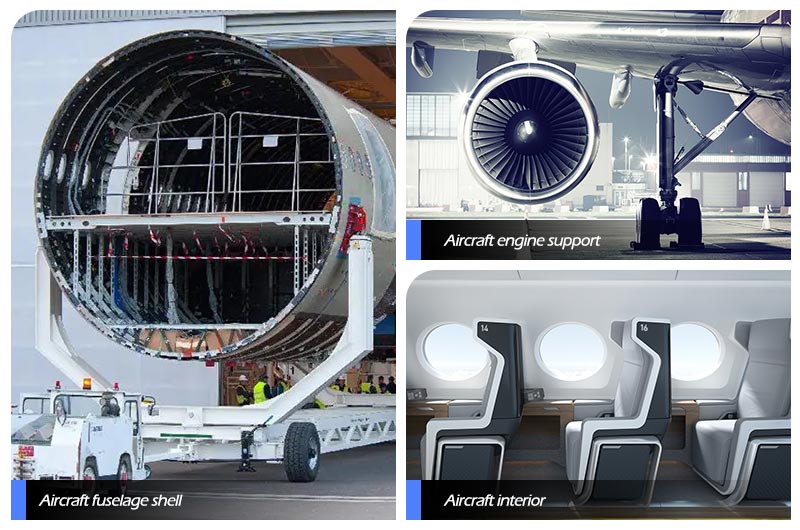

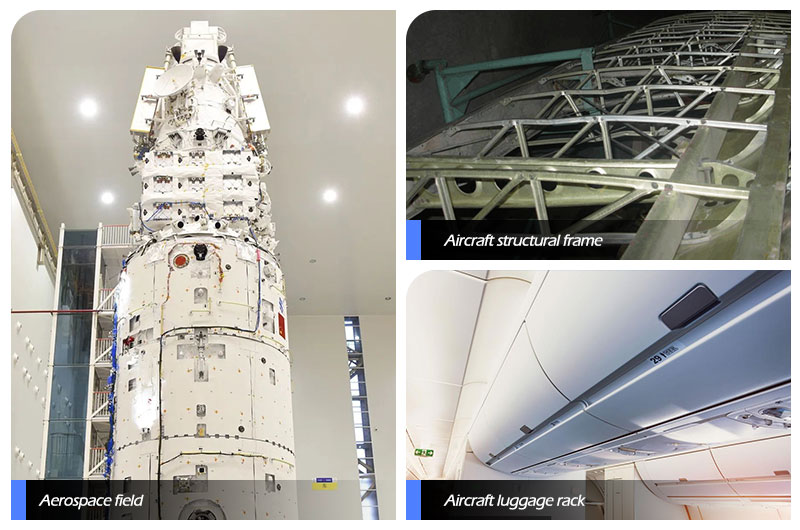

7149 aviation aluminum alloy profile is an aluminum alloy material with high strength and excellent corrosion resistance. It is mainly used to manufacture structural components in the aerospace field, such as aircraft fuselage, wing spar, engine support structure, etc.Quick Quote

Why choose Chalco Aluminum's 7149-T73511 aluminum extrusion profile?

Quality could full meet world wide aviation standard

AMS 4343 7149-T73511 Extrusion AMS 4167

Production and management comply with international aviation quality system certification

AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Specs of 7149 (UNS A97129) aluminum extrusion profile

| Specification | |

| Alloy | 7149 |

| Temper | 73511, T6, T651, T7351, T7451 |

| Open Profile dimensions | Min 4mm*3mm, Max.850mm*50mm. |

| Closed profiles dimension | Min. 6.35mm *1mm, Max. 573mm*10mm. |

| Weight per meter | Min. 0.03kg/m, Max. 124kg/m |

| Profile length | Maximum 28m(standard 6000mm) |

| Standard |

AMS 4343 7149-T73511 Extrusion AMS 4167 |

| Extrusion Type | Dimension range (inches) | Wall thickness range (inches) |

| 7149 aluminum round tube | 1-10 | 0.125-0.75 |

| 7149 aluminum square tube | 1-8 | 0.125-0.5 |

| 7149 aluminum rectangular tube | 1*2-8*12 | 0.125-0.5 |

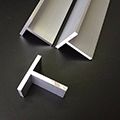

| 7149 aluminum angle | 1*1-8*8 | 0.125-0.5 |

| 7149 aluminum T-profile | 1*1-6*6 | 0.125-0.5 |

| 7149 aluminum U-profile | 1*0.5-6*2 | 0.125-0.5 |

| 7149 extruded aluminum round bar diameter | Φ0.20-8.0 | - |

| 7149 extruded aluminum square bar diameter | 0.20-8.0 | - |

| 7149 extruded aluminum flat bar specifications | Thickness: 0.006-1.6 Width: 0.4-8.0 | - |

| 7149 extruded aluminum hexagonal bar diameter | 0.2-8 | - |

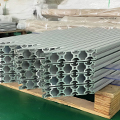

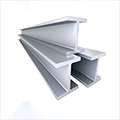

7149 aerospace grade aluminium extruded profile products

7149 Aluminum flat bar

Commonly used in construction, mechanical engineering and other fields. With good strength and stability, it can be used for bearing, supporting and other applications.

Contact us now

7149 Extruded Bar

With high strength and excellent cutting performance, it can be used in bearing, connecting, transmission and other applications.

Contact us now7149 Extruded Tube

Shape: Round, square, rectangular, and oval profiles...

With excellent corrosion resistance and good thermal conductivity, it can be used to transmit fluids, gases and electrical signals, etc.

Contact us now

7149 Extruded Profile in Other Shapes

Shape: D-shaped, C-shaped, L-shaped, angle and custom profiles...

Application: Various structures and components, including fuselage frames and interior fittings.

Contact us nowTypes and uses of 7149 aluminum extrusion profile

7149 T6 aluminum alloy extrusion Quick Quote

It obtains the highest strength and hardness after artificial aging, the yield strength is about MPa 540, the tensile strength is about MPa 650, and the elongation is about 8%. Structural parts and components for aerospace applications.

7149 T651 aluminum alloy extrusions Quick Quote

After cold working and artificial aging treatment, it obtains a certain strength and hardness, the yield strength is about MPa 400, the tensile strength is about MPa 520, and the elongation is about 14%. It is suitable for structural parts and components in aviation, aerospace, national defense, transportation and other fields.

7149 T7351 aluminum alloy profile Quick Quote

Based on the T651 temper, it undergoes stress relief aging treatment to obtain higher strength and hardness. The yield strength is about MPa 410, the tensile strength is about MPa 540, and the elongation is about 12%. It is suitable for structural parts and components in the fields of aviation, spaceflight, and national defense.

7149 T7451 aluminum extrusion Quick Quote

On the basis of the T7351 temper, it undergoes additional artificial aging treatment to obtain higher strength and hardness. The yield strength is about MPa 470, the tensile strength is about MPa 600, and the elongation is about 8%. It is suitable for structural parts and components in the fields of aviation, spaceflight, and national defense.

Chemical Composition of 7149 aluminum extrusion profile

| 7149 Alloy % | |

| Si | 0.15 |

| Fe | 0.20 |

| Cu | 1.20-1.90 |

| Mn | 0.20 |

| Mg | 2.0-2.90 |

| Cr | 0.10-0.22 |

| Ni | - |

| Zn | 7.2-8.20 |

| Ti | 0.10 |

| Al | Remainder |

Mechanical property of 7149-T73511 aluminum extrusion profile

| Mechanical property | |

| Physical property | Value |

| Density | 2.81 g/cm3 |

| Elastic Modulus | 72.4 GPa |

| Melting point | 582-652 °C |

| Thermal expansion coefficient | 23.5 µm/m°C |

| Thermal conductivity | 167 W/mK |

| Conductivity | 35.7-37.2% IACS |

| Hardness(HB) | 175-190 |

| Other property | Value |

| Yield strength | 535 MPa |

| Tension strength | 635 MPa |

| Elongation | 9% |

| Fatigue strength (S-N curve, 107 cycles) | 50 MPa |

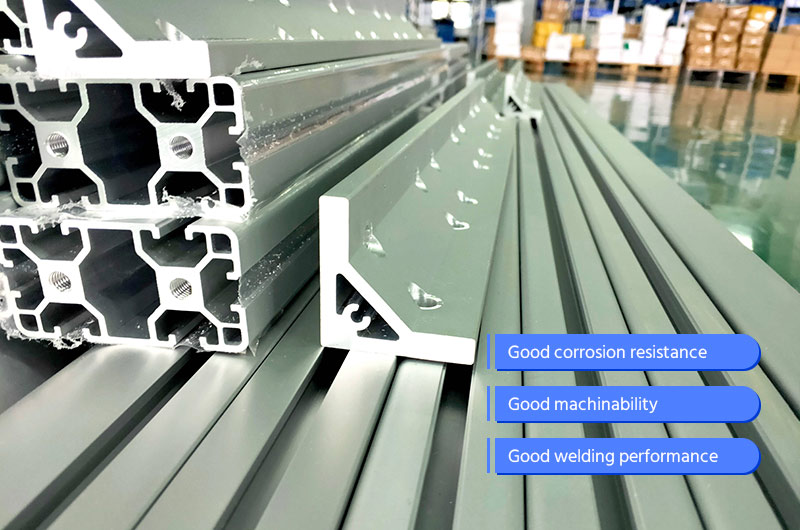

| Corrosion resistance | Good corrosion resistance, suitable for marine environment, but not suitable for strong acid or alkali environment. |

