Delivery methods include: FOB, CFR, CIF, EXW, DHL door to door, and Air express.

More payment methods depend on your choice.