In the field of door and window materials, aluminum doors and windows have gradually replaced plastic steel doors and windows, especially in villas, hotels and high-end buildings. Aluminum doors and windows use aluminum extruded profiles as the frame, and the leaf materials are the stressed base materials. They are a kind of aluminum doors and windows aluminum or aluminum plastic composite doors and windows.

According to customer needs, Chalco can provide aluminum alloy door and window profiles of various models, surface treatments, shapes, colors, etc. Contact us to start your one-stop shopping experience.

Specifications of aluminum alloy door and window profiles

| Alloy | 6063, 6063A, 6061, 6463, 6463A, 6060, 6005, 6082 etc. |

| Temper | T3, T4, T5, T6, T7, T8 |

| Thickness | Thickness of ordinary profile: 0.8mm—1.4mm |

| Thickness of anodic oxidation protection: 8-12μ | |

| Ordinary spraying thickness: 60-100μ | |

| Shape | Square, angular, flat, hollow, oval, triangle, U, L, T, H or customized. |

| Surface Treatment | Anodizing: 7~23μ; silver, champagne, bronze, black, gold, titanium, imitation steel, etc. |

| Electrophoresis: 12-25μ; silver, champagne, black, gold, titanium, etc. | |

| Powder coating: 60~120μ; white, black, bronze, gray, green, etc. | |

| Polishing: mechanical polishing or chemical polishing; silver, nickel, gold, black, etc. | |

| Fluorocarbon coating: customized color according to customer samples. | |

| Imitation wood color: ordinary wood color or customized wood color. | |

| Color | silver, white, black, bronze, champagne, gold or custom |

| Deep processing capacity | drilling, punching, bending, CNC, aluminum alloy profile processing, precision cutting, etc. |

| Quality Certification | ISO 9001:2015, ISO 14001:2015, CQM |

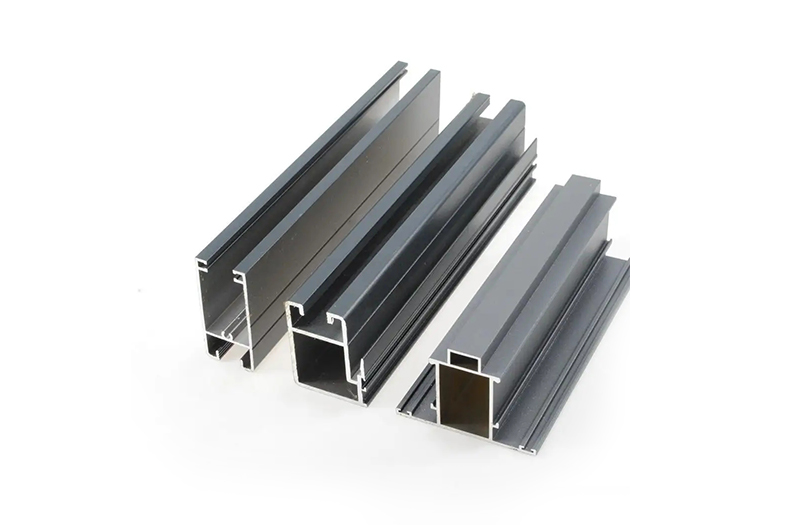

Common aluminum alloy door and window profiles

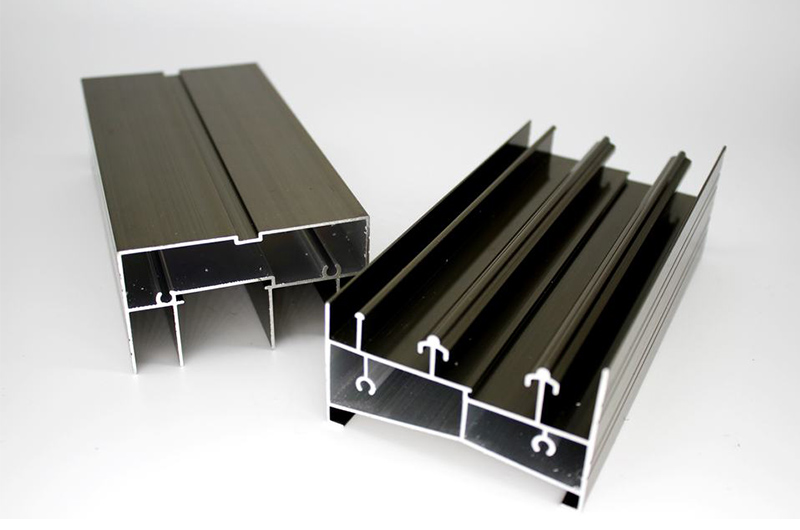

Thermal insulation aluminum extruded profiles for doors and windows

Thermal insulation aluminum extrusions are important components in any door and window system. It refers to the reinforced polyamide strip between the internal and external aluminum profiles, which forms an insulating barrier in the window frame. More exactly, it makes the aluminum framed window form a barrier between the inner and outer sashes to prevent heat conduction loss.

Thermal insulation aluminum extruded profiles for window frames

| Alloy | 6063 |

| Temper | T5-T8 |

| Shape | square or round |

| Color | different colors, customizable |

| Precision | +-0.15mm |

| Surface Treatment | polishing, powder coating, anodizing, electrophoresis, polishing |

| Processing | high-precision numerical control processing, precision cutting, drilling, milling |

- High quality thermal insulation aluminum profiles for windows.

- Excellent heat and sound insulation effect.

- Non flammable.

- High quality, scratch resistant and deformation resistant.

- Enduring and durable.

Thermal break profiles

| Alloy | 6061 6063 |

| Temper | T3-T8 |

| Thickness | >0.7mm |

| Color | different colors, customizable |

| Precision | +-0.15mm |

| Surface treatment | polishing, powder coating, anodizing, electrophoresis, polishing |

| Processing | high-precision numerical control processing, precision cutting, drilling, milling |

- High quality thermal insulation aluminum profiles for doors.

- Exquisite appearance.

- High calorific value and low U value.

- Good water and air tightness.

- Resistance to moisture, pollutants and ultraviolet rays.

- Dustproof and easy to maintain.

Top insulation door, window and curtain wall aluminum profiles

| Alloy | 6000 series |

| Temper | T3-T8 |

| Quality Certification | ISO9001, ISO14000, ISO10012 |

| Alloy or not | alloy |

| Application | for windows and doors |

| Thickness | >0.7mm |

- High quality curtain wall thermal insulation aluminum alloy profiles.

- Air tight, waterproof, heat insulation, heat insulation, anti-aging, impact resistance.

- Environmentally friendly.

- Corrosion resistance and fuzzing resistance.

- Modern look.

Coated aluminum profiles for doors and windows

Common surface treatment processes for aluminum doors and windows are electrophoretic coating, fluorocarbon spraying, wood grain transfer coating, anodizing, and electrostatic powder coating. In most cases, after good surface treatment, aluminum profiles have good atmospheric corrosion resistance. It is moisture-proof, sunscreen, flame proof, aging proof, high-temperature deformation proof, low-temperature embrittlement proof, durable and stable, and suitable for various climates.

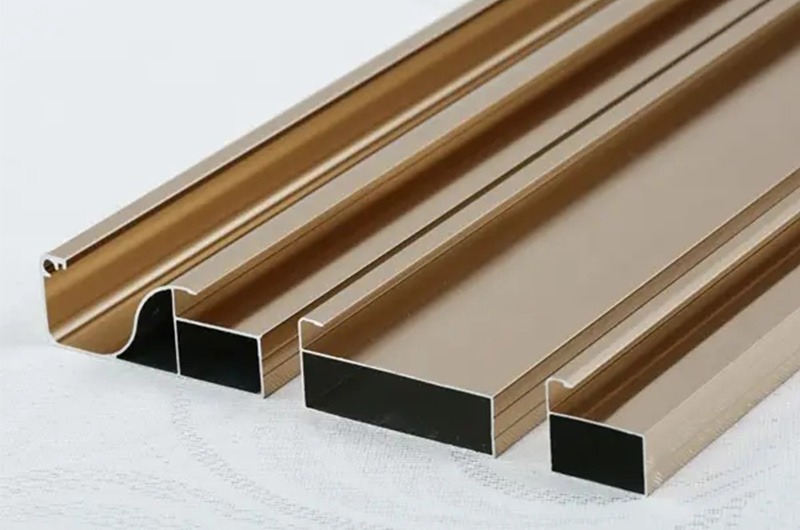

Anodized aluminum profiles for champagne colored doors and windows

| Alloy | 6063 |

| Temper | T3-T8 |

| Surface treatment | anodic oxidation |

| Thickness | >0.7mm |

| Color | champagne |

- High quality door and window aluminum profiles, anodized surface.

- High corrosion resistance, high weather resistance and good wear resistance.

- Excellent materials, smooth and delicate edges, elegant appearance.

- Multiple colors are available. Lasting color, fadeless.

Powder coated aluminum sliding window profiles

| Alloy | 6063 |

| Temper | T3-T8 |

| Surface treatment | powder coating |

| Thickness | >0.7mm |

| Color | any color can be customized |

- High quality aluminum profiles for sliding windows.

- Economical and practical materials.

- Powder coating on the surface, any color can be customized.

- Easy to operate and durable.

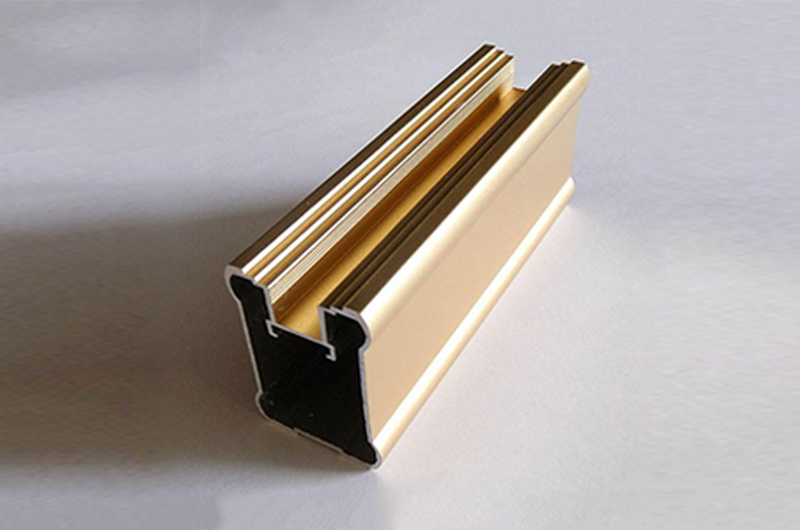

Electrophoretic aluminum door profiles, roller shutter doors, sliding door profiles

| Alloy | 6000 series |

| Temper | T3-T8 |

| General profile thickness | 0.8 - 5.0 mm |

| Thickness of anodic oxidation protection | 8 - 25 um |

| Powder coating color thickness | 40 - 120 um |

| Color | wine red, silver, champagne, black, etc. |

| Shape | triangle, U profile, L profile, T profile, H profile, customizable |

- Multiple patterns and colors for your choice.

- Strictly control of the surface finish, few scratches.

- Accurate mold and size.

- Standard alloy composition.

- Both ends of the profile are very flat without burrs.

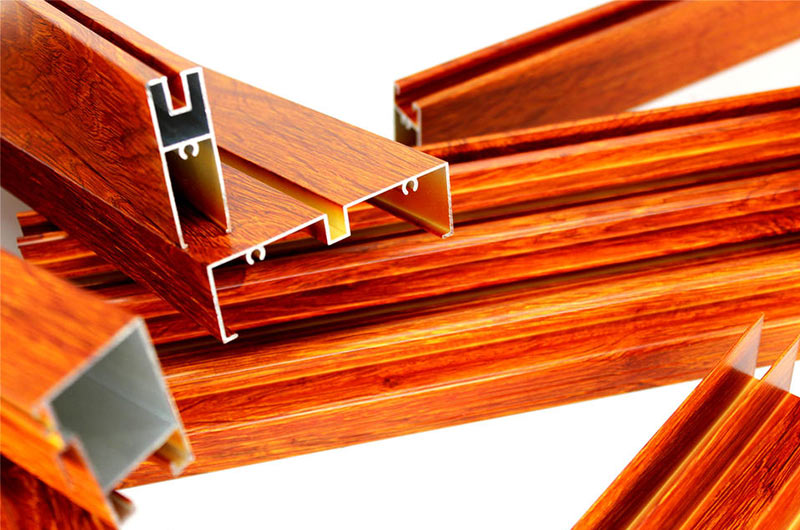

Wood faced aluminum door and window profiles

| Alloy | 6063 |

| Temper | T3-T8 |

| Thickness | >0.7mm |

| Color | wood grain series |

- High quality aluminum profiles for doors and windows with wooden grain on the surface.

- The wood like texture are formed by new technology; hand feel and film transfer are permissible.

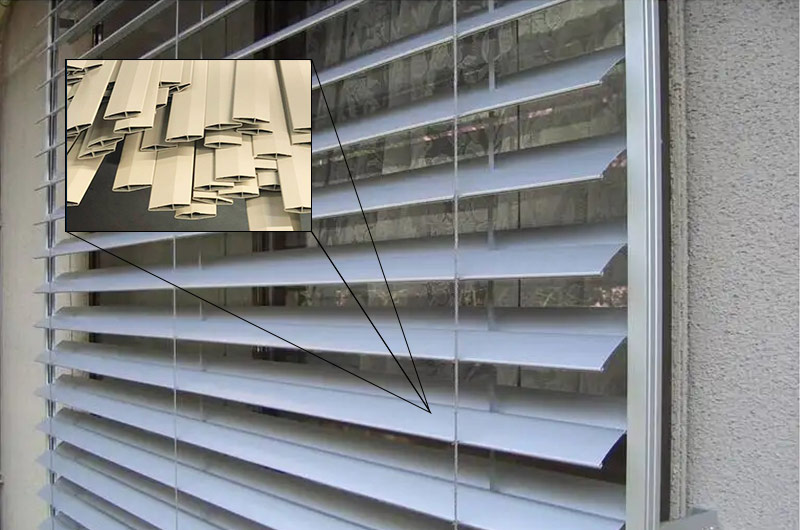

Louver aluminum alloy profile

Aluminum alloy louver frame profile

| Alloy and Temper | 6061&6063-T5, T6 |

| Surface treatment | polishing, anodizing, powder coating, electrophoresis, wood grain |

| Color | powder coated white and various customized colors |

| Thickness | 0.4mm and above, 0.7-1.3mm, or customized |

| Anodizing | 7~23μ |

| Powder coating | 60~120μ |

| Electrophoresis | 12-25μ |

- Affordable, lightweight and durable.

- It is made of light aluminum alloy with beautiful appearance. The silver white surface is full of metallic luster.

- The aluminum alloy surface can be wiped with detergent, not easy to rust and fade.

Aluminum louver profiles for windows

| Alloy | 6061 6063 |

| Temper | T5, T6 |

| Thickness | 0.6-1.25 mm |

| Surface treatment | powder coating, anodizing, wood grain, etc. |

- Sound and noise reduction. The blades of aluminum alloy louver are generally double-layer hollow design. When the blades are completely closed, they can effectively isolate the impact of external noise.

- Aluminum alloy shutters also have high temperature resistance and UV protection functions. It can prevent indoor wooden furniture from being harmed by ultraviolet rays and effectively insulate outdoor high temperature.

- Types of louvers available: aluminum louvers include aluminum louver cladding, aluminum louvers, sun shading louvers, sun shading extruded louvers, aluminum louver fences, aluminum louver vents, external aluminum louvers, and elliptical profiles.

Aluminum roll window profile

| Alloy | 6000 series |

| Temper | T4-T6 |

| Thickness | 1.0mm and above, or customized |

| Shape | B-type, T-slot, etc. |

| Processing method | milling |

| Delivery time | 20-25 days, additional 10 days for mold production |

- The rolling window is directly exposed to the natural environment. The use of A-grade aluminum materials ensures the durability of the product.

- Excellent surface treatment process to better maintain its shape and color.

Packaging of aluminum alloy profiles for doors and windows

Because of the particularity of its surface treatment, aluminum alloy door and window profiles have strict requirements on product packaging and transportation.

Standard packaging

For powder coating/anodizing/polishing: packaging+batten+steel

For polishing: pear velvet+heat shrinkable film

Special packaging

Standard packaging+additional paper

Plastic protective film+wooden strip+steel trolley

Advantages of aluminum alloy profile doors and windows

Strong plasticity

Aluminum profiles are metal materials. Aluminum add various metal elements to make various alloys, which have advantages that other alloy profiles cannot match. Aluminum alloys has light weight and high strength, and can be extruded into a variety of complex cross-section profiles meeting the requirements of door and window design for various new sections.

Good sealing performance

The bridge cutoff aluminum alloy profiles have strong air tightness, water tightness, heat insulation and sound insulation, and are suitable for various specific applications in the door and window industry.

Long service life

Aluminum alloy profiles have the advantages of light deadweight, high strength, corrosion resistance, small deformation, strong fire resistance, etc., with a service life of more than 50 years.

Energy conservation and environmental protection

The aluminum alloy profiles are made of new thermal insulation materials. A cold and hot bridge is formed between the inner and outer profiles to minimize the thermal conductivity of aluminum alloy and achieve good thermal and sound insulation effects.

Excellent weather resistance

The aluminum alloy profile has been treated by various processes, and its surface has the characteristics of acid resistance, alkali resistance, air pollution resistance, acid rain resistance, ozone resistance, ultraviolet resistance, etc. It can maintain the inherent color and luster for a long time.

Good decorative effect

The surface of aluminum alloy profiles has been processed by various surface treatments, such as powder spraying, anodizing, electrophoretic coating, wood grain transfer printing and other surface treatment technologies. There are many colors and styles to choose from. It can meet the needs of all kinds of architectural decoration and make the building look more beautiful.