| Welding performance | Good weldability, suitable for conventional welding methods. |

| Processing performance | It has good forming and processing properties, and can be applied to extrusion, stretching, rolling and other processing methods. |

| Heat treatment properties | It can be regulated by solid solution and aging heat treatment to improve the strength and hardness of the material. |

Features of 7149 aluminum extrusion profile

High strength: 7149 aluminum alloy is a high-strength aluminum alloy with high yield strength and tensile strength, which can meet the strict requirements for strength in the aerospace field.

Good processing performance: 7149 aluminum alloy has good processing performance, and can be manufactured by extrusion, casting, forging, rolling, etc., which is convenient for processing and manufacturing in production.

Good corrosion resistance: 7149 aluminum alloy has good corrosion resistance and can work in harsh environmental conditions, such as ocean, high humidity and other environments.

Excellent low-temperature performance: 7149 aluminum alloy has excellent low-temperature performance, can maintain good strength and toughness at extremely low temperatures, and is suitable for low-temperature applications in the aerospace field.

Lightweight: 7149 aluminum alloy has a lower density and is lighter than traditional materials such as steel, which helps to reduce the weight of aircraft and improve fuel efficiency.

Recyclable: 7149 aluminum alloy is an environmentally friendly material that can be recycled and reused, in line with the concept of sustainable development.

Other hot selling aerospace aluminum extrusion profile products in Chalco

2014 aerospace profile

2219 aerospace profile

6061 aerospace profile

6063 aerospace profile

7050 aerospace profile

2024 aerospace profile

What precautions should be taken when purchasing aluminum extrusion profile?

Specifications: First, determine the required specifications and dimensions, including parameters such as length, width, height, and wall thickness, to ensure that you can purchase profiles that meet the requirements.

Temper: 7149 aluminum extrusions have various states, such as T6, T73, T73511, etc. The performance and application range of different tempers are also different, and it is necessary to choose the temper that meets the use requirements.

Quality: attention should be paid to checking the surface quality, appearance, dimensional accuracy and straightness of profiles to ensure compliance with standards and requirements.

Use: Different profiles need to be selected for different shapes and properties. You must fully understand your own use requirements and choose the appropriate profile.

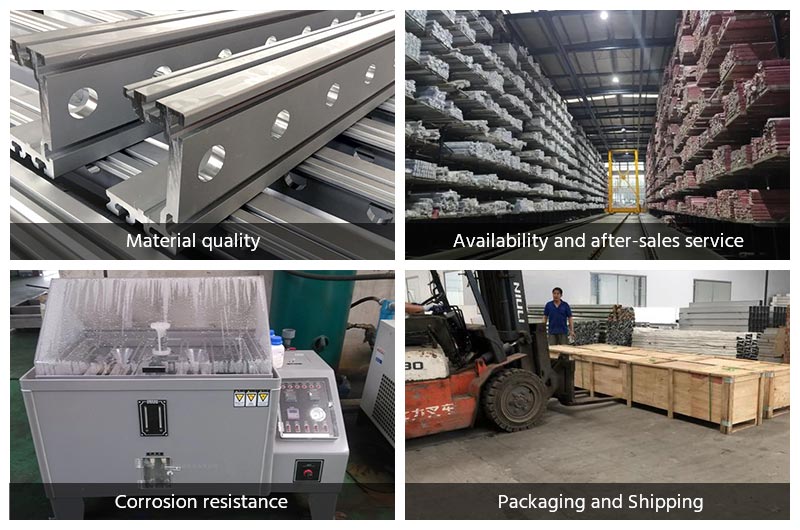

Manufacturer's reputation: choose a reputable and qualified manufacturer or supplier to ensure the quality of profiles and the reliability of after-sales service.

In short, before purchasing 7149 aluminum extrusions, you need to carefully confirm your needs, choose the appropriate profile specifications and status, and purchase from regular manufacturers or suppliers to ensure that the quality and performance of the products meet the requirements.