6063 aluminum flat bar, known for its good processability and electrical conductivity, is widely used in aviation, military molds, construction, decoration, and aluminum bus bars manufacturing.

6063 aerospace aluminum bars are high-quality materials known for their excellent strength, corrosion resistance, and machinability. Widely used in aircraft manufacturing, they're preferred for their versatility in fabricating aircraft structures and aerospace components.

Why choose Chalco Aluminum's 6063 T5/T6/T52 aluminum bar?

Production and management comply with international aviation quality system certification

AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949Quality could full meet world wide aviation standard

BS H9 Alloy 6063

DTD 372B 6063 Bars and Sections

AMS 4156 6063-T6 Extrusions

QQ-A-200/9 6063

Specs of 6063 T5/T6/T52 aluminum flat bar

| Alloy | 6063 |

| Temper | T4, T5, T6, T52, O |

| Out diameter | 6mm-150mm |

| Length | 4000mm, 6000mm |

| Standard | BS H9 Alloy 6063 DTD 372B 6063 Bars and Sections AMS 4156 6063-T6 Extrusions QQ-A-200/9 6063 |

| 6063 Aluminum Flat Bar Stock Sizes | 3*10; 3*15; 3*20; 3*25;3*30; 3*40; 3*50; 4*20;4*25;4*30;4*40; 4*50 |

Chalco 6063 aerospace aluminum bar hot selling alloy series

-

6063 T4 aluminum bar

used for components in structures with low stress requirements, such as frame supports.

Adequate strength Good formability -

6063 T6 aluminum bar

5083 aluminum alloy has strong corrosion resistance, can withstand extremely low temperature, and is suitable for application and low -temperature storage tanks in the ocean.

High strength Hardness -

6063 T5 aluminum bar

5083 aluminum alloy has strong corrosion resistance, can withstand extremely low temperature, and is suitable for application and low -temperature storage tanks in the ocean.

Excellent formability Corrosion resistance -

6063 T52 aluminum bar

5083 aluminum alloy has strong corrosion resistance, can withstand extremely low temperature, and is suitable for application and low -temperature storage tanks in the ocean.

Higher tensile strength Lower formability

Chalco 6063 aircraft aluminium rod hot selling product

-

6063 aerospace alumunum CF bar

-

6063 aerospace Al extruded bar

-

6063 aerospace alumunum forged bar

-

6063 aerospace aluminum round bar

-

6063 aerospace aluminum square bar

-

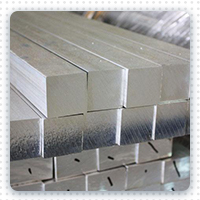

6063 aerospace aluminum flat bar

-

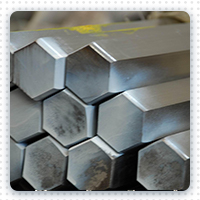

6063 aerospace aluminum hex bar

Chemical composition of 6063 aluminum alloy

| 6063 Alloy % | |

| Si | 0.20-0.60 |

| Fe | 0.35 |

| Cu | 0.10 |

| Mn | 0.10 |

| Mg | 0.45-0.90 |

| Ti | 0.10 |

| Al | Remainder |

Mechanical property of 6063 aluminum bar

| Alloy | Temper | Tension strength(MPa) | Yield strength(MPa) | Elongation(%) | Hardness(HB) |

| 6063 | O | ≤90 | ≤50 | ≥15 | ≤35 |

| T4 | ≥130 | ≥60 | ≥12 | 50-75 | |

| T5 | ≥160 | ≥110 | ≥8 | 60-85 | |

| T6 | ≥205 | ≥170 | ≥8 | 75-90 |

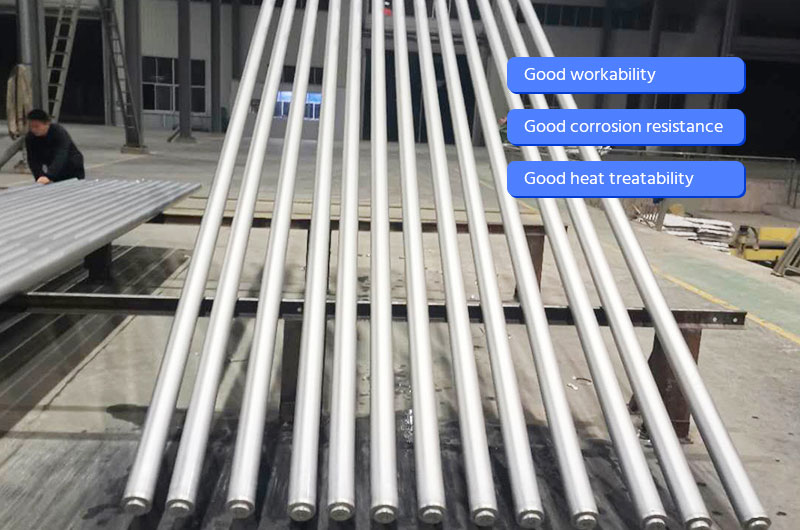

Features of 6063 aluminum bar

- Lightweight and strong: 6063 aluminum is lightweight, making it ideal for aerospace where both strength and low weight are essential.

- Superb machinability: it's easy to process, suitable for creating diverse aerospace components.

- Corrosion resistance: resistant to harsh aerospace environments, ensuring component durability.

- High thermal conductivity: offers excellent heat conduction, valuable for aerospace applications.

- Recyclable: environmentally friendly, as aluminum alloys are recyclable.

- Great conductivity: ideal for aerospace sectors requiring high electrical conductivity, like power, electronics, and communications.

FAQ for purchasing 6063 aluminum bar

Q1: How do I select the right specifications for 6063 aluminum bars?

A: When purchasing, you should specify the required specifications, such as diameter, length, and cross-sectional shape, to ensure you get the right product for your needs.

Q2: What are the different tempers for 6063 aluminum bars, and how do I choose the right one?

A: 6063 aluminum bars come in various tempers like T5, T6, T52, etc. You should confirm the desired temper at the time of purchase based on your specific application requirements.

Q3: What surface treatment options are available for 6063 aluminum bars, and how can I choose the appropriate one?

A: The surface of 6063 aluminum bars can be anodized, sprayed, coated, and more. You should specify your desired surface treatment method when purchasing to match your application needs.

Q4: How should I evaluate a supplier's reputation and service quality when buying 6063 aluminum bars?

A: It's important to research and consider a supplier's reputation, service quality, and customer reviews to ensure the purchased product and service quality are reliable.

Other hot selling aerospace aluminum bar products in Chalco

2024 aerospace aluminum bar

2618 aerospace aluminum bar

2017 aerospace aluminum bar

7075 aerospace aluminum bar

7050 aerospace aluminum bar

6061 aerospace aluminum bar

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